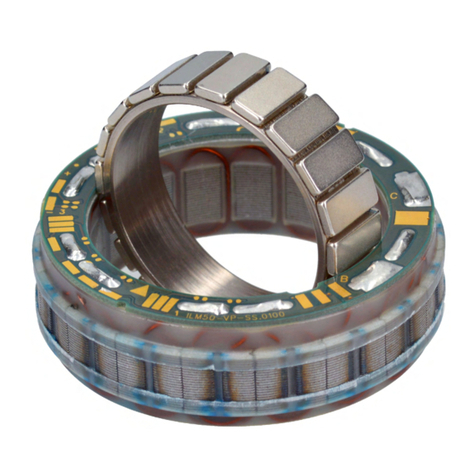

Assembly Instructions | ILM-E Servo Kits

3Edition 10/2021 EN

Contents

1 Introduction ....................................................................................................................... 4

1.1 Notes on the assembly instructions ......................................................................... 4

1.2 Description ................................................................................................................ 4

1.3 Revision index ........................................................................................................... 5

1.4 Supplementary documents ...................................................................................... 5

1.5 Explanation of the symbols used ............................................................................. 5

1.6 Training ...................................................................................................................... 5

1.7 Declaration of incorporation .................................................................................... 5

1.8 Serial number ............................................................................................................ 5

1.9 Warranty .................................................................................................................... 6

1.10 Transportation and storage .................................................................................... 6

1.11 Environmentally-friendly disposal ........................................................................... 7

1.12 Trademarks ............................................................................................................... 7

2 Safety ................................................................................................................................. 8

2.1 Hazard classification ................................................................................................. 8

2.2 Target group ............................................................................................................. 8

2.3 Intended use ............................................................................................................. 9

2.4 Working environment and operation ..................................................................... 9

2.5 Safety instructions for the ILM-E servo kit ............................................................ 10

2.6 Warning labels ......................................................................................................... 11

3 Technical data .................................................................................................................. 12

3.1 Data sheet ................................................................................................................. 12

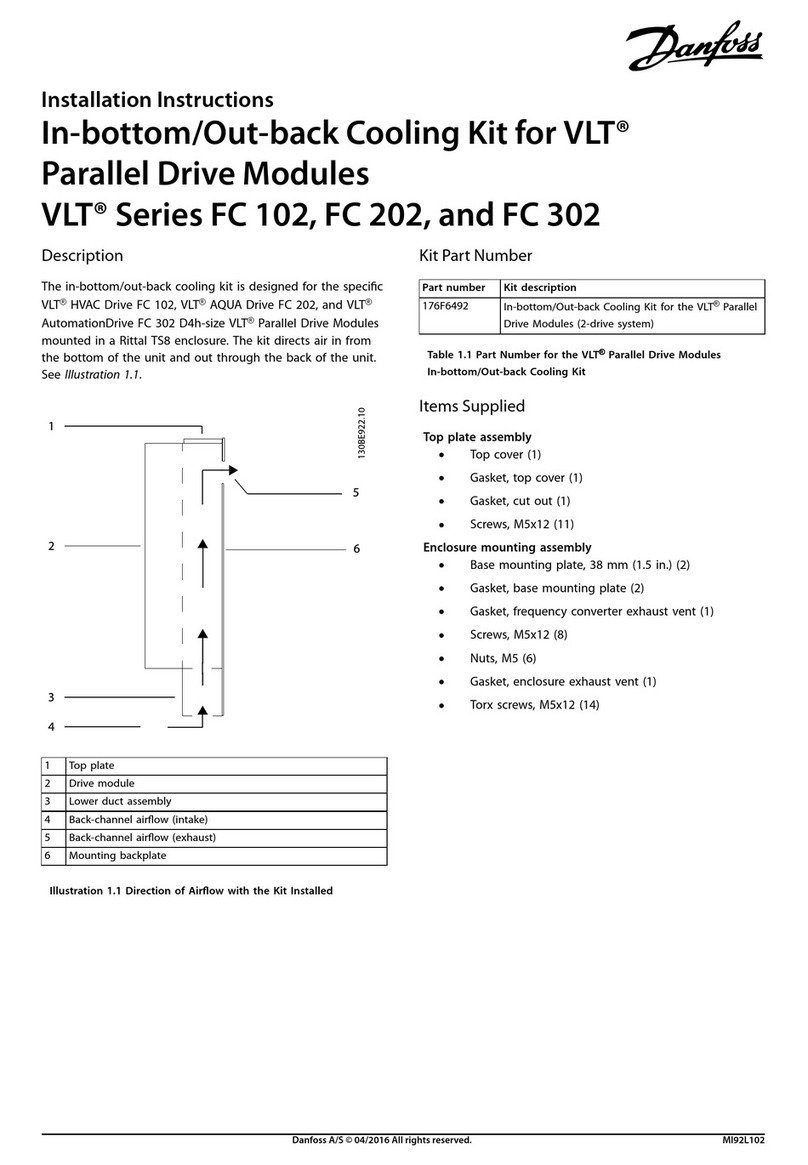

3.2 Connection diagram (star-serial configuration) .................................................... 12

3.3 Installation dimensions ........................................................................................... 13

4 Solder pads on the connection board ........................................................................... 14

5 Assembly .......................................................................................................................... 15

5.1 Stator ........................................................................................................................ 17

5.1.1 Tools and equipment required ........................................................................ 17

5.1.2 Shrink-fitting .................................................................................................... 18

5.2 Rotor ....................................................................................................................... 20

5.2.1 Tools and equipment required ...................................................................... 20

5.2.2 Bonding process ............................................................................................ 21

5.2.3 Inserting the rotor into the stator ................................................................ 22

6 Declaration of incorporation .......................................................................................... 23