e n g l i s h | 3

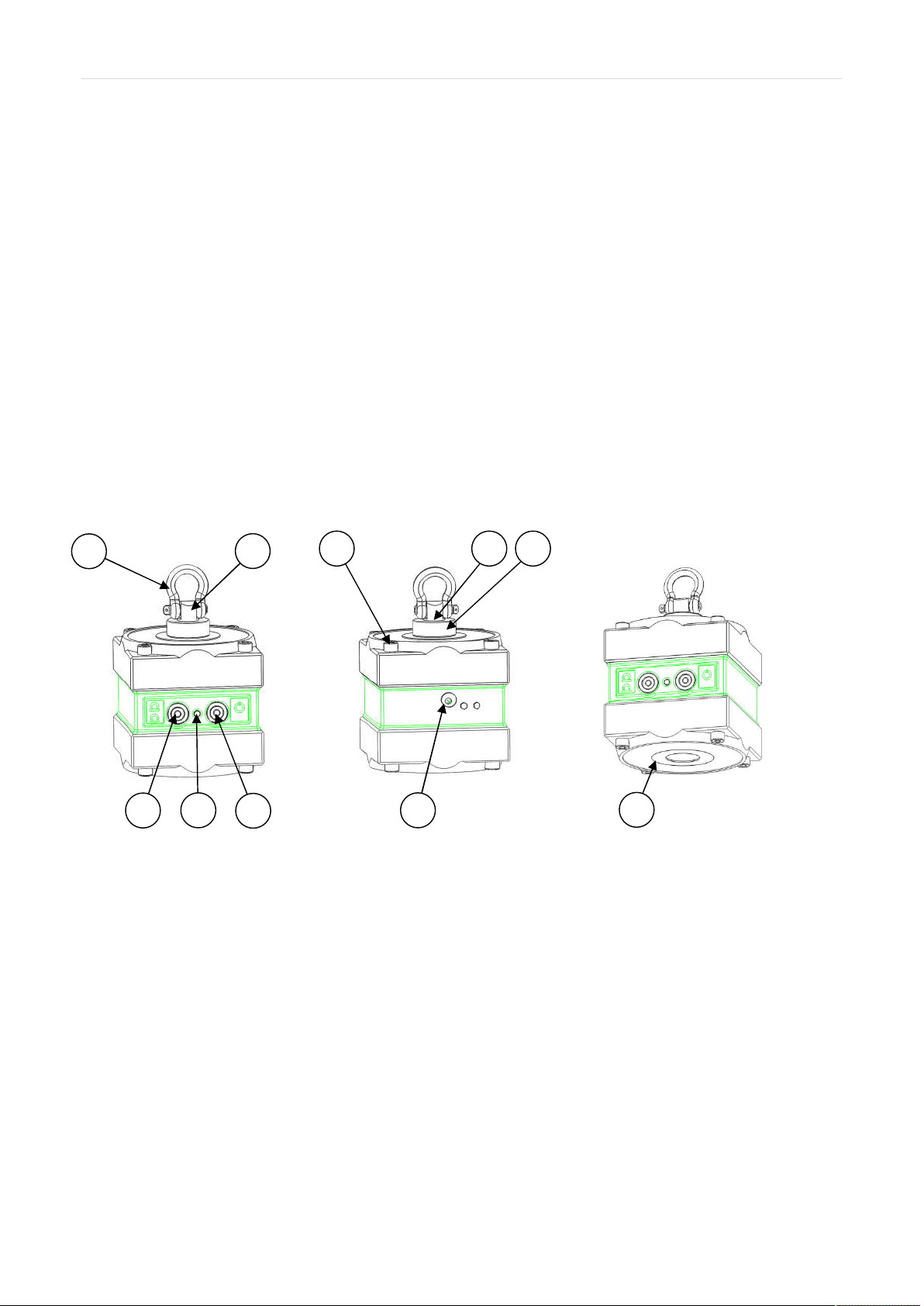

Ixtur LI-120

General Product Information

Automatic Lifting Magnet LI-120 manufactured by Ixtur, is electrically controlled lifting equipment, which

creates magnetic holding force with a permanent-magnet. LI-120 is a flexible and user-friendly device for

professional use. LI-120 can be utilized either manually with operation buttons or automatically with built-in

load-sensing system.

Energy efficiency. Automatic Lifting Magnet LI-120 has bi-stable operational structure, which means that the

device does not consume energy while maintaining the magnet's ON (attached) or OFF (released) -state.

Because of bi-stable structure the design solutions have low energy consumption. The switching between

states is controlled with a short electrical pulse. This increases the number of lifts to over one thousand with

one complete battery charge.

Serviceability. Automatic Lifting Magnet LI-120 has low energy consumption which has removed the

requirement for an external power source. This allows a compactly integrated package with a chargeable

battery. Low energy consumption extends operating time, which results to long and efficient working without

interruptions.

Safety. Automatic Lifting Magnet LI-120 produces a magnetic holding force beneath it's magnetic lifting

surface only with loads made of ferromagnetic materials. Automatic Lifter LI-120 activates the magnetic lifting

surface only with a sufficiently small air gap. Automatic Lifter LI-120 leaves the magnet in its latest state

('attach' or 'release') in case the power is lost. The battery status can be checked from the device and low

capacity is indicated by blinking lights. Automatic operation mode of Automatic Lifter LI-120 allows the

operator to stay clear of the load during lifting without the need to go to the lifting area.

Purpose of the Product

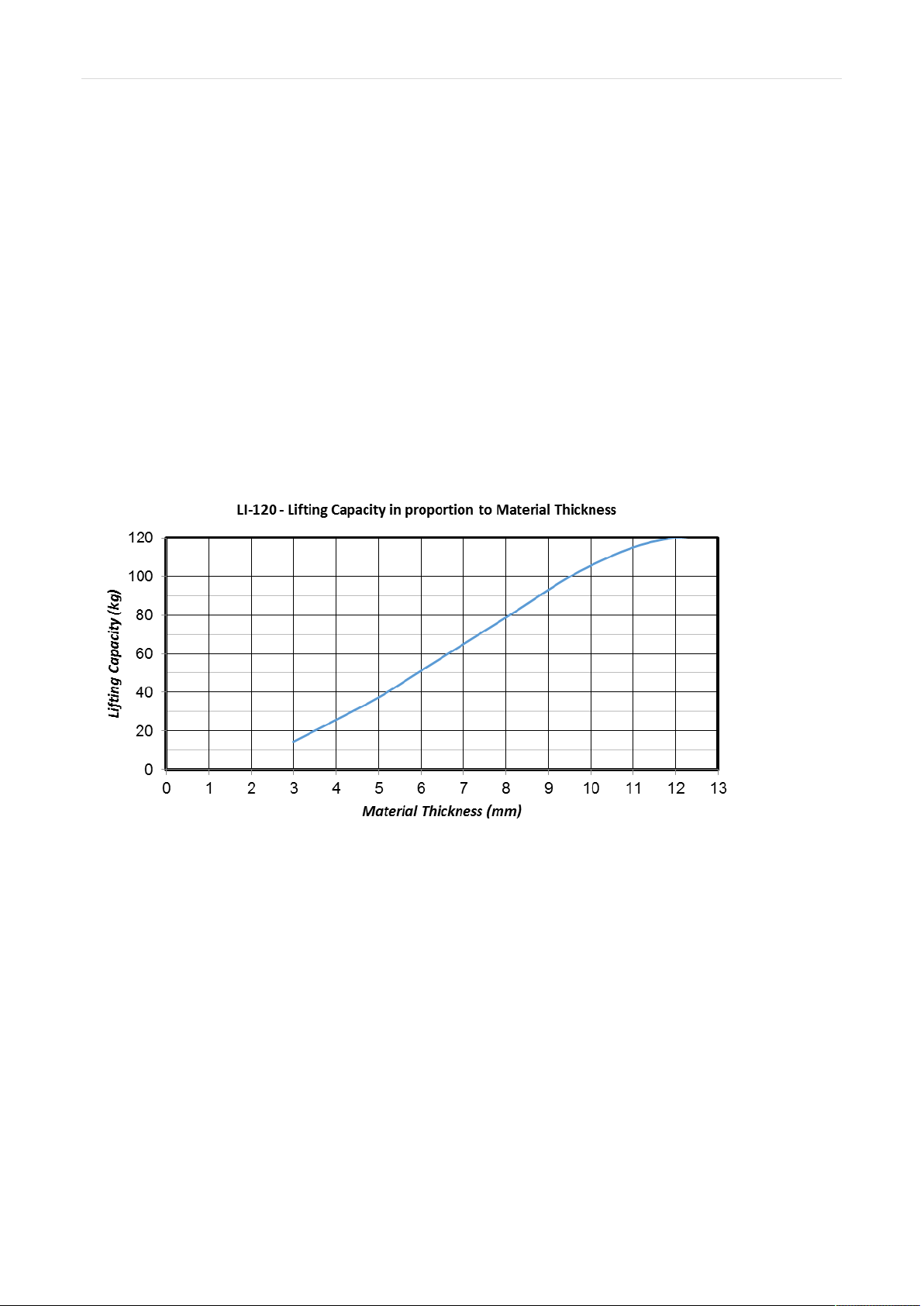

Automatic Lifting Magnet LI-120 is a portable and detachable lifting equipment, which is intended for

temporary lifting and transportation of loads made of ferromagnetic materials.

Lifting Magnet LI-120 is intended for such lifting operations where the use of other mechanical hoist systems

would be slow or when the accessibility of either hoist system or load would be poor and would require the

operator to go to the lifting area during the lift.

Lifting Magnet LI-120 is not intended for permanent attachment to load items.

In case Lifting Magnet LI-120 is used as a component, in order to integrate one or several Lifting

Magnet LI-120 devices to larger lifting system, or to connect the devices to one another, permanently

or temporarily, in all such cases it is the responsibility of the designer, the manufacturer and the

operator of the device or the system to ensure that local and national safety regulations and general

safety policies are met.