TOUGH-WORKS DP8 User manual

8-INCH DRILL PRESS

INSTRUCTION

MANUAL

IMPORTANT:

For your own safety, read and follow all of the Safety

Guidelines and Operating Instructions before operating

this product.

DP8

2

TABLE OF CONTENTS

SPECIFICATIONS

TABLE OF CONTENTS

TABLE OF CONTENTS ...............................................................................................

2

SAFETY GUIDELINES ................................................................................................

8

PACKAGE CONTENTS ..............................................................................................

10

KEY PARTS DIAGRAN

..................................................................................................

11

ASSEMBLY INSTRUCTIONS........................................................................................

12

OPERATION .................................................................................................................

13

MAINTENANCE ............................................................................................................

15

TROUBLESHOOTING GUIDE .....................................................................................

16

EXPLONED VIEW .........................................................................................................

18

PARTS LIST ..................................................................................................................

19

WARRANTY ..................................................................................................................

20

ELECTRICAL SAFETY .................................................................................................

9

SPECIFICATIONS ......................................................................................................

2

DP8

Motor 120V, 60Hz

Speed 620~3100RPM

Chuck size 1/2 in.

Taper JT33

Spindle travel 2 in.

Swing 8 in.

Drilling capacity 1/2 in.

DP8

Model

250WPower

Net weight 33 lb.

BD4603

SAFETY GUIDELINES

SAFETY GUIDELINES - DEFINITIONS

3

WARNING ICONS

Your power tool and its Instruction Manual may contain “WARNING ICONS”(a

picture)symbol intended to alert you to and/or instruct you how to avoid a potentially

hazardous condition). Understanding and heeding these symbols will help you operate

your tool

better and safer. Shown below are some of the symbols you may see.

SAFETY ALERT: Precautions that involve your safety.

DANGER: Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not

avoided,may result in minor or moderate injury.

NOTICE: Used without the safety alert symbol indicates potentially

hazardous situation which, if not avoided, may result in property damage.

WARNING

!

DANGER

!

CAUTION

!

NOTICE

PROHIBITION

WEAR EYE PROTECTION: Always wear safety goggles or safety glasses with

side shields.

WEAR RESPIRATORY AND HEARING PROTECTION: Always wear respiratory

and hearing protection.

READ AND UNDERSTAND INSTRUCTION MANUAL: To reduce the risk of injury,

user and all bystanders must read and understand instruction manual before using

this product.

KEEP HANDS AWAY FROM THE MOVING PART AND CUTTING SURFACE:

Failure to keep your hands away from the moving part and cutting surface will

result in serious personal injury.

SUPPORT AND CLAMP WORK

Some dust created by power sanding, sawing, grinding,drilling and other construction

activities contains chemicals known to the state of California to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

Lead from lead-based paints.

Crystalline silica from bricks and cement and other masonry products.

Arsenic and chromium from chemically-treated lumber.

WARNING

!

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work

DP8

SAFETY GUIDELINES

with approved safety equipment, such as those dust masks that are specially designed

sanding, sawing, grinding, drilling, and other construction activities. Wear protective

clothing and wash exposed areas with soap and water. Allowing dust to get into your

mouth, eyes, or lay on the skin may promote absorption of harmful chemicals.

WARNING

!

4

To avoid electrical hazards, fire hazards or damage to the tool, use proper circuit protection.

This tool is wired at the factory for 110-120 Volt operation. It must be connected to a 110-120

Volt /15 Ampere time delay fuse or circuit breaker. To avoid shock or fire, replace power cord

immediately if it is worn, cut or damaged in any way.

Before using your tool, it is critical that you read and understand these safety rules. Failure to

follow these rules could result in serious injury to you or damage to the tool.

DP8

GENERAL SAFETY INSTRUCTIONS

BEFORE USING THIS POWER TOOL

Safety is a combination of common sense,

staying alert and knowing how to use your

power tool.

To avoid mistakes that could cause serious

injury, do not plug the tool in until you have

read and understood the following.

Read all instructions before operating

product.Failure to follow all instructions listed

below may result in electric shock, fire and

/or serious injury.

1. READ and become familiar with the

entire Instruction Manual. LEARN

the tool’s application, limitations and

and possible hazards.

2. KEEP GUARDS IN PLACEand in working

order.

3. KEEPWORK AREACLEAN. Cluttered

areas and benches invite accidents.

4. DO NOT USE IN DANGEROUS

ENVIRONMENTS. Do not use power tools

in damp locations, or expose them to rain

or snow. Keep work area well lit.

5. KEEP CHILDREN AWAY. All visitors and

bystanders should be kept a safe distance

from work area.

6. DO NOT FORCE THE TOOL. It will do the

job better and safer at the rate for which it

was designed.

7. WEAR PROPER APPAREL.Do not wear

loose clothing, gloves, neckties, rings,

bracelets or other jewelry which may get

caught in moving parts. Nonslip footwear

is recommended. Wear protective hair

covering to contain long hair.

8. ALWAYS WEAR EYE

PROTECTION. Any power tool can

throw foreign objects into the eyes

ALWAYS wear Safety Goggles (not

glasses) that comply with ANSI Safety

standard Z87.1. Everyday eyeglasses

have only impact–resistant lenses. They

ARE NOT safety glasses. NOTE:Glasses

or goggles not in compliance with ANSI

Z87.1 could seriously injure you when

they break.

9. WEAR A FACE MASK OR

DUST MASK.Sanding operation

produces dust.

10. DISCONNECT TOOLS FROM POWER

SOURCE before servicing, and when

changing accessories such as blades,

bits and cutters.

WARNING

!

BD4603

5

12. USE RECOMMENDED ACCESSORIES.

Consult this Instruction Manual for

recommended accessories. The use of

improper accessories may cause risk of

injury to yourself or others.

13. NEVER STAND ON THE TOOL. Serious

injury could occur if the tool is tipped

or if the cutting tool is unintentionally

contacted.

14. MAINTAIN TOOLS WITH CARE. Keep

tools sharp and clean for best and safest

performance. Follow instructions for

lubricating and changing accessories.

DP8

and could cause permanent eye damage.

11.USE PROPER EXTENSION CORDS.

Make sure your extension cord is in

good condition.When using an extension

cord, be sure to use one heavy enough

to carry the current your product will draw.

An undersized cord will result in a drop

in line voltage and in loss of power

which will cause the tool to overheat.

The table on page 8 shows the correct

size to use depending on cord length

and nameplate ampere rating. If in

doubt, use the next heavier gauge.

The smaller the gauge number, the

heavier the cord.

15.CHECK FOR DAMAGED PARTS.

Before further use of the tool, a guard or

other part that is damaged should be

SAFETY GUIDELINES

DRILL PRESS SAFETY

6

18.

Dust generated from certain materials

can be hazardous to your health. Always

operate saw in well-ventilated area and

provide for proper dust removal.

19.

People with electronic devices, such

as pacemakers, should consult their

physician(s) before using this product.

close proximity to a heart pacemaker

could cause interference or failure of the

pacemaker.

20. WEAR HEARING PROTECTION

to reduce the risk of induced

hearing loss.

WARNING

!

DANGER

!

carefully checked to determine that it

will operate properly and perform its

intended function– check for alignment

of moving parts, binding of moving parts,

breakageof parts, mounting and any other

conditions that may affect its operation.

A guard or other part that is damaged

should be properly repaired or replaced.

16. NEVER LEAVE THE TOOL RUNNING

UNATTENDED. TURN THE POWER “OFF”.

Do not walk away from a running tool until

the blade comes to a complete stop and the

tool is unplugged from the power source.

17. DO NOT OVERREACH. Keep proper footing

and balance at all times.

For your own safety, do not try to use your

drill press or plug it in until it is completely

assembled and installed according to the

instructions, and until you have read and

understood this instruction manual:

WARNING

!

to move during certain operations, bolt the

workbench to the floor.

2. THIS DRILL PRESS is intended for use in

dry conditions, indoor use only.

3. WEAR EYE PROTECTION. USE a face or

dust mask along with safety goggles if

drilling operation is dusty.

USE ear protectors, especially during

extended periods of operation.

4. DO NOT wear gloves, neckties, or loose

clothing.

5. DO NOT try to drill material too small to

be securely held.

6. ALWAYS keep hands out of the path of

a drill bit.

Avoid awkward hand positions where a

sudden slip could cause your hand to move

into the drill bit.

7. DO NOT install or use any drill bit that

exceeds 175 mm (7 in.) in length or extends

150 mm (6 in.) below the chuck jaws.

They can suddenly bend outward or break.

8. DO NOT USE wire wheels, router bits,

shaper cutters, circle (fly) cutters,

or rotary planers on this drill press.

9. WHEN cutting a large piece of material,

make sure it is fully supported at the table

height.

10.DO NOT perform any operation freehand.

ALWAYS hold the workpiece firmly against

the table so it will not rock or twist. Use

clamps or a vise for unstable workpieces.

11.MAKE SURE there are no nails or foreign

objects in the part of the workpiece to

be drilled.

1. YOUR DRILL PRESS MUST BE BOLTED

securely to a workbench. In addition,

if there is any tendency for your drill press

12. CLAMP THE WORKPIECE OR BRACE IT

against the left side of the column to

prevent rotation. If it is too short or the

table is tilted, clamp it solidly to the table

and use the fence provided.

13. IF THE WORKPIECE overhangs the table

such that it will fall or tip if not held, clamp

it to the table or provide auxiliary support.

14. SECURE THE WORK. Use clamps or a vise

to hold the work when practical. It’s safer

SAFETY GUIDELINES

DP8

BD4603

7

than using your hand and it frees both

hands to operate tool.

15. WHEN using a drill press vise, always

fasten to the table.

16. MAKE SURE all clamps and locks are firmly

tightened before drilling.

17. SECURELY LOCK THE HEAD and table

support to the column, and the table to

the table support before operating the

drill press.

18. NEVER turn your drill press on before

clearing the table of all objects (tools,

scraps of wood, etc.)

19. BEFORE STARTING the operation, jog

the motor switch to make sure the drill

bit does not wobble or vibrate.

20. LET THE SPINDLE REACH FULL SPEED

before starting to drill. If your drill press

makes an unfamiliar noise or if it vibrates

excessively, stop immediately, turn the

drill press off and unplug. If do not restart

the unit until the problem is corrected.

21. DO NOT perform layout assembly or set

up work on the table while the drill press

is in operation.

22. USE THE RECOMMENDED SPEED for any

drill press accessory and for different

workpiece material. READ THE INSTRUC

TIONS that come with the accessory.

23. WHEN DRILLING large diameter holes,

clamp the workpiece firmly to the table.

Otherwise, the bit may grap and spin the

workpiece at high speeds.

DO NOT USE fly cutters or multiple-part

hole cutters, as they can come apart or

become unbalanced in use.

24. MAKE SURE the spindle has come to a

complete stop before touching the

workpiece.

25. TO AVOID INJURY from accidental

starting, always turn the switch “OFF”

and unplug the drill press before installing

or removing any accessory or attachment

or making any adjustment.

26. KEEP GUARDS IN PLACE and in working

order.

27. USE ONLY THE SELF-EJECTING TYPE

SAFETY GUIDELINES

CHUCK KEY as provided with the drill

press.

28.

TO AVOID BEING PULLED INTO THE

SPINNING TOOL - Tie back long hair and

roll long sleeves above elbows.

WARNING

!

29. Drum sanders must never be operated

on this drill press at a speed greater

than the speed rating of the drum sander.

30.

Feed workpiece into a sanding drum or

other approved accessory, against the

direction of rotation.

31.

A kickback occurs when workpiece

suddenly binds on the cutting edge of

the tool and the workpiece is thrown by

the cutter in the direction of the cutter’s

rotation. This can cause serious injury.

32.

Do not allow familiarity (gained from

frequent use of your drill press) to become

commonplace. Always remember that

a careless fraction of a second is sufficient

to inflict severe injury.

WARNING

!

WARNING

!

WARNING

!

DP8

8

DANGER

DP8

LASER SAFETY

This tool is equipped with a patented precision

cross-pattern laser alignment and centering

guide.

1. Do not stare directly at the laser beam.

Eye damage may occur if you deliberately stare

into the beam.

2. The laser light beam

used in this system is Class II with maximum 1

mW and 660 nm wavelengths.

AVOID DIRECT

EYE EXPOSURE.

3. The laser must be used and maintained in

accordance with the manufacturer ’s instructi-

ons:

• Never aim the beam at any person or an object

other than the workpiece.

• Do not project the laser beam into the eyes of

others.

• Always ensure the laser beam is aimed at a

workpiece without reflective surfaces as the

laser beam could be reflected into your eyes or

the eyes of others.

!

SAFETY GUIDELINES

DO NOT MODIFY THE PLUG PROVIDED.

IMPROPER CONNECTION

grounding conductor can result in risk of

electric shock. The conductor with the green

insulation (with or without yellow stripes) is

or replacement of the electrical cord or plug

grounding conductor to a live terminal.

Total Extension Cord Length

25 8 50 15 100 30 125 40

3-10

10.1 - 12

12.1 - 16

BD4603

9

CHECK

with a qualied electrician or service

personnel if you do not completely understand

the grounding instructions, or if you are not sure

the tool is properly grounded.

GROUNDING INSTRUCTIONS

IN THE EVENT OF A MALFUNCTION OR

BREAKDOWN,

grounding provides a path of

least resistance for electric current and reduces

the risk of shock. This tool is equipped with an

electric cord that has an equipment grounding

conductor and grounding plug. The plug

MUST

be plugged into a matching receptacle that is

properly installed and grounded in accordance

with ALL local codes and ordinances.

WARNING

!

!

ELECTRICAL SAFETY

DP8

GROUNDING INSTRUCTIONS

In the event of an electrical malfunction or short

circuit, grounding reduces the risk of electric

shock.The motor of this machine is wired for 120 V

single phase operation and is equipped with a

3-conductor cord and a 3-prong grounding plug

to fit a grounded type receptacle B. Do not rem-

ove the 3rd prong (grounding pin) to make it fit

into an old 2-hole wall socket or extension cord.

If an adaptor plug is used C, it must be attached

to the metal screw of the receptacle.

Fig. A

Note :The use of an adaptor plug is illegal in some

areas,includingCanada.Check your local codes.

If you have any doubts or if the supplied plug

does not correspond to your electrical outlet,

consult a qualified electrician before proceeding.

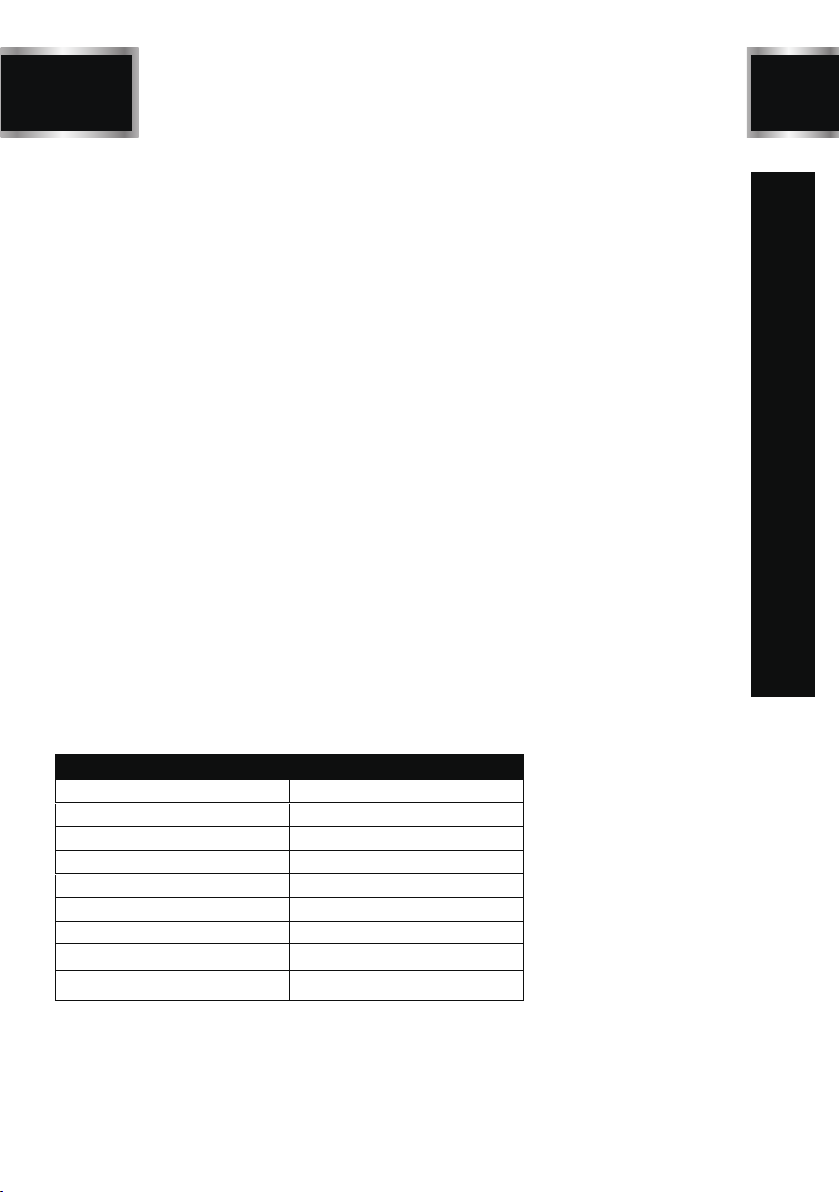

EXTENSION CORDS

If you find it necessary to use an extension cord

with your machine, use only 3-wire extension

cords that have 3-prong grounding plug and a

matching 3-pole receptacle that accepts the

tool’s plug. Repair or replace a damaged ext-

ension cord or plug immediately. Make sure

the cord rating is suitable for the amperage

listed on the motorI.D. plate. An undersized

cord will cause a drop in line voltage resulting

in loss of power and overheating.The accom-

panying chart shows the correct size extension

cord to be used based on cord length and motor

I.D. plate amp rating.

Feet Meters

Amp

Rating

(amp)

Feet Meters Feet Meters Feet Meters

18 ga. 16 ga. 14 ga. 14 ga.

16 ga. 16 ga. 14 ga. 14 ga.

14 ga. 12 ga. Not Recommended

Use only UL or CSA approved extension cords

Do not allow familiarity with your tool to make

your careless. Remember that a careless fra-

ction of a second is sufficient to inflict severe

injury.

IMPORTANT

!

The warnings, cautions and instructions det-

ailed in this manual cannot cover all possible

conditions and situations that occur. It must

be understood by the operator that common

sense and caution are factors that cannot be

built into this product, but must be supplied

by the operator.

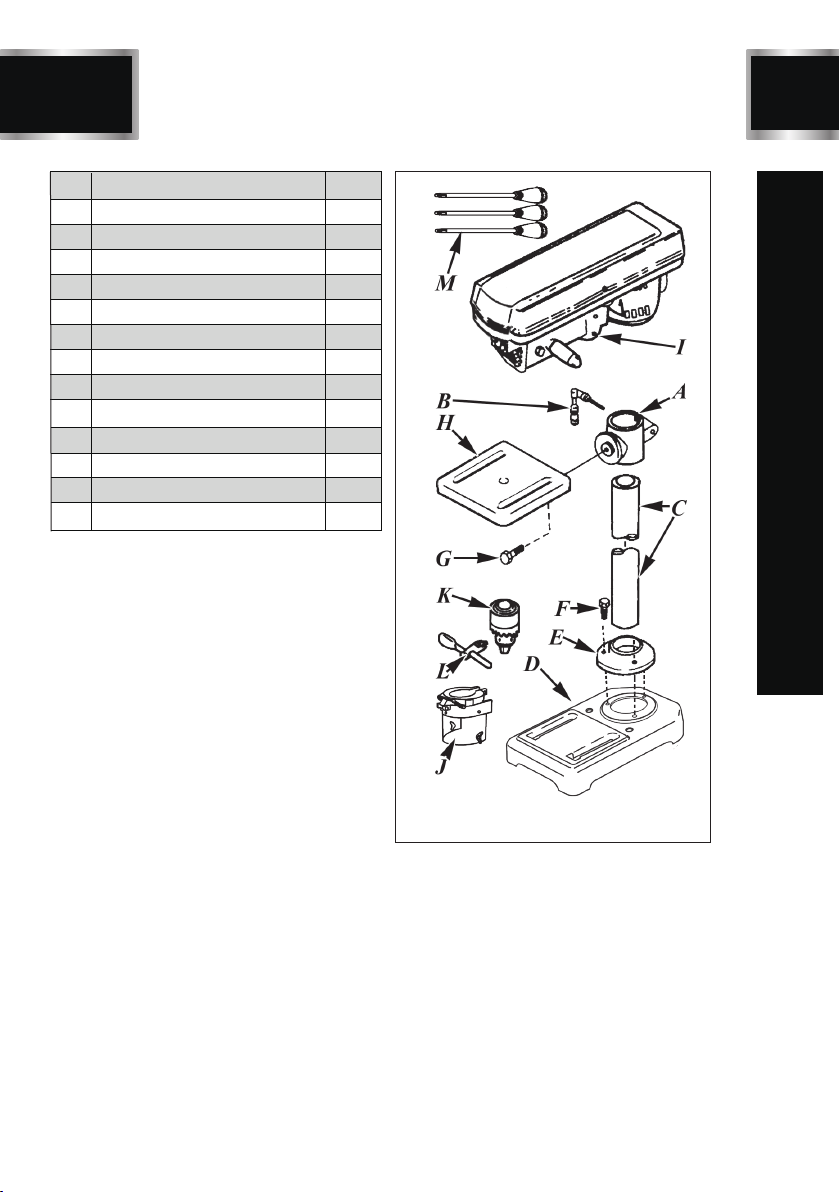

PACKAGE CONTENTS

10

No. Description Qty.

1

1

1

1

1

3

1

1

1

1

1

1

3

A Table support bracket

B Support lock handle

C Column

D Base

E Column support collar

F M8 x 20 hex head screw

G Table bevel lock screw

H Table

I Head assembly

J Chuck guard

K 1/2" Chuck

L Chuck key

M Feed handles

DP8

Fig. B

BD4603

11

KEY PARTS DIAGRAN

DP8

A Table support bracket

B Support lock handle

C Column

D Base

E Column support collar

G Table bevel lock screw

H Table

J Chuck safety guard

K 1/2” chuck

M Feed handle

N On /Off switch

O Switch lock-out key

P Quill return spring

Q Depth stop rod & nuts

R Motor pivot

S Laser switch

T Motor

U Belt & pulley cover

V Depth scale and indicator

W Head lock set-screws

X Cover handle

Y Belt tension lock

ASSEMBLY INSTRUCTIONS

12

BD4603

WARNING

!

For your own safety, never connect plug to

power source outlet until all assembly steps are

complete and you have read and understood

the safety and operating instructions.

The drill press is a heavy power tool and should

be lifted with the help of two PEOPLE OR MORE

to safely assemble it.

DP8

1. Install 3 pcs. M8 x 20 bolts (F,fig 2),threading

them into the base (D, fig 2 & 3) through the

column support collar (E, fig 2 & 3) and tighten

them with a wrench.

2. Slide the table support bracket (A, fig 2 & 3)

onto the column.

3. Install the support lock handle (B, fig 2 & 3)

from the left side into the table support, align the

table with the base and and tighten the support

lock handle by hand.

4. Lift the head assembly (I, fig.1) above and slide

it onto the top of the column.

Note :

The head assembly is heavy and you may

require assistance from a second person.

5. Align the head assembly with the table and

base.

6. Using a 4mm hex (Allen) key, fasten the head

assembly in place by tightening the head lock

set screws (W, fig3) in the right side of the head

casting.

7. Screw the three feed handles (M, fig 2 & 3)

into the the threaded holes in the hub. Instead

of using the knobs for leverage and possibly

stripping them,use a wrench on the flats at the

threaded ends of the handles to tighten.

8. Clean out the tapered hole in the chuck (K,

fig 2 & 3), removing any grease, anti-rust coating

or dirt you find.

9. Clean grease, coating and dirt from the tap-

eredspindle tip with a clean cloth.

10. Open the chuck's jaws as far as they will

go so they are fully retracted into the chuck.

11. Push the chuck up on the spindle as far as

possible.Lightly tap the lower end of the chuck

with a piece of wood to ensure the chuck fits

tightly on the spindle.

12. Install an M5 x 12 pan head screw from the

inside of the pulley cover through the hole and

attach the knob (X, fig 3) to the outside.

1. Locate the laser switch (S, fig 3) on the left

side of the head assembly.

2. Press the tab located below the laser switch

(fig .C) and raise the cover.

3. Insert 2 "AA" batteries, oriented in the dire-

ctions indicated.

4. Close the switch cover.

LASER BATTERIES

Fig. C

Remove the laser light batteries when the tool

is to be stored without use for a few days or

more. If left in position, the batteries might leak

and damage the laser light assembly. Damage

due to leaking batteries is not covered under the

warranty.

CAUTION

!

BD4603

13 DP8

OPERATION

Before using this machine, the operator should

carefully read over this operation manual and

acquaint himself with the construction, controls

and drive system of the drill press.

WARNING

!

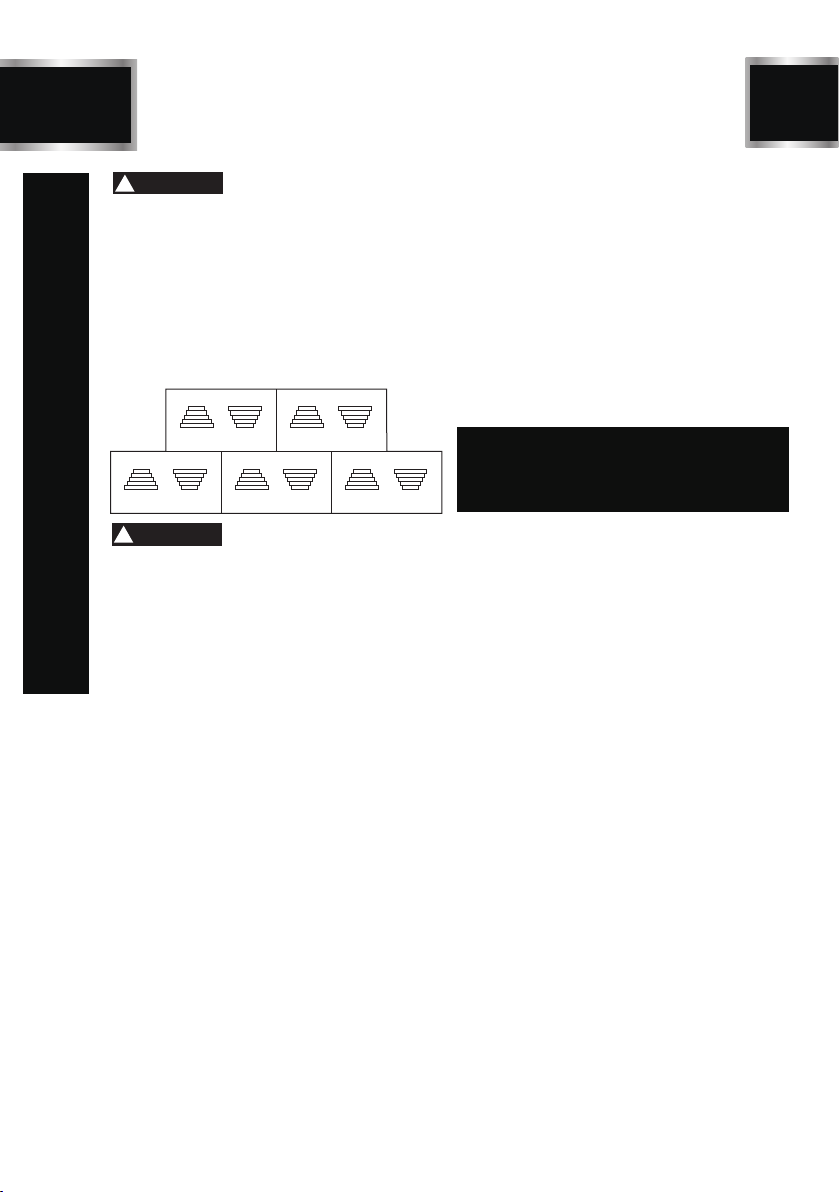

Set The Speed

rpm: 620 tr/min

spindle

broche

motor

moteur

rpm: 1100 tr/min

spindle

broche

motor

moteur

rpm: 1720 tr/min

spindle

broche

motor

moteur

rpm: 2340 tr/min

spindle

broche

motor

moteur

rpm: 3100 tr/min

spindle

broche

motor

moteur

DP2001 belt spindle label

1. Open the belt & pulley cover (U, fig 2 & 3) and

choose the best speed for the drilling operation

planned and install the belt in the correct posit-

ion on the pulleys to produce that speed.

2. To move the belt, loosen the belt tension lock

knob (Y, fig 3) on the right side of the head ass-

embly, and let the motor pivot forward so that it

reduces the distance between the drive (motor)

pulley and the spindle pulley.

3. Place the belt on the two pulleys according to

the needed spindle speed.

4. Re-tension the belt when it is set in position by

pivoting the motor away from the spindle (front)

end of the drill press head and re-tighten the belt

tension lock knob.

5. Close the cover.

Be sure the drill press is turned off and unplugged

when the belt & pulley cover is open and you have

your hands in that area.

WARNING

!

Drill Bit

6. Insert the drill bit into the chuck (K, fig 3) far

enough to obtain maximum grip from the chuck

jaws. Make sure the drill bit is centered in the

chuck.

7. Insert the chuck key (L,fig 2) and turn it cloc-

kwise to tighten (and counter-clockwise to loosen)

the drill bit.Tighten the chuck sufficiently to prevent

the bit slipping in the jaws during drilling.As a

test, turn the drill press on and immediately off to

check if the drill bit wobbles.

Table Adjustment

8. To position the table (H, fig 2) vertically, loosen

the support lock handle (B, fig 2) and raise or

lower the table to the desired position. Re-tighten

the support lock handle.

9. Line up the drill bit with the table center hole

when through-boring to avoid damage to the

table.

10. To tilt the table, loosen the table bevel lock

screw (G, fig 2) under the table, tilt the table to

the desired angle (you can use the bevel scale

on the support as a rough gauge) and re-tighten

the table bevel lock screw.

Note :

It is a good idea to always check that the angle

is correct with a protactor or a combination

square.

Depth Control

11. The drilling depth may be controlled by watc-

hing the indicator and depth scale (V fig 3),on the

left side of the drill press head, or it can be

regulated quite precisely by setting the depth

stop nuts on the depth stop rod (Q, fig 3).

12. Check that the chuck key is not in the chuck

and that the drill bit is not contacting the workpie-

ce. Check that the workpiece is properly anch-

ored on the table. Be sure that all the safety rules

at the front of this manual are followed.

Laser

13. Place a work piece on the table.

14. Turn the laser switch to the on (I) position.

15. Lower the drill bit to meet the work piece. The

two laser lines should cross where the drill meets

the work piece.

16. If the laser needs to be adjusted:

● Using a hex wrench, turn the laser adjustment

hex screws (3) counterclockwise.

● Move the laser light housing until the two lines

intersect where the drill meets the work piece.

DO NOT stare directly at the laser lines.

● Re-tighten the adjustment hex screws .

DriLling

17. Turn the switch on.

18. Use the feed handles to push the drill bit slowly

14

DP8

OPERATION

into the material.Particularly in wood drilling, ease

up on the pressure when nearing the point where

the drill bit is about to emerge on the other side of

the workpiece.

19. After drilling a hole, do not release the feed

handle but restrain it lightly, allowing the spring to

raise spindle sleeve gently to its original position.

20. Turn off the drill press.

21. Switch off the laser.

After switching off, never leave the machine un-

attended until it has come to a complete stop.

WARNING

!

In case of any trouble or abnormal noise arising

during this operation, stop the motor at once,

unplug the machine from the power source and

find out the cause. Do not resume until the problem

has been solved.

WARNING

!

BD4603

15

MAINTENANCE

DP8

For your own safety, turn the switch off

and remove the plug from the power source

outlet before adjusting, maintaining or

lubricating your drill press.

WARNING

!

To avoid electrocution or fire, any repairs to

electrical systems should be done by an

authorized repair center.

WARNING

!

1. If power cord is worn, cut or damaged in

any way, have it replaced immediately.

2. After use, blow out or vacuum sawdust and

metal chips that may have accumulated in and

on the motor, the belt and pulley housing, and

the table.

3. Ball bearings are packed with grease at the

factory. They require no further lubrication.

The ball bearings in the spindle and the V-belt

pulley assembly are greased and permanently

sealed.

4. Periodically pull down and lubricate the

grooves in the spindle and the rack (teeth of

the quill), usually about every three months.

5. Occasionally apply a light coat of paste wax

to the column and table to help keep these

surfaces clean and rust-free.

6. Lubricate the table bracket and locking knobs

if they become difficult to use.

7. Cut off the power supply when not in use.

Note :

SERVICE AND REPAIRS should be made by

qualified repair technicians at an authorized

repair center. Improperly repaired tools could

cause serious shock or injury.

Note :

REPLACEMENT PARTS. When servicing,

use only the manufacturer’s recommended

replacement dentical replacement parts

and accessories.

16

BD4603

To avoid injury from an accidental start, turn the switch OFF and unplug the tool before

moving, or making adjustments.

• Consult your Sears Service Center if for any reason the motor will not run.

PROBLEM PROBLEM CAUSE SUGGESTED CORRECTIVE ACTION

Noisy operation

1. Hand grain in wood or lengths

of cutting utes and/ or angles

not equal.

2. Bent drill bit.

Wood splinters

on underside.

WARNING

!

1. Incorrect belt tension.

2. Dry spindle.

3. Loose spindle pulley.

4. Loose motor pulley.

1. Adjust tension. See section “ASSEMB

LYTENSIONING BELT”

2. Lubricate spindle. See Section

“LUBRICATION”.

3. Check tightenness of retaining nut

on pulley, and tighten if necessary.

4. Tighten set screw in motor pulley.

Drill bit burn.

1. Incorrect speed.

2. Chips not coming out of hole.

3. Dull drill bit.

4. Feeding too slowly.

5. Not lubricated.

1. Change speed. See Section “ BASIC

DRILL PRESS OPERATION SPEEDS

AND BELT REPLACEMENT"

2. Retract drill frequently to clear chips.

3. Resharpen drill bit or replace with new bit.

4. Feed fast enough – allow drill to cut.

5. Lubricate drill. See Section “BASIC DRILL

PRESS OPERATION-FEEDING”

Run out of drill

bit pointdrilled

hole not round.

1. Resharpen drill bit correctly.

2. Replace drill bit.

1. No backup material under

workpiece.

1. Use backup material. See Section

“BASIC DRILL PRESS OPERATION”.

Workpiece torn

loose from hand.

1. Not supported or clamped

properly.

1. Support workpiece or clamp it. See Section

“BASIC DRILL PRESS OPERATION”.

Drill bit binds in

workpiece.

1. Workpiece pinching drill bit,

or excessive feed presure.

2. Improper belt tension.

1. Support workpiece or clamp it. See

Section “BASIC DRILL PRESS OPERATION”.

2. Adjust tension. See Section” ASSEMBLY –

TENSIONING BELT”

TROUBLESHOOTING GUIDE

DP8

BD4603

17

PROBLEM PROBLEM CAUSE SUGGESTED CORRECTIVE ACTION

1. Bent drill bit.

2. Worn bearings.

3. Drill bit not properly

installed in chuck.

4. Chuck not properly installed.

Quill returns

too slow or

too fast.

Excessive drill

bit runout or

wobble.

1. Use a straight drill bit.

2. Replace bearings.

3. Install drill properly. See Section

“BASIC DRILL PRESS OPERATION”

and “ASSEMBLY”.

4. Install chuck properly. See Section

“ASSEMBLY –INSTALLING THE

CHUCK”.

1. Coil spring has improper

tension.

1. Adjust spring tension. See Section

“ ASSEMBLY – ADJUSTMENTS

–QUILL RETURN SPRING”.

Chuck will not

stay attached

to spindle. It

falls off when

trying to install.

1. Dirt, grease, or oil on the

tapered inside surface of

chuck or on the spindle’s

tapered surface.

1. Using a non-alcohol based

cleaner, clean the tapered

surface of the chuck and

spindle to remove all dirt,

grease and oil. See Section

“ASSEMBLY – INSTALLING

THE CHUCK”.

DP8

TROUBLESHOOTING GUIDE

18

EXPLONED VIEW

DP8

BD4603

19

PARTS LIST

DP8

POS. DESCRIPTION QTY.

11

21

33

41

51

61

71

81

93

10 3

11 1

12 1

13 1

14 2

15 1

16 1

17 1

18 2

19 1

20 1

21 1

22 2

23 2

24 2

25 2

26 1

27 2

28 4

29 1

30 1

31 4

32 4

33 1

34 2

35 1

36 2

37 2

38

Base

Column support

Screw, hex hd. M8 x 20

Column tube

Table support

Table clamp

Table

Screw hex hd. M12 x 25

Knob

Feed handle rod

Shaft pinion

Hex nut M8

Socket set screw

Hex socket set screw M8 x 8

Motor stop spring

Motor stop

Laser localizer

Motor

Pulley, motor

Hex socket set screw M8 x 10

Hex screw M8 x 25

Washer 8

Lock nut M8

Head

Bushing, rubber

Washer, foam

Guard

V-belt, K26

Washer 6

Pan head screw M6 x 12

Screw, pan M5 x 10

Hex.soc screw M6 x 6

Knob

Screw, pan hd. M5 x 10

Clamp, cord

Pulley, spindle 1

POS. DESCRIPTION QTY.

39 Retaining ring 22 1

40 Pulley insert 1

41 Bearing, ball 6203 2

42 Spacer 1

43 Retaining ring 17 1

44 Pointer 1

45 Depth stop rod 1

46 Nut, hex M10 4

47 Screw, hex. soc. set M8 x 8 1

48 Cap, spring 1

49 Spring, tension 1

50 Star washer 5 2

51 Spring washer 5 2

52 Screw, pan hd. M5 x 6 2

53 Box, switch w/depth scale 1

54 Screw, pan hd. M5 x 14 2

55 Switch plate 1

56 Screw, pan hd. ST4.2 x 9.5 2

57 Switch 1

58 Gasket, quill 1

59 Bearing, ball 6201 2

60 Tube, quill 1

61 Washer 6 1

62 Eye shield 1

63 Hex nut M6 1

64 Retaining ring 11 1

65 Shaft, spindle 1

66 Chuck 1

67 Key, chuck 1

68 Wrench, hex "L" S3 1

69 Wrench, hex "L" S4 1

70 Cord & plug 1

71 Battery compartment 1

72 Screw, pan M4 x 10 2

73 Battery 2

74 Lid, cell box 1

75 Switch, laser 1

76 Hex nut M5 2

DP8

20

BD4603

ONE-YEAR LIMITED WARRANTY

WARRANTY

Having Problems ?

Give us a chance to help you before returning this product

Email :

After the phone:(844) 866-5687

Table of contents