Toyo Single Axis Series User manual

Installation Manual

Toyo Single Axis Series

www.toyorobot.com

VER.E-201401

www.toyorobot.com

1

Chapter

Content

Page

1.

General Safety Precaution

2

1-1

Symbol used within the chapter

2

1-2

Essential caution items

3

1-3

Safety function required for the actuator

7

1-4

Safety measure of the system

8

1-5

Trial run

9

1-6

When working inside the safeguard enclosure

10

1-7

Automatic operation

11

1-8

Adjustment and inspection

12

1-9

Repair and modification

13

2.

Warranty

14

3.

Part’s Name

15

4.

Installation

16

4-1

Transportation

16

4-2

Installation environment and base requirement

17

4-3

Driver motor assembly

18

4-4

Installation

28

5.

Inspection and Maintenance

30

5-1

Inspection and maintenance frequency

31

5-2

Applying grease

33

5-3

Replacing and adjusting the dust proof plate

35

5-4

Consumable

37

6.

Trouble Shooting

38

6-1

When there is noise during operation

38

6-2

When actuator does not operate

40

Index

www.toyorobot.com

2

In order to use TOYO’s product safely and correctly, please make sure to read

through with correct understanding of the content of the entire manual and the

general safety precaution before using or installation of the actuator.

The main purpose of this manual is to prevent personal injury or damage of

the actuator and equipment, please follow the instructions listed and take notes

on all of the warning and caution.

1-1 Symbol used within the chapter

WARNING

Fail to follow the WARNING instruction may cause severe injury and

serious threat endangering the life to the personals around the

actuator.

DANGER

Fail to follow the DANGER instruction will cause severe injury and

serious threat endangering the life to the personals around the

actuator.

CAUTION

Fail to follow the WARNING instruction may cause severe injury to the

personals around the actuator and the damage to the actuator or

equipment.

It is not possible to list all of the safety measures while

operating/installing around the robot. Apart from following the safety

instruction, please go through the entire manual to build a full knowledge of the

safety rules in order to make correct judgments when around the robot.

1.General Safety Precaution

www.toyorobot.com

3

1-2 Essential caution items

Particularly important cautions for handling or operating the actuator are

described below. In addition, safety information for installation, operation,

inspection and maintenance are listed in the related chapter of this manual,

please comply the safety measures for safe use of the robot.

a) Automatic operation

DANGER

Severe injury and serious threat endangering the life will occur if impact with

moving parts.

Install a safeguard (protective enclosure), which covers the entire

movement range of the actuator, to avoid anyone entering. This is to

prevent anyone suffering from injury due to being stuck by moving parts.

Install a safety interlock that triggers emergency stop when the door or

panel is opened.

Install safeguards so that no entre is allowed except through the door or

panel with safety interlocked equipped.

Stay outside of the safeguard during operation.

Activate emergency stop before entering the safeguard.

b) Use caution to prevent hand or fingers from being caught by the moving parts.

WARNING

Moving part may cause pinch or crush of hands and fingers, keep hands and fingers

away from moving parts.

c) Operation

Be sure to read through the warning labels and this manual carefully, and

make sure you have thoroughly understood the contents before attempting

installation and operation of the product.

A double checking of this chapter before starting to operate the product is

always a good idea.

Please do NOT proceed any actions not being mentioned in the manual.

WARNING

Improper installation or incorrectly operation may cause severe injury and

www.toyorobot.com

4

serious threat endangering the life.

d) Do not use the product in the environment filled with inflammables or

explosives.

WARNING

The product is not designed to operate under the environment where inflammable or

explosive substances are present; use of the actuator in such environment might

result fire hazard.

e) Do not use the product in locations with possibly electromagnetic

interference.

WARNING

Avoid using the robot in locations subject to electromagnetic interference,

electrostatic discharge or radio fervency interference. Malfunctions might

otherwise occur.

f) Use caution when releasing the brake on a vertical axis actuator.

WARNING

The vertical axis will slide down when brake are released, and may cause

hazardous situation.

Use a support to prop the vertical axis before releasing the break, while

emergency stop is activated.

Be careful not to get caught between the axis and the installing base when

releasing the brake to perform direct teaching.

g) Provide safety measure for end effector (gripper)

WARNING

End effector must be designed and manufactured so that they create no hazards

(for example, a workpiece that comes loose) even if power source (electricity

or air pressure) is cut off or power fluctuation occur.

If there are possible danger that the object hold by the end effector may fly

off or drop off, please provide appropriate safety measures, taking the

consideration of the object dimension, size, weight, temperature and chemical

properties.

www.toyorobot.com

5

www.toyorobot.com

6

h) Use caution when dissemble the motor for vertical axis actuator.

WARNING

The vertical axis will slide down when motor is dissembled, and may cause

hazardous situation.

Use a support to prop the vertical axis before disassembly of the motor,

while emergency stop is activated.

Be careful not to get caught between the vertical axis parts and the

installing base.

i) Take the following safety precaution during inspection of controller.

WARNING

When touching external parts of the controller, such as terminals or

connectors, are required for inspection, please make sure to turn off the

power switch of the controller and cut off the main power source to prevent

possible electrical shock.

Never touch internal parts of a controller.

j) Please consult with us before dealing with failure or malfunction of actuator.

WARNING

Continue on using a failure or malfunctioned actuator may cause injury to the

personals or further damage to the actuator or equipment, please contact your

TOYO’s sales office or dealer for trouble shooting.

k) The surface of motor and decelerator may get really hot after automatic

operation.

WARNING

The surface of the motor and the deceleration gearbox are extremely hot after

automatic operation, burns will be caused if touched. Please allow they to cool

down if inspection is required. Allow the surface temperature to drop down to

reasonable range after power off.

l) Do not remove, alter or damage the warning labels on the actuator.

WARNING

www.toyorobot.com

7

Removing or altering the warning labels on the actuator may cause accident by

others.

Make sure the warning labels are not blocked or hidden by other equipment or

devices.

Make sure the warning labels are clearly visualized from outside of the

safeguard.

m) Electrical grounding

WARNING

Please ground the actuator and the controller to prevent electrostatics or

electrical shock.

n) Use correct parameter settings.

WARNING

The actuator must be operated with correct tolerable moment of inertia and

acceleration coefficients according to the manipulator tip mass and moment of

inertia. If these are not correct, drive unit service life may end prematurely,

and damage to actuator parts or may result residual vibration during position.

www.toyorobot.com

8

1-3 Safety function required for the actuator

a) Power overload detection.

When motor overload occurs, the detection activates and cut off servo power.

b) Soft limit sensors

Soft limits can be set on each axis to limit the working envelope in manual

operation after return-to-home and during automatic operation.

NOTE. Working envelope is the area limited by soft limits.

c) Mechanical stopper

If the servo power has suddenly been shut off during high-speed operation by

emergency stop or safety functions, these mechanical stoppers prevent the axis

from exceeding the movement range. No mechanical stopper is provided on the

rotating axis.

NOTE. Movement range is the area limited by mechanical stoppers.

WARNING

Axis movement will not stop immediately after servo power supply is cut off by

emergency stop or other safety functions.

d) Brake for vertical axis

An electromagnetic brake installation is essential on the vertical axis to

prevent sliding down of the axis when servo power is cut off. This brake shall be

working when the controller is off, or when the vertical axis servo power is off

even with controller is on. The vertical axis brake can be released by means of

the programming unit or by commands in the program when controller is on.

WARNING

The vertical axis will slide down when brake are released, and may cause

hazardous situation.

Use a support to prop the vertical axis before releasing the break, while

emergency stop is activated.

Be careful not to get caught between the axis and the installing base when

releasing the brake to perform direct teaching.

www.toyorobot.com

9

www.toyorobot.com

10

1-4 Safety measure of the system

Since the actuator is commonly in conjunction with an automated system, danger is

more likely to occur from the automated systems instead of from actuator itself.

Thus, appropriated safety measure must be taken on the part of the system

manufacturer according to the individual system. The system provider shall

provide a proper instruction manual for safe and correct operating or service of

the system.

www.toyorobot.com

11

1-5 Trial run

After installation, adjustment, inspection or maintenance, follow below

procedures to make trial runs.

a) If a safeguard enclosure has not yet implied after installation of the

actuator, rope off or chain off around the movement area of the actuator in

place of the safeguard, and observe the following points.

Use sturdy, stable posts which will not fall over easily.

The rope or chain should be easily visible by everyone around the actuator.

Place a sign to keep personal from entering the movement range of the

actuator.

b) Check the following before turn on the controller.

If the actuator are securely and correctly installed.

If the electrical connection are correctly and properly wired.

If other connections such as pressured air supply or grounding connection

proper?

If the actuator correctly connect to peripheral equipment.

Has the safety measure been taken?

If the installation location meet the specific environmental requirement.

c) Check the following after turn on the controller from outside of the safeguard

enclosure.

If the actuator start and stop as intended, if the operation mode can be

selected correctly.

If each axis move as intended within the soft limit.

If the end effector act as intended.

If the signal transmissions to the end effector and peripheral equipment

are correct.

If emergency stop work.

If the teaching and playback function are normal.

If the safeguard enclosure and interlock are working as intended.

If the actuator move correctly during automatic operation.

www.toyorobot.com

12

1-6 When working inside the safeguard enclosure.

a) When working inside the safeguard enclosure is required, always turn off the

controller and place a clear visual indication showing that the actuator is

been adjusted or serviced. This is to prevent others from touching the

controller switch or operation panel.

b) With the following two cases where powering off is not an option:

1. Soft limit settings, please follow the precautions and procedures for each

section.

2. Teaching

When performing teaching inside the safeguard enclosure, comply with the

instructions listed below.

(1)Before entering the safeguard enclosure.

Visual check if there is any hazard inside the safeguard enclosure.

Check that that programming unit MPB or DPB operate correctly.

Make sure there is no failure within actuator.

Double check if emergency stop work correctly.

Select teaching mode and prohibit automatic operation.

(2)Never enter the movement range of the actuator while inside the

safeguard enclosure.

www.toyorobot.com

13

1-7 Automatic operation

a) Before start, please check the following:

There is no one inside the safeguard enclosure.

The programming unit and tools are in their specified locations.

The alarm or the error lamps of the actuator and the equipment has not been

triggered.

The safeguard enclosure is securely installed with safety interlock active.

b) Observe the following during automatic operation or in case there are errors

occurred.

After the automatic operation has started, check the operation status and

warning lamps to ensure that the actuator is in automatic operation.

Never enter the safeguard enclosure while automatic operation is active.

In case an error has occurred within the actuator or peripheral equipment,

obey the following procedure before entering the safeguard enclosure.

1. Activate the emergency stop to stop the actuator completely.

2. Place a sign on the starting switch, indicating that the actuator is

been inspected, this is to prevent others from touching the start switch

or restart the actuator.

www.toyorobot.com

14

1-8 Adjustment and inspection.

Please do not attempt any installation, adjustment, inspection or maintenance of

the actuator unless it is stated within this manual.

Please refer to the following chapters for details.

www.toyorobot.com

15

1-9 Repair and modification.

Please do not attempt any repair, part replacement or modification of the

actuator unless it is stated within this manual. The involved actions required

qualified technician with professional knowledge and skills, proceed without the

knowledge and skills may result hazards.

www.toyorobot.com

16

Warranty Period

The warranty period is effective for:

18 Months (one year and half) after shipment from Taiwan factory.

12 Months (one year) after installation.

Whichever period meets first.

Exceptions to warranty

The warranty will not apply in the following cases:

Fatigue arising due to the passage of time, nature wear or tear occurring

during operation (nature fading of painted or plated surfaces, deterioration

of parts subjects to wear)

Consumables.

Damage due to earthquake, storms, floods, thunderbolts, fire or any other

natural or man-made calamities.

Trouble caused by actions prohibited by this manual.

Modifications of the product not approved by TOYO or TOYO’s sales

representative.

Use of any other than genuine parts or specified lubricant or grease.

Insufficient or incorrect maintenance or inspection.

Repair or service done by non-authorized dealer.

In addition, we will be responsible for repairing our own product, but are not

responsible for other losses caused by the failure of our product.

Service coverage

We will provide the following service.

Guide for installation and trial operation.

Guide for maintenance.

Guide or training on technical operation and wiring.

Guide on programming.

2.Warranty

www.toyorobot.com

17

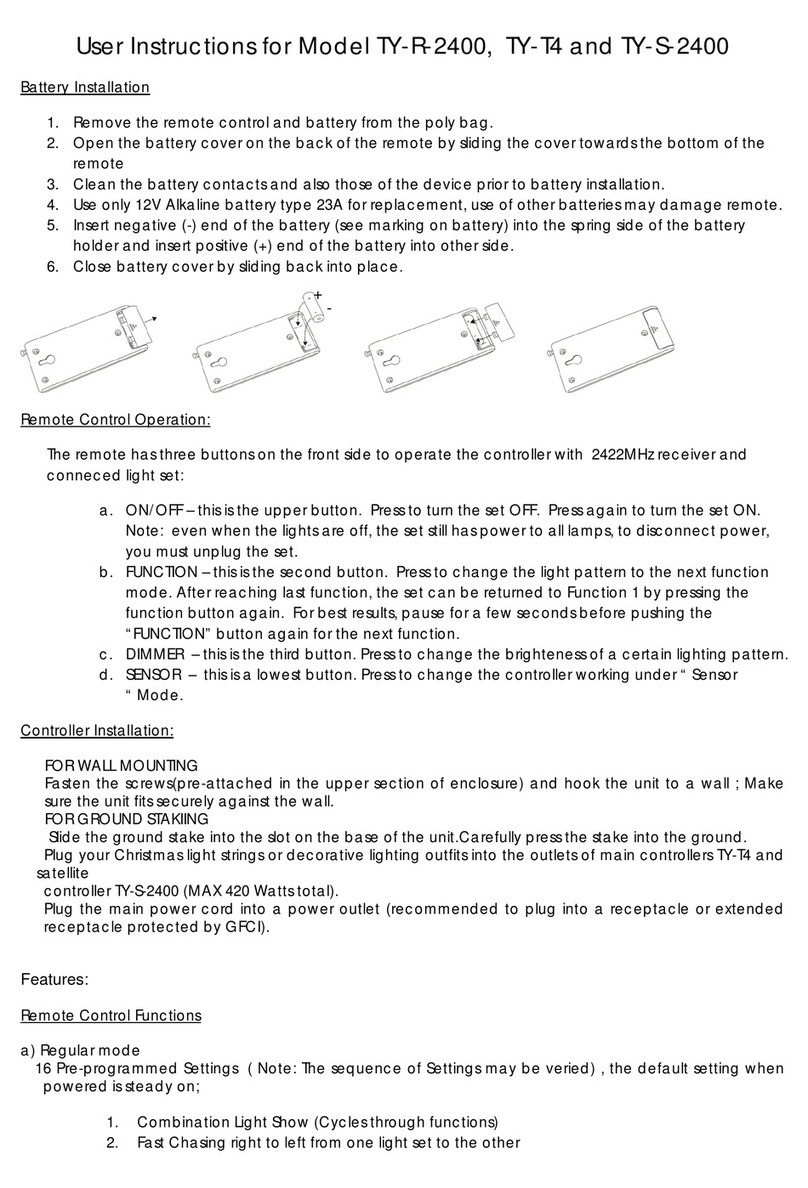

①Motor end

②Motor Opposite Side

③Carriage

④Main Body

⑤Dust proof cover

⑥Side cover

⑦Top Cover

⑧Coupling cover

3.Part’s Name

○

1

○

1

○

1

○

2

○

2

○

2

○

3

○

3

○

3

○

4

○

4

○

5

○

5

○

8

○

7

○

6

www.toyorobot.com

18

4-1 Transportation

All personal shall bare safety measure while transporting the actuator

regardless the method used, proper gears such as safety helmets and gloves shall

be equipped. The weight of the product is stated in the specification sheet,

please select suitable means to transport.

In case transported by hoists, make sure to use the ropes which can handle

the weight. Please also make sure the rope is properly positioned where the

product is balanced while lifted.

In case transported by folk lifter or cart, make sure the product is properly

positioned to keep its balance and the parts which stands out of the folk or

cart will not collide into any other objects.

The following parts of the actuator are not suitable part to apply force for

transportation.

Carriage.

End plates either sides.

Top Cover.

Any cables whether power cable or signal signals, if the motor is

installed.

4. Installation

www.toyorobot.com

19

4-2 Installation environment and base requirement

The environmental requirement or restriction for Toyo’s actuator is:

Item

ETH

ECH

Surrounding

temperature while

operating.

0~45℃

0~45℃

Surrounding

humidity while

operating.

35~85% RH

35~85% RH

Maximum

installation

height.

0~1000m above sea level.

0~1000m above sea level.

Surrounding

Avoid the following environment:

Near water, cutting liquid, dust, metal chips or solvents.

Environment filled with corrosive gas or liquid.

Environment filled with flammable materials in any forms.

Locations where surrounded by electro-magnetic

disturbance, statistic or radio-wave emitting.

Locations where there are vibration sources nearby or

easily collided.

Please provide enough space for service.

Installation base requirement:

Correct installation base

Incorrect installation base

a) The installation base should be solid and rigid to sustain the vibration

from operation, also must be able to sustain the weight of the actuator

plus the working piece.

b) The installation base must be even, within the range of±0.05mm/500mm.

c) The installation base must be bigger than the mounting surface, and has

Table of contents

Other Toyo Controllers manuals

Popular Controllers manuals by other brands

FMS

FMS BKS600A operating manual

Plecter Labs

Plecter Labs Crystal Focus Saber Core V7.5 user manual

Kramer

Kramer RC-8RKL user manual

opto engineering

opto engineering LTDVE2CH-20F instruction manual

LOVATO ELECTRIC

LOVATO ELECTRIC ATL500 instruction manual

MELKUS & SIEGERT

MELKUS & SIEGERT KABLOREG ECO - M instructions

JLCooper Electronics

JLCooper Electronics ES-SloMo Operation manual

Zeva

Zeva MC1000SP manual

Amphenol

Amphenol nrgSMART CTRL System configuration guide

Bennett

Bennett 515-XP Installation & service manual

cashco

cashco PA1 Installation, operation & maintenance manual

Sinclair

Sinclair SDV 6 SWC-61 User & installation manual