Zeva MC1000SP User manual

Zero emission

Vehicles AustrAliA

http://www.zeva.com.au

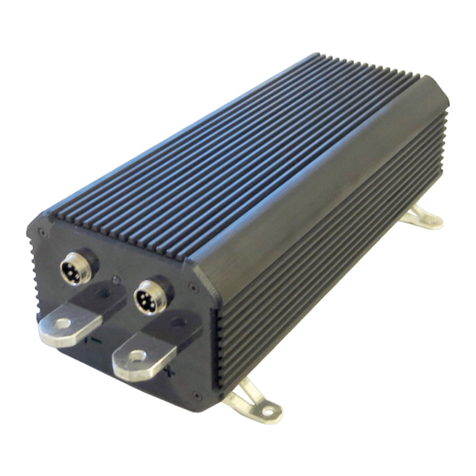

MC1000SP

150VDC 1000A motor controller

for Series DC and PM DC motors

TABLE OF CONTENTS

page

1) Introduction 1

2) Safety Warning 1

3) Tech Support and Warranty Information 1

4)FeaturesandSpecications 2

5) Installation 3

6) Power Wiring 4

7) Control Wiring 6

8) Operation 8

9) Customising your Settings 10

INTRODUCTION

Congratulations on your purchase of a ZEVA MC1000SP motor controller.

The MC1000SP represents the culmination of many years development, utilising the latest in power

semiconductorstocreateoneofthemostefcientEVmotorcontrollersavailable–over99%at

all times. Also featuring dual microprocessors for redundant safety, an advanced throttle algorithm

for the smoothest driving experience, silent operation at all times, a compact weather-resistant air-

cooledhousing,andcongurableoperatingparametersviasimpleserialconnection.

Wehopeitprovidesyouyearsofreliableservice.

SAFETY WARNING

Electric vehicle motor controllers are high powered devices which involve potentially lethal

voltages and currents. Proper precautions and electrical safety procedures should always be

observed,voltagesabove110VDCshouldbeconsidereddangerous,andvehiclesshouldnever

beworkedonwhilemaincontactor(s)areengaged.Pleasereadthismanualcarefullybeforeusing

the controller to ensure correct installation and operation. If you are unsure of anything, please

contactusbeforeproceeding.

Wehaveendeavouredtomakeasafeandreliableproductwhichperformsasdescribed,however

since ZEVA has no control over the integration of its products into a vehicle, we can assume no

responsibilityforthesafetyorfunctionalityofthecompletedvehicle.

Itisuptotheendusertodeterminethesuitabilityoftheproductsforthepurposeemployed,and

theenduserassumesallrisksassociated.Productsshouldonlybeinstalledbysuitablyqualied

andexperiencedpersons,andshouldalwaysbeusedinasafeandlawfulmanner.

TECH SUPPORT AND WARRANTY INFORMATION

TheMC1000SPmotorcontrolleriscoveredbya12monthwarrantyagainstmanufacturingfaults

or failures under normal operating conditions. The warranty does not cover misuse of the product,

including but not limited to: excessive voltage or reversed polarity on input terminals, short

circuits on output terminals, excessive voltages applied to control wiring, opening of housing and/

ormodicationofinternals,severeimpactdamage(e.gduetovehiclecrashes),submersion in

water.

Wehavetakengreat careto designasafe andreliable product,butfaults canhappen. Ifyou

believe your motor controller has a fault, please contact us via our website to discuss. If it is

determinedthatahardwarefaultisthelikelycause,wewillprovideanRMAnumberandreturn

address to proceed with repairs.

Ifyouhaveanyquestionsnotcoveredbythismanual,pleasecontactusviaourwebsite:

http://www.zeva.com.au/Contact

1

FEATURES AND SPECIFICATIONS

FEATURES:

Smooth,hybridthrottleresponseforfamiliardrivingfeel•

Thermalcutbackandover-tempprotection•

Congurableparametersviaserialprogrammingcable•

MulticolourstatusLEDplusoptionalremotestatusLED•

Tough,weather-resistantaluminiumhousing(approxIP44)•

Compatiblewithoptionalexternalwatercoolingblockforhighersustainedpower•

Adjustablemotoridlingfunctionforautomaticgearboxesormaintainingauxiliaries•

Supportformostthrottletypesincluding3-wire0-5V,2-wire0-5KΩ,andHEPApedals.•

Fully isolated logic and power electronics•

RobustI/Oprotectscontrolleragainstexternalwiringfaults•

Highpedallockout(protectsagainstnon-zerothrottleonstartup)•

Self diagnostics with error detection including overcurrent, low voltage on power and logic•

supplies, internal parameter corruption, and internal sensor faults.

Independenthardwareovercurrentprotectionsystem(“desat”detection)•

SPECIFICATIONS:

Batteryvoltagerange:12-144Vnominal(9-180Vabsolutemaximum)•

Max 45x LiFePO4 cells, 40x LiCo cells, 12x 12V lead acid

Currentrating:1000Apeak(1minute),300Acontinuous•

Power:150kWpeak,45kWcontinuous•

Powerdevicetype:MOSFET•

On-statevoltagedrop:0.6Vatfullpower,0.2Vatcontinuousrating•

Switchingfrequency:16KHz•

Operatingtemperature:-20˚Cto90˚C(thermalcutbackfrom60˚C)•

Logicpowersupply:12Vnominal(8-18Vrange),200mAmax,internallyfused•

Dimensions:310x130x95mmhousingonly,365x156x106mmincterminalsandbrackets•

Weight:4.5kg•

PACKAGE CONTENTS:

1x MC1000SP motor controller•

4xM8x25bolts,washers,andnuts•

1x 5-pin plug, 1x 6-pin plug•

1xUSB-Serialprogrammingcable•

1xRGBLEDforremotestatuslight•

1x User manual•

INSTALLATION

Themotorcontrollermaybeinstalledinanyorientation.Usually,installationclosetothemotor

isbestinordertokeeppowerwiringtothemotorshort.Theenclosureisweatherresistantbutnot

100%waterproof,soitisbestinstalledinalocationwithsomeprotectionfromtheelements.Ifit

maybeinthedirectpathofwater,splashguardsarerecommended.

Thecontroller’scontinuouspowercapabilitiesdependsomewhatontheamountofairowaround

thecaseforconvectioncooling.Iftheinstalllocationhasverylittleairow,thecontrollermay

benetfromaddedconvectioncoolingviafansorducting.(Orforhighestsustainedpower,the

controllermaybebase-mountedtoawatercoolingblock.)

Controller dimensions and mount locations

Themotorcontrollercomeswithbracketsformountingwithfour6mmor1/4”boltsona142

x 260mm spacing. Flat washers and spring washers under the heads of mounting bolts are

recommendedtopreventtheboltsfromlooseningovertimeduetovibration.

Alternativelythemountingbracketsmayberemoved,andthefourholesunderneaththehousing

usedtofastentoapanelfrombeneath.TheholesareM6threadona70x260mmspacing.

Caution: Since these threaded holes penetrate the housing, ensure that bolts do

not extend more than 20mm into the case or they may damage components inside!

32

POWER WIRING

REMEMBER..

The traction circuits in electric vehicles involve very high power levels, with potentially lethal

voltagesandcurrentsinvolved.Alwaysobserveproperprecautionsandsafetyprocedureswhen

workingonelectricvehicles.Alwayswearsafetyglasses,useinsulatedtoolswherepossible,and

checkfordangerousvoltageswithamultimeterbeforeundertakinganymaintenance!

Ifyouareunsure,alwaysconsultwithanexperiencedEVtechnicianbeforeproceeding.

TYPICAL WIRING DIAGRAM

Thediagrambelowshowsthebasicpowerwiring.Orangelinesrepresentpowercables,which

shouldbe50sqmmor1/0AWGinsize,orlarger.Controlwiringto/fromcontrollernotshown.

Basic power wiring diagram for MC1000SP controller

Caution: Always double check power wiring before turning the system on for the

rst time, because reversed polarities or short circuits can do a lot of damage!

When rst powering up the completed system, wiring mistakes or faulty throttle

devices could cause unexpected power to the motor, which risks injury or vehicle

runaway. It is highly recommended that the drive wheels be off the ground, and

that nobody is standing in front of or behind the vehicle at the time.

TIPS FOR BEST PERFORMANCE

Power cables around 50sqmm or 1/0AWG in size are recommended for all power wiring•

betweenbatteriesandmotorcontroller,and50-95sqmm(1/0to4/0AWG)cablebetweenthe

motorcontrollerandmotor,whereaveragecurrentsarehigher.Itisbesttousedoubleinsulated

cablewithanorangesheathforcompliancewithelectricalstandards.

Ensure all power terminals and connections in your traction circuit are clean and tight. Always•

useeitherspringwashersorNylocnutstoensureconnectionswillnotloosenfromvibration

overtime.Poorconnectionshavea higher resistance, whichcancausethemtobecomehot

whenconductinglargecurrents–inextremecases,causingdamagetocomponents.

It is essential to have a precharge device to charge up the motor controller’s internal capacitor•

bankbeforeclosingthemaincontactor.Closingthemaincontactorwithoutrstprecharging

thecontrollercausesahugecurrentspikewhichdamagescontactors,typicallyweldingtheir

contactstogether.A1KΩ10Wprechargeresistorpermanentlyacrossthemaincontactorcan

work,butisnotthesafestsolutionasdoesnottrulyisolatethecontrollerwhenthekeyisoff,

anditwillmaintainvoltageonthecontrolleratalltimes.Abettersolutionisa2-stageautomatic

prechargersuchasourZEVASmartPrecharger,oranEVMSwithbuilt-inprecharger.

Ensure you have an appropriately rated main contactor and fuse protecting your traction circuit.•

Examples of suitable contactors are the Kilovac EV200 or LEV200, Gigavac GX14,Albright

SW200, or Nanfeng ZJW400A.

Forafuse,a500AsemiconductortypewithsufcientDCvoltageratingisrecommended,such•

asthosefromBussmann,Ferraz-Shawmut,Mersen,Littelfuse,etc.Largefusestendtobevery

slowtoblow,typicallyabletocarrytwicetheirratedcurrentforabout1minute.Assuchitis

besttouseafusewitharatingslightlyabovethecontinuousratingofthemotorcontroller,rather

than one rated for the maximum motor controller current.

TheMC1000SPmotorcontrollerusesaluminiumbusbars.Aluminiumitselfisagoodconductor•

ofelectricity,butunfortunatelythe (invisible)aluminium oxidewhichforms on itssurfaceis

a poor conductor. The power terminals are supplied cleaned and with a thin layer of Noalox

contactpasteappliedtopreventre-oxidation.Thispasteshouldbeleftontheterminalswhen

areattachingpowercables.(Theforceoftighteningtheboltswillpushthegreaseoutandseal

the contact area.)

The power cables in electric vehicles carry a large amount of power, and can emit a lot of•

electromagneticinterference(EMI)dependingontheirphysicallayout.TominimiseEMI,itis

besttokeepthepositiveandnegativecablesclosetogether–boththepowercablesfrombattery

packtocontroller,andcontrollertomotor.TofurtherreduceEMI,thecablesmaybetwisted

aroundeachother.(ForfurtherdetailsonwhytwistingcablestogetherishelpfulforEMI,referto

http://www.wikipedia.com/wiki/Twisted_Pair)

54

CONTROL WIRING

PLUG IDENTIFICATION

TheMC1000SPusestwoaviation-stylescrew-lockplugsforallcontrol/lowpowerconnections,

onewith5pinsforthepowerinputandstatusLEDoutputconnections,andtheotherwith6pins

forthethrottleandserialprogrammingconnections.Thediagrambelowshowspinidentications

as viewed on the controller case.

Gnd

12V

B

G

R

5V

Gnd

ThrB

ThrA

Rx

Tx

LED

Identication of pins on control wiring plugs Pins for remote LED

Plug 1:

5V:Outputpowersupplyforthrottleand/•

or serial communications devices. Max

50mAoutput(internallyfused,w/reset)

Gnd:Groundconnectionforthrottle•

ThrottleA:Firstthrottleinput,usuallythe•

analog level, 0-5V input

Throttle B: Second throttle input, either•

enableswitchor2ndanalog,0-5Vinput

Tx/Rx:Transmitandreceivepinsforserial•

communications, 5V TTL

Plug 2:

12V:Connecttoakey-switched12Vsupply•

sothecontrollercomesonwhenthekeyis

turned on. Often wired in parallel with your

main contactor. Maximum voltage range

8-18V input

Gnd:Connecttoground/vehiclechassis•

R/G/B: Red, green and blue channels for•

statusLEDoutput.5Voutputs,2KΩoutput

impedance (max 2.5mA). Gnd terminal

of LED is grounded to chassis (or shares

ground pin on same plug).

WIRING UP THE PLUGS

The plugs are opened using a small jewellers screwdriver to remove the screw on the side of the

rearshell,whichthencomesawaywithasmallcounterclockwisetwist.

Feedwiresthroughthebackoftherearshellbeforeattachingtothepinstoensurethecasecan

gotogetheragainafterwiresareattached.Forreliableconnections,besureto“tin”(addsolderto)

boththewiresandthecontactsbeforesolderingthemtogether.

Theshellalsohasacablestressreliefclampattherearwhichcanbefasteneddowntoholdthe

cables.Ifyourcablesaretoosmallfortheclamptoengage,youcanwrapsomeinsulationtape

aroundthemtoincreasethediameterandensuretheclampisabletoholdtheminplace.

Plugs for control wiring: Disassembled (left), wiring (middle), complete (right)

Sincethelogicwiringisnecessarilyquiteclosetothetractioncircuitpowercables,toavoid•

ElectromagneticInterference(EMI)itisbesttouseshieldedcables,ortwistwires(suchas12V

andGround)together.Alsoavoidrunninglogicwiringinparallelwithpowercablesforlong

distances,asitincreasesnoiseduetocrosstalk.

Thelogicboardonlyrequires200mAcurrent,soassmallasAWG28wiremaybeusedforthe•

powersupply.However,ifnotenclosedinashieldedsheath,itisbesttouselargercablearound

18AWG+forbettermechanicalstrength/durability.

All control wiring is galvanically isolated from the power terminals. In most cases the control•

wiringwillshareacommonground(thevehiclechassis)withyourvehicle’sexisting12Vsystem,

and the traction circuit should remain electrically isolated for safety.

THROTTLE DEVICE

The MC1000SP controller supports a variety of different throttle types.

Type 1, 0-5V Hall Effect throttle:• Any throttle device which outputs a 0-5V level representing

0-100%throttlemaybeused.Non-contact Hall Effecttypesarethebestoption due to their

reliabilityandvirtuallyunlimitedlifespan.TheyshouldhavethreewirestoconnecttoGnd,5V

andThrottleA(0-5Vlevel).TheThrottleBpinshouldbeconnectedto5Vthroughtheenable

switchonthepotbox(COMandNCterminals)forredundantsafetyincaseofhallsensorfault.

Type 2, 2-wire 0-5KΩ: • Although not considered a great option due to their tendency to wear

outandbecomeunreliableovertime,legacy2-wireresistive0-5KΩpotboxes(suchastheCurtis

PB-6)canbeused.ThetwothrottlewiresconnecttoThrottleAand 5V (either polarity).The

enableswitchshouldbewiredbetween5VandThrottleB,usingtheCOMandNCterminals.

ThecontrollerwillhavetobeprogrammedviaserialinterfaceforThrottleType2.

Type 3, Hall Effect Pedal Assembly (HEPA):• HEPApedalsarebecomingtheindustrystandard

forthrottledevicesinvehiclesastheyofferhighreliabilityandsafetythroughtheuseofdual

(redundant)halleffectsensors.AvarietyofdifferentHEPApedalsareavailable,typicallyhaving

6 wires for two independent 3-wire hall effect type throttles. The MC1000SP was designed to

workwiththoseprovidingdualanalogoutputsofaround0.7V–3.5Vand1.4V–4.2V.Usethe

Gndand5VpinsonPlug2toprovidepowertobothsensors.The0.7-3.5Vsignalconnectsto

ThrottleAandthe1.4V-4.2VsignaltoThrottleB.WithaHEPAthrottle,thecontrollercandetect

a throttle fault if any four of the wires are disconnected, or if either of the throttle sensors are

faulty.BesuretocongurethecontrollerforThrottleType3.

76

OPERATION

TIPS FOR BEST PERFORMANCE

Manydriversareaccustomedtokeepingrevslowintheirpetrolvehiclesinordertomaximise

efciency,sincepetrolenginesareveryinefcientathighrevs.Well,electricdrivesystemsarethe

otherwayaround!Thesinglemosteffectivewaytomaximiseperformancefromyourmotorand

controlleristokeepyourmotorrevshigh–around3000-4000rpmwithmostSeriesDCmotors.

Foragivenpoweroutput,drivinga motorat higherspeed uses more voltagebut lesscurrent,

whichreducescopperlossesinthemotorandresistiveheatinginthecontroller.Droppingdown

agearreducesmotorampsbyabout30%,whichcanactuallyhalvetheheatgeneratedinyour

controller–andhencedoublethecontinuouspowercapability.(Caution:MostSeriesDCmotors

areratedto5000rpmmaxsobecarefulnottoexceedthisspeed!)

THERMAL PROTECTION

Ifyourcontrollerheatsinktemperaturereachesabout70˚C(150˚F),thecontrollerwillcommence

thermalcutback,smoothlyreducingpowertomitigatefurtherheating.ThestatusLEDwillash

green/redwhileinthisstate.Ifthecontrollertemperaturereaches90˚C(200˚F),thecontrollerwill

shut down completely to avoid overheating which could damage components.

The controller’s power rating depends somewhat on airow to cool the housing. If you are

experiencingthermalcutbacks,itmaybeusefultoaddfansorductstoincreaseairow.Driving

more slowly and keeping motor revs high will also help keep the motor controller cooler. If

thermalproblemspersist, it maybe useful toadda watercooling systemorexternal heatsink,

whichcanbematedtothebaseofthecontroller(withthermalpasteinbetween).

12V LOGIC SUPPLY

The MC1000SP has an internal regulated power supply on its 12V input which allows it to operate

safelyandcorrectlyoveraninputvoltagerangeof8-18VDC.Asasafetyprecaution,thecontroller

willshutdownifitdetectsthecontrolvoltageinputdipbelow8V.

Inmostinstallationsthiswillneverhappen,butifyour12Vbatteryand/orDC/DCconverterisvery

weak,thevoltagemaydipwhenloadssuchasheadlightsareturnedon,whichcantripoutthe

motorcontroller.Thisshouldberectiedbybyttingastrongerbatteryand/orDC/DCconverter.

MOTOR IDLING FUNCTIONALITY

TheMC1000SPincludesabasicmotoridlefunctionality,basedonalowtargetspeedwithlow

torquelimit.ItdoesnotuseanRPMsensorforspeedfeedback,sothespeedmayvarydependingon

load.HoweveritisasimpleandeffectivesolutionforEVconversionswithautomatictransmissions

(whichrequirethemotortokeepturningtomaintainoilcirculationinthegearbox),orforvehicles

using OEM power steering pumps, air-conditioning compressors, alternators, etc.

The idle speed and torque are congured via serial programming.Voltage effectively controls

targetmotorspeedandcurrentcontrolsthetorqueitwillusetogetthere.Idealvalueswilldepend

onyourmotorandvehicle,butagoodstartingpointis6Vidlevoltageand100Aidlecurrent.

Caution: Electric motors can suffer damage if they remain stalled with current

owing for extended periods of time. Idle functionality is NOT recommended for

“direct drive” vehicles, and in the case of vehicles with manual transmissions, be

sure to put the clutch in when coming to a stop.

INTERNAL CAPACITOR WARNING

Motorcontrollershavealargebankofcapacitorsontheirinput,whichcanretainitschargefora

longtimeafterthecontrollerispoweredoff.Exercisecautionifundertakingvehiclemaintenance

soonafterdriving,astheremaybesignicantvoltageacrossthecontroller’sinputpowerterminals,

even if your main contactor is open. Always measure the voltage across the controller with a

multimeterbeforeperforminganymaintenance.

LED STATUS AND ERROR CODES

TheMC1000SPhasanRGBstatusLEDonitsfrontpanel,andtheoptionforaremotestatusLED

wiredtoyourvehicle’sdash.ThisLEDcanprovidevisualfeedbackonthecontroller’soperating

status.Thefollowingtablesummarisesthecodesyoumayencounter(multipledotsrepresenting

aashsequence):

LED Code Condition Comment

Controller on (Noerrors)

Thermalcutback Controllertemperatureabove60˚C.Powerreduces

slowly towards thermal shutdown threshold.

Thermal shutdown Controllertemperatureabove90˚C.Thermal

shutdown until temperature reduces.

Battery voltage low Voltageatpowerterminalsbelowminimumsetting.

Powerstagedisableduntilvoltageincreases.

Supply voltage low Supplyvoltagebelow8VDC.Latchesonforsafety.

Fix 12V supply then power cycle controller.

Throttle error Invalid voltage or level mismatch on throttle. Error

latchesonforsafetyuntilzerothrottleisdetected.

Highpedallockout Non-zerothrottledetectedatstartup.Mayindicate

foot on pedal, or a faulty throttle device.

Corrupt settings Fault in the internal memory. Will automatically

revert to default settings on next startup.*

Desaterror Hardwareovercurrentfault.Mayindicatedamageto

internal power devices or short circuit in motor.*

98

Internal sensor fault An internal sensor returned an invalid value.*

*Theserareerrorsmayindicateahardwarefaultinthecontroller–pleasecontactus!

Caution: There are no user-serviceable parts inside the controller.

Do not attempt to open the controller as this will void warranty!

CUSTOMISING YOUR SETTINGS

TheMC1000SPstoresavarietyofoperatingsettingsinmemorywhichmaybemodiedbytheuser

viatheprovidedserialprogrammingcable.Itshouldworkwithanypersonalcomputerwhichhas

aUSBportandserialcommunicationssoftware–themostcommonexamplebeingHyperterminal

forMicrosoftWindows.Themotorcontrollercanonlybeprogrammedwhenrstpoweredup.

Onceyoustarttodrive,serialprogrammingwillbeautomaticallydisableduntilthecontrolleris

next turned on.

AUSBtoserialprogrammingcableissuppliedwiththemotorcontroller.Ifyourcomputerdoesn’t

recogniseitwhenyourstplugin,youmayneedtoinstallthedrivers.Acopymaybedownloaded

from:http://www.zeva.com.au/WinSerialDriver.zip

ThefollowingdemonstrateshowtosetupHyperterminal,butshouldbeeasilytranslatedforother

serialcommunicationssoftware.Thebasicsettingsare9600bps,8-bitdata,noparity,1stopbit,

noowcontrol.(NotethattheCOMportnumbermayvary.)

Hyperterminal settings windows

Onceyourconnectionwindowisup,pressEscapeandalistofavailablesettingsshouldappear

asper the followingimage. Press the appropriate number to select a parameter, thentype the

newvalueandpressReturntosave.Theacceptableparameterrangeisshown,andthecontroller

will automatically cap the parameter to this range if an invalid value is entered. At any time,

pressingEscapewillreturn tothemainmenu. Once nished,simplyunplug the programming

cable(settingsaresavedautomatically).

Hyperterminal Connection Window

Minimumbatteryvoltage:Thissettingcanbeusefultoavoidoverworkingorover-discharging•

yourbattery,bysettingittowhatevervoltagerepresentsalowstateofcharge(atbattery).Note

thatthiscannotreplaceaproperbatterymanagementsystemforprotectingyourcells!

Maximummotorvoltage:Ifusingamotorratedtoalowervoltagethanyourbatterypack,you•

can use this setting to ensure that the motor controller will not overspeed the motor.

Maximummotorcurrent:Invehicleswithsmallermotors,youmaywishtoreducemaximum•

motorcurrentinordertoavoiddamagingyourmotorfromovercurrent.Most6”orlargerSeries

DCmotorswillbenewiththemaximum600Asetting.

Maximumbatterycurrent:Ifusingsmallorweakbatteries,youcanadjustthissettingtoavoid•

overworkingyourbatteries.(Thistypicallydoesnoteffectaccelerationwhensettingoff,butmay

reduce high speed performance.)

Throttleramprate:Thisvariesthe rateat whichthe throttleisallowedtorampup.Asetting•

of zero gives instant throttle response, with numbers 1–4 giving increasingly gentle throttle

ramps.

Throttle type:The MC1000SP supports three throttle types: (1)Three wire 0-5V analog plus•

Enable(2)Twowire0-5KΩplusenableand(3)HallEffectPedalAssembly(HEPA).Pleaserefer

totheControlWiring:ThrottleDevicesectionforfurtherdetails.

Idlevoltageandcurrent:Thesecanbeusedtoenablemotoridlingfunctionality.Becarefulto•

leavetheseaszerounlessyouaresureyouneedthem,asitcancausethemotortorunnon-stop!

RefertotheOperation:MotorIdlingsectionformoreinformation.

1110

Table of contents

Other Zeva Controllers manuals

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions