Columbus JACK/Regent

2222 S. Third St., Columbus, Ohio 43207-2402 USA

Model 179D1100-56

50 Ton Alligator Axle Jack

Page 1 of 5

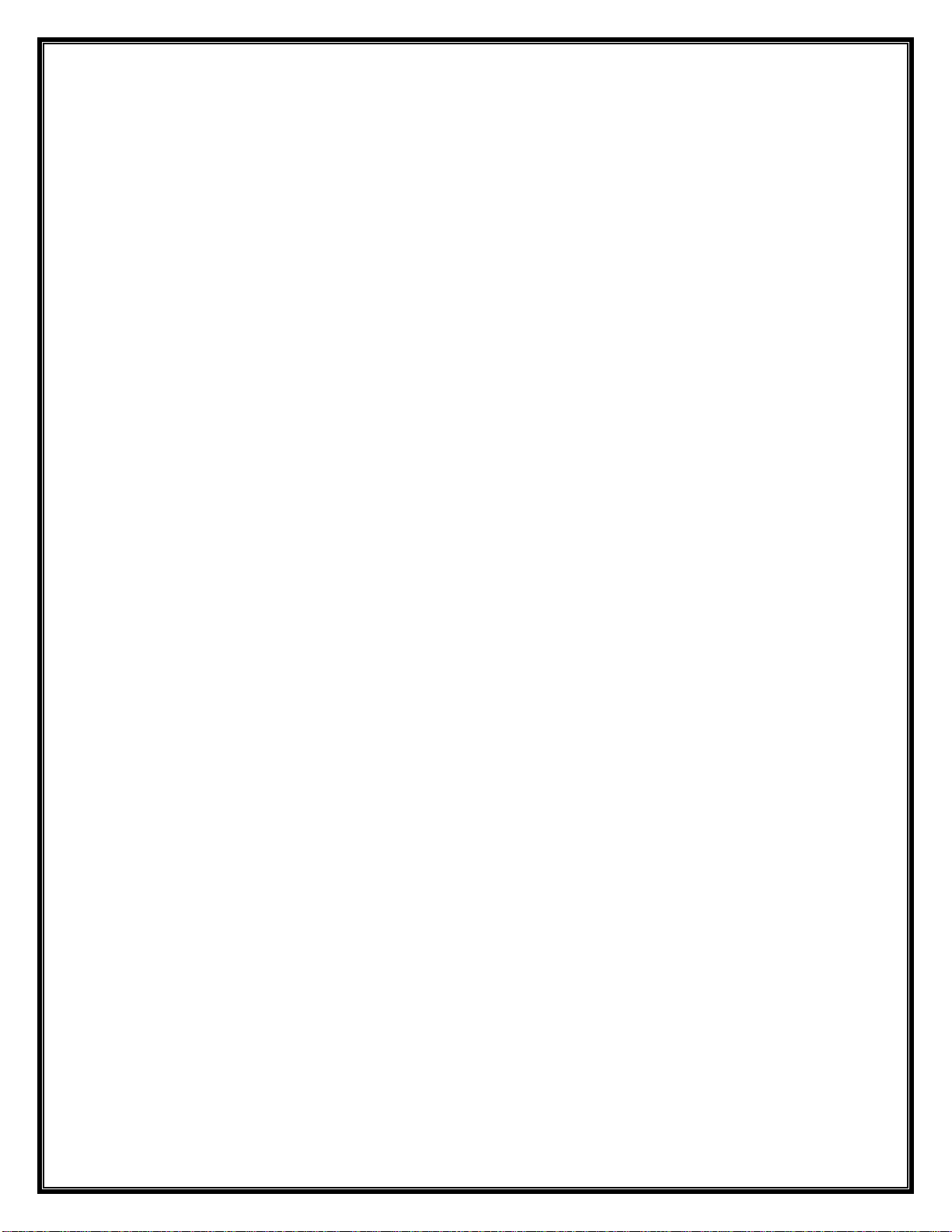

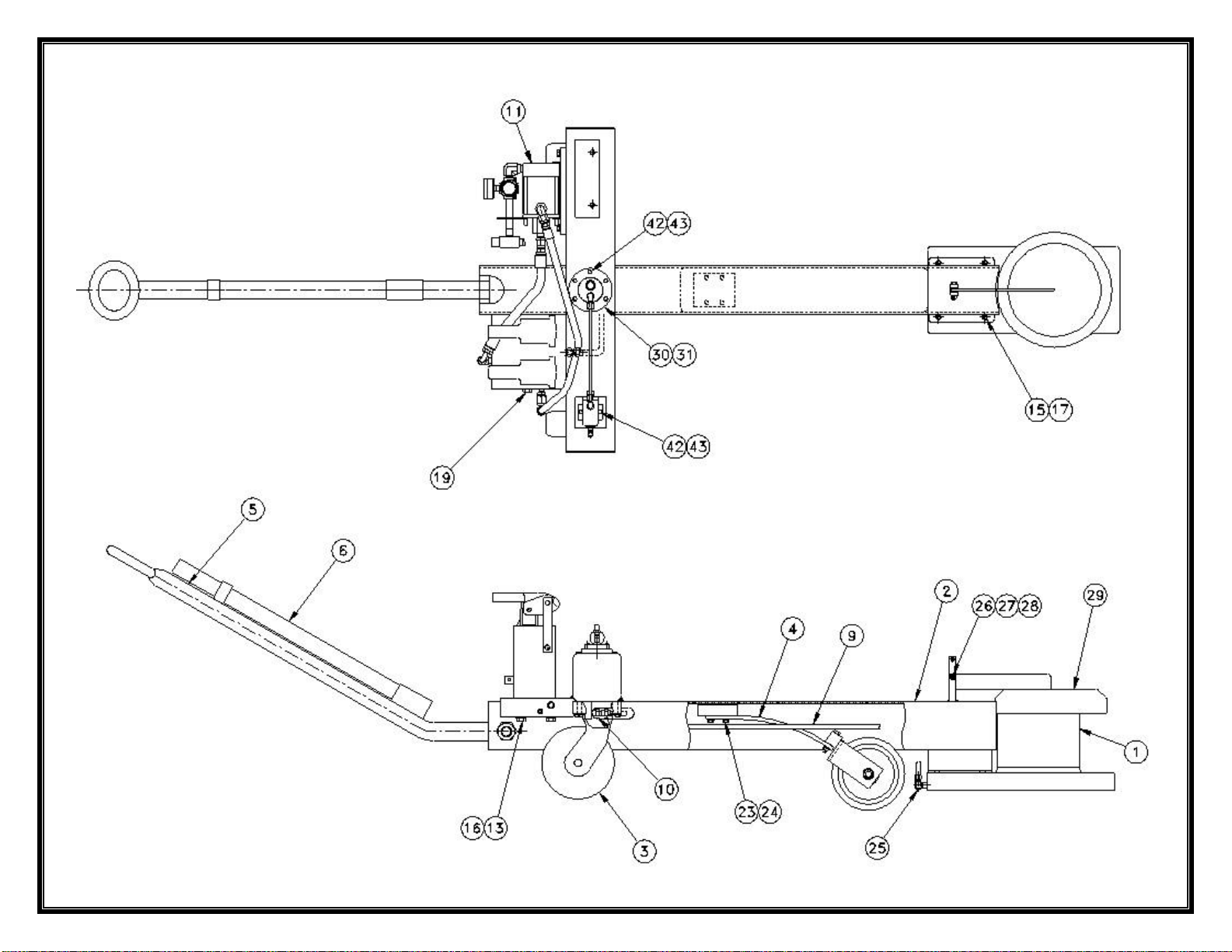

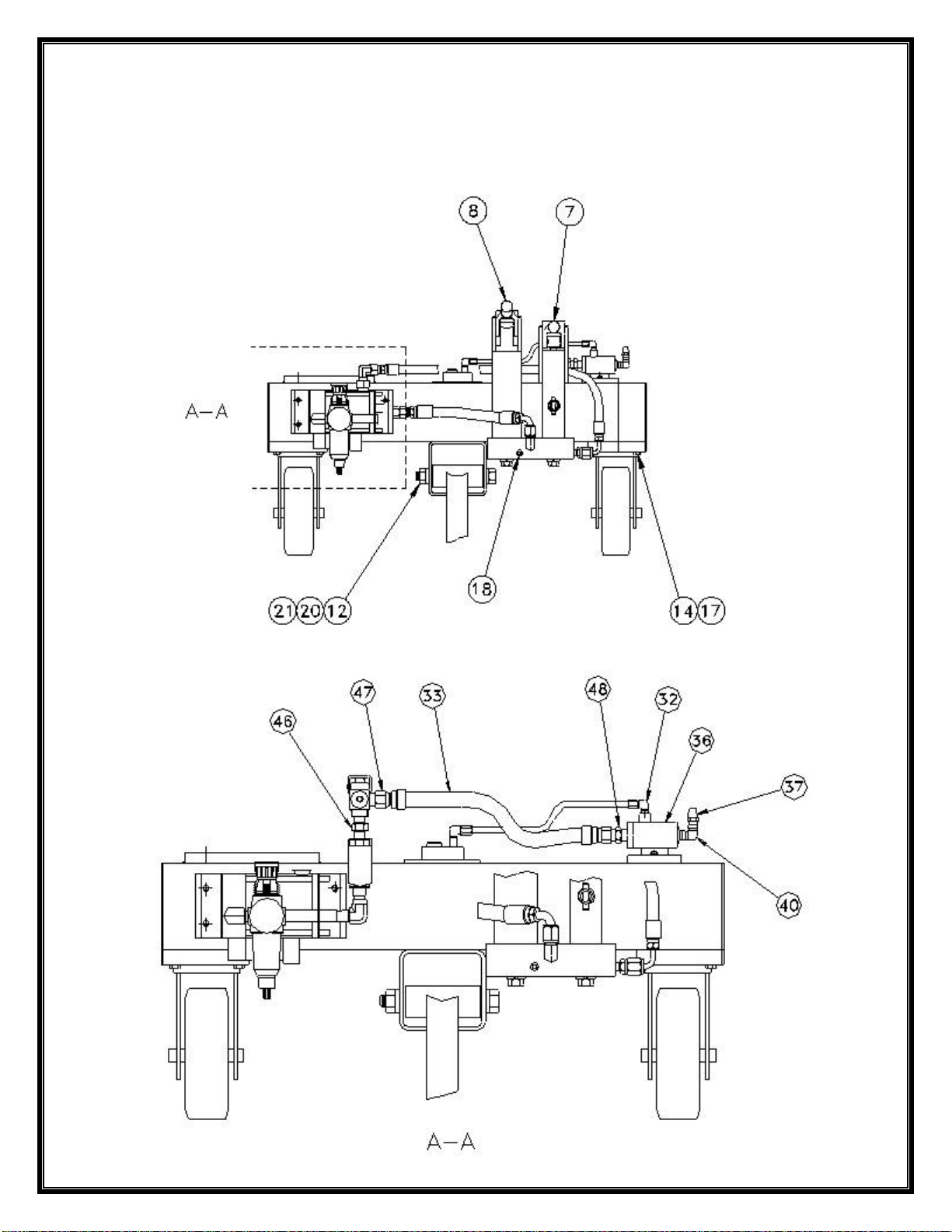

Figure 1

FIG. & UNITS

ITEM PART NUMBER DESCRIPTION PER

NO. ASS'Y

1- 179D1100-56 50 Ton Alligator Axle Jack .................... Ref.

-1 179C1200 Lift Assembly ............................................. 1

-2 179C1400-D Frame Weldment ....................................... 1

-3 200-6UV Swivel Caster ............................................. 2

-4 349D1014 Spring Assembly ........................................ 1

-5 117C1406 Towbar ....................................................... 1

-6 469B1211 Handle ........................................................1

-7 566-06 Pump Assembly ......................................... 1

-8 566-02 Pump Assembly ......................................... 1

-9 SST-10000 3/8” OD x .065 Wall Stainless Tube ........................................ A/R

-10 457-00602 Male Connector ......................................... 1

-11 179-1832 Hydraulic Pump ......................................... 1

-12 371-26440 Hex Head Cap Screw ................................ 1

-13 371-20180 Hex Head Cap Screw ................................ 4

-14 371-16070 Hex Head Cap Screw................................. 8

-15 377-16060 Sch Head Cap Screw................................. 4

-16 346-10032 Lock Washer .............................................. 4

-17 346-10024 Lock Washer ............................................ 12

-18 488-00002 Hex Socket Plug 1/8” ................................. 1

-19 488-00004 Hex Socket Plug 1/4” ................................. 1

-20 MS51922-57 Self Locking Nut ......................................... 1

-21 345-11048 Flat Washer ............................................... 2

-22 160B604 Operating Instruction Plate ........................ 1

-23 372-14090 Hex Head Cap Screw ................................ 4

-24 346-10020 Lock Washer .............................................. 4

-25 456-00604 90 Degree Male Elbow............................... 1

-26 371-12100 Hex Head Cap Screw ................................ 1

-27 333-41200 Hex Nut ...................................................... 1

-28 346-10016 Lock Washer .............................................. 1

-29 179C2002 Cover Assembly ......................................... 1

-30 179-2000 Access Plate Weldment ............................. 1

-31 179-2004 Gasket ....................................................... 1

-32 456-10602-A Male Elbow ................................................ 1

-33 450A5961 Hose ....................................................... A/R

-34 488-00008 Pipe Plug ................................................... 1

-35 450A3202 Valve .......................................................... 1

-36 SC-284 Vacuum Pump ........................................... 1

-37 450A5960 Muffler ........................................................ 1

-38 456-10606-A Male Elbow ................................................ 1

-39 485-40404 Male Run Tee ............................................ 1

-40 484-00404 Female Pipe Elbow .................................... 1