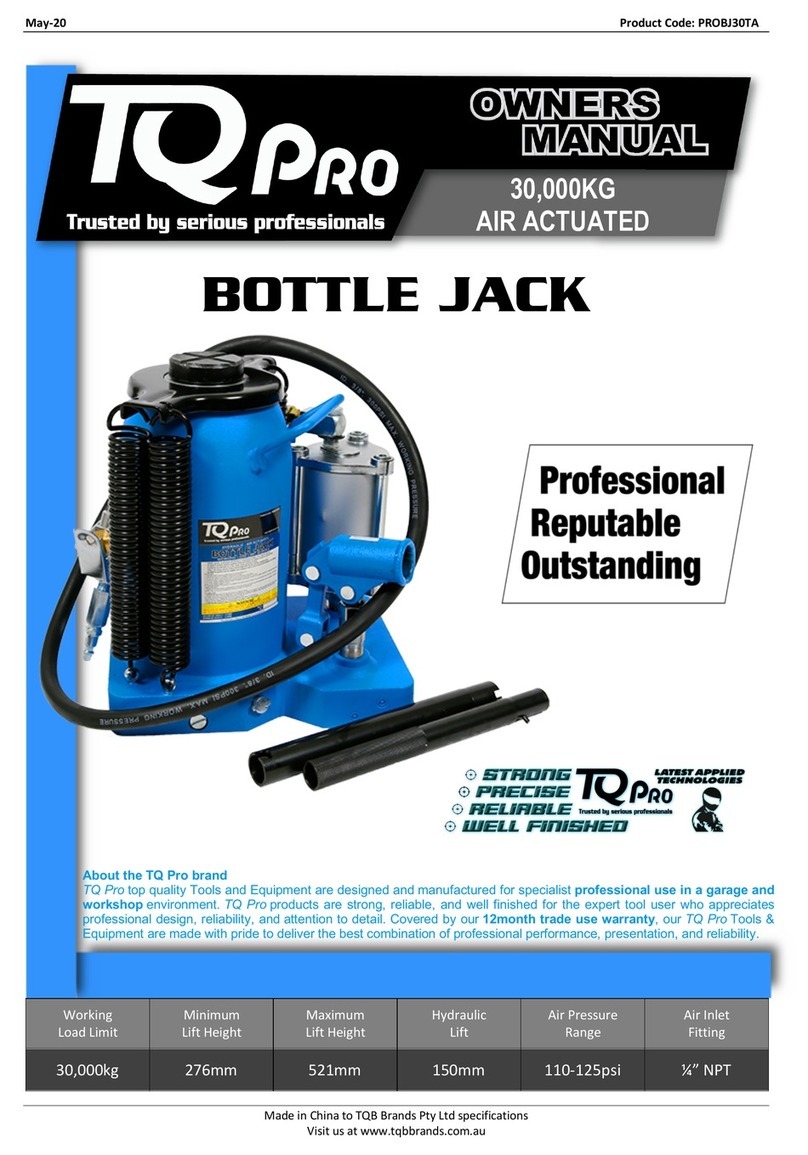

TQ Pro PROTRJA20T User manual

Aug-20 Product Code: PROTRJA20T

Made in China to TQB Brands Pty Ltd specifications

Visit us at www.tqbbrands.com.au

TRUCK JACK

Working

Load Limit

Minimum

Height

Maximum

Height

Hydraulic

Lift

Adjustable

Screw

Operating

Air Pressure

20,000kg

215mm

541mm

141mm

85mm

145-175psi

20,000KG

TRUCK JACK AIR ACTUATED

About the TQ Pro brand

TQ Pro top quality Tools and Equipment are designed and manufactured for specialist professional use in a garage and

workshop environment. TQ Pro products are strong, reliable, and well finished for the expert tool user who appreciates

professional design, reliability, and attention to detail. Covered by our 12month trade use warranty, our TQ Pro Tools &

Equipment are made with pride to deliver the best combination of professional performance, presentation, and reliability.

May-20 Product Code: PROTRJA20T

Made in China to TQB Brands Pty Ltd Specifications Page 2

Visit us at www.tqbbrands.com.au

WARNING INFORMATION

IMPORTANT: READ ALL INSTRUCTIONS BEFORE USE

WARNING

The instructions and warnings contained in this manual should be read and understood before using or operating this equipment.

Do not allow anyone to use or operate this equipment until they have read this manual and have developed a thorough

understanding of how this equipment works. Failure to observe any of the instructions contained in the manual could result in

severe personal injury to the user or bystanders, or cause damage to the equipment and property. Keep this manual in a

convenient and safe place for future reference.

Whilst every effort has been made to ensure accuracy of information contained in this manual, the TQ Pro policy of continuous

improvement determines the right to make modifications without prior warning.

CONTENT

WARNING INFORMATION .........................................................................................................................................................................................2

CONTENT ...................................................................................................................................................................................................................2

SAFETY INSTRUCTIONS ..............................................................................................................................................................................................3

ASSEMBLY, OPERATION & PREVENTATIVE MAINTENANCE.......................................................................................................................................4

TROUBLESHOOTING ..................................................................................................................................................................................................7

WARRANTY................................................................................................................................................................................................................8

TQ Pro top quality Tools and Equipment are designed and manufactured for specialist professional use in a garage and

workshop environment. TQ Pro products are strong, reliable, and well finished for the expert tool user who appreciates

professional design, reliability, and attention to detail. Covered by our 12 month trade use warranty, our TQ Pro Tools &

Equipment are made with pride to deliver the best combination of professional performance, presentation, and reliability.

May-20 Product Code: PROTRJA20T

Made in China to TQB Brands Pty Ltd Specifications Page 3

Visit us at www.tqbbrands.com.au

SAFETY INSTRUCTIONS

WARNING

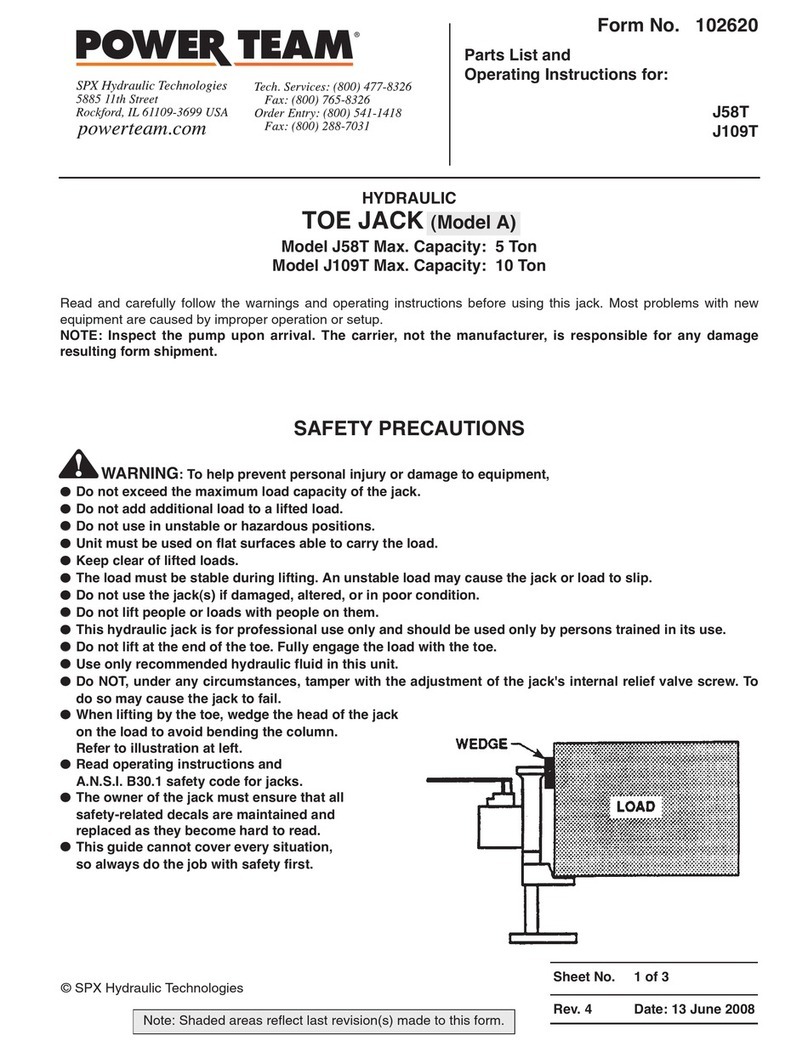

FAILURE TO READ THESE WARNINGS MAY RESULT IN PROPERTY DAMAGE & PERSONAL INJURY

Support load by appropriate means after lifting

Do not exceed rated capacity

Centre load on the jack

Only use attachments and/or adapters supplied with or

sold specifically for the jack

Only lift areas of the vehicle designated by the vehicle

manufacturer.

Use as lifting device only

Use only on hard, level surface

Do not modify jack

SAFETY OPERATING INSTRUCTIONS

DO NOT exceed the maximum lifting load capacity of 20,000kg.

Only use this Truck jack on a surface that is stable, level, smooth, dry and capable of sustaining the load. Keep the surface

free from unrelated materials and ensure that there is adequate lighting.

DO NOT use on tarmac, or any other soft surface as the Truck Jack may sink or topple.

Vehicle must be properly and adequately supported with AS Approved Support Stands immediately after the lift and

before commencing work with this Truck Jack.

Always centre the load on the saddle of this Truck Jack and be sure the vehicle is stable before raising or lowering.

DO NOT operate this Truck Jack when you are tired or under the influence of alcohol, drugs or any intoxicating medication.

DO NOT allow untrained persons to operate this product and DO NOT make any modifications to this product.

DO NOT tamper with the safety valve.

DO NOT use brake fluid or any other improper fluid to refill or top up the hydraulic system of this Truck Jack. Only use

good quality hydraulic jack oil.

DO NOT expose the Truck Jack to rain or any other kind of inclement weather.

Use a qualified person to maintain the Truck Jack in good condition. Keep the Truck Jack clean for best and safest

performance.

Use approved personal protection safety equipment such as eye protection, non skid boots, full face impact shield and

heavy duty work gloves. Keep proper footing and balance, do not overreach.

This Truck Jack should be used for lifting and lowering only. The raised load should be supported on approved support

stands. No person should get any part of the body under a load that is supported by this jack.

Position the jack to only lift on the areas of the load specified by the vehicle manufacturer.

Use support stands –after lifting the load always support the load with appropriately rated support stands before working

on the load.

Do not overload this jack beyond its rated capacity. Overloading this jack beyond its rated capacity can cause damage to

or failure of the jack.

Keep hands & feet clear of the jack hinge mechanism & ground contact area when lowering the load.

NEVER LIFT THE LOAD OFF AIRBAG BRACKETS. ALWAYS LIFT OFF AN AXLE OR CHASSIS LIFT POINT

THIS JACK IS A LIFTING DEVICE ONLY & IS DESIGNED FOR LIFTING PART OF THE TOTAL VEHICLE/LOAD.

DO NOT MOVE OR DOLLY THE VEHICLE/LOAD WHILST THE VEHICLE/LOAD IS ON THE JACK.

May-20 Product Code: PROTRJA20T

Made in China to TQB Brands Pty Ltd Specifications Page 4

Visit us at www.tqbbrands.com.au

ASSEMBLY, OPERATION & PREVENTATIVE MAINTENANCE

1. FEATURES

The TQ Pro Air Actuated Hydraulic Garage Jack is designed to operate either manually or pneumatically for lifting and lowering,

but not sustaining load. This 20,000kg Heavy-Duty Air/Hydraulic Bottle Jack is the perfect choice for a wide variety of uses.

The power of air makes it easy to lift farm vehicles, trucks, lawn mowers, heavy equipment and other large loads. The manual

function allows for normal operation anywhere, even without an air supply. These strong, reliable and well finished jacks are

carefully constructed from the highest grades of rugged steel. The super strong hydraulic pump utilises wear-resistant

American Made XTP double sealing ring technology. Only the finest quality of Hydraulic Oil is used that has been tested from

-25°C - 60°C.

FEATURES

American made seals

Double Sealing Function using XTP Industry Sealing

Telescopic air actuation lift (air-hydraulic pump)

Long T-handle lets you easily position your jack under vehicle

Self-Returning Lowering and Lifting Switch

Internal and External Cylinders hard chromed

High manoeuvrability & deep reach under vehicles

Extension adaptors / saddle plates

Large rubber wheels

2. ASSEMBLY

Step 1:

Screw toggle (taped to bottom of carton with handle in) into the top of the handle.

Remove axle from rear of jack.

May-20 Product Code: PROTRJA20T

Made in China to TQB Brands Pty Ltd Specifications Page 5

Visit us at www.tqbbrands.com.au

Step 2:

Insert hoses from Handle into rear of jack as pictured below.

Step 3:

Insert handle base into slot and thread axle through jack and handle.

Lock in place with circlip

PLEASE NOTE:

TO LOWER THE JACK, THE SAME AMOUNT OF FREE AIR FLOW IS REQUIRED AS WHEN LIFTING

3. BEFORE USE

Prior to each use conduct a visual inspection checking for abnormal conditions, such as cracked welds, leaks, and damaged,

loose, or missing parts.

Consult the vehicle owner’s manual to determine the location of lift points.

Be sure to set the vehicle in park with the emergency brake on and wheels securely chocked.

Be sure that the vehicle and the jack are on a hard, level surface.

May-20 Product Code: PROTRJA20T

Made in China to TQB Brands Pty Ltd Specifications Page 6

Visit us at www.tqbbrands.com.au

4. OPERATION

1. This jack is equipped with a handle position lock. To adjust the handle, release the lock device by pulling the lever up. The

lever is spring loaded so, so it should lock into the desired position.

2. Make sure the jack and load are on a hard level surface.

3. Always set the vehicle parking brake and block the wheels.

4. Check the placement of the jack. The load must be centred on the jack saddle. Avoid jack wheel obstructions such as

gravel, tools, or uneven expansion joints.

5. Position the jack under the load using the manufacturer's recommended lifting points on the chassis.

6. Connect compressed air supply to the jack. (Compressed air should be clean, dry, and regulated at 120-170psi). Install an

air filter/lubricator in the workshop air-line, because water in the airline will damage the jack.

7. Rotate the lever RIGHT to the UP position. (To stop air operation, simply release the grip on the lift control trigger).

Continue to pump the jack until the head cap reaches the load.

8. Before raising the load, double check and verify the saddle is centred and has full contact with the specified lifting point.

9. Rotate the lever RIGHT to the UP position (To stop air operation, simply release the grip on the lift control trigger).

Continue to pump the jack to lift the load to the desired height.

10. Always immediately position approved support stands under the load at points that will provide stable support in

accordance with the vehicle or load manufactures recommendations.

11. Always lower the load slowly onto the support stands by rotating the lever LEFT to the DOWN position.

12. Carefully lower the load onto the support stands by rotating the lever to the DOWN position

Lowering the load

1. Raise the load by following Steps 2-9

2. Raise the load high enough to allow clearance for the support stands to be removed by rotating the lever to the Right

UP position.

3. Carefully remove the support stands

4. Grasp the jack handle firmly. Securely hold onto the jack handle so that your hands do not slip and ensure the release

valve does not lower rapidly.

5. Carefully open the release valve by slowly rotating the LEVER to the LEFT DOWN position.

6. Once the load has been lowered, remove the jack from beneath the load, and fully retract the ram to prevent exposure

to dirt and grime.

5. INSPECTION

Prior to each use conduct a visual inspection checking for abnormal conditions, such as cracked welds, leaks, and

damaged, loose, or missing parts.

The jack shall always be maintained in accordance with the maintenance instructions (Section 7). No alterations or

modifications shall be made to this Jack.

Inspections shall be performed in accordance with this owner’s manual.

The jack must be inspected immediately if it is believed to have been subjected to abnormal load or shock.

Owners and /or operators should be aware that repair of this product may require specialised equipment and knowledge

(refer to maintenance section).

6. STORAGE

This jack should always be stored in a dry location on a level surface with the lift ram pistons in the fully retracted position,

where it will not be exposed to corrosive vapours, abrasive dust, or any other harmful elements.

May-20 Product Code: PROTRJA20T

Made in China to TQB Brands Pty Ltd Specifications Page 7

Visit us at www.tqbbrands.com.au

7. MAINTENANCE

Monthly maintenance is recommended. Lubrication is critical to jacks as they support heavy loads. Any restriction due to

dirt, rust, etc, can cause either slow movement or cause extremely rapid jerks damaging the internal components. The

following steps are designed to keep the jack well maintained and operational.

Important: Dirt is the greatest single cause of failure in hydraulic units. Keep the jack clean and well lubricated to prevent

foreign matter from entering the system. If the jack has been exposed to rain, snow, sand, or grit it must be cleaned before

it is stored or used.

Only use replacement parts that are approved by the manufacturer. Disconnect the air supply before performing any

maintenance operation.

Lubricate the ram, linkages, saddle, wheels and pump mechanism with light Hydraulic oil.

Visually inspect for cracked welds, bent, loose, missing parts or hydraulic oil leaks.

Any hydraulic jack found to be damaged, worn or operates abnormally must be removed from service until repaired by

an authorised service representative.

Regularly clean all surfaces and maintain all labels and warnings.

Check and maintain the hydraulic ram oil level.

Check the ram every three months for any sign of rust or corrosion. Clean as needed and wipe with a clean oily cloth.

When not in use always leave the saddle and ram all the way down.

Always store your jack in the fully retracted position. This will help protect critical areas from corrosion. Do not use brake

or transmission fluids or regular motor oil as they can damage the seals.

ONLY USE HIGH QUALITY HYDRAULIC FLUID –ISO68

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

ACTION

Jack will not lift

Control valve in wrong position.

Low/no oil in reservoir.

Air-locked system.

Load is above capacity of jack.

Delivery valve and/or bypass valve not

working correctly.

Seals worn out or defective.

Not enough air pressure

Turn control valve knob clockwise.

Fill with oil and bleed system.

Bleed system.

Use correct equipment.

Clean to remove dirt or foreign matter. Replace oil.

Install appropriate seal kit.

Ensure constant air delivery of above 120psi

Jack lifts only partially

Too much or not enough oil

Check oil level

Jack advances slowly

Pump not working correctly

Leaking seals

Install seal kit, or replace power unit

Install seal kit

Jack lifts load, but

doesn’t hold

Cylinder packing is leaking

Valve not working correctly (suction,

delivery, release or bypass).

Air-locked system

Install seal kit

Inspect valves. Clean and repair seat surfaces

Bleed system as per instructions

Jack leaks oil

Worn or damaged seals

Install seal kit

Jack will not retract

Control valve in wrong position

Air Pressure to low

Move Control valve to DOWN position

Ensure constant air delivery of above 120psi

Jack retracts slowly

Cylinder damaged internally

Send jack to authorised service centre

PLEASE NOTE:

TO LOWER THE JACK, THE SAME AMOUNT OF FREE AIR FLOW IS REQUIRED AS WHEN LIFTING

8. SERVICE & REPAIR

Any TQ Pro Jack found damaged in any way, or found to be worn or operates abnormally should be removed from service

until repaired by an authorised service agent. Owners and / or operators should be aware that repair of this product may

require specialised equipment and knowledge. Only authorised parts, labels, decals shall be used on this equipment. Annual

inspection of the Bottle Jacks is recommended and can be made by an authorised repair facility to ensure that your equipment

is in optimum condition and that the equipment has the correct decals and safety labels specified by the manufacturer.

May-20 Product Code: PROTRJA20T

Made in China to TQB Brands Pty Ltd Specifications Page 8

Visit us at www.tqbbrands.com.au

WARRANTY

TQ Pro products have been carefully tested and inspected before shipment and are guaranteed to be free from defective materials

and workmanship for a period of 12 months from the date of purchase except where tools are hired out when the guarantee

period is ninety days from the date of purchase.

Should the machine develop any fault, please return the complete tool to your nearest authorised warranty repair agent or contact

TQB Brands Pty Ltd Warranty team –warranty@tqbbrands.com.au.

If upon inspection it is found that the fault occurring is due to defective materials or workmanship, repairs will be carried out free

of charge. This guarantee does not apply to normal wear and tear, nor does it cover any damage caused by misuse, careless or

unsafe handling, alterations, accident, or repairs attempted or made by any personnel other than the authorised TQB Brands Pty

Ltd repair agent.

This guarantee applies in lieu of any other guarantee expressed or implied and variations of its terms are not authorised.

Your TQB Brands Pty Ltd guarantee is not effective unless you can produce upon request a dated receipt or invoice to verify your

proof of purchase within the 12 month period.

Consumer Guarantee

Our goods come with a guarantee that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement

or refund for a major failure and compensation for any other reasonably foreseeable loss or damage. You are also entitled to have

the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

All images and illustrations shown are for reference purposes only. All information, specifications and illustrations in this manual

are based on the latest information available at the time of publication and are subject to change without notice. The information

in this manual is periodically revised to ensure the latest information is included. Download the latest version of this manual and

other related technical documentation from www.tqbbrands.com.au.

Table of contents

Other TQ Pro Jack manuals