4

MOHAWK MODEL TR-110 & TR-120

MOHAWK WARRANTIES

EFFECTIVE DATE: 12/1/2015*

READ THIS WARRANTY IN ITS ENTIRETY

GENERAL WARRANTY INFORMATION:

MOHAWK’S OBLIGATION UNDER THIS WARRANTY IS LIMITED TO REPAIRING OR REPLACING ANY PART OR PARTS

RETURNED TO THIS FACTORY, TRANSPORTATION CHARGES PREPAID BY CUSTOMER WITH AUTHORIZED RETURN

(RGA), WHICH PROVE UPON INSPECTION TO BEDEFECTIVE AND WHICH HAVE NOT BEEN MISUSED. DAMAGE OR

FAILURE TO ANYPART DUE TO FREIGHT DAMAGE OR LACK OF REQUIRED REGULAR DOCUMENTED MAINTENANCE IS

NOT COVERED UNDER THIS WARRANTY. ALL WARRANTY CLAIMS MUST BE PERFORMED IN ACCORDANCE TO

MOHAWK’S WARRANTY PARTS RETURN POLICY (CONTACT MOHAWK’S SERVICE DEPARTMENT FOR MORE

INFORMATION).

THIS WARRANTY DOES NOT COVER MIS-DIAGNOSING OF UNIT OR PARTS RETURNED THAT ARE NON-DEFECTIVE. THIS

WARRANTY DOES NOT COVER ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES INCLUDING, BUT NOT LIMITED TO,

LOST REVENUES OR BUSINESS HARM. THIS EQUIPMENT HAS BEEN DESIGNED FOR USE IN NORMAL VEHICLE

MAINTENANCE APPLICATIONS. A SPECIFIC INDIVIDUAL WARRANTY MUST BE ISSUED FOR UNITS THAT DEVIATE FROM

INTENDED USAGE, SUCH AS HIGH CYCLE USAGE IN INDUSTRIAL APPLICATIONS, OR USAGE IN EXTREMELY ABUSIVE

ENVIRONMENTS. MOHAWK RESERVES THE RIGHT TO DECLINE RESPONSIBILITY WHEN REPAIRS OR MODIFICATIONS

HAVE BEEN MADE OR ATTEMPTED BY OTHERS WITHOUT WRITTEN AUTHORIZATION FROM .. THIS

WARRANTY DOES NOT COVER LABOR OR TRANSPORTATION. THIS WARRANTY DOES NOT COVER DOWNTIME

EXPENSES INCURRED WHEN UNIT IS IN REPAIR. THE LIFT MUST BE REGISTERED WITHIN 30 DAYS OF INSTALLATION

BY MAILING SUPPLIED WARRANTY REGISTRATION CARD TO MOHAWK AND MUST BE SIGNED BYA LICENSED

ELECTRICIAN. THE MODEL NUMBER AND SERIAL NUMBER OF THE EQUIPMENT MUST BE FURNISHED WITH ALL

WARRANTY CLAIMS. THIS WARRANTY STATEMENT CONTAINS THE ENTIRE AGREEMENT BETWEEN

.AND THE PURCHASER UNLESS OTHERWISE SPECIFICALLY EXPRESSED IN WRITING. THIS NON-TRANSFERABLE

WARRANTY APPLIES TO THE ORIGINAL PURCHASER ONLY.

THIS WARRANTY DOES NOT COVER NORMAL SURFACE WEAR ITEMS, ITEMS SUBJECT TO ABRASION, OR ITEMS USED

IN A CORROSIVE ENVIRONMENT. SOME ITEMS ON LIFTARE SUBJECT TO NORMAL “WEAR AND TEAR” AND ARE NOT

COVERED UNDER THIS WARRANTY.

STRUCTURAL AND MECHANICAL COMPONENTS (ALL LIFTS):

STRUCTURAL AND MECHANICAL COMPONENTS OF THIS UNIT ARE GUARANTEED FOR THE BELOW STATED TIME

FRAME, SPECIFIC TO MODEL LISTED, FROM THE DATE OF SHIPMENT FROM FACTORY, AGAINST DEFECTS IN

WORKMANSHIP AND/OR MATERIALS WHEN LIFT IS INSTALLED AND USED ACCORDING TO SPECIFICATIONS.

25-YEARS STRUCTURAL / 10 YEARS MECHANICAL: TWO-POST MODELS A-7, SYSTEM IA-10, LC-12, LMF-12, TP-

16, TP-18, TP-20, TP-26, TP-30. STRUCTURAL ITEMS COVERED INCLUDE LEG, CARRIAGE, SWING ARM AND

SLIDER WELDMENTS (EXCLUDING NORMAL WEAR AREAS AS STATED ABOVE). MECHANICAL ITEMS COVERED

INCLUDE ROLLER BEARINGS AND LIFTING CHAIN.

5-YEAR: MODELS TL-7.

3-YEAR: MODELS TR-19, TR-25, FL-25, TR-30, TR-33, TR-35, TR-50, TR-75, TR-110, TR-120, MP-SERIES LIFTS.

2-YEAR: MODELS PARALLELOGRAM SERIES LIFTS.

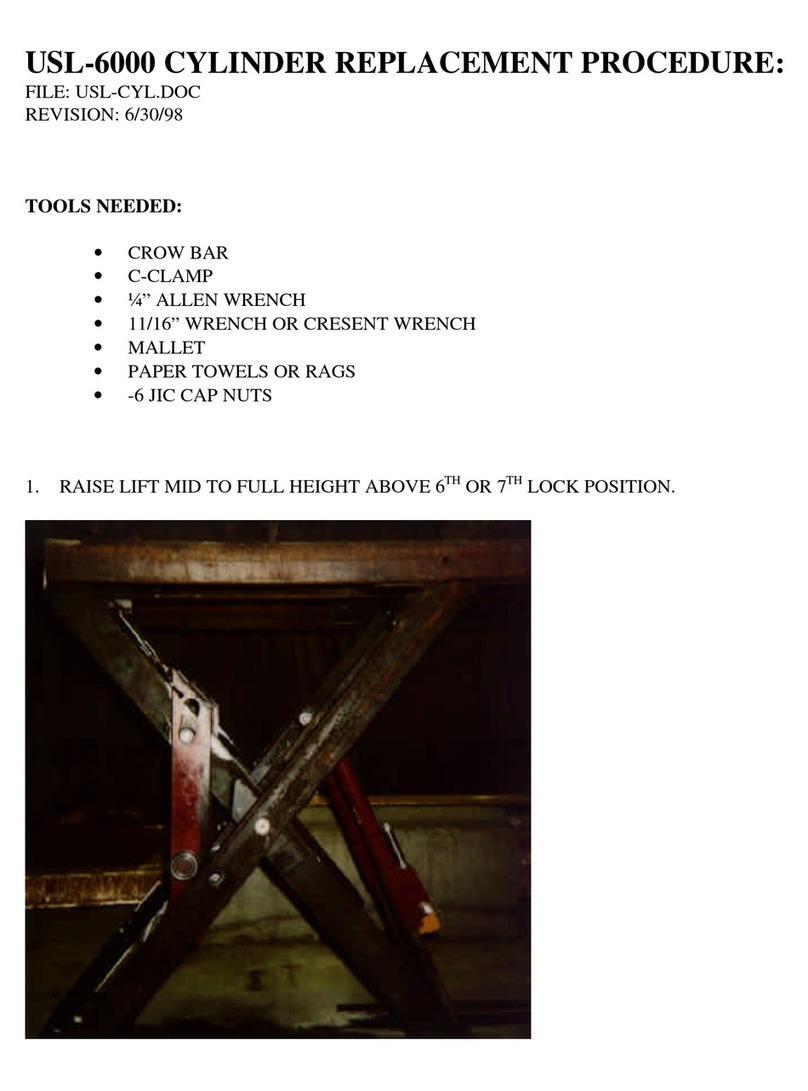

1-YEAR: MODELS TD-1000, TD-2000, CT-1000, USL-6000.

POWER UNIT (ALL LIFTS):

LL POWER UNIT COMPONENTS (MOTOR, PUMP AND RESERVOIR) ARE GUARANTEED FOR TWO YEARS FOR PARTS,

FROM THE DATE OF SHIPMENT FROM FACTORY, AGAINST DEFECTS IN WORKMANSHIP AND/OR MATERIALS WHEN THE

LIFT IS INSTALLED, WIRED BY A LICENSED ELECTRICIAN AND USED ACCORDING TO SPECIFICATIONS.

ELECTRICAL COMPONENTS (ALL LIFTS):

LL ELECTRICAL COMPONENTS (EXCLUDING MOTOR) ARE GUARANTEED FOR ONE YEAR FOR PARTS, FROM THE

DATE OF SHIPMENT FROM FACTORY, AGAINST DEFECTS IN WORKMANSHIP AND/OR MATERIALS WHEN THE LIFT IS

INSTALLED AND USED ACCORDING TO SPECIFICATIONS. SEE WARRANTY EXCEPTIONS SECTION FOR BATTERIES.

PNEUMATIC-AIR COMPONENTS (ALL LIFTS):

LL PNEUMATIC (AIR) COMPONENTS (I.E. AIR CYLINDERS AND POPPET AIR VALVES) ARE GUARANTEED FOR ONE

YEAR FOR PARTS, FROM THE DATE OF SHIPMENT FROM FACTORY, AGAINST DEFECTS IN WORKMANSHIP AND/OR

MATERIALS WHEN THE LIFT IS INSTALLED AND USED ACCORDING TO SPECIFICATIONS. COMPONENTS IN A

PNEUMATIC SYSTEM THAT ARE NOT PROPERLY REGULATED, LUBRICATED AND CONDITIONED WITH AN AIR DRYING

SYSTEM ARE NOT COVERED UNDER WARRANTY.

HYDRAULIC COMPONENTS (ALL LIFTS):

EXCLUDING CYLINDERS AND PUMPS (COVERED IN OTHER SECTIONS), ALL HYDRAULIC COMPONENTS (I.E. VALVES

ND FITTINGS) ARE GUARANTEED FOR ONE YEAR FOR PARTS, FROM THE DATE OF SHIPMENT FROM FACTORY,

GAINST DEFECTS IN WORKMANSHIP AND/OR MATERIALS WHEN THE LIFT IS INSTALLED AND USED ACCORDING TO

SPECIFICATIONS.