TQ Pro PROTL500A User manual

May-20 Product Code: PROTL500A

Made in China to TQB Brands Pty Ltd specifications

Visit us at www.tqbbrands.com.au

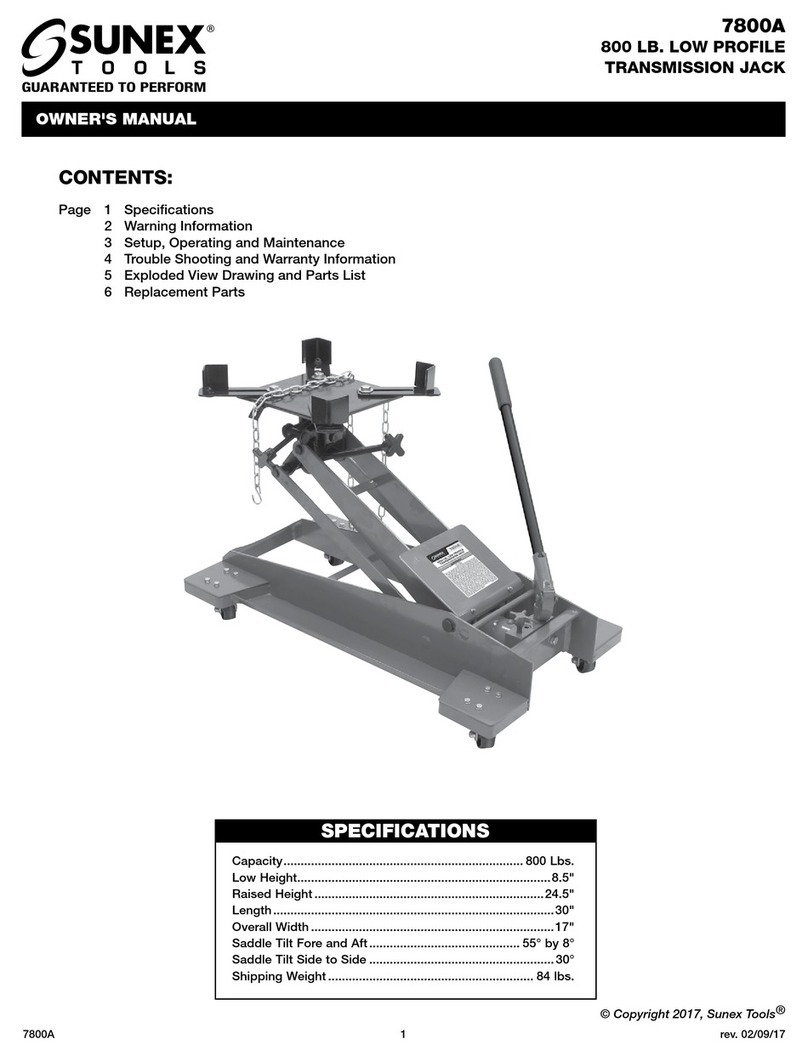

TRANSMISSION LIFTER

Working

Load Limit

Minimum

Saddle Height

Maximum

Saddle Height

Saddle Tilt

Adjustments

Operating

Air Pressure

Nett

Weight

500kg

940mm

1940mm

55˚Fwd 91˚Bck

55˚Left 16˚Right

110-125psi

68.5kg

500KG

AIR/HYDRAULIC

About the TQ Pro brand

TQ Pro top quality Tools and Equipment are designed and manufactured for specialist professional use in a garage and

workshop environment. TQ Pro products are strong, reliable, and well finished for the expert tool user who appreciates

professional design, reliability, and attention to detail. Covered by our 12month trade use warranty, our TQ Pro Tools &

Equipment are made with pride to deliver the best combination of professional performance, presentation, and reliability.

Product Code: PROTL500A

Made in China to TQB Brands Pty Ltd specifications Page 2

Visit us at www.tqbbrands.com.au

WARNING

IMPORTANT: READ ALL INSTRUCTIONS BEFORE USE

WARNING

The instructions and warnings contained in this manual should be read and understood before using or operating this equipment.

Do not allow anyone to use or operate this equipment until they have read this manual and have developed a thorough

understanding of how this equipment works. Failure to observe any of the instructions contained in the manual could result in

severe personal injury to the user or bystanders, or cause damage to the equipment and property. Keep this manual in a

convenient and safe place for future reference.

Whilst every effort has been made to ensure accuracy of information contained in this manual, the TQB Brands Pty Ltd policy of

continuous improvement determines the right to make modifications without prior warning.

CONTENT

WARNING ....................................................................................................................................................................................................... 2

CONTENT ........................................................................................................................................................................................................ 2

SAFETY INSTRUCTIONS .................................................................................................................................................................................... 3

ASSEMBLY, OPERATION, PREVENTITIVE MAINTENANCE ................................................................................................................................... 4

PARTS LIST DIAGRAM ...................................................................................................................................................................................... 8

PARTS LIST ...................................................................................................................................................................................................... 9

WARRANTY ................................................................................................................................................................................................... 11

TQ Pro top quality Tools and Equipment are designed and manufactured for specialist professional use in a garage and

workshop environment. TQ Pro products are strong, reliable, and well finished for the expert tool user who appreciates

professional design, reliability, and attention to detail. Covered by our 12 month trade use warranty, our TQ Pro Tools &

Equipment are made with pride to deliver the best combination of professional performance, presentation, and reliability.

Product Code: PROTL500A

Made in China to TQB Brands Pty Ltd specifications Page 3

Visit us at www.tqbbrands.com.au

SAFETY INSTRUCTIONS

SAFETY OPERATING INSTRUCTIONS

Save these instructions. For your safety, read, understand, and follow the information provided with and on this 500kg

Telescopic Air/Hydraulic Transmission Lifter before using.

• DO NOT exceed the maximum lifting load capacity of 500kg.

• Only use this telescopic Transmission Lifter on a surface that is stable, level, smooth, dry and capable of sustaining the

load. Keep the surface free from unrelated materials and ensure that there is adequate lighting.

• DO NOT use on tarmac, or any other soft surface as the transmission may sink or topple.

• Vehicle must be properly and adequately supported before commencing work with this Transmission Lifter.

• This transmission lifter is used as an aid in the removal and installation of a transmission or a differential as individual

components. DO NOT use it for any other purpose than it is designed for.

• Always centre the load on the saddle of this Transmission Lifter and be sure the transmission is stable and secure before

raising or lowering.

• DO NOT use the telescopic Transmission Lifter to lift or support a heavy load such as a differential with axle or a

transmission with bell housing which is bulky and difficult to balance, and may cause the Transmission Lifter to tip over

and lead to equipment damage and/or serious personal injury.

• Never move this telescopic Transmission Lifter with a load any higher off the ground than necessary and always move it

slowly and carefully.

• Transfer the load immediately to appropriate support device for service or repair.

• DO NOT operate this telescopic Transmission Lifter when you are tired or under the influence of alcohol, drugs or any

intoxicating medication.

• DO NOT allow untrained persons to operate this product and DO NOT make any modifications to this product.

• DO NOT tamper with the safety valve.

• DO NOT expose the telescopic Transmission Lifter to rain or any other kind of inclement weather.

• When servicing, use only TQ Pro identical replacement parts. Use of any other parts will void the warranty.

• Use the right product for the job. There are certain applications for which this Telescopic Transmission Lifter was designed.

Do not modify the Telescopic Transmission Lifter and do not use the Telescopic Transmission Lifter for a purpose for which

it was not intended.

TQ Pro top quality Tools and Equipment are designed and manufactured for specialist professional use in a garage and

workshop environment. TQ Pro products are strong, reliable, and well finished for the expert tool user who appreciates

professional design, reliability, and attention to detail. Covered by our 12 month trade use warranty, our TQ Pro Tools &

Equipment are made with pride to deliver the best combination of professional performance, presentation, and reliability.

Product Code: PROTL500A

Made in China to TQB Brands Pty Ltd specifications Page 4

Visit us at www.tqbbrands.com.au

ASSEMBLY, OPERATION, PREVENTITIVE MAINTENANCE

1. FEATURES

This TQ Pro 2-Stage Air/Hydraulic Telescopic Transmission Lifter offers a wide range of versatility designed to help increase

workshop productivity. For use with car and light truck transmissions. The universal mounting head provides a wide four way

tilt range and the wide base is enhanced by four heavy-duty steel swivel castors for safer manoeuvring around the workshop.

This Transmission Lifter is equipped with an air operated hydraulic system with smooth hydraulic lift and descent. The fast lift

foot operated pump and release valve keep the mechanic’s hands free during use. The height and cradle adjustability of this

telescopic Transmission Lifter makes it great for any transmission installation or removal.

2. ASSEMBLY

Unpack the product and check contents with the exploded drawing and the parts list. Should there be any damaged or missing

parts, contact your place of purchase immediately.

1. Attach the two leg assemblies (43) to the hydraulic main body (30) using bolts (50), washers (49), lock washers (48).

2. Fit the 4 castors (47,52) to the legs using washers (45), lock washers (46) & nuts (44).

3. Screw the cradle kit (51) onto the top of the lift ram rod, then assemble the adaptor as per the exploded drawing.

3. BEFORE USE

Prior to use conduct a visual inspection checking for abnormal conditions, such as cracked welds, leaks, and damaged, loose,

or missing parts.

1. Following assembly and before first use, loosen the Air Vent Screw (26) then leave the Transmission Lifter for one hour

to allow the hydraulic oil to settle before bleeding the system.

Bleeding Instructions

2. Remove the Oil Filler Bung/Breather and if required, top up with *32 Grade hydraulic oil until the oil is

lapping the bottom of the Oil Filler Hole then replace the Oil Filler Bung/Breather.

3. Start with the Pump Pedal Assembly in the raised position.

4. Depress the Pump Pedal to full stroke and hold in that position. With a Hex key undo the Pump Bleed

Screw 1 full turn counter-clockwise, aerated oil will begin to exit the Pump Bleed screw housing until a

clear stream of oil with no air bubbles flows from the Pump Bleed Screw housing.

5. Tighten the Pump Bleed Screw and raise the Pump Pedal to fully raised position, repeat instructions 1 to

4 until no air bubbles appear in the oil stream at the bleeder housing.

At this stage, the Pedal Pump Assembly should be clear of air.

In the next steps the Lift Ram assembly bleeding procedure is described

6. Start with the Pump Pedal Assembly in the raised position.

7. With an Allen key undo the Lift Ram Bleed Screw 1 full turn counter clockwise, aerated oil will begin to

exit the Lift Ram Bleed Screw housing until a clear stream of oil with no air bubbles flows.

8. Tighten the Lift Ram Bleed Screw and raise the Pump Pedal to fully raised position.

9. Repeat instructions 6 to 8 until no air bubbles appear in the oil stream at the bleeder housing and tighten

the Lift Ram Bleed Screw.

10. Recheck the oil level as described in step 1 and top up to correct oil level if required.

At this point both the Pump and Lift Ram should be free of air.

Air Motor Pump Bleeding Instructions

11. With the lift ram in the fully lowered position, use an Allen key to undo the Lift Ram bleed screw 1 full turn

anticlockwise.

12. Connect the air supply to the air motor trigger assembly and hold the air motor trigger open for a minimum of 10

seconds , aerated oil will begin to exit the bleed screw housing until a clear stream of oil with no air bubbles flows.

13. While holding the Air Motor trigger open Tighten the pump bleed screw and release the trigger.

14. Recheck the oil level as described in step 1 and top up to correct oil level if required.

At this point the Manual Pump, Air Motor Pump and Lift Ram should be free of air and the Lifter ready for operation.

Oil Filler

Bung/Breather

Pump Pedal

Assembly

Hex

Key

Pump Pedal

Assembly

Pump Pedal

Assembly

Pump

Bleed

Screw

Pump Pedal

Assembly

Lift Ram

Bleed

Screw

Oil Filler

Bung/Breather

Lift Ram

Product Code: PROTL500A

Made in China to TQB Brands Pty Ltd specifications Page 5

Visit us at www.tqbbrands.com.au

15. Test the hydraulic power unit without load by raising it to full height.

16. Lower the fully extended hydraulic ram by pushing the foot operated Release Pedal (34) down gently to control the rate

of descent.

17. Your Hydraulic Transmission Lifter is ready for use.

*The range of TQPro Transmission Lifters use 32 Grade Hydraulic Oil for the correct operation and compatibility with the seals

used in their construction.

4. OPERATION

WARNING

Vehicle must be properly and adequately supported before commencing work with this telescopic Transmission Lifter.

To remove transmission from raised vehicle

1. Always loosen the Air Vent Screw (26) before use.

2. Roll the Transmission Lifter into position and lock the Castor Wheel (47) brakes.

3. Connect the air supply and push the Air Trigger Valve (54) or Pump the foot operated Lift Pedal (38) until the Transmission

Cradle (04) reaches the desired height.

NOTE: Follow the vehicle manufacturer's recommended procedures for removing the load as outlined in the vehicle

service manual or repair guide.

4. Carefully centre the load on the cradle. Ensure the load's centre of gravity is centred on the cradle and the transmission

is stable and secure. Use the chains to secure the load.

NOTE: Before lowering the load check to ensure all tools and personnel are clear and it is safe to lower the load.

5. SLOWLY and CAREFULLY push the foot operated Release Pedal (34) to lower the load to its lowest position.

NOTE: The speed of lowering is controlled by pressure on the release valve. The more the valve is opened the more

rapidly the load descends. Always ensure the decent is slow and controlled.

6. Once the load is lowered, release the castor wheel brakes.

7. CAREFULLY and SLOWLY move the transmission lifter from under the vehicle.

8. Immediately transfer the load to a bench top or appropriate support device for service or repair.

To install transmission into raised vehicle

1. Always loosen the Air Vent Screw (26) before use.

2. Roll the Transmission Lifter into position and lock the Castor Wheel (47) brakes.

3. Transfer the load from the bench top or appropriate support device to the Transmission Lifter.

4. Carefully centre the load on the cradle. Ensure the load's centre of gravity is centred on the cradle and the transmission

is stable and secure. Use the chains to secure the load.

5. Unlock the Castor Wheel brakes and carefully roll the transmission lifter into position beneath the vehicle and lock the

castor wheel brakes.

6. Connect the air supply and push the Air Trigger Valve (54) or Pump the foot operated Lift Pedal (38) until the Transmission

reaches the desired height.

NOTE: Follow the vehicle manufacturer's recommended procedures for installing the load as outlined in the vehicle

service manual or repair guide.

7. SLOWLY and CAREFULLY push the foot operated Release Pedal (34) to lower the load to its lowest position.

NOTE: The speed of lowering is controlled by pressure on the release valve. The more the valve is opened the more

rapidly the load descends. Ensure the decent is slow and controlled.

8. Once the cradle is lowered, release the castor wheel brakes.

9. CAREFULLY move the transmission lifter from under the vehicle.

10. When work is complete, ensure the cradle is at its lowest position and tighten the air vent screw to store.

WARNING

Dangerous dynamic shock loads are created by quick opening and closing the release valve when the load is being lowered.

The resulting overload may cause hydraulic system failure which could cause property damage and/or severe personal injury.

Product Code: PROTL500A

Made in China to TQB Brands Pty Ltd specifications Page 6

Visit us at www.tqbbrands.com.au

5. INSPECTION

Prior to each use conduct a visual inspection checking for abnormal conditions, such as cracked welds, leaks, and damaged,

loose, or missing parts.

6. STORAGE

This TQ Pro Transmission Lifter should always be stored in a dry location on a level surface, disconnected from the air supply

with the cradle fully lowered and the Air Vent Screw closed.

7. MAINTENANCE

Monthly maintenance is recommended. Lubrication is critical to Transmission Lifters as they support heavy loads. Any

restriction due to dirt, rust, etc, can cause either slow movement or cause extremely rapid jerks damaging the internal

components. The following steps are designed to keep the Transmission Lifter well maintained and operational.

Pivots and pins in all manual pump and release mechanisms [marked X] should be lubricated with a

Light Bearing Grease or 30/40W Machine Oil to ensure long life and prevent premature wear.

Wheel axles and Castor ball races should be lubricated with a Light Bearing Grease or 30/40W

Machine Oil to ensure long life and prevent premature wear.

Cradle Pins, Pivots and Threaded Adjustor Rods [marked X] should be lubricated with a Light Bearing

Grease or 30/40W Machine Oil to ensure long life and prevent premature wear.

Periodically grease the ram shaft divider with a light bearing grease via the grease nipple provided.

Air motors require a minimum of 10 ml of a suitable lubricant such as SAE 32 Grade Hydraulic Oil or

Air Tool Lubricant at weekly intervals dependant on usage where daily/constant use may require

lubrication to occur more frequently.

Important: Dirt is the greatest single cause of failure in hydraulic units. Keep the transmission lifter clean and well lubricated

to prevent foreign matter from entering the system. If the Transmission Lifter has been exposed to rain, snow, sand, or grit

it must be cleaned before it is stored or used.

Pivots

& Pins

and

Wheel Axle

Lubricate

Castor Ball Race

with a heavy

30/40W machine oil

Lubricate all

Pivots Pins &

Threaded Rods

Lubricate

Ram shaft

with light

bearing

grease

via the

nipple

Product Code: PROTL500A

Made in China to TQB Brands Pty Ltd specifications Page 7

Visit us at www.tqbbrands.com.au

Important: Use only quality grade hydraulic jack oil. Avoid mixing different types of fluid and NEVER use brake fluid, turbine

oil, transmission fluid, motor oil or glycerine. Improper fluid can cause premature failure of the Transmission Lifter and the

potential for sudden and immediate loss of load. We recommend PENRITE HYDRAULIC JACK OIL or equivalent.

Periodically check the piston rod for signs of rust or corrosion. Clean exposed areas with a clean oiled cloth.

• A coating of light lubricating oil to pivot points and axles will help to prevent rust and ensure that castors, foot pedals and

pump assemblies move freely. Periodically lubricate the pivot points and axles with a light lubricating oil as needed.

• When equipment efficiency drops, bleed air from hydraulic system. Bleed the hydraulic system to eliminate any air in the

system by pushing down the release foot pedal (13) down and pumping the lift foot pedal (14) 15-20 times.

• With the Transmission Lifter in the lowest position remove the air vent screw (16) to check the hydraulic oil level. If it is

not adequate, add high quality hydraulic jack oil as necessary. Insert and tighten the air vent screw. Then bleed away air

from the hydraulic system.

• Leave the Transmission Lifter for 60mins to allow oil to settle before bleeding the hydraulic system.

• Follow the Bleeding Instructions (Section 3: Before Use) to bleed the hydraulic system and eliminate any air in the system.

• To ensure best performance and longer equipment life replace the complete hydraulic oil at least once a year.

• With the Transmission Lifter in its lowest position remove the Air Vent Screw, lay the Transmission Lifter on its side and

drain the oil into a suitable container.

• Ensure that no dirt gets into the system.

• Set the Transmission Lifter in its level upright position, fill with approved hydraulic jack oil.

• Replace the Air Vent Screw and bleed away air from hydraulic system as described in Section 3: Before Use.

It is recommended that an annual inspection be conducted by a qualified technician.

WARNING: Never use sandpaper or abrasive material on these surfaces.

To check the oil level, be sure the lifter is in its lowest position. Remove the oil filler plug. The oil level should be at the

bottom of the filler plug hole. You can visually see the oil, or test with your finger. If the oil level is low, add good quality

hydraulic lifter oil ISO VG32. Do not use brake fluid as brake fluid will damage the seals.

8. SERVICE & REPAIR

Any Transmission Lifter is found damaged in any way, or found to be worn or operates abnormally it should be removed

from service until repaired by an authorised service agent. Owners and / or operators should be aware that repair of this

product may require specialised equipment and knowledge. Only authorised parts, labels, decals shall be used on this

equipment. Annual inspection of the transmission lifter is recommended and can be made by an authorised repair facility

to ensure that your equipment is in optimum condition and that the equipment has the correct decals and safety labels

specified by the manufacturer.

Product Code: PROTL500A

Made in China to TQB Brands Pty Ltd specifications Page 8

Visit us at www.tqbbrands.com.au

PARTS LIST DIAGRAM

Product Code: PROTL500A

Made in China to TQB Brands Pty Ltd specifications Page 9

Visit us at www.tqbbrands.com.au

PARTS LIST

TQ Pro top quality Tools and Equipment are designed and manufactured for specialist professional use in a garage and

workshop environment. TQ Pro products are strong, reliable, and well finished for the expert tool user who appreciates

professional design, reliability, and attention to detail. Covered by our 12 month trade use warranty, our TQ Pro Tools &

Equipment are made with pride to deliver the best combination of professional performance, presentation, and reliability.

Part #

Description

QTY

Part #

Description

QTY

1

Dust Ring

1

29

Oil Pad

1

2

O-Ring

1

30

Pump

1

3

U-Ring

1

31

U-Limit

1

4

Round Nut

1

32

Lock Washer

1

5

O-Ring

1

33

Screw

1

6

Piston Rod

1

34

Release Pedal

1

7

Retaining Ring

1

35

Pin

1

8

Dust Ring

1

36

Cotter Pin

1

9

O-Ring

1

37

Flat Washer

2

10

U-Ring

1

38

Foot Pedal

1

11

Round Nut

1

39

Retaining Ring

4

12

O-Ring

1

40

Connection Rod

2

13

Piston Rod

1

41

Pin

2

14

Retaining Ring

1

42

Pin

1

15

Cap

1

43

Base

2

16

Screw

1

44

Nut

4

17

Steel Ball

1

45

Lock Washer

4

18

O-Ring

1

46

Flat Washer

4

19

Seat

1

47

Caster

4

20

Oil Pad

2

48

Flat Washer

4

21

Oil Tank

1

49

Lock Washer

4

22

Pin

1

50

Bolt

4

23

Cotter Pin

3

51

Saddle

1

24

Handle

1

52

Screw

2

25

Handle Sleeve

1

53

Hose Joint

1

26

Air-Venting Screw

1

54

Air Trigger Valve

1

27

Seal

1

55

Air Hose

1

28

Cylinder

1

Product Code: PROTL500A

Made in China to TQB Brands Pty Ltd specifications Page 10

Visit us at www.tqbbrands.com.au

TROUBLESHOOTING

Problem

Symptom

Cause

Conclusion

Solution

Lifter will not

lift using foot

pump

Pump has no

resistance, lift ram

will not raise

Release pedal valve

pin obstructed

Air in hydraulic system

Load weight exceeds

lift capacity

Pump circuit

protection valve

actuated

Overload actuated

Dirt under release pin

retainer

Air cavitation in pump

and/or lift ram

Higher capacity lifter

required

Pump circuit protection

valve needs reset

Relief valve needs reset

Hold pedal down and

clean out pin cavity

with an air duster

Bleed system as per

instructions

Select higher

capacity lifter

Depress release

pedal, valve will

reset

Contact qualified

technician for repairs

Lifter will not

hold load

Load cannot be

sustained, lift ram

drops under load

Pump pedal rises

Release valve not

tightly closed

Damaged main seal

Main check valve

obstructed

Bypass through release

valve

Replace main ram seals

Replace main check valve

ball and reseat valve seat

Ensure release valve

tightly closed

Contact qualified

technician for repairs

Lifter will not

lower after

unloading

Lift ram rises after

retracting

Lift ram will not

retract

Reservoir overfilled

and breather closed

Breather closed

Ram failure due to

reservoir pressurised

caused by excess

reservoir level and closed

breather valve

Breather closed causing

hydraulic lock

Fully retract ram and

drain excess oil and

bleed system as per

instructions

Open breather and

bleed system

Contact qualified

technician for repairs

Poor lift

performance

Pump has no

resistance, lift ram

will not raise to full

stroke

Fluid level low

Air trapped in system

breather closed, pump

failure due to

cavitation caused by

air pressure build up

in reservoir

Fill fluid to correct level

Lift ram raised for

extended period causing

air ingress to hydraulic

system

Fill fluid to correct

fluid level and bleed

system

With ram fully

retracted, open the

breather to let

pressurised air

escape bleed system

Contact qualified

technician for repairs

Product Code: PROTL500A

Made in China to TQB Brands Pty Ltd specifications Page 11

Visit us at www.tqbbrands.com.au

WARRANTY

TQ Pro products have been carefully tested and inspected before shipment and are guaranteed to be free from defective materials

and workmanship for a period of 12 months from the date of purchase except where tools are hired out when the guarantee

period is ninety days from the date of purchase.

Should this piece of equipment develop any fault, please return the complete tool to your nearest authorised warranty repair

agent or contact TQB Brands Pty Ltd Warranty team – warran[email protected]m.au.

If upon inspection it is found that the fault occurring is due to defective materials or workmanship, repairs will be carried out free

of charge. This guarantee does not apply to normal wear and tear, nor does it cover any damage caused by misuse, careless or

unsafe handling, alterations, accident, or repairs attempted or made by any personnel other than the authorised TQB Brands Pty

Ltd repair agent.

This guarantee applies in lieu of any other guarantee expressed or implied and variations of its terms are not authorised.

Your TQB Brands Pty Ltd guarantee is not effective unless you can produce upon request a dated receipt or invoice to verify your

proof of purchase within the 12 month period.

Consumer Guarantee

Our goods come with a guarantee that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement

or refund for a major failure and compensation for any other reasonably foreseeable loss or damage. You are also entitled to have

the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

All images and illustrations shown are for reference purposes only. All information, specifications and illustrations in this manual

are based on the latest information available at the time of publication and are subject to change without notice. The information

in this manual is periodically revised to ensure the latest information is included. Download the latest version of this manual and

other related technical documentation from www.tqbbrands.com.au.

Table of contents