TOUGH-WORKS TLGS625 User manual

INSTRUCTION

MANUAL

IMPORTANT:

For your own safety, read and follow all of the Safety

Guidelines and Operating Instructions before operating

this product.

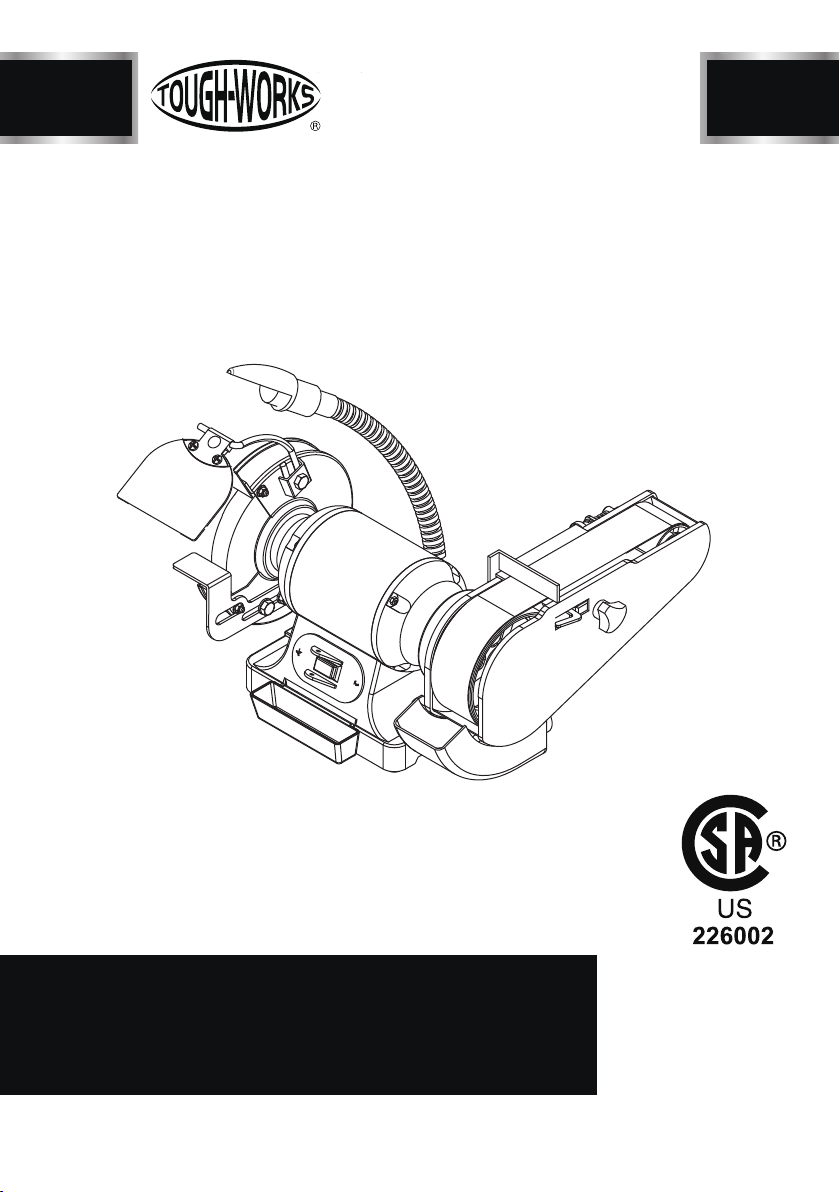

TLGS625

2"X 28" BELT AND 6" WHEEL

BENCH GRINDER SANDER

2

TABLE OF CONTENTS

SPECIFICATIONS

Motor 120V, 60Hz , 2.5A

Speed (no load) 3450RPM

Belt size 2" x 28"

Wheel size

TABLE OF CONTENTS

TABLE OF CONTENTS ...............................................................................................

2

SAFETY GUIDELINES ................................................................................................

4

PACKAGE CONTENTS ..............................................................................................

7

KEY PARTS DIAGRAN

..................................................................................................

8

ASSEMBLY INSTRUCTIONS........................................................................................

10

OPERATION .................................................................................................................

12

MAINTENANCE ............................................................................................................

15

TROUBLESHOOTING GUIDE .....................................................................................

17

EXPLONED VIEW .........................................................................................................

18

PARTS LIST ..................................................................................................................

19

WARRANTY ..................................................................................................................

20

ELECTRICAL SAFETY .................................................................................................

6

SPECIFICATIONS ......................................................................................................

2

6"x3/4"x1/2"

TLGS625

BD4603

SAFETY GUIDELINES

3TLGS625

GENERAL SAFETY GUIDELINES

BEFORE USING THIS POWER

TOOL

• Operate in a safe work environment. Keep

your work area clean, well lit and free of

distractions.

• Keep anyone not wearing the appropriate s

afety equipment away from the work area.

• Store tools properly in a safe and dry location.

Keep tools out of the reach of children.

• Do not install or use in the presence of flam-

mable gases, dust or liquids.

• Always wear impact safety goggles that

provide front and side protection for the eyes.

Wear a full-face shield if your work creates

metal filings or wood chips. (Eye protection

equipment should comply with ANSI Z87.1

standards.)

• Wear gloves that provide protection based on

the work materials or to reduce the effects of

tool vibration.

• Non-skid footwear is recommended to main-

tain footing and balance in the workenvironment.

• Wear the appropriate rated dust mask or

respirator.

• Do not operate any tool when tired or under

the influence of drugs, alcohol or medications.

• Avoid wearing clothes or jewelry that can b-

ecome entangled with the moving parts of a

tool. Keep long hair covered or bound.

• Do not overreachwhen operating the tool.

Proper footing and balance enables better

control in unexpected situations.

• Securely hold the material using both hands.

Applying the material to the grinder with only

one hand can result in a loss of control.

• Never use a tool with a cracked or worn gri-

nding wheel. Change the grinding wheel

before using.

• Replace cracked wheel immediately. Use only

flanges supplied with the grinder.

• Clean dust and debris from beneath the gri-

nding wheels frequently.

• Do not start the tool if the grinding wheel is in

contact with the workpiece.

• Always ensure the safety guards are attached

correctly and do not operate the bench grinder

without the guards attached. Adjust the dista-

nce between the wheel and the tool rest to

maintain a 1/16 in. or less separation as the

diameter of the wheel decreases with use.

• Use an appropriate dust respirator when working

for an extended period of time. This will help

prevent breathing in the fine dust created while

grinding.

• Do not grind on the sides of grinding wheels

unless they are specifically designed for that

purpose.

• Before using the tool on the workpiece, run the

tool at the highest speed, without a load, for at

least 30 seconds in a safe position. Stop im-

mediately if there is any vibration or wobbling

that could indicate poor installation or a poorly

balanced grinding wheel.Check the tool to

determine the cause.

• Do not allow the motor to overload or overheat.

Take breaks to rest the tool.

• Do not subject the grinding wheel to any lateral

pressure as it may damage the tool or cause

it to kickback.

ADDITIONAL SPECIFIC SAFETY

RULES

1. Only use a grinding wheel with the correct arbor

size and shape that matches the grinder’s

spindle.

2. Ensure the grinding wheel has a clean edge.

Check the grinding wheel for wear or chipping

and replace if necessary.

3. Never install more than one grinding wheel at

a time unless the tool and wheels are design-

ed for that purpose.

4. A large amount of sparks will be created when

working with a grinding wheel. Hold the tool

so that sparks fly away from you and other

persons or flammable materials. Have a fully

charged fire extinguisher present.in the event

of a fire.

5. Do not subject the grinding wheel to any

lateral pressure as it may damage the

tool or cause it to kickback.

SAFETY GUIDELINES

4

TLGS625

6. Disconnect tool from power source before

cleaning, servicing, changing parts/accessor-

ies or when not in use.

7. Protect yourself against electric shocks when

working on electrical equipment. Avoid body

contact with grounded surfaces. There is an

increased chance of electrical shock if your

body is grounded.

8. Do not expose tool to rain or water entering a

power tool will increase the risk of electric shock.

9. Do not disconnect the power cord in place of

using the ON/OFF switch on the tool.This will

prevent an accidental startup when the power

cord is plugged into the power supply.

10. Do not alter any parts of the tool or accessories.

All parts and accessories are designed with

built-in safety features that may be compro-

mised if altered.

11. Make certain the power source conforms to

requirements of your equipment.

12. Do not allow the tool to run without load for an

extended period of time, as this will shorten

its life.

13. Do not cover the air vents. Proper cooling of

the motor is necessary to ensure normal life

of normal life of the tool.

14. Avoid unintentional starting. Ensure the switch

is off when connecting to the power source.

15. In the event of a power failure, turn off the

machine as soon as the power is interrupted.

interrupted. The possibility of accidental injury

could occur if the power returns and the unit is

not switched off.

16.Disconnect the power source before installing

or servicing the tool.

17. After making adjustments, make sure that any

adjustment devices are securely tightened.

18. Remove adjusting keys and wrenches before

turning the tool on. A wrench or a key that is left

attached to a rotating part of the tool increases

the risk of personal injury.

19. Never forcethe tool. Excessive pressure could

break the tool, resulting in damage to your

workpiece or serious personal injury.If your tool

runs smoothly under no load, but does not run

smoothly under load, then excessive pressure

is being used.

20. Do not touch an operating motor. Motors can

operate at high temperatures.

21. Only use accessories that are specifically

designed for use with the tool. Ensure the

accessory is tightly installed.

22. Only use an accessory that exceeds the No

Load Speed rating.

23. Do not touch an operating motor. Motors can

operate at high temperatures and can cause

a burn injury.

24. Insert the power cord plug directly to the power

supply whenever possible. Use extension cords

or surge protectors only when the tool's power

cord cannot reach a power supply from the work

area.

25. Do not operate this tool if the power cord is fr-

ayed or damaged as an electric shock may

occur, resulting in personal injury or property

damage.

26. Inspect the tool's power cord for cracks, fraying

or other faults in the insulation or plug before

each use.

27. Discontinue use if a power cord feels more than

comfortably warm while operating the tool.

28. Keep all connections dry and off the ground to

reduce the risk of electric shock. Do not touch

plug with wet hands.

29. Do not allow people, mobile equipment or ve-

hicles to pass over unprotected power cords.

30. This tool vibrates during use. Repeated or long-

term exposure to vibration may cause tempo-

rary or permanent physical injury, particularly

to the hands, arms and shoulders.

ELECTRICAL SAFETY

BD4603

5TLGS625

A separate electrical circuit should be used for your

machines. This circuit should not be less than #12

fuse. If an extension cord is used, use only 3-wire

extension cords which have 3-pronged grounding

type plugs and matching receptacle which will

accept the machine’s plug. Before connecting the

machine to the power line, make sure the switch

is in the "OFF" position and be sure that the ele-

ctric current is of the same characteristics as

indicated on the machine. All line connections

should make good contact.Running

on low voltage

wire and should be protected with a 20-A time-lag

will damage the machine.

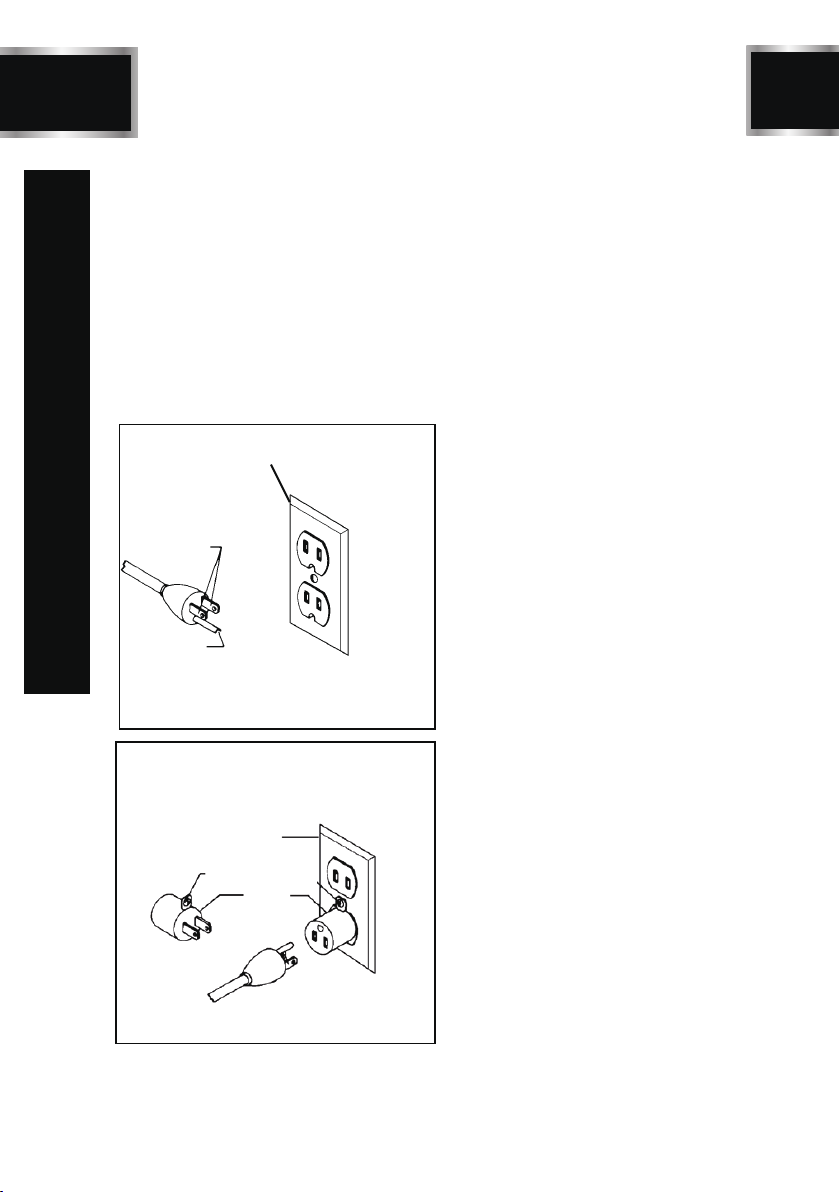

GROUNDED

OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

GROUNDED OUTLET

BOX

GROUNDING

MEANS

ADAPTER

Figure. 1

Figure. 2

MOTOR SPECIFICATIONS

Your machine is wired for 120 V, 60Hz

alternating current. Before connecting the

machine tothe power source, make sure

the switch is in the "OFF" position.

GROUNDING INSTRUCTIONS

!

DANGER!

DO NOT EXPOSETHE MACHINE TO RAIN OR

OPERATE THE MACHINE IN DAMP LOCATIONS.

THIS MACHINE MUST BE GROUNDED

WHILE IN USE TO PROTECT THE OPERATOR

All grounded, cord-connected machines: In the

event of a malfunction or breakdown,grounding

provides a path of least resistance for electric

current to reduce the risk of electric shock. This

machine is equipped with an electric cord having

an equipment grounding conductor and a gro-

unding plug.

FROM ELECTRIC SHOCK.

The plug must be plugged into a matching outlet

that is properly installed and grounded in accor-

dance with all local codes and ordinances.

Do not modify the plug provided–if it will not fit

the outlet, have the proper outlet installed by a

qualified electrician.

Improper connection of the equipment-grounding

conductor can result in risk of electric shock. The

conductor with insulation having an outer surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or repl-

acement of the electric cord or plug is necessary,

do not connect the equipment-grounding condu-

ctor to a live terminal.

Check with a qualified electrician or service per-

sonnel if the grounding instructions are not com-

pletely understood, or if in doubt as to whether the

machine is properly grounded.

Use only 3-wire extension cords that have 3-pronged

grounding type plugs and matching 3-conductor

receptacles that accept the machine’s plug, as shown

in Fig. A.Repair or replace damaged or worn cord

immediately.

6

TLGS625

MINIMUM GAUGE FOR CORD SETS

Use proper extension cords. Make sure your extension

cord is in good condition and is a 3-wire extension

cord which has a 3-pronged grounding type plug

and matching receptacle which will accept the ma-

chine’s plug. When using an extension cord, be

sure to use one heavy enough to carry the current

of the machine. An undersized cord will cause a

drop in line voltage, resulting in loss of power and

overheating. The table shows the correct gauge

to use depending on the cord length. If in doubt,

use the next heavier gauge. The smaller the gauge

number, the heavier the cord.

Ampere rating of

the tool

(120V circuit only)

More

than

Total length of cord

Minimum Gauge for the

extension cord (AWG)

Not more

than

In all cases,make certain the receptacle in que-

stion is properly grounded.

If you are not sure,have a electrician check the

receptacle.

WARNING!

!

ELECTRICAL SAFETY

BD4603

7

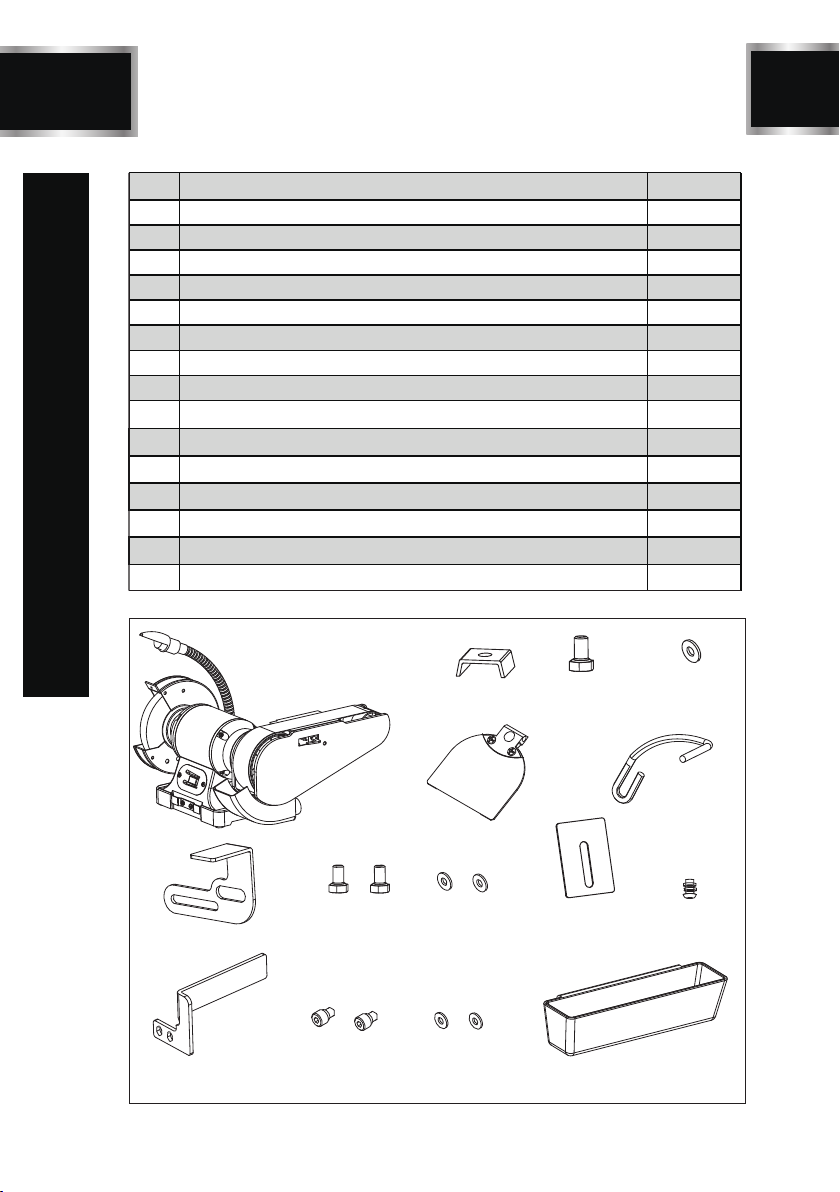

PACKAGE CONTENTS

TLGS625

Description Qty.

Bench grinder sander 1

1

Flat washer D8 1

Hex bolt M8x14 1

Work table deflector

1

Hex column screw M5x12

1

Flat washer D5

2

Coolant tray

Philips screw + flat washer + spring washer M5X10

2

1

1

1

Spark deflector

2

2

1

Pressing block

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

No.

1234

Eyeshield+Eyeshield pressing plate assy

5

Tool rest

Flat washer D8

Hex bolt M8x10

6

7 8 910 11

12 13 14 15

1

Eyeshield bracket

8

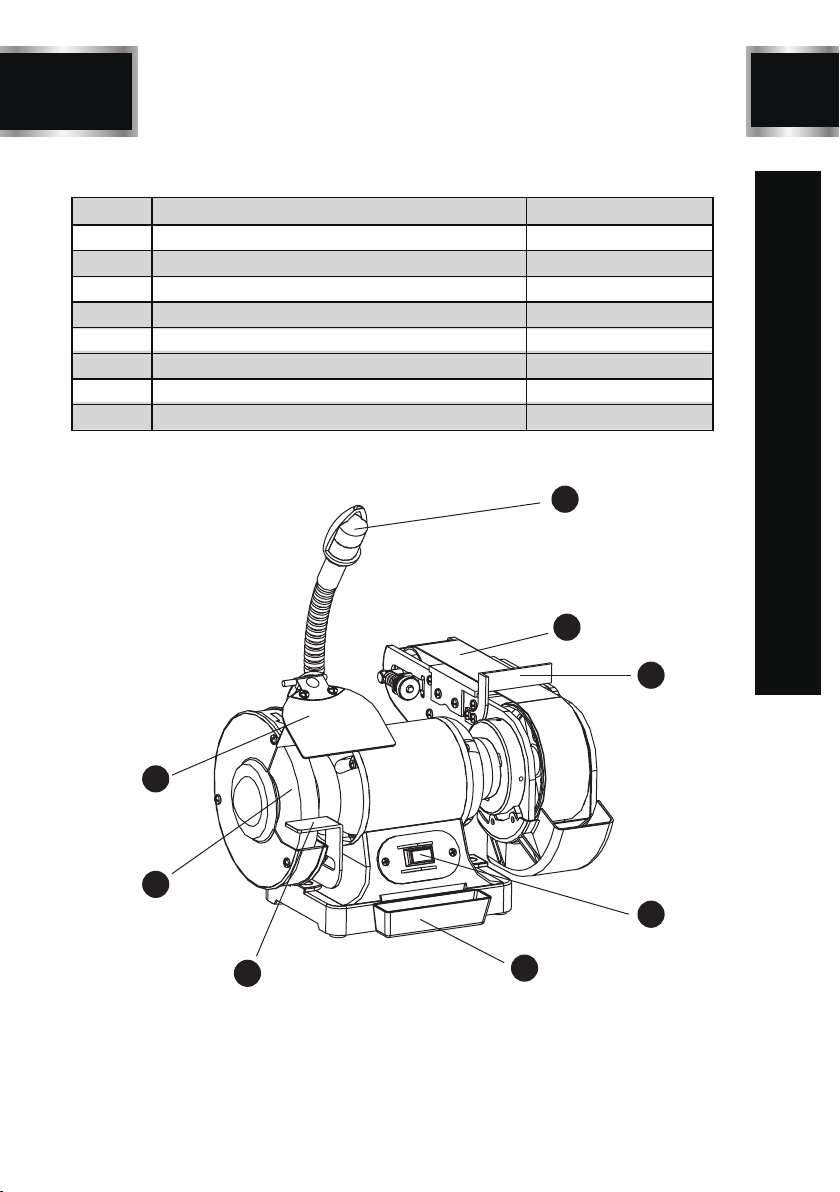

KEY PARTS DIAGRAN

TLGS625

1

2

4

3

5

6

7

8

No. Description Qty.

1LED work light 1

2Sanding belt

Work table deflector

1

3

ON/OFF switch

1

4

Coolant tray

1

5

Tool rest

1

6

Grinding wheel

1

7

Eyeshield assy

1

81

BD4603

9TLGS625

ASSEMBLY INSTRUCTIONS

The tool rest attaches to the inward side of

the guard and provides a surface that must

be used to support the workpiece during

operation.Certain types of grinding/sanding

may require jigs or accessories that will be

used with the tool rests to assure the proper

angle of the workpiece against the wheel.

Failure to install and use the tool rest can lead

to serious personal injury.

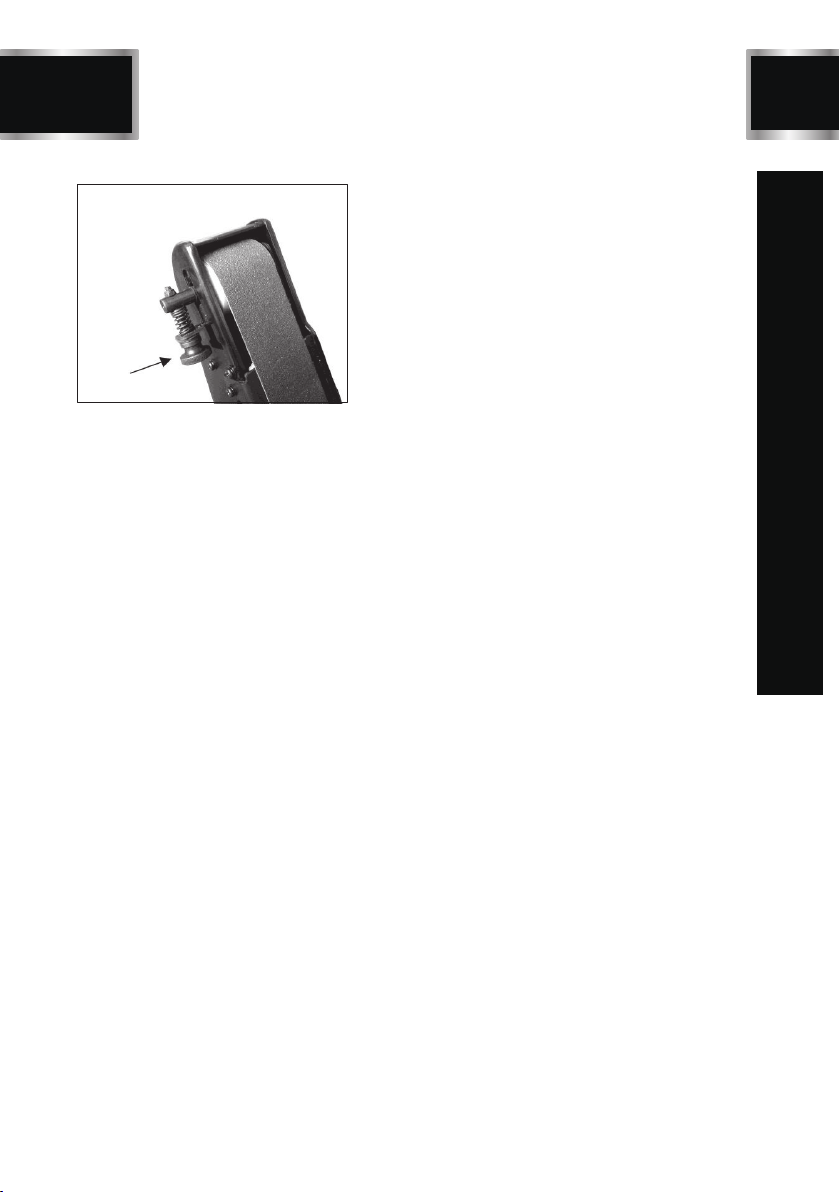

To install the tool rests:

1.Loosely attach the tool rests perpendicular

to the belt or wheel surface with the knob

bolts, 5 mm washers and hex nuts.

2.To adjust the angle of the sanding belt

tool rest, use a square or a protractor to

set the angle of the tool rest in relation

to the sanding belt.

3.Adjust both tool rests approximately 1/16

to 1/8 in. from the grinding wheel and the

sanding belt and tighten the knob bolts.

(in Fig.3)shows the correct adjustment

for the tool rest at the grinding wheel.

INSTALLATION TOOL RESTS

Figure 3

The spark guard must be installed and posi-

tioned 1/8 in. from the grinding wheel to minimize

sparks flying towards the operator. The eye

shield must be positioned between the grinding

wheel and the operator's face to protect the

operator from flying debris. This is not a rep-

lacement for safety glasses!

To install the spark guard and eye shield:

1.Using the included 5 mm screw and washer,

install the spark guard as shown(in Fig.4).

SPARK GUARD & EYE SHIELD

2. Attach the eye shield to the support bracket

with the included 6 mm carriage bolt and hex

nut.Use the 8 mm hex bolt and washer to attach

the support bracket to the grinder.

Figure 4

BELT TRACKING

Tracking the sanding belt means to center the

belt on its rollers, so that it runs balanced and

does not make contact with the sides of the

belt cover.

To track the sanding belt:

1. Disconnect the machine from the power

supply.

2. Rotate the grinding wheel.

3. As you rotate the grinding wheel,watch how

the sanding belt rides on the upper roller.If

the belt is tracking properly, the sanding belt

should be centered between the sides of the

belt cover as shown (in Fig. 5).

4. While spinning the wheel, turn the tracking

control knob counterclockwise to make the

belt move to the left, or turn the tracking

control knob clockwise to make the belt move

to the right (in Fig. 6).

5. After the belt is centered, spin the grinding

wheel approximately ten times to ensure

that the belt continues to track properly.

Figure 5

10

TLGS625

ASSEMBLY INSTRUCTIONS

Figure 6

DUST PORT

The dust port is located behind the sanding belt,

below the belt roller.

The operning is 1-1/2in.in diameter and can be

connected to a utility vacuum or a dust collector.

To connect the dust port to a dust collection

system:

1. Place a hose clamp over the dust hose.

2. Slide th hose over the dust port.

3. Secure the hose airtight with the hose clamp.

4. Check the hose with a light tug to ensure it is

secure.

BD4603

11

WARNING

!

OPERATION

TLGS625

The operation of any grinder can result in

foreign objects being thrown into your eyes,

which can result in severe eye damage.

Before beginning power tool operation, always

wear safety goggles or safety glasses with

side shields and a full face shield when needed.

We recommend Wide Vision Safety Mask for

use over eyeglasses or standard safety gl-

asses with side shields.

TEST RUN

Once mounting is complete and adjustments are

done to your satisfaction, you are ready to test

the machine.

To test run the grinder/sander:

1. Plug the machine into the power source.

2. Stand to the side of the grinding wheel and

turn the grinder ON.

The machine should run smoothly with little or

no vibration or rubbing noises. Strange or un-

usual noises should be investigated and corr-

ected before operating the machine further.

If the machine seems okay, stay out of the line

of rotation of the grinding wheel and let it run for

1 to 2 minutes to make sure the wheel is stru-

cturally sound.

All grinding wheels have the potential of b-

reaking apart during operation,causing serious

personal injury or death! Always stand to the

side of the grinder when turning it ON and

wear the proper safety equipment to protect

yourself.

WARNING

!

The grinder is a safe tool when used properly.

In addition to the safety instructions in this man-

ual, the most important safety consideration is to

use common sense at all times. What may be

okay in one situation, may not be safe in another.

Read the following statements to protect yourse-

lf before grinding:

• Make sure all guards and eye shields are in

place.

BEFORE GRINDING

• Remember that grinding often produces sparks.

DO NOT allow anyone to stand in the path of the

sparks. DO NOT grind near flammable liquids or

gases.

• Wear the proper protective clothing. Remember

that particles flying off of a grinding wheel will be

traveling very fast. Wear safety glasses or a face

shield, a dust mask, earplugs, a leather apron and

heavy leather boots.

• DO NOT lean into the workpiece in a manner that

may cause your hands to move into the spinning

wheel if the workpiece slips off.

• Concentrate on the task at hand. STOP grinding/

sanding if there are distractions.

NOTICE! The grinder is designed for use with

hard metals only. Soft metals and wood pro-

ducts should only be used on the sanding belt.

They will quickly load the grinding wheel surface

and ruin its abrasive qualities.

OPERATING GRINDER

To grind with the grinding wheel:

1. Fill the coolant tray 3/4 full with water.

2. Move the red switch to the ON position.

3. Allow the machine to run for at least 1 full minute

to ensure that the grinding wheel is safe for use.

4. Grasp the workpiece tightly and properly support

it on the tool rest.

5. Place the workpiece against the front surface of

the wheel with moderatepressure, moving it back

and forth in a steady, even motion.

6. Regularly dip the workpiece into the coolant tray

to cool it off.

7. When you are ready to stop the grinder, move the

red switch to the OFF position. At this point, DO

NOT continue grinding and DO NOT manually

stop the grinding wheel with your workpiece!

Note: Using too much pressure will slow the motor

and may damage the wheel. Using too little pres-

sure will make the workpiece bounce around and

you will not make good contact with the wheel.

CAUTION! The sanding belt will remove large amo-

unts of material quickly, including your skin. DO NOT

touch the sanding belt and always position your

hands so they will not slip into the belt or get caught

SANDING

12

BD4603 TLGS625

in the belt.

OPERATION

The2in.sanding belt on the machine works great

for non-ferrous metals and wood products. A wide

variety of belts are also available for many types

of materials and stages of finishing.

To sand a workpiece:

1. Before starting the machine, adjust the angle

of the tool rest so your workpiece is supported

and the area you wish to sand is parallel with

the sanding belt as illustrated(in Fig 7).

2. With the machine plugged into power, stand

to the side of the grinding wheel and move

the red switch to the ON position.

Figure 7

3. Allow the machine to run for at least 1 full mi-

nute to make sure that the grinding wheel is

not going to fly apart and injure you, then move

to the front of the machine.

4. Grasp the workpiece tightly and properly

support it on the tool rest.

5. Press the workpiece evenly against the sa-

nding belt with light pressure (see Fig 8 and 9).

DO NOT press hard. Let the rotation of the

belt do the work.

6. Remove your workpiece regularly to check

the progress the sander has made.

Remember you can always remove more

material but you cannot add it.

7. When you are finished sanding, move the red

switch to the OFF position. DO NOT continue

sanding and DO NOT manually stop the san-

ding belt with your workpiece.

Figure 8

Figure 9

13 TLGS625

MAINTENANCE

1. Maintain the tool with care. A tool in good con-

dition is efficient, easier to control and will have

fewer problems.

2. Inspect the tool components periodically.Repair

or replace damaged or worn components.

3. Follow instructions for lubricating and changing

accessories.

4. When servicing, use only identical replacement

parts. Only use accessories intended for use with

this tool. Replace damaged parts immediately.

5. Maintain the tool’s label and name plate.These

carry important information.

6. Wheels should be dressed periodically to mai-

ntain grinding efficiency,especially if they become

clogged from grinding soft metals. Use a grinding

wheel dresser to restore the wheel’s original

shape.

7. Keep all parts in working order. Check to dete-

rmine that the guard or other parts will operate

properly and perform their intended function.

8. A guard or other part that is damaged should be

properly repaired or replaced. Do not perform

makeshift repairs. Use the parts list provided to

order replacement parts.

9. Disconnect tool when changing grinding wheels.

10. Replace a cracked wheel immediately and use

only flanges supplied with the grinder.

Only qualified service personnel should repair the

tool. An mproperly repaired tool may present a

hazard to the user and/or others.

WARNING

!

Your safety depends, on a large part, on the co-

ndition of the wheel during grinding.A wheel in poor

condition may break apart during rotation,injuring

the operator, a bystander and possibly causing

property damage.

To properly care for your wheel, follow these tips:

• Always transport, store and handle wheels with

care. Wheels may be damaged if they are dro-

pped or if heavy objects are stacked on them.

• Select the right grinding wheel for the job. DO

NOT grind material that is not designed for the

wheel.

• Select the right wheel for the machine. A mac-

hine that rotates at a higher RPM than the wheel

WHEEL CARE

rating may cause the wheel to fly apart.

• Mount the wheels properly (see Replacing

Wheels). Never use a wheel with the wrong

arbor size for the grinder.

• DO NOT abuse the wheel by jamming the work

into the grinding wheel with excessive force.

• Grinding on the side of the wheel may cause

wheel damage.

• Dress the grinding wheel when the surface loses

its abrasive quality or bite.

Dressing restores the grinding wheel’s abrasive

quality. Whenever the front surface of the wheel

loses its abrasive qualities (loading or polishing),

then the wheel should be dressed.

To dress the grinding wheel:

1. With the machine plugged into power, stand

to the side of the grinding wheel and move the

red switch to the ON position.

2. Allow the machine to run for 1 full minute to

make sure that the grinding wheel is not going

to fly apart and injure you, then move to the

front of the machine.

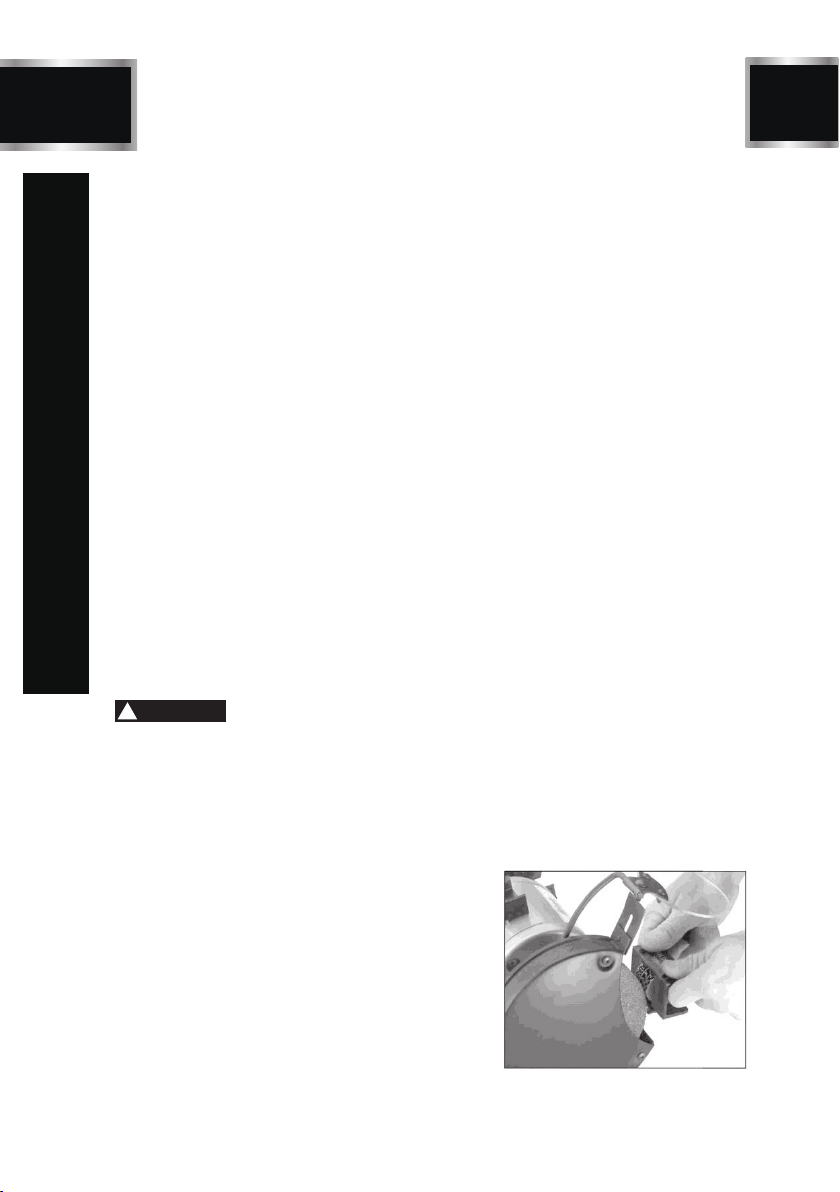

3.Hold the dressing tool firmly on the tool rest

with both hands and press it lightly against

the front surface of the grinding wheel as

shown( in Fig10).

4.Move the dressing tool in a side-to-side motion,

while keeping it even with the front surface of

the grinder.

5.Regularly pull the dressing tool away from the

wheel for visual inspection and repeat Steps 3

&4 until the surface of the wheel appears to be

restored to its normal color and texture.

WHEEL DRESSING

Figure 10

14

TLGS625

MAINTENANCE

Before mounting a new grinding wheel, it must

be inspected. DO NOT assume that a wheel

is in sound condition because it is new. Dam-

age can occur during shipping, with age or

exposure to moisture.

Visually inspect the wheel. Look for any cr-

acks, chips, nicks or dents in the wheel’s

surface. DO NOT use the wheel if you see any

of these, Perform a Ring Test. This

test will

give you an indication of any internal damage

that may not be obvious during

a visual inspection.

To perform a Ring Test:

1. Make sure the wheel that you test is clean

and dry; otherwise, you may get false results.

2. Balance the wheel with your finger in the

hole if size permits, If this is not possible,

hang the wheel in the air with a piece of

cord or string looped through the hole in

the centert.

WHEEL INSPECTION

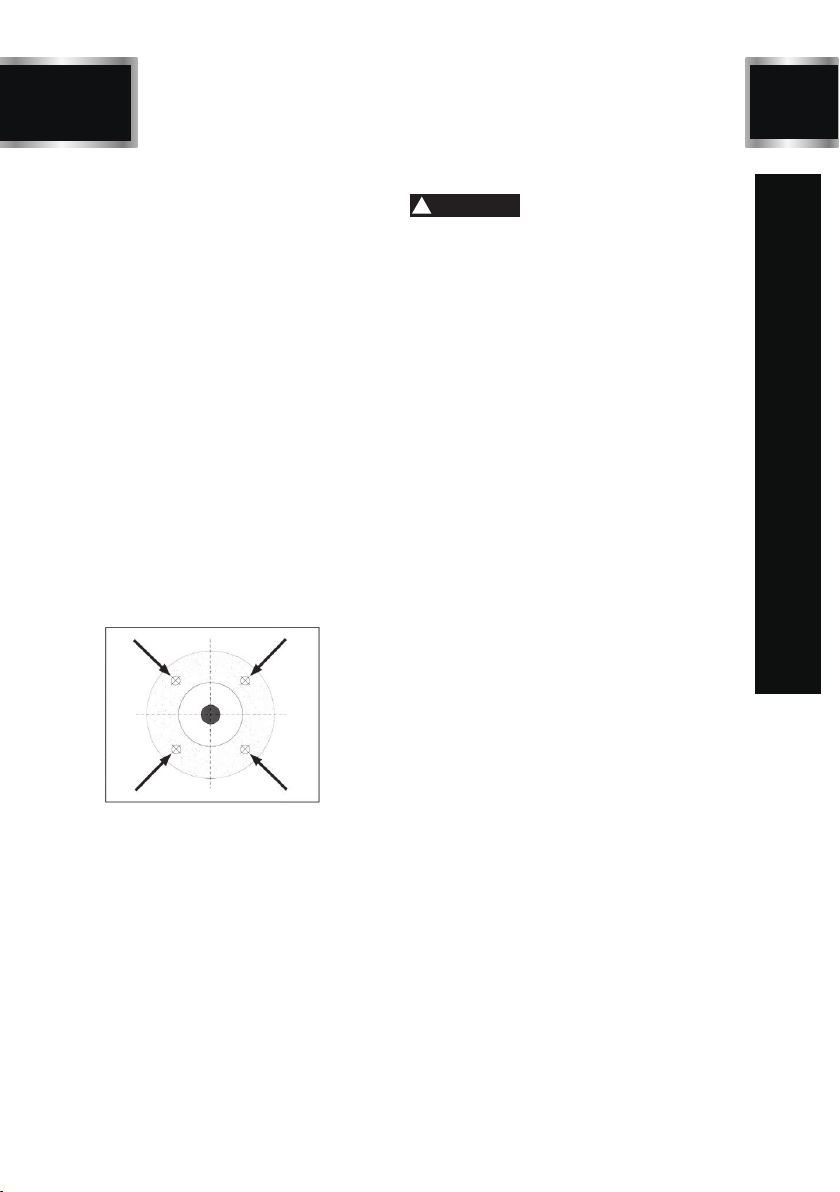

3. At the spots shown in Figure 11, gently

tap the wheel with a light non-metallic

device such asthe handle of a screwdriver

or a wooden mallet.

4. An undamaged wheel will emit a clear me-

tallic ring or "ping" sound in each of these

spots. A damaged wheel will respond with

a dull thud that has no clear tone.

5. DO NOT use it if you determine from the

ring test that the wheel is damaged.

Figure 11

REPLACING WHEELS

The wheel guard assembly must be re-

moved in order to mount or dismount a

grinding wheel.

To remove/mount a wheel:

1. Disconnect the grinder from the power

supply.

2. Remove the three Phillips head screws

and nuts that go through the outer guard.

Take off the outer guard and the rim

guard.

3. Use a wrench on the nut that holds the

wheel on the arbor. Hold the wheel to

prevent it fromturning with your other

hand.The grinding wheel arbor has a

left-handed thread. Loosen the nut by

turning it clockwise.

4. Remove the outer wheel flange and p-

aper disc. Pull the wheel free from the

arbor.There will also be a paper disc

and a wheel flange on the back side of

the wheel which should also be removed.

5. Mount the new wheel in the reverse o-

rder or as shown in Figure 12. Always

make certain there is are paper or fiber

discs between the wheel flanges and

the wheel itself.Tighten the nut snugly

but DO NOT over-tighten.Over-tightening

can crack the wheel.

6. Re-install the guards and shields.

7. Run a new wheel for at least one minute

while standing clear of the line of rota-

tion.If a wheel does have defects it will

generally fail as soon as it gets up to

full speed.

The hazards of using a damaged wheel

include flying chunks of sharp abrasive

material that could cause serious injury

or death. Inspect every grinding wheel

before it is mounted and DO NOT use a

damaged grinding wheel!

WARNING

!

BD4603

15 TLGS625

8. Replacement wheels must have a mi-

nimum rated No Load Speed and a

diameter as listed in the Specifications

section.

Many belts are available with different grit

sizes.

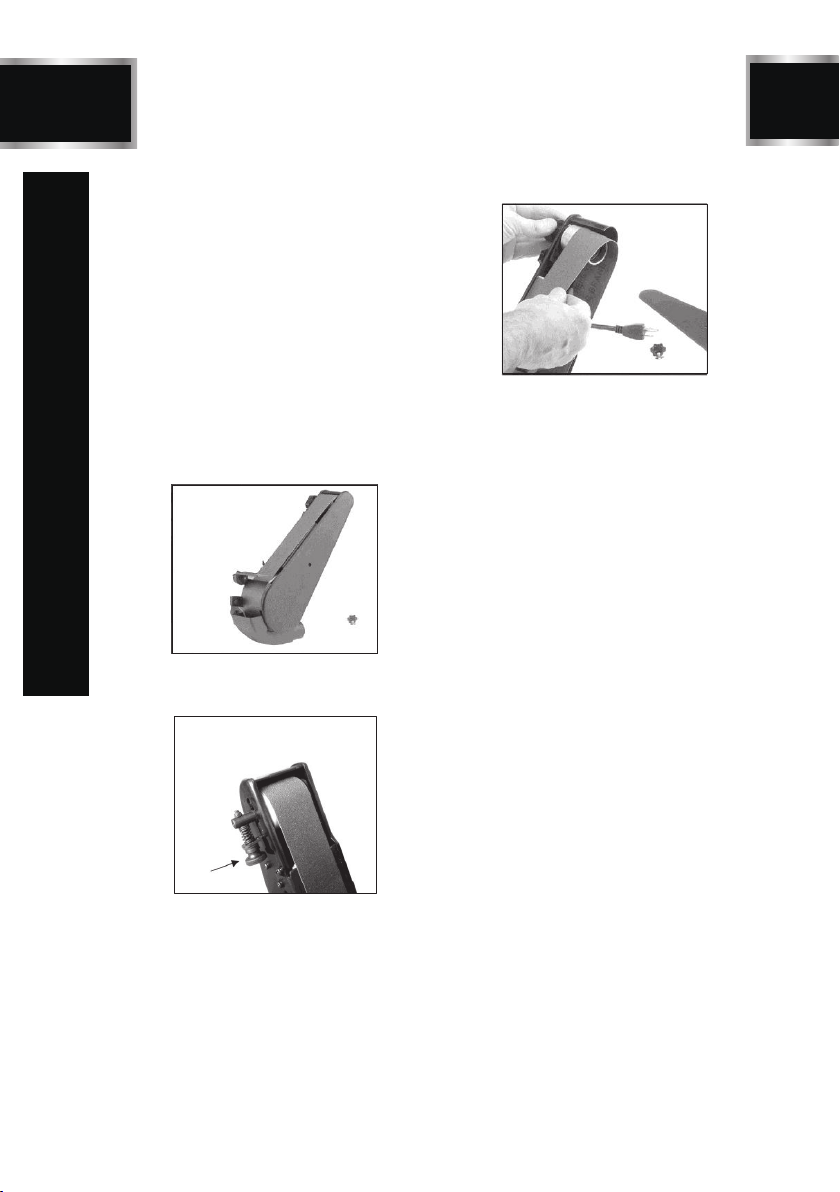

To remove/replace a sanding belt:

1. Disconnect the machine from the power

supply.

2. Remove the star knob from the right-

hand sanding belt cover as shown (in

Fig 13) and remove the cover.

3. Loosen the sanding belt tension knob,

as shown (in Fig 14).

4. Pull the sanding belt tension knob down

with one hand and work the sanding belt

off the rollers with the other hand as

shown( in Fig15).

5. Install the new sanding belt in the reverse

order of removal and replace the belt

cover.

6. Track the new sanding belt before tu-

REPLACING SANDING BELT

Figure 13

Figure 14

Figure 15

rning the machine on (see Belt Tracking).

MAINTENANCE

16

BD4603 TLGS625

TROUBLESHOOTING GUIDE

Problem(s) Possible Cause(s) Suggested Solution(s)

Grinder won’t start.

1. Blown line fuse or tripped

circuit breaker.

2. Low line voltage.

3. Material wedged between

wheel and guard.

4. Defective switch.

5. Defective, blown capacitor.

6. Defective circuit board.

1. Replace with fuse of proper size, if

fuse is blown. Reset tripped breaker.

2.Check power supply for voltage and

correct as needed.

3.Turn grinder off and remove material.

4.Replace switch.

5.Replace capacitor

6.Replace circuit board.

Excessive

vibration.

1. Improper mounting of

grinder or accessories.

2.

Grinding wheel out of balance.

1. Remount bench grinder.

2.

Dress wheels or replace wheels.

Motor overheating.

1. Excess pressure required

to grind material.

2. Grinding on side of wheel.

3. Motor not turning freely

(without power).

1. Dress or replace wheels.

2.

Grind only on face of wheel.

3.

Clean around wheels and shaft

and/

or replace bearings.

Fuses are being

blown or circuit

breakers tripped.

1. Overloading due to binding.

2. Defective plug.

3. Defective cord.

4. Defective switch.

1.

Clean around wheels and shaft

and/

or replace bearings.

2. Replace plug.

3. Replace cord.

4. Replace switch.

Machine slows

when operating.

1. Depth of cut too great. 1. Slow down the rate of movement of

the workpiece into wheel.

Wavy condition on

1. Machine vibrating.

2. Workpiece not being held

firmly.

3. Wheel face uneven.

4. Wheel is too hard.

Make sure machines is securely

mounted on a solid surface.

2.

1.

Use a holdingdevice to firmly

retain the workpiece.

3. Dress the grinding wheel.

4. Use softer wheel, or reduce the

feed rate.

surface of workpiece.

Lines on surface of

workpiece.

1. Impurity on wheel surface.

2. Workpiece not being held

tightly.

1. Dress the grinding wheel.

2. Use a holding device to firmly retain

the w orkpiece.

1. Improper type of grinding

wheel.

2. Improper feed rate.

3. Coolant required.

Burning spots or

cracks in the

workpiece.

1. Try a wheel which is softer style

or a coarser grit.

2. Slow down the rate of movement

of the workpiece into w heel.

3. Add optional coolant system or

introduce coolant by hand .

BD4603

17 TLGS625

TROUBLESHOOTING GUIDE

Problem(s) Possible Cause(s) Suggested Solution(s)

Wheel dulls quickly,

grit falls off.

1. Depth of cut too great.

2. Wheel is soft.

3. Wheel diameter too small.

4. Bad wheel dress.

5. Defective wheel bonding.

1. Slow down the rate of movement

of the workpiece into w heel.

2. Wheel too soft for the material.

being ground, select harde r bond.

3. Replace the wheel.

4. Dress the wheel.

5. Consult manufacturer of grinding

wheel.

Wheel clogs and

workpiece shows

burn marks.

1. Wheel is too hard.

2. Feed rate too slow.

3. Bad wheel dress.

4. Coolant required.

1. Wheel too hard for the material

being ground, select softer bond .

2. Increase the rate of movement of

the workpiece into wheel.

3. Dress the wheel.

4. A dd optional coolant system or

introduce coolant by hand.

18

EXPLONED VIEW

TLGS625

BD4603

19 TLGS625

PARTS LIST

1 Philips Screw M5x 48 3

2 Left Guard Cover 1

3 Hex Nut, IType M12 Left 1

4 Flange 2

5 Grinding Wheel Φ150x20xΦ12.7 60#

6 Philips Screw +Spring Washer Assy. M5x10

7 Left Guard Assy. 1

8 Spark Deflect

9

10 Left Tool Rest 1

11 Flat Washer D8 4

12 Eyeshield Pressing Plate 1

13 Outer Hex Bolt M8X 10 2

14 Hex Nut M6 1

15 Switch 1

16 Philips Screw M4X 10 5

17 Left Eyeshield Bracket 1

18 Pressing Block 1

19 Hex Bolt M8X14 1

20 Eyeshield 1

21 Dome Screw M6X 16 1

22 Philips Screw M4x135 4

23 Flat Washer D4 4

24 End Caps 2

25 LED Bulb 12V0.36W 1

26 Philips Screw + Flat Washer +

Spring Washer Assy.

27 Outer toothed LockingWas her D4 2

28 Cord Bushing 1

29 Cord Clip 1

30 Flat Washer D10 1

31 Locking Nut M10 x1 1

32 Wavy Washer D35 1

33 Bearing 6202RZ 2

34 Stator 1

35 Rotor 1

36 Hex Nut M4 4

37 Power Cord 1

38 LED Assembly 1

39 Hex Bolt M5X20 1

40 Philips Screw M5X 8 4

41 Adjusting Screw 1

42 Hex Bolt M5X 10 2

43 Fixing Disc 1

44 Work Table Deflector 1

1

6

1

7

Philips Screw + Flat Washer +

Spring WasherAssy. M5x10

M4x8 3

45 Flat Washer D5 4

46 Limit Plate 1

47 Coolant Tray 1

48 Hex Nut M5 3

49 Hex Nut M4 2

50 Philips Screw M4 x8 4

51 Philips Screw + Spring Washer Assy. M6x18 2

52 Capacitor 16uF/300V 1

53 Compressing Spring 1

54 Work Table 1

55 Base Plate 1

56 Rubber Foot 4

57 Philips Screw + Flat Washer Assy. M4x12 4

58 Base 1

59 Switch Plate 1

60 Nut M5 2

61 Low Temperature Bearing 6200 2

62 Coolant Tray Clip 1

63 Idle Roller 1

64 Nut M12 1

65 Washer D10 1

66 Dust Cover 1

67 Bushing 2

68 Right Guard 1

69 Supporting Plate 1

70 Adjusting Spring 1

71 Hex Column Screw M5X12 4

72 Guide Frame Assy. 1

73 Philips Screw + SpringWasher Assy. M5X16 3

74 Rotating Disc 1

75 Belt 50x710 mm 80 # 1

76 Right Guard Cover 1

77 Pressing Plate 1

78 Driving Wheel 1

79 Knob M5X18 1

80 Hex Screw M6X 6 3

81 Big Flat Washer D5 4

82 ldling Shaft 1

83 Wrench 1

84 Nut M8 1

85 Rubber Washer 1

86 Capacitor support 1

87 Hex nut M8 1

88 Lamp cover 1

89 Bushing 1

Part Description Qty Description Qty

Part

20

BD4603 TLGS625

Having Problems ?

Give us a chance to help you before returning this product

Email :

After the phone:(844) 866-5687

ONE-YEAR LIMITED WARRANTY

WARRANTY

45 Flat Washer D5 4

46 Limit Plate 1

47 Coolant Tray 1

48 Hex Nut M5 3

49 Hex Nut M4 2

50 Philips Screw M4 x8 4

51 Philips Screw + Spring Washer Assy. M6x18 2

52 Capacitor 16uF/300V 1

53 Compressing Spring 1

54 Work Table 1

55 Base Plate 1

56 Rubber Foot 4

57 Philips Screw + Flat Washer Assy. M4x12 4

58 Base 1

59 Switch Plate 1

60 Nut M5 2

61 Low Temperature Bearing 6200 2

62 Coolant Tray Clip 1

63 Idle Roller 1

64 Nut M12 1

65 Washer D10 1

66 Dust Cover 1

67 Bushing 2

68 Right Guard 1

69 Supporting Plate 1

70 Adjusting Spring 1

71 Hex Column Screw M5X12 4

72 Guide Frame Assy. 1

73 Philips Screw + SpringWasher Assy. M5X16 3

74 Rotating Disc 1

75 Belt 50x710 mm 80 # 1

76 Right Guard Cover 1

77 Pressing Plate 1

78 Driving Wheel 1

79 Knob M5X18 1

80 Hex Screw M6X 6 3

81 Big Flat Washer D5 4

82 ldling Shaft 1

83 Wrench 1

84 Nut M8 1

85 Rubber Washer 1

86 Capacitor support 1

87 Hex nut M8 1

88 Lamp cover 1

89 Bushing 1

Table of contents

Other TOUGH-WORKS Sander manuals

Popular Sander manuals by other brands

DELMEQ

DELMEQ 706500AN instruction manual

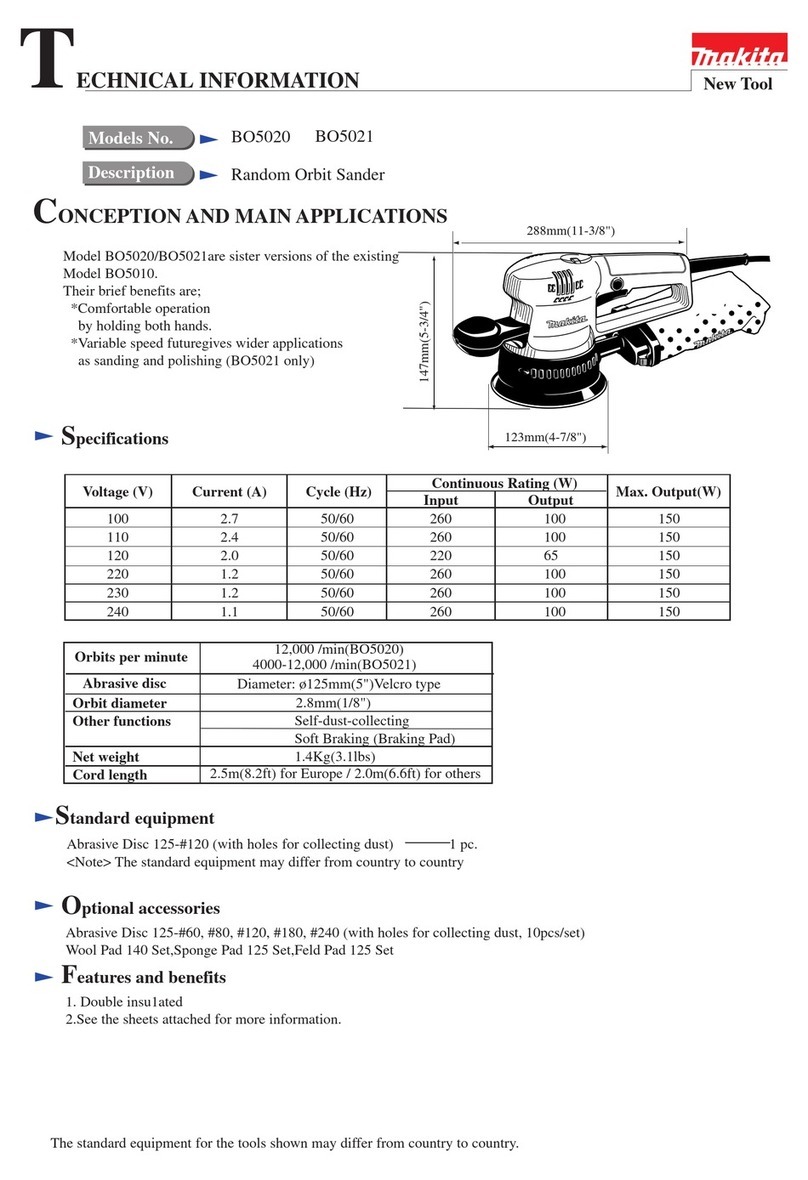

Makita

Makita BO5020 technical information

Steel City

Steel City TITANIUM Series owner's manual

Dynabrade

Dynabrade Mini-Dynorbital Silver Supreme 69500 Safety, operation and maintenance manual

VITO

VITO PRO POWER VILGE710 instruction manual

Kalamazoo

Kalamazoo 2FSM instruction manual