1-3

FEATURES (SELLING POINTS)

■Major selling points

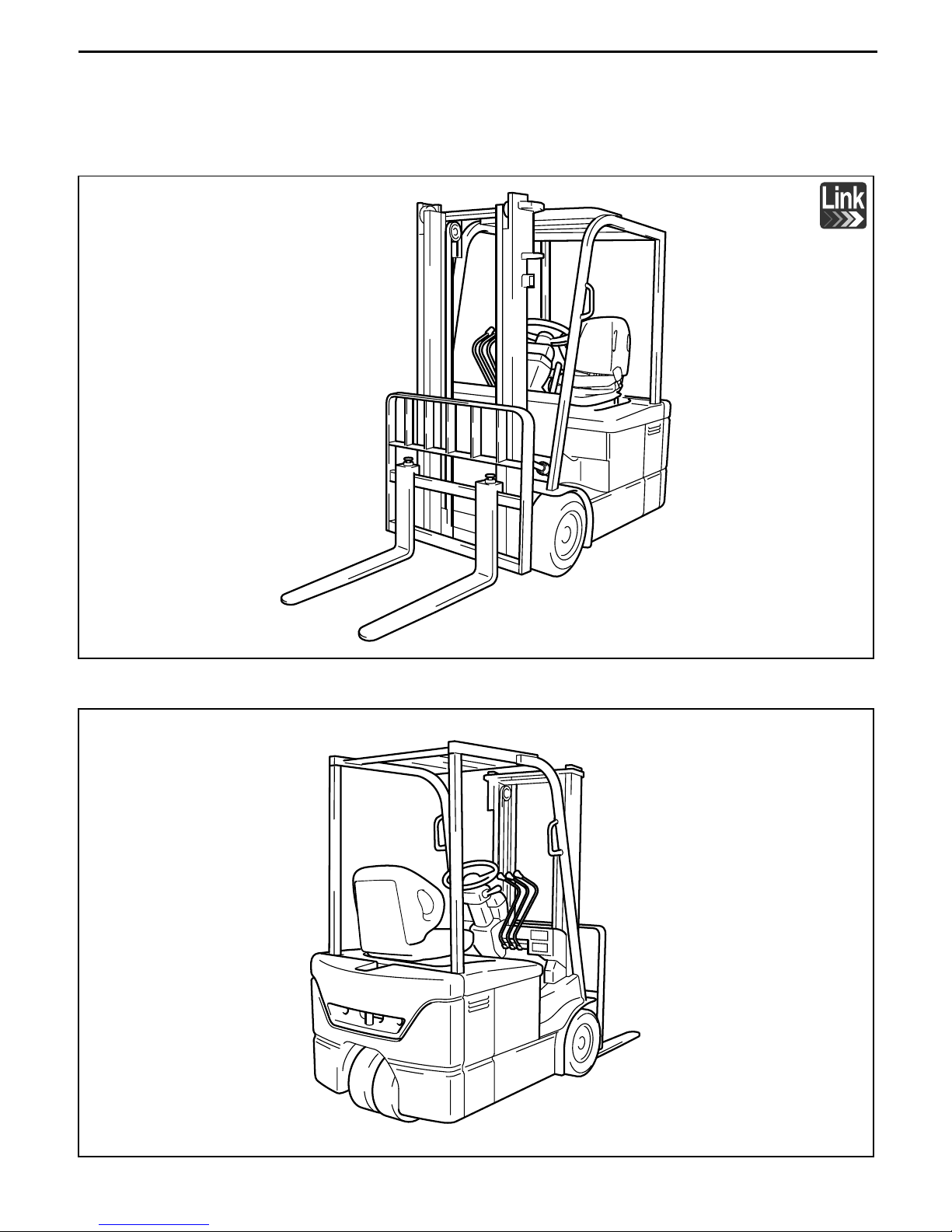

The greatest feature of the new models is adoption of the AC motor drive system. New features of the 7FB

series have also been adopted in many places.

1. Adoption of AC Motor Drive System

What is AC motor drive system?

The conventional DC motor drive system uses a controller for battery current chopping (ON and OFF)

to control the motor power by changing the chopping ratio to realize from inching at the time of starting

up to the maximum power.

The controller in the AC motor drive system converts the battery current to a three-phase alternate

current, whose sine wave form (frequency and waveform height) varies to control the motor power.

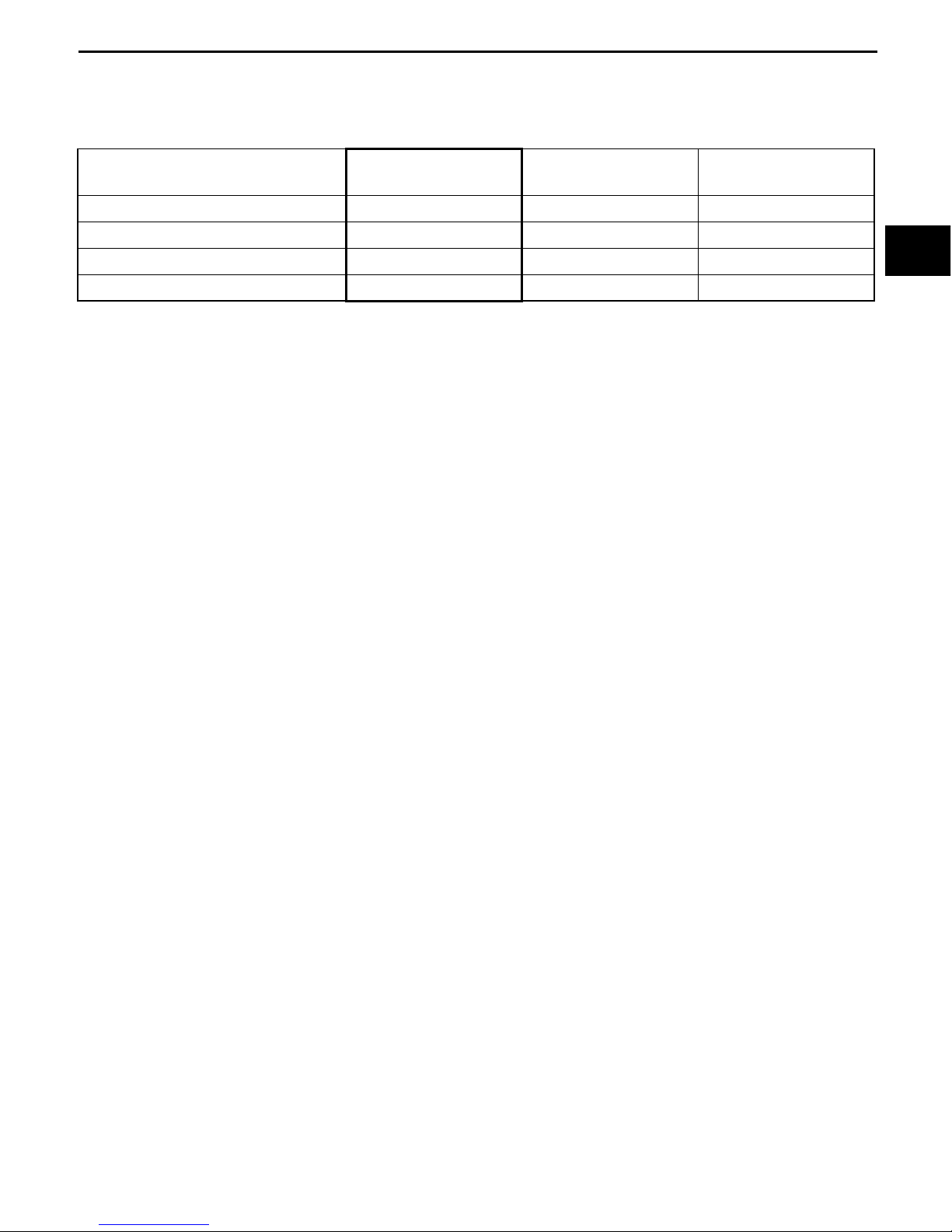

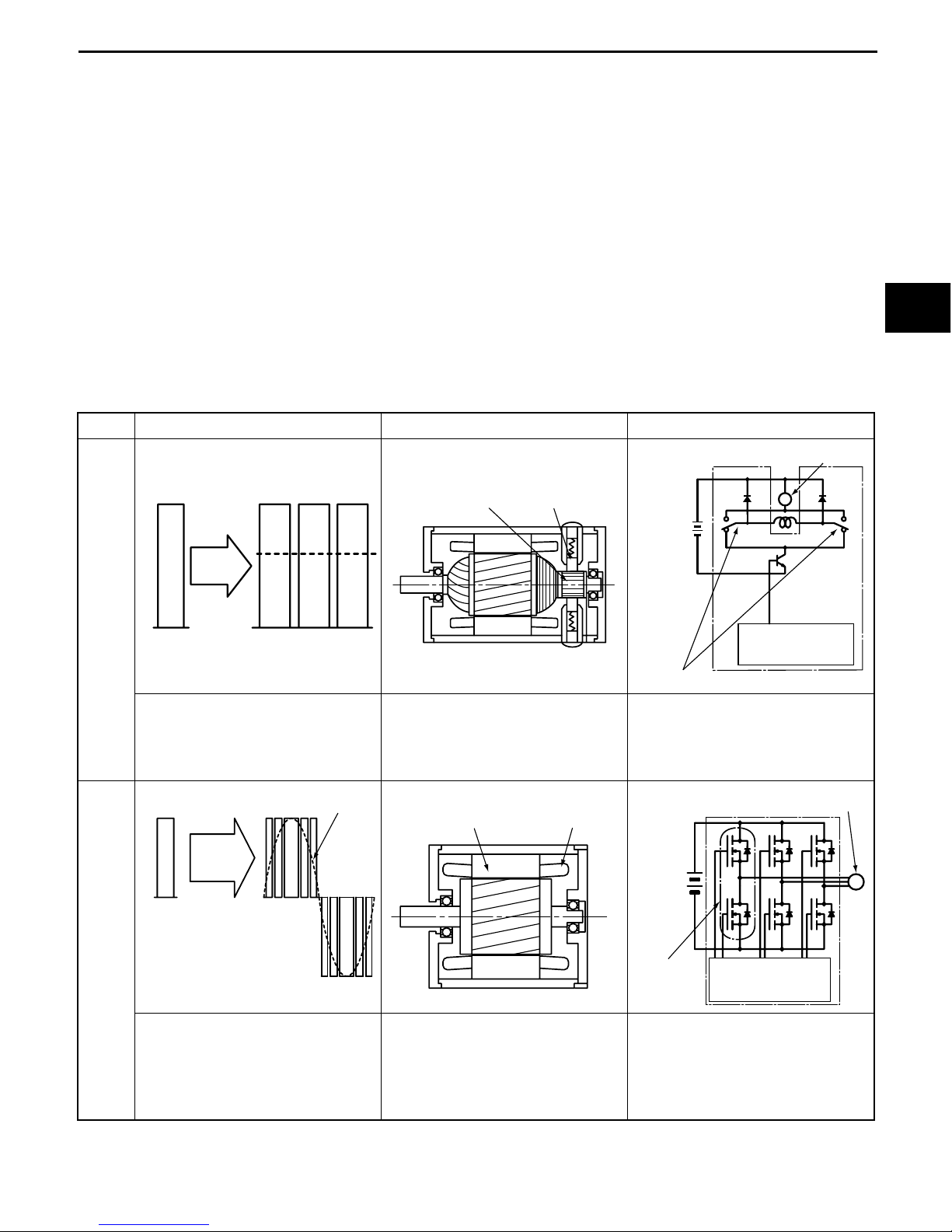

The table below compares the motor voltage, motor structure and the controller between the AC

system and DC system.

Comparison between the DC and AC systems

Motor voltage Motor structure Controller

DC

sys-

tem

• Conversion from battery DC

voltage into the mean volt-

age by the chopper

• Need of brush and commu-

tator maintenance

• Complicated structure

• Relatively easy by mean DC

voltage control

• Need of contactor for rotat-

ing direction change

AC

sys-

tem

• Conversion from battery DC

voltage into the AC voltage

by the controller

• No brush and commutator

(maintenance-free)

• Compact and lightweight

• Conversion from DC into

three-phase AC by the mod-

ule

• No need of contactor for

rotating direction change

Battery voltage Motor voltage

Con-

troller

Mean voltage

ON ON ON

Commutator Brush M

Motor

Contactor

Microcomputer

control

Battery

Battery voltage

Con-

troller

Motor voltage

Sine wave Stator core Stator coil

M

Microcomputer

control

Motor

1 Phase

Battery

2

3

1