TOX PRESSOTECHNIK Powerpackage Q Series User manual

Original operating instructions

TOX® Powerpackage line-Q

Type Q-S, Q-K

TOX® PRESSOTECHNIK

Riedstrasse 4

D-88250 Weingarten

www.tox-pressotechnik.com

Edition:05/25/2020, Version: 2

GmbH & Co. KG

2TOX_Manual_Powerpackage_line-Q_en

Table of contents

TOX_Manual_Powerpackage_line-Q_en 3

Table of contents

1 Important information

1.1 Legal note ................................................................................................... 7

1.2 Exclusion of liability ..................................................................................... 7

1.3 Conformity................................................................................................... 7

1.4 Validity of the document.............................................................................. 8

1.4.1 Content and target group ............................................................................ 8

1.4.2 Other applicable documents ....................................................................... 8

1.5 Gender note ................................................................................................ 8

1.6 Displays in the document ............................................................................ 9

1.6.1 Display of warnings ..................................................................................... 9

1.6.2 Display of general notes............................................................................ 10

1.6.3 Highlighting of texts and images ............................................................... 10

2 Safety

2.1 Basic safety requirements......................................................................... 11

2.2 Organizational measures .......................................................................... 11

2.2.1 Safety requirements for the operating company ....................................... 11

2.2.2 Selection and qualifications of personnel.................................................. 12

2.3 Fundamental hazard potential................................................................... 13

2.3.1 Electrical hazards...................................................................................... 13

2.3.2 Thermal hazards ....................................................................................... 13

2.3.3 Pneumatic hazards ................................................................................... 13

2.3.4 Contusions ................................................................................................ 14

2.3.5 Hydraulic hazards ..................................................................................... 14

2.3.6 Electromagnetic hazards........................................................................... 15

2.3.7 Laser ......................................................................................................... 15

2.3.8 Hazardous substances.............................................................................. 15

2.4 Safety device on the product..................................................................... 16

2.4.1 Safety device of system ............................................................................ 16

Table of contents

4TOX_Manual_Powerpackage_line-Q_en

3 About this product

3.1 Intended use ............................................................................................ 17

3.1.1 Safe and correct operation........................................................................ 17

3.1.2 Foreseeable misuse.................................................................................. 18

3.2 Product Identification................................................................................. 18

3.2.1 Position and content of the type plate ....................................................... 18

3.3 Function description of Powerpackage ..................................................... 18

3.4 Product overview of Powerpackage line-Q ............................................... 19

3.4.1 Product attributes of Powerpackage line-Q............................................... 19

3.5 Optional equipment ................................................................................... 20

3.5.1 Additional optional equipment ................................................................... 20

4 Technical data

4.1 Type sheet and data sheet........................................................................ 21

4.2 Compressed air quality and pneumatic connection .................................. 21

4.3 Tightening torques .................................................................................... 21

4.3.1 Tightening torques for flange mounting the drive...................................... 21

4.3.2 Tightening torques on the piston rod......................................................... 21

4.4 Press force table ....................................................................................... 22

4.5 Specification for hydraulic oil..................................................................... 22

5 Transport and storage

5.1 Safety during transport.............................................................................. 25

5.2 Lifting device ............................................................................................. 26

5.3 Temporary storages .................................................................................. 26

5.4 Dispatch for repair..................................................................................... 26

6 Installation

6.1 Safety during installation .......................................................................... 27

6.2 Installing drive ........................................................................................... 28

6.3 Installing accessories ................................................................................ 29

6.3.1 Installing electronic pressure switch (ZDO)............................................... 29

Table of contents

TOX_Manual_Powerpackage_line-Q_en 5

6.3.2 Installing position sensors of stroke monitoring for forward and return stroke

(ZHU) ........................................................................................................ 31

6.3.3 Installing the external linear position sensor (ZHW).................................. 33

6.3.4 Installing pressure control in the power stroke line (ZDK)......................... 35

6.3.5 Installing external power stroke connection (ZKHZ) ................................. 36

6.3.6 Installing external power stroke release (ZKHF) and power stroke deactiva-

tion (ZKHD) ............................................................................................... 37

6.3.7 Preparing external power stroke supply.................................................... 38

6.3.8 Installing the stroke frequency optimization (ZHO) ................................... 39

6.3.9 Installing the speed reduction for power stroke venting ............................ 41

6.3.10 Installing tool coupling (ZWK) ................................................................... 42

7 Commissioning

7.1 Safety during the commissioning .............................................................. 43

7.2 Requirements for the commissioning........................................................ 44

7.2.1 Measuring connection and control connection.......................................... 44

7.3 Avoidance of dynamic oil leakage............................................................. 45

7.3.1 Setting speed ratio of return stroke to fast approach stroke ..................... 46

7.3.2 Set the speed ratio between power stroke and power stroke venting (op-

tional) ........................................................................................................ 46

7.4 Setting control throttle 'X' .......................................................................... 47

7.5 Setting total length of stroke (optional)...................................................... 48

8 Operation

8.1 Safety in operation .................................................................................... 49

8.2 Requirements for operation....................................................................... 50

8.3 Operating drive.......................................................................................... 50

9 Troubleshooting

9.1 Safety during troubleshooting ................................................................... 51

9.2 Searching for causes of fault..................................................................... 52

Table of contents

6TOX_Manual_Powerpackage_line-Q_en

Maintenance table of Powerpackage

10 Maintenance

10.1 Safety during maintenance ....................................................................... 57

10.2 Requirements for maintenance ................................................................. 59

10.2.1 Set system to maintenance position ......................................................... 59

10.3 Checking oil level ...................................................................................... 60

10.4 Refilling oil and venting drive .................................................................... 61

10.5 Lowering of oil level................................................................................... 64

10.6 Checking hydraulic hoses ......................................................................... 65

11 Repairs

11.1 Safety during repairs ................................................................................. 67

11.2 Changing seals ......................................................................................... 67

12 Disassembly and Disposal

12.1 Safety during disassembly and disposal ................................................... 69

12.2 Decommissioning...................................................................................... 70

12.3 Shutdown .................................................................................................. 70

12.4 Disassembling........................................................................................... 71

12.5 Disposal .................................................................................................... 71

13 Appendices

13.1 DECLARATION OF INCORPORATION ................................................... 73

Index

Important information

TOX_Manual_Powerpackage_line-Q_en 7

1 Important information

1.1 Legal note

All rights reserved.

Operating instructions, manuals, technical descriptions and software pub-

lished by TOX®PRESSOTECHNIK GmbH & Co. KG ("TOX®PRES-

SOTECHNIK") are copyright and must not be reproduced, distributed and/

or otherwise processed or edited (e.g. by copying, microfilming, translation,

transmission in any electronic medium or machine-readable form). Any use

- including of extracts - contrary to this condition is prohibited without ap-

proval in writing by TOX®PRESSOTECHNIK and may be subject to crimi-

nal and civil legal sanctions.

If this manual refers to goods and/or services of third parties, this is for ex-

ample only or is a recommendation by TOX®PRESSOTECHNIK.

TOX®PRESSOTECHNIK does not accept any liability or warranty/guaran-

tee with reference to the selection, specifications and/or usability of these

goods and services. The use and/or representation of trademarked brands

that do not belong to TOX®PRESSOTECHNIK are for information only; all

rights remain the property of the owner of the trademarked brand.

Operating instructions, manuals, technical descriptions and software are

originally compiled in German.

1.2 Exclusion of liability

TOX®PRESSOTECHNIK has checked the contents of this publication to

ensure that it conforms to the technical properties and specifications of the

products or plant and the description of the software. However, discrepan-

cies may still be present, so we cannot guarantee complete accuracy. The

supplier documentation included with the system documentation is an ex-

ception.

However, the information in this publication is checked regularly and any

required corrections are included in subsequent editions. We are grateful

for any corrections and suggestions for improvement. TOX®PRES-

SOTECHNIK reserves the right to revise the technical specifications of the

products or plant and/or the software or documentation without prior notice.

1.3 Conformity

The product is compliant with EU guidelines.

See separate EU-declaration of conformity or installation declaration.

Important information

8TOX_Manual_Powerpackage_line-Q_en

1.4 Validity of the document

1.4.1 Content and target group

This manual contains information and instructions for the safe operation

and safe maintenance or servicing of the product.

All information in this manual is up to date at the time of print.

TOX®PRESSOTECHNIK reserves the right to make technical changes

that improve the system or increase the standard of safety.

The information is intended for the operating company as well as oper-

ating and service personnel.

1.4.2 Other applicable documents

In addition to the available manual, further documents can be supplied.

These documents must also be complied with. Other applicable documents

can be, for example:

additional operating manuals (e.g. of components or of a whole sys-

tem)

Supplier documentation

Instructions, such as software manual, etc.

Technical data sheet

Safety data sheets

Data sheets

1.5 Gender note

In order to enhance readability, references to persons that also relate to all

sexes are normally only stated in the usual form in German or in the corre-

sponding translated language in this manual, thus e.g. "operator" (singular)

for male or female, or "operators" (plural) for male or female". This should

in no way convey any gender discrimination or any violation of the principle

of equality, however.

Important information

TOX_Manual_Powerpackage_line-Q_en 9

1.6 Displays in the document

1.6.1 Display of warnings

Warning signs indicate potential dangers and describe protective mea-

sures. Warning signs precede the instructions for which they are applicable.

Warning signs concerning personal injuries

DANGER

Identifies an immediate danger!

Death or severe injuries will occur if appropriate safety measures are not

taken.

èMeasures for remedial action and protection.

WARNING

Identifies a potentially dangerous situation!

Death or serious injury may occur if appropriate safety measures are not

taken.

èMeasures for remedial action and protection.

CAUTION

Identifies a potentially dangerous situation!

Injury may occur if appropriate safety measures are not taken.

èMeasures for remedial action and protection.

Warning signs indicating potential damage

NOTE

Identifies a potentially dangerous situation!

Property damage may occur if appropriate safety measures are not taken.

èMeasures for remedial action and protection.

Important information

10 TOX_Manual_Powerpackage_line-Q_en

1.6.2 Display of general notes

General notes show information on the product or the described action

steps.

Identifies important information and tips for users.

1.6.3 Highlighting of texts and images

The highlighting of texts facilitates orientation in the document.

üIdentifies prerequisites that must be followed.

1. Action step 1

2. Action step 2: identifies an action step in an operating sequence that

must be followed to ensure trouble-free operation.

wIdentifies the result of an action.

uIdentifies the result of a complete action.

èIdentifies a single action step or several action steps that are not in an

operating sequence.

The highlighting of operating elements and software objects in texts facili-

tates distinction and orientation.

<In square brackets> identifies operating elements, such as buttons,

levers and (valves) stopcocks.

''with quotation marks'' identifies software display panels, such as win-

dows, messages, display panels and values.

In bold identifies software buttons, such as buttons, sliders, check-

boxes and menus.

In bold identifies input fields for entering text and/or numerical values.

Safety

TOX_Manual_Powerpackage_line-Q_en 11

2 Safety

2.1 Basic safety requirements

The product is state of the art. However, operation of the product may in-

volve danger to life and limb for the user or third parties or damage to the

plant and other property.

For this reason the following basic safety requirements will apply:

Read the operating manual and observe all safety requirements and

warnings.

Operate the product only as specified and only if it is in perfect techni-

cal condition.

Remedy any faults in the product or the plant immediately.

2.2 Organizational measures

2.2.1 Safety requirements for the operating company

The operating company is responsible for compliance with the following

safety requirements:

The operating manual must always be kept available at the operation

site of the product. Ensure that the information is always complete and

in legible form.

In addition to the operating manual, the generally valid legal and other

binding rules and regulations must be provided for the following content

and all personnel must be trained accordingly:

– Work safety

– Accident prevention

– Working with hazardous substances

– First aid

– Environmental protection

– Traffic safety

– Hygiene

The requirements and contents of the operating manual must be sup-

plemented by existing national regulations (e.g. for prevention of acci-

dents and for environmental protection).

Instructions for special operating features (e.g. work organization, work

processes, appointed personnel) and supervisory and reporting obliga-

tions must be added to the operating manual.

Safety

12 TOX_Manual_Powerpackage_line-Q_en

Take action to ensure safe operation and make sure that the product is

maintained in a functional condition.

Only allow authorized persons access to the product.

Ensure that all personnel work with awareness of safety and potential

dangers with reference to the information in the operating manual.

Provide personal protective equipment.

Maintain all safety and information on dangers regarding the product

complete and in legible condition and replace as required.

Do not make any changes, carry out attachments or conversions to the

product without the written approval of TOX®PRESSOTECHNIK. Ac-

tion contrary to the above will not be covered by the warranty or the op-

erating approval.

Make sure that the annual safety inspections are carried out and docu-

mented by an expert.

2.2.2 Selection and qualifications of personnel

The following safety requirements are applicable for the selection and quali-

fications of personnel:

Only appoint persons to work on the plant who have read and under-

stood the operating manual, and in particular, the safety instructions

before starting work. This is particularly important for persons who only

work on the plant occasionally, e.g. for maintenance work.

Only allow persons appointed and authorized for this work access to

the plant.

Only appoint reliable and trained or instructed personnel.

Only appoint persons to work in the danger zone of the plant who can

perceive and understand visual and acoustic indications of danger (e.g.

visual and acoustic signals).

Ensure that assembly and installation work and the initial commission-

ing are performed exclusively by qualified personnel who have been

trained and authorized by TOX®PRESSOTECHNIK.

Maintenance and repairs must be performed by qualified and trained

personnel only.

Ensure that personnel who are being trained, instructed or are in an ap-

prenticeship can only work on the plant under the supervision of an ex-

perienced person.

Have work on electrical equipment performed only by electricians or

trained persons under the direction and supervision of an electrician in

accordance with the electrotechnical regulations.

Safety

TOX_Manual_Powerpackage_line-Q_en 13

2.3 Fundamental hazard potential

Fundamental hazard potentials exist. The specified examples draw atten-

tion to known hazardous situations, but are not complete and do not in any

way provide safety and risk awareness action in all situations.

2.3.1 Electrical hazards

Attention should be paid to electrical hazards particularly inside the compo-

nents in the area of all assemblies of the control system and motors of the

installation.

The following basically applies:

Have work on electrical equipment performed only by electricians or

trained persons under the direction and supervision of an electrician in

accordance with the electrotechnical regulations.

Always keep the control box and/or terminal box closed.

Before commencing work on electrical equipment, switch off the main

switch of the system and secure it against being switched back on in-

advertently.

Pay attention to the dissipation of residual energy from the control sys-

tem of the servomotors.

Make sure that the components are disconnected from the power sup-

ply when carrying out the work.

2.3.2 Thermal hazards

The drive works in continuous operation and can become hot and cause

burns when touched.

Wear individual protective equipment.

Before starting work, make sure that surfaces have cooled down suffi-

ciently.

2.3.3 Pneumatic hazards

Attention must be paid to pneumatic hazards particularly on the pneumatic

supply lines and connection points.

The following basically applies:

Allow work to be carried out on pneumatic equipment by authorized

service personnel only.

Wear individual protective equipment.

Safety

14 TOX_Manual_Powerpackage_line-Q_en

Do not exceed the permissible pressure.

First switch on compressed air when all hose connections have been

established and secured.

Do not uncouple any hoses under pressure.

If hoses slip off, switch off the compressed air supply immediately.

2.3.4 Contusions

Contusions and hand injuries can occur in the radius of action of the prod-

uct.

The following applies generally:

Make sure that that no persons are located in the danger area during

operation.

During necessary work in the danger area (e.g. maintenance, clean-

ing), secure the system against unexpected, accidental and unautho-

rized activation.

Make sure that parts or tools cannot fall down or descend as a result of

stored energy. Use appropriate fuses.

2.3.5 Hydraulic hazards

Attention must be paid to hydraulic hazards particularly on the supply lines,

connection points and vent points.

The following applies generally:

Allow work to be carried out on hydraulic equipment by authorized ser-

vice personnel only.

Wear individual protective equipment.

Do not exceed the permissible pressure.

Do not remove any hoses under pressure.

Never vent hydraulic components under pressure.

Safety

TOX_Manual_Powerpackage_line-Q_en 15

2.3.6 Electromagnetic hazards

Electromagnetic hazards must be observed in the area of electromagneti-

cally vibrating or oscillating components.

Regular work on and with electromagnetically vibrating or oscillating com-

ponents can lead to disturbances in the blood circulation of the fingers as

well as neurological and motoric dysfunctions.

Basically applies:

Use antivibration gloves according to EN ISO 10819:1997 for neces-

sary work!

Electromagnetic fields can influence pacemakers (PM) and other im-

plants through indirect effects. Avoid possible malfunctions.

2.3.7 Laser

Depending on the model and features, lasers can be installed for the pur-

pose of recognition. There is a danger of looking into the laser in some situ-

ations. If this is not avoided, eye injuries may result.

2.3.8 Hazardous substances

The following safety requirements apply when handling chemical sub-

stances:

Observe the applicable safety regulations on handling chemical sub-

stances and the information on the manufacturer's safety data sheets

of hazardous substances.

Wear individual protective equipment.

In the event of eye or skin contact, rinse the affected area, change con-

taminated clothing and visit a doctor if necessary. Provide appropriate

equipment (eye wash bottle, washbasin) near the workplace.

Groundwater hazardous substances must not get into the ground or

sewage system. Collect groundwater hazardous substances and dis-

pose of them properly.

Safety

16 TOX_Manual_Powerpackage_line-Q_en

2.4 Safety device on the product

Safety devices are important components of the safety concept and help to

prevent accidents.

2.4.1 Safety device of system

A superordinate safety concept must be developed.

About this product

TOX_Manual_Powerpackage_line-Q_en 17

3 About this product

3.1 Intended use

The hydropneumatic drive performs the strokes that are generally defined

as fast approach stroke, power stroke and return stroke. The drive is in-

tended for installation in machines or robot tongs with the following techni-

cal applications:

Installing, pressing

Punching, pressing (of function elements)

Riveting, crimping, flaring

Punching, piercing

Embossing, marking

Tensioning, clamping, crimping

Pressing, compressing

Clinching, joining

This incomplete machine may not be commissioned until it has been ascer-

tained that the incomplete machine in which the component is to be in-

stalled complies with the requirements of the Machinery Directive (2006/42/

EC).

3.1.1 Safe and correct operation

Intended use includes the following conduct:

Only operate with the components for which it is specified.

Follow all instructions in this operating manual.

Comply with the specified maintenance intervals and perform mainte-

nance work correctly.

Operate in compliance with the conditions of the technical data.

Operation with fully assembled and functional safety devices.

Activities may only be carried out by persons who are qualified or au-

thorized for this purpose.

Any other use or application beyond this does not come under the scope of

intended use.

About this product

18 TOX_Manual_Powerpackage_line-Q_en

3.1.2 Foreseeable misuse

Use contrary to intended use includes the following foreseeable misuse:

Operation under conditions that deviate from the technical data.

Operation without fully assembled and functional connections.

Operation without fully assembled and functional safety devices.

Modifications to the product without prior approval by the TOX®PRES-

SOTECHNIK and the approving authority.

Incorrect parameterization.

Execution of activities by persons who are not qualified or authorized to

do so.

The operating company is exclusively responsible for all personal injury and

property damage resulting from non-intended use. Non-intended use will

not be covered by the warranty or the operating approval of the complete

plant.

3.2 Product Identification

3.2.1 Position and content of the type plate

Designation on the type plate Meaning

Type Product designation

No. Serial number

ΔV [ml] Lowering volume

Indicates the amount of oil that must be

discharged again after completely filling.

Pmax Maximum pressure

Type code structure

Type key Description

X-S 008. 3030. 100. 12

X-S 008. 3030. 100. 12 Identifies the series type such as X-S, S, K, etc.

X-S 008. 3030. 100. 12 Indicates the press force in [tons].

X-S 008. 3030. 100. 12 Indicates the version.

X-S 008. 3030. 100. 12 Indicates the length of the total stroke.

X-S 008. 3030. 100. 12 Indicates the length of the power stroke.

3.3 Function description of Powerpackage

See Design and installation guideline.

About this product

TOX_Manual_Powerpackage_line-Q_en 19

3.4 Product overview of Powerpackage line-Q

5

4

2

1

34

2

1

5

3

6

6

1 Working piston 2 Compressed air supply return stroke [2]

3 Control throttle 'X' 4 Compressed air supply fast approach

stroke [4]

5 Oil filling nipple 6 Power stroke valve

Fig.1 Product overview type Q-S, Q-K

For product versions and product attributes see the design and installation

guideline.

3.4.1 Product attributes of Powerpackage line-Q

Type Q-S Type Q-K

Intensifier and working part are interconnected with

a tension rod in a sandwich construction.

Intensifier and working part are connected with an

intermediate flange (compact construction).

Including power stroke valve and control throttle 'X'.

Equipped with mechanical spring.

Including power bypass ZLB with hydraulic end position cushioning ZHD in the upper final position.

Including fixed stop with elastomer cushioning in the lower final position.

Prepared for stroke monitoring ZHU.

Prepared for external linear position sensor ZHW.

About this product

20 TOX_Manual_Powerpackage_line-Q_en

3.5 Optional equipment

3.5.1 Additional optional equipment

Type Product attributes

ZHW Linear position sensor

The travel sensor indicates the absolute actual position

of the piston.

For external installation (for series line-Q and line-X to

Q-S/Q-K 30, X-SX-K 30).

ZHU Stroke monitoring

Determines the position of the working piston during

forward stroke and return stroke via the external sen-

sor.

ZDK Pressure regulation in power stroke line

Make possible the individual adjustment of the press

force with a manual pressure valve or electrical propor-

tional valve.

ZKHZ External power stroke connection

Enables the connection of the power stroke valve with

an electrically actuated 3/2-way valve.

ZWK Tool coupling

Connects the drive and tool flexibly to prevent trans-

verse forces from affecting the drive.

ZDO Electronic pressure switch

Records the oil pressure in the high-pressure part as

system pressure and visualizes it via a four-digit LED

display.

The set switching function allows 2 output signals to be

created.

ZHO Stroke frequency optimization

Reduces the cycle time.

Replaces the existing power stroke valve with one of

the next size.

ZPS Pressing force sensor

Measures the press forces in the direction of the pres-

sure.

Tab.1 Optional equipment

For optional equipment, see data sheet and brochure TOX®-Powerpack-

age.

http://tox-pressotechnik.com/

This manual suits for next models

2

Table of contents

Other TOX PRESSOTECHNIK DC Drive manuals

Popular DC Drive manuals by other brands

GFA

GFA ELEKTROMAT SE 9.24 WS-25,40 installation instructions

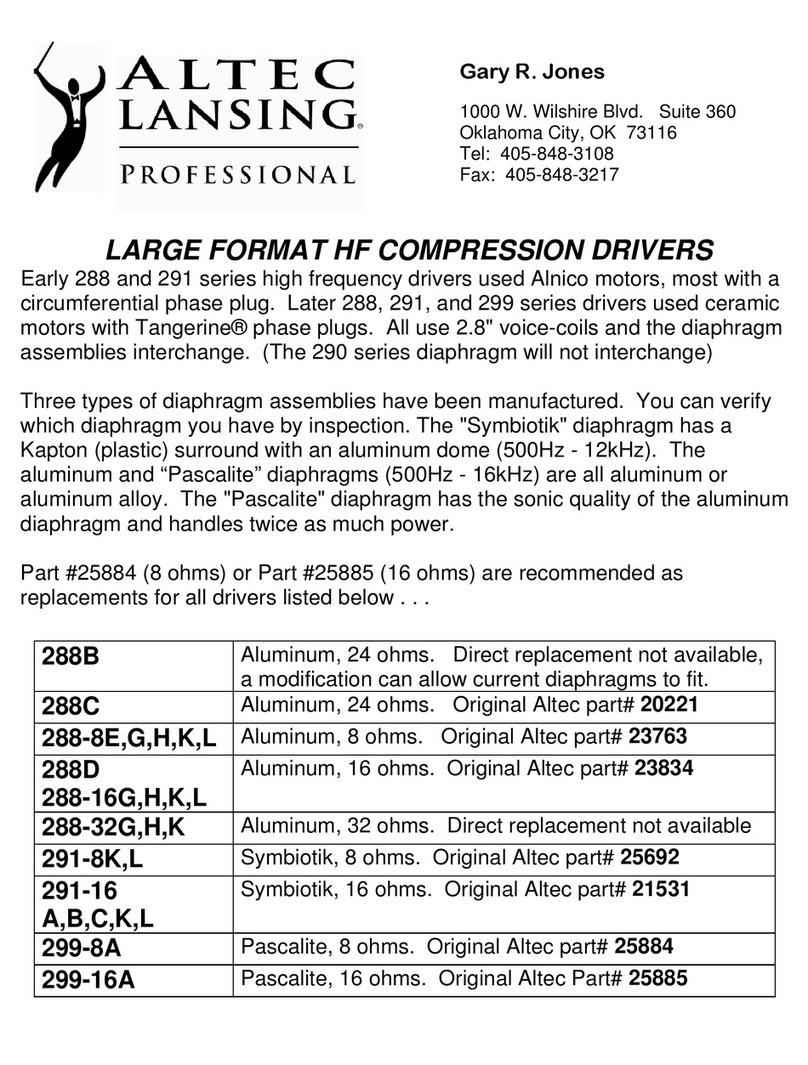

Altec Lansing

Altec Lansing HF DRIVER CROSS REFERENCE MASTER LIST Reference

CNCdrive

CNCdrive DG4S Series manual

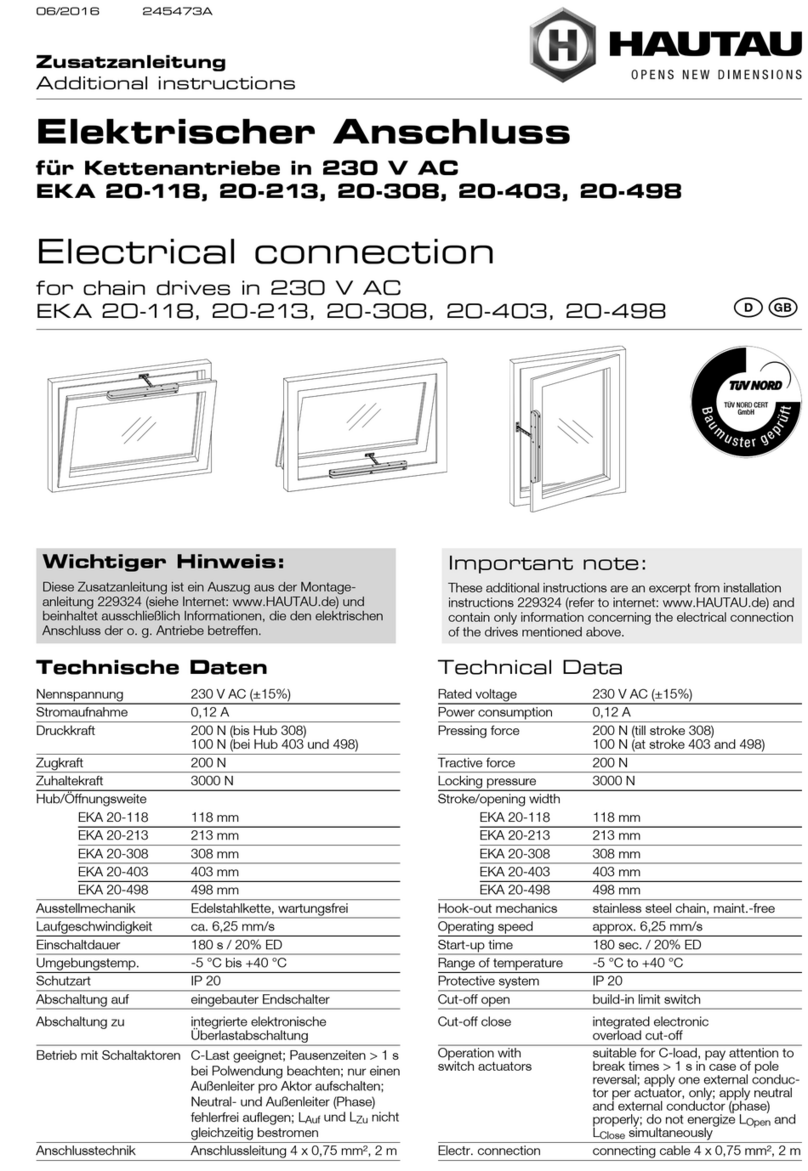

HAUTAU

HAUTAU EKA 20-118 Additional instructions

AB Quality

AB Quality PowerFlex 700S quick start guide

Dakota Digital

Dakota Digital ECD-200BT manual