Contents

1. Introduction..............................................................................................2

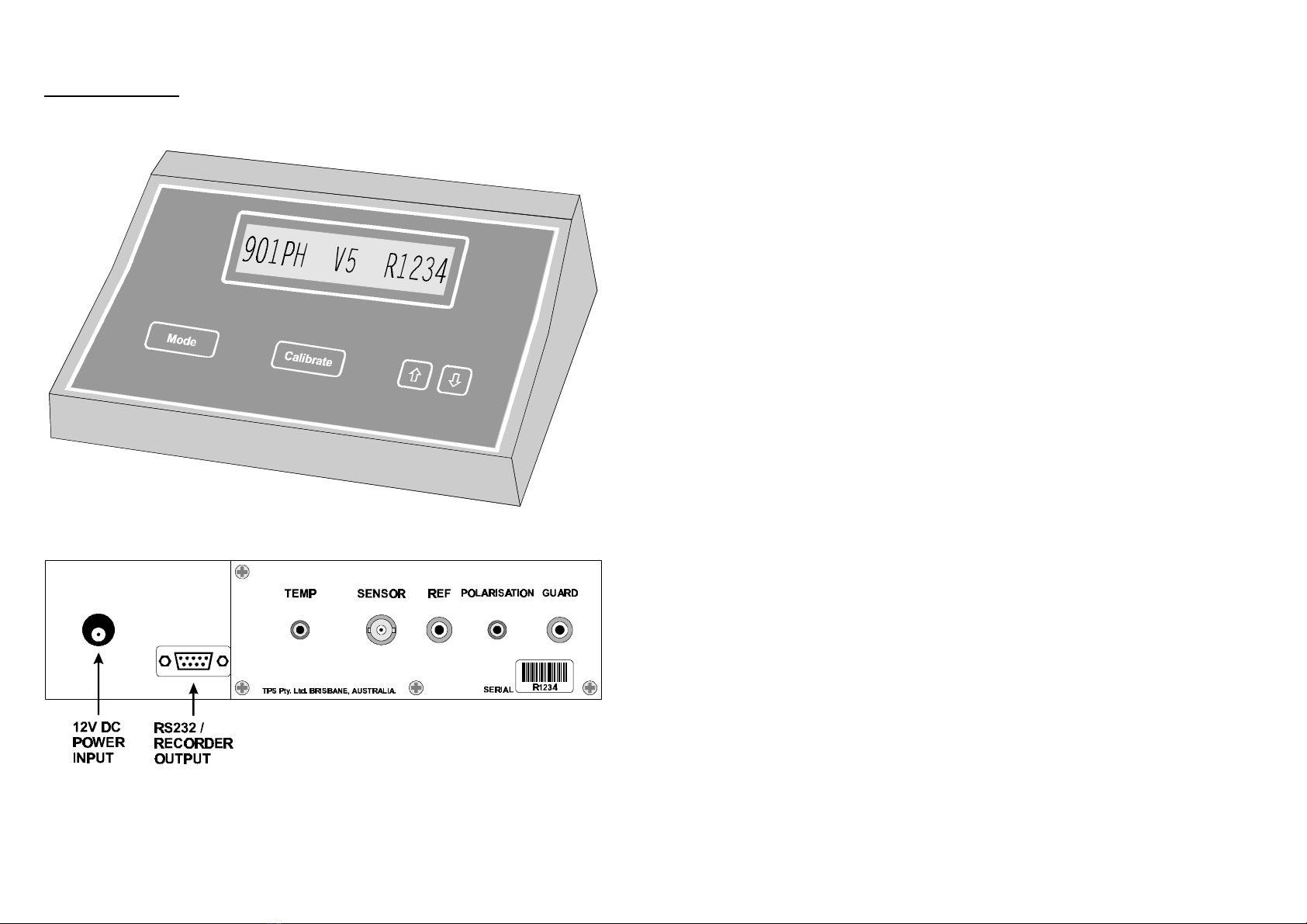

1.1 901-PH Display and Controls............................................................................2

1.2 901-PH Rear Panel Connectors..........................................................................2

1.3 901-PH Front Panel...........................................................................................3

1.4 Unpacking Information .....................................................................................4

1.5 Specifications....................................................................................................5

2. Operating Modes......................................................................................6

3. pH Calibration ..........................................................................................7

3.1 Calibration Procedure........................................................................................7

3.2 Calibration Notes ..............................................................................................8

3.3 Calibration Messages ........................................................................................9

4. mV Calibration........................................................................................ 10

5. Temperature Calibration........................................................................ 10

5.1 Calibration Procedure......................................................................................10

5.2 Calibration Notes ............................................................................................11

5.3 Calibration Messages ......................................................................................11

5.4 Manual Temperature Setting ...........................................................................12

6. RS232 Port.............................................................................................. 13

6.1 Setting the Baud Rate......................................................................................13

6.2 Sending Readings to the RS232 Port................................................................13

6.3 RS232 Configuration ......................................................................................14

6.4 Communication and Statistical Software..........................................................14

6.5 Commands......................................................................................................14

6.6 Data Format....................................................................................................15

7. Recorder Output Option ........................................................................ 16

7.1 RS232 / Recorder Output Socket Connections .................................................16

8. Selecting Buffers for Automatic Buffer Recognition............................ 17

9. Initialising the 901-PH............................................................................ 18

10. Troubleshooting..................................................................................... 19

10.1 General Error Messages ..............................................................................19

10.2 pH and mV Troubleshooting .......................................................................20

10.3 Temperature Troubleshooting......................................................................21

11. Appendices............................................................................................. 22

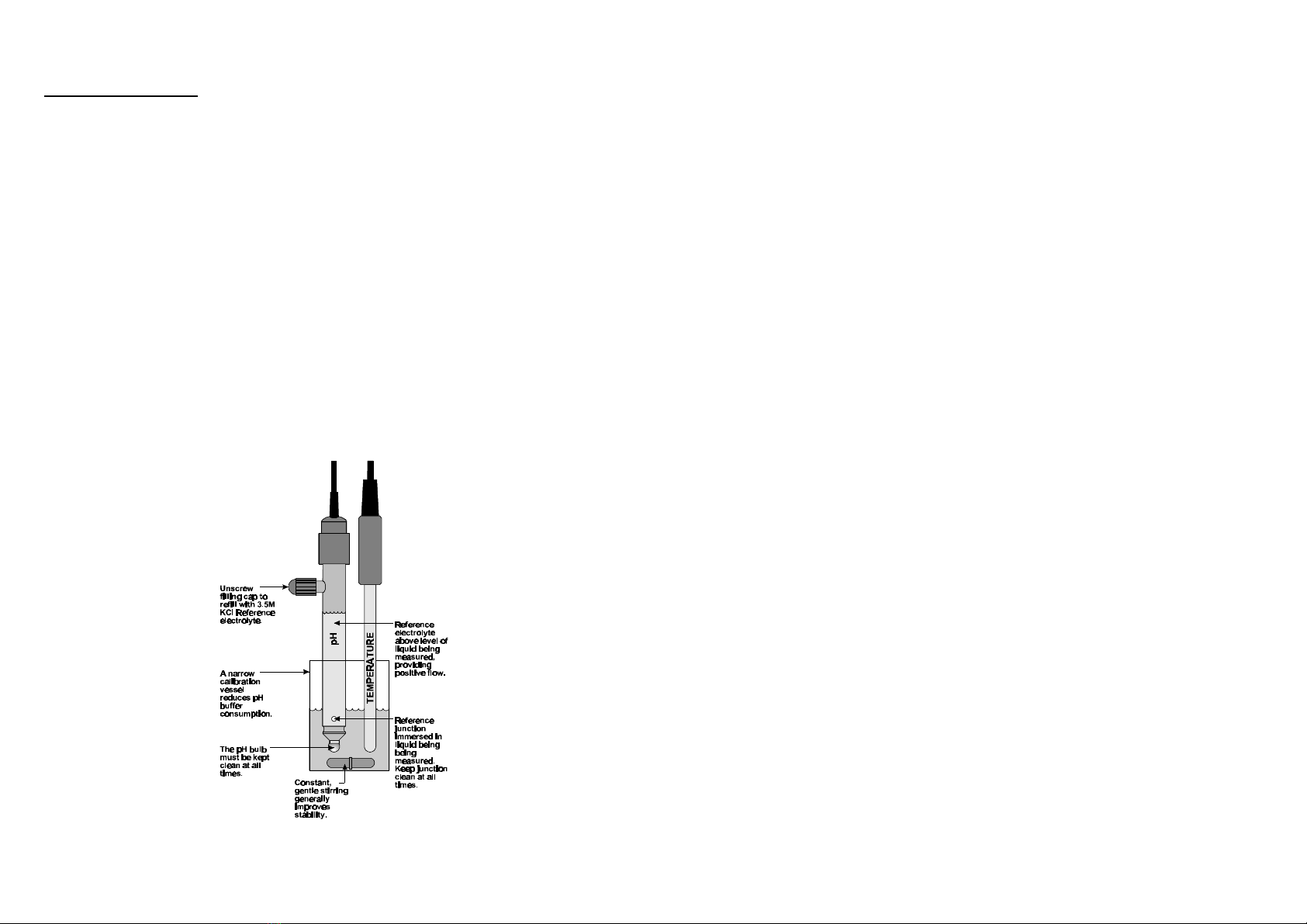

11.1 pH Sensor Fundamentals.............................................................................22

11.2 Polarisation Output Connector.....................................................................24

11.3 Guard Connector.........................................................................................25

11.4 Checking the reference junction of a pH sensor............................................25

11.5 Determining if an instrument or sensor is faulty...........................................26

12. Warranty ................................................................................................. 27