Moog DS2020 Mounting instructions

DS2020

MAINTENANCE AND USER MANUAL

SINGLE AXIS DIGITAL SERVO DRIVE

INDEX

1. OVERVIEW 5

5

5

5

6

1.1. Manual contents

1.2. Utilized symbols

1.3. Package content

1.4. Required qualifications of the users

1.5. Applicable laws 6

2. SYSTEM DESCRIPTION 7

7

9

9

10

10

11

11

12

14

14

15

20

21

21

21

2.1. Product structure

2.1.1. Product description

2.1.2. Storage and working conditions

2.1.3. Standard models of modules

2.1.4. Module codification

2.2 Features and components details

2.2.1 Electrical data

2.2.2 Mechanical data

2.2.3 Trasducers

2.2.4 Connectors

2.2.4.1 Connectors layout

2.2.5 Filters

2.2.6 Braking resistence

2.2.7 Line inductors

2.3 Cables

2.4. Safety and usage guidelines 22

DS2020

L-MAS2-E-161

2.4.1. General description of security features

22

2.4.2. STO safety feature

22

2.4.2.1. Description

22

2.4.2.2. Directives on safety

23

2.4.3. Usage Guidelines of the drivers

23

3.CERTIFICATIONS25

25

3.1. CE

3.2. Safety and SafeTorque Off

26

4. ELECTRICAL AND MECHANICAL INSTALLATION 27

27

27

27

28

28

29

30

30

30

31

31

32

32

33

33

33

33

34

34

34

34

36

36

37

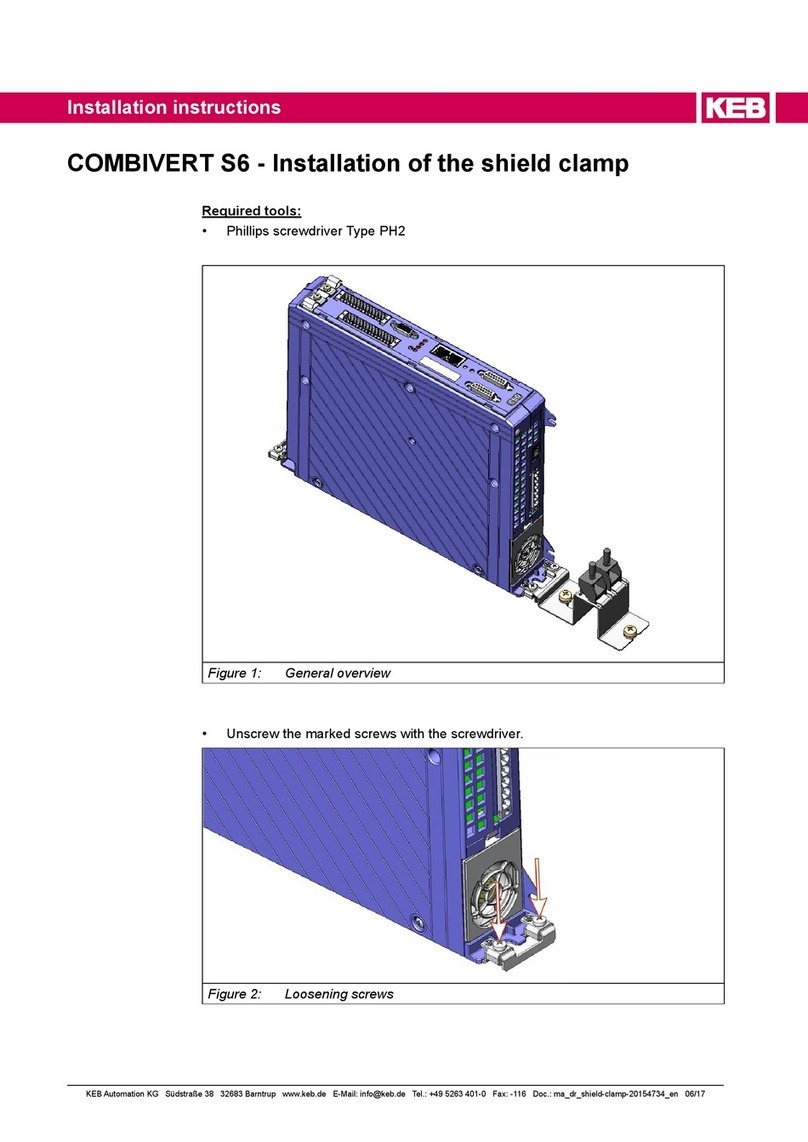

4.1 Tools and equipment

4.2. Mechanical installation

4.2.1. Assembly of the various components

4.3. Electrical Installation and thermal rating

4.3.1 Safety and general instructions

4.3.2. Thermal rating of the electrical panel

4.3.2.1. Drive axis module dissipation

4.3.2.2. Thermal dissipation of the accessories

4.3.3. Auxiliary power characteristics

4.3.4. Grid connection

4.3.4.1. Types of electrical networks

4.3.4.2. Protection components

4.3.4.3. Ground connection

4.3.5. Drive wiring

4.3.5.1. Grounding

4.3.5.2. Connecting the Power cable

4.3.5.3. Braking resistor connection

4.3.5.4. Auxiliary power connection

4.3.5.5. Signal connection

4.3.5.6. Motor cable connection

4.3.5.7. Brake cable connection

4.3.5.8. I / O signal connection

4.3.5.9. STO signal connection

4.3.5.10. Transducer connection

4.3.5.11. Connecting the Fieldbus - X8, X9, X10 connectors

38

5. COMMISSIONING VIA GUI 39

39

40

40

40

41

42

5.1. Safety

5.2. Dx2020 GUI

5.2.1. Overview

5.2.2. Minimum PC requirements

5.2.3 Dx2020GUI installation

5.2.4 GUI-drive connection

5.2.5 Layout

43

DS2020

L-MAS2-E-161

2

5.2.6. Firmware update (BootLoader) 45

5.2.7. How to access to Online Help

45

5.3. System configuration 45

5.3.1. Identifying an axis module 46

5.3.2. Motor parameters configuration 46

5.3.3. Trasducers configuration

47

5.3.3.1. Sensorless

47

5.3.4. I/O configuration

48

5.3.5. Control loops configuration

51

5.3.5.1 Control mode configuration

51

5.3.5.2 Torque loop parameters configuration

51

5.3.5.3 Speed loop parameters configuration

51

5.3.5.3.1 Filter configuration

52

5.3.5.4 Configuration of the position loop parameters

53

5.3.6. Fault configuration

54

5.3.7. Application parameters

55

5.3.8. Commands and modes configuration

56

5.4. Power Supply

58

5.5 STOactivation

58

5.5.1 Autophasing

59

5.6 Axis enablement

59

5.7. Oscilloscope function and log files (*.UCX)

60

5.7.1 Log configuration

60

5.7.2 Start logging

60

5.7.3 View logs

61

5.7.4 UCX file management

61

5.8 Using the GUI in OFFLINE mode

62

5.9 Contextual help menus for parameter management

62

6. TROUBLESHOOTING 63

63

63

63

64

65

66

66

66

66

66

67

67

68

6.1. Introduction

6.2. Power section anomalies

6.3. Drive anomalies

6.3.1. Alarms on the power section

6.3.2. Alarm for out of tolerance VBUS voltage

6.3.3. Drive or motor overtemperature

6.3.4. Removal of STO signal

6.3.5. Errors on memory devices

6.3.6. Corrupted Data Fault

6.3.7. Brake Chopper Fault

6.3.8. Errors on feedback devices

6.3.9. Synchronization, Interrupt Time and Task Time Error

6.3.10. EtherCAT Faults

6.3.11. Alarms related to the control loops

68

DS2020

L-MAS2-E-161

3

6.3.12. CAN Bus alarms

68

6.4. Alarm display in 'Analog' operating mode

69

6.5. Faults during the GUI-drive connection

72

7. SAFE TORQUE OFF SAFETY FEATURE 73

73

73

74

74

75

75

76

76

78

80

80

80

81

81

7.1. Application

7.2. Installation risk assessment

7.3. Safe Torque Off

7.3.1. Characteristic values according to UNI ENISO 13849-1

7.3.2. Characteristic values according to CEI EN62061

7.4. Safety requirements

7.5. Safe Torque Off circuit

7.6. Safe Torque Off connections

7.7. Example of an application

7.8. Installation and maintenance procedure Safe Torqueo

Off 7.9. Assembly and serial tests

7.10. Identification of the STO function on the plate

8 Annexes

8.1 Glossary

8.2 Conversion Table Metric / AWG 84

DS2020

L-MAS2-E-161

4

1. OVERVIEW

1.1. Manual contents

This manual provides information to the user to ensure proper installation and optimal functioning of the

digital servo drives, DS2020 series.

All information contained herein, including methods, techniques and concepts are the exclusive property

of Moog Casella and may be neither copied nor used without specific authorization. Moog reserves the

right to modify products, and related documentation, at any time, without notice.

The following materials are also available:

•QUICK GUIDE - INSTRUCTIONS AND GUIDELINES FOR FIRST START

•MAINTENANCE AND USER MANUAL (this document)

•FIELDBUS MANUAL

•SOFTWARE Dx2020 GUI

1.2. Utilized symbols

Danger that can result in death or serious injury

Notification of an important information

Danger that can result in minor injury and / or property damage

1.3. Package contents

The complete supply of DS2020 drives includes:

•One DS2020 drive module

•Anchoring support for the screens

Note: a possible connector kits must be ordered

individually and is supplied separately.

DS2020

L-MAS2-E-161

5

1.4. Required qualifications of the users

This manual is intended for qualified personnel, that is having the following skills, depending on the tasks performed:

Transport: The staff must have notions of handling components sensitive to electrostatic charges

Unpacking: The staff must have knowledge of handling of components sensitive to shock and electrostatic discharge

Installation: The staff must have notions of installation of electrical equipment

Startup: The staff must have extensive technical knowledge of electrical drives and their technology.

Info

The qualified personnel must know and observe the following standards: IEC 60364, IEC

60664, and all relevant national accident prevention regulations.

ATTENTION

When the drive is in operation there is a risk of death, serious injury or serious damage to property.

Therefore, the installer is required to ensure that the safety instructions detailed in this manual are read,

understood and observed by all personnel responsible for the operation of the drive.

1.5. Applicable laws

The DS2020 drives meet the Low Voltage Directive (2006/95 / EC) and EMC Directive (2004/108 / EC).

The safety function "Safe Torque Off" (STO) integrated in the drive complies with the Machinery Directive

(2006/42 / EC).

To comply with the European Directives, the drive meets the requirements of the relevant harmonized

installation standards EN 50178 (LVD), EN61800-3 (EMC) and EN 61800-5-2 (Safety of machinery).

The DS2020 drives are CE certified.

DS2020

L-MAS2-E-161

6

2. SYSTEM OVERVIEW

2.1. Product structure

2.1.1. Product description

The DS2020 drive represents Moog Casella's new generation of digital servo drives for the control of brushless

synchronous or asynchronous motors. It is constituted by a single stand alone module powered directly by an

AC network and by an auxiliary voltage of 24 Vdc

The digital control system of the motors and the diagnosis functions of the DS2020 series, are realized using a

microprocessor.

DS2020

L-MAS2-E-161

7

Control functions Implementation of the Torque, Speed and Position loops

Command protocols EtherCAT, CANopen and “Analog”

Configuration/

Commissioning

Via GUI : Dx2020GUI, allows to configure, calibrate and

control the drive.

Diagnostic Via GUI

Positioning transducers • Resolver standard

• Encoder Incremental TTL

• Encoder Stegmann Sinusoidal Absolute Single/Multi-Turn with

HYPERFACE communication

• Encoder Hedenhain Sinusoidal Absolute Single/Multi-Turn with

ENDAT communication

Sensorless mode

User Interface

Dx2020GUI

Data logging

From GUI

AC/DC conversion Three-phase input bridge with soft start

Power range From 120 Vac to 480 Vac +/- 10 %

PWM frequency 8 kHz (from 2 to 16 kHz configurable by Software)

Encoder simulation Simulated encoder output with programmable number of pulses

Auxiliary power supply voltage

+ 24 Vac +/- 10 %

Rated current From 2 to 48 Arms

Peak current From 4 to 96 Arms

Analog inputs 2 inputs +/- 10 volt differential

Analog outputs 2 output +/- 10 volt single ended

Digital inputs 2 digital inputs opto isolated

Digital outputs 1 Digital output opto isolated

Communication interface for

set-up

• RS422 PC

• USB PC

• EtherNET or CANopen PC (option)

Motor brake control Integrated

Braking resistor Integrated (Esternal optional)

Electromagnetic compatibility EMC filters

Cooling

Forced air, with integrated fans in each module

DS2020

L-MAS2-E-161

8

2.1.2. Storage and working conditions

Operating environment

temperature

from 0 °C to 40 °C

up to55 °C with current derating

Storage temperature

from -25 °C to 55 °C

Transport temperature

from -25 °C to 70 °C

Motor overheating protection PTC or NTC

Relative humidity

5...95 %

without condensation

Mounting altitude

Up to 1000 m, up to 2000 m with output current derating

Certification

CE

Protection

IP20

Pollution rating

Resistenza meccanica

conforme a EN 60721-3-3

Vibration: 3 mm for frequencies between 2 and 9 Hz

Vibration: 1 g for frequencies between 9 and 200 Hz

Shock: 98 m/s2 (10 g) for 11 ms

Machine safety

STO (Safe Torque Off) SIL3 PLe

2.1.3. Standard models of modules

L50A L50A L75A L75A L75B

Dimensions [mm]

50 50 75 75 75

Rated current [Arms]

2 4 6 8 12

Peak current [Arms] 4

8 12 16 22

The module code is found on a plate on the side of the module.

To request any kind of information about a specific module it is essential to communicate to Moog Casella all the

data indicated on the plate, which identifies each individual module.

The year and week of construction are identified by the field 'Date' The first two digits of the number are for the year

the second two indicate the week (example DATE 1607: 2016, week 7).

L85A L85A L125A L125A

85 85 125 125

16 24 32 48

32 48 64 96

Example of a drive plate

Model code

Rated data

STO function

Date

Serial Number

Moog Italiana S.r.l. - CASELLA SITE - Via Avosso 94, 16015 Casella (GE) - Italy

2 or less (normally allowed only non-conductive pollution. However, occasionally we

can expect a temporary conductivity caused by the condensation only when the drive

is idle or powered)

DS2020

L-MAS2-E-161

9

2.1.4 Module codification

To identify the different models it is necessary to refer to the following codification

The first two characters are "CH" and are used to identify the DS2020 family

Version

1Standard model

ESpecial model

Mechanical configuration - Hardware

ValueType /

Width

Rated

Current

Peak

Current

02 Single / 50 mm

L50A 2 Arms 4 Arms

04 Single / 50 mm

L50A 4 Arms 8 Arms

06 Single / 75 mm

L75A 6 Arms 12 Arms

08 Single / 75 mm

L75A 8 Arms 16 Arms

12 Single / 75 mm

L75B 12 Arms 22 Arms

(1) Standard version

(2) Values attributed by Moog

X2 / X3 - Transducer type and Serial link type

RS422

ValueType

R (1)RESOLVER SERIAL

TRESOLVER USB

EENCODER SINCOS SERIAL

UENCODER SINCOS USB

G TTL SINGLE ENDED SERIAL

HTTL FULL DIFFERENTIAL SERIAL

L TTL SINGLE ENDED USB

MTTL FULL DIFFERENTIAL USB

Fieldbus configuration

ValueType

0Analog references (1)

1 CanBus configuration

(option)

2 EtherCAT configuration

(option)

Hardware Revision

Value - Internal coding (2)

Special configurations

00 Standard

Special variation

Value - Internal coding (2)

CH-

To order a connector kit

Connector kit code Transducer type and Serial link type

BC8901-R RESOLVER SERIAL

RESOLVER USB

BC8902-R

ENCODER SINCOS SERIAL

ENCODER SINCOS USB

TTL SINGLE ENDED SERIAL

TTL FULL DIFFERENTIAL SERIAL

TTL SINGLE ENDED USB

TTL FULL DIFFERENTIAL USB

16 Single / 85mm

L85A16 Arms 32 Arms

24 Single /85mm

L85A 24 Arms 48 Arms

32 Single / 125mm

L125A 32 Arms 64 Arms

48 Single / 125mm

L125A48 Arms 96 Arms

Value - Internal coding (2)

DS2020

L-MAS2-E-161

10

2.2. Features and components details

2.2.1. Electrical data

Electrical data

L50A L75A – L75B

Network power

supply voltage From 120 Vac to 480 Vac +/- 10 %

Auxiliary voltage

24 Vdc +/-10%

Rated currentArms from 2 to 4 from 6 to 12

Peak current Arms from 4 to 8 from 12 to 22

Protections

Cooling

Forced air, with built-in fans

L85A L125A

Protection with thermal reading of the heat sink temperature and estimation of the

temperature of the power module junction. Insufficient voltage (Under Voltage) or

excessive voltage (over voltage) detection

DS2020

L-MAS2-E-161

11

from 16 to 24

from 32 to 48

from 32 to 48

from 64 to 96

7.5 (0.30)

4.5 (0.18)

180 (7.09)

199.40 (7.85)

50 (1.97)

203 (7.99)

215 (8.46)

170 (6.69)

21 (0.83)

7.5 (0.30)

4.5 (0.18)

180 (7.09)

199.40 (7.85)

75 (2.95)

203 (7.99)

215 (8.46)

170 (6.69)

21 (0.83)

Module 50 mm (1,97 inch)

Module 75 mm (2,95 inch)

2.2.2 Mechanical data

Mechanical data

L50 L75

Weight [Kg]

1,493 2,344

Height [mm]

215

Width [mm]

50 75

Depth [mm]

199.4

L85 L125

5,633 8,000

85 125

243,2

DS2020

L-MAS2-E-161

12

224 (8.82)

243.20 (9.57)

310 (12.20)

34.5 (1.36)

355 (13.98)

85 (3.35)

50 (1.97)

7.5 (0.30)

4.5 (0.18)

343 (13.50)

310 (12.20)

34.5 (1.36)

224 (8.82)

243.20 (9.57)

355 (13.98)

7.5 (0.30)

4.5 (0.18)

343 (13.50)

Module 125mm (4.92 inch)

125 (4.92)

90 (3.54)

Module 85mm (3.35 inch)

DS2020

L-MAS2-E-161

13

2.2.4 Connectors

Front view

(connector disposition common to all sizes)

Bottom view (connector disposition for sizes L50 and L75)

X1:+24V

X2 : Resolver or

Encoder interface

X3: Serial link or USB

interface

X4: Simulated

Encoder or

RS232 interface

X5: Input/Output

Digital I/O

Drive OK

Restart

X6: STO interface

Display

Space for options

X7: Can Open

X8: Ethercat Out

X9: Ethercat In

X10: Motor brake

(Power and Command)

X11:

-Power In

-Motor power Out

-Brake resistor

2.2.3. Trasducers

The DS2020 can manage the following transducers:

•Resolver standard

•Encoder Incremental TTL

•Encoder Stegmann Sinusoidal Absolute Single/Multi-Turn with HYPERFACE communication

•Encoder Hedenhain Sinusoidal Absolute Single/Multi-Turn with ENDAT communication

•Sensorless Mode

Bottom view (connector disposition for sizes L85 and L125)

X11:

Brake

resistor

X12:

Motor

power

Out

X13:

Power In

Analog I/O

DS2020

L-MAS2-E-161

14

Power In, Motor power Out, Brake resistor

All sizes

Below is the list of connectors

Connector

X1 +24 Volt Auxiliary power supply

X2 Resolver or Encoder motor feedback

X3 Interface USB or RS422

X4 Programmable digital connector

X5 Analog digital I/O

X6 Interface STO

X7 Can Open Fieldbus (Optional)

X8 Ethercat Out Fieldbus (Optional)

X9 Ethercat In Fieldbus (Optional)

X10 Motor brake connector (Power and Command)

X11

Info:

It is possible to have the connector X7 (Connection via CANopen) or, depending on the

configuration of the drive code, the X8-X9 connectors (connection via EtherCAT)

2.2.4.1 Connector layout

The connector pin tables are shown below

X1 - Auxiliary power supply

X2 - Motor Feedback

Pin

Function

1 + 24 Volt

2 0 Volt

1

2

X11

X12 Motor power Out

X13 Power In

L50/L75 only

L85/L125 only

X2 - Encoder TTL

X2 - Encoder

Stegmann

X2 - Encoder ENDAT

Heidenhain

Pin

Function Function Function

+ 5V (max 100 mA) REFSIN B-

2

GND GND 0 V

W- REFCOS A-

4

W+ US UP

V+ DATA+ DATA+

6

V- N.C. N.C.

A+ PTC PTC

8

A- N.C. CLOCK+

C+ +SIN B+

10

C- N.C. 0 V SENSE

U+ +COS A+

12

U- N.C. UP SENSE

B- DATA- DATA

-

14

B+ PTC PTC

PTC N.C. CLOCK-

15

13

11

9

7

5

3

1

Brake resistor

Function

DS2020

L-MAS2-E-161

15

X2 – Resolver

Pin

Function

1

S4

2

S2

3

GND

4

S3

5

S1

6

TEMP

7

R2

8

TEMP

9

R1

5

4

3

2

1

9

8

7

6

8

7

6

5

4

3

2

1

15

14

13

12

11

10

9

X4 Digital I/O Programmable

Pin

Definition Function

1

RX+

Data+ reception

2

N.C. Non connected

3

TX+ Data+Transmission

4

N.C Non connected

5

N.C Non connected

6

RX- Data- reception

7

0V

0V Reference

8

TX- Data-Transmission

9

N.C Non connected

1

6

1

3

5

7

2

4

6

8

Pin

Definition Function

1

USB_+5V

Power

2

USBDM USB- data channel

3

USBDP USB+ data channel

4

0V 0V Reference

5

Shield Shield

6

Shield

Shield

9 poles RS422 communication interface

USB_B communication interface

3

4

2

1

5

6

Pin

Definition Function

1

+24V_EXT

Output voltage 24Vdc 200 mA

2

A+ Channel A

3

A- Channel A inverted

4

B+

Channel B

5

B- Channel B inverted

6

C+ Channel C

7

C-

Channel C inverted

8

0V 0V reference

X3 - Serial (RS422) or USB Interface

The X3 connector can be either a 9-pin RS422 or a USB type B

Info: The 24 Volt power supply provided on the connector, can be used to feed external devices

Info: We recommend the use of a shielded twisted cable for connection between devices and Drive.

DS2020

L-MAS2-E-161

16

5

9

X5 Analog digital I/O connector

Info: The two grounds on pins 8 and 16 are separated to increase the rejection to electrical noise

induced by wirings.

Programming X5 connector analog digital I/O:

Analog Input 1 and 2 options

Torque reference

Speed reference

Position reference

Current limitation (maximum output torque)

Analog Out 1 and 2 options

Measured voltage DC BUS

Current measured Iq

Current reference Iq

Measured phase current U

Measured phase current V

Motor speed measured

Internal test variable

PIN

DEFINITION FUNCTION

1 IN AN 1 +

2 IN AN 1 -

Analog negative input 1, 12 bit resolution, sampling 3.9

us (256 kHz)

3 IN AN 2 +

4 IN AN 2 -

Analog negative input 2, 12 bit resolution, sampling 3.9

us (256 kHz)

5 OUT AN 1

Analog output 1, 12 bit resolution

6 OUT AN 2

Analog output 2, 12 bit resolution

7 +24VOLT

24 volts input for the power supply of the digital output

8 0 VOLT

Common ground for digital I / O

9 OUT DIG 1

Digital output 1, optoisolated

10

NC

NC

11 DRIVE_OK

Drive ok contact

12 DRIVE_OK

Drive ok contact

13 IN DIG 1

Digital input 1, fast, optoisolated

14 IN DIG 2

Digital input 2 fast, optoisolated

15 RESTART

Reset of the module

16 0 VOLT

Common ground for analog I / O

1

3

5

7

2

4

6

8

9 10

11 12

13 14

15 16

X6 STO interface

Pi

n

Definition

Function

1

+24 V S1

STO power input

2

0 V S1

0 Volt

3

+24 V S2

STO power input

4

0 V S2

0 Volt

5

FEEDBACK Contact S1

6

FEEDBACK Contact S2

1

3

2

4

65

Positive Analog Input 1, 12 bit resolution, sampling

3.9 us (256 kHz)

Positive Analog Input 2, 12 bit resolution, sampling

3.9 us (256 kHz)

DS2020

L-MAS2-E-161

17

Reset button

When pressed causes the initialization of the drive control section; a long press (> 3 seconds) causes access to the

boot routine of the drive and the ability to download a different version of the control SW, through the GUI.

LED 7-segment display

Indicates the axis state after the insertion of the auxiliary 24 V.

The meaning of the different messages is reported in the following table:

Mesage on display Status

Note

I

Intialization The drive has completed the initialization phase

S

Ready The drive is ready to be enabled

E

Enabled The drive is controlling the motor

F

Fault The drive is in alarm

8 blinking

Boot

b fixed light

Boot The drive is being programmed via EtherCAT

Info

If the operation mode choice is Analog, in the event of fault, the letter F would follow a 2-digit code that identifies

the alarm present. The correspondence can be found in paragraph 6.4.

X7 CAN option

Info

The PC connection via CAN Drive is currently performed using a USB adapter CAN IXXAT Automation

(www.ixxat.com) VCI V3 model; other models or devices can be added to the GUI on request.

N° pin

Name Function

1 Reserved not associated to a function

2 CAN L Negative terminal CAN line

3 CAN_GND Logic 0 CAN line

4 Reserved not associated to a function

5 Shield (optional))

6 GND (optional) Logic 0 CAN line (optional)

7 CAN_H Positive terminal CAN line

8 Reserved not associated to a function

9 CAN_V+ Power supply line CAN (supplied by power adapter)

CAN_shield (optional)

6

9

The drive is being programmed via serial line RS422 or via USB

DS2020

L-MAS2-E-161

18

1

5

6

9

1

5

X8 – X9 EtherCat Option

The cable used is an Ethercat standard one, the connector is a RJ45.

X10 - Integrated brake motor

Info

The brake control circuit must be powered from the outside, through X10.

Attention

The connection to the motor brake by itself alone does not guarantee the personnel's safety.

In particular, the vertical loads require an additional mechanical brake to operate in a certifiably safe

manner.

Notice

The brake cannot monitor autonomously if the voltage level is sufficient to its own operation.

Consequently, it is necessary to measure the voltage on the input of the brake and always verify the

functionality during release and braking, in particular in the case of connections with long cables or

cables with reduced section, that are subject to significant voltage drops.

The brake can be enabled in four different ways:

1. According to logic defined by the user condition (disable / enable the axis)

2. With a command via fieldbus

3. With a suitably programmed digital input

4. Through special command via the GUI software

Pin

Function

1 0 Volt

2 + 24 Volt

3 0 Volt

4 Brake output

5

Therm. Prot.

6

Therm. Prot.

LED Nome Descrizione

X9- RUN EtherCAT

RUN Indicator

OFF - The drive is in the state

INIT

BLINKING - The drive is in the state

PRE-OPERATIONAL

SINGLE FLASH - The drive is in the state

SAFE-OPERATIONAL

ON - The drive is in the state

OPERATIONAL

FLICKERING - The drive is in the state

BOOTSTRAP

X9- L/A EtherCAT

Link/Activity

OFF - The input Ethernet port is

closed

ON - The input Ethernet port is

open

FLICKERING - The input Ethernet port is

open and there is network

activity

X8– L/A EtherCAT

Link/Activity

OFF - The output Ethernet port

is closed

ON - The output Ethernet port

is open

FLICKERING - The output Ethernet port

is open and there is

network activity

DS2020

L-MAS2-E-161

19

EtherCat

-

-

-

-

-

-

-

-

1

2

3

4

5

6

7

8

TX+

TX-

2V5

2V5

RX+

RX-

SHIELD

SHIELD

SHIELD

SHIELD

13-14

X11, X12, X13 - Power connections

Definition Function

U2, V2, W2, Motor connection

GND

Connection to power ground through M5 stud

U1, V1, W1

Connection to the three-phase network

RRe, RR

Connection to external brake resistor

RRi, RR

Bridge to use the internal braking resistor

X11 connection - sizes L50 and L75

X11-X12-X13 connections - sizes L85 and L125

The cable must be shielded. The screen connection towards ground can be closed with a conductive strap, with whom connect

the cable to the metal bracket fixed under the drive.

2.2.5 Filters

To ensure proper compatibility with the EMC standards insert between the network and drive an EMC filter code AT6009 and

AT6010 or a model with equivalent features.

Code

AT6009 / AT6010

Rated current 3 x (400/480 V), 50/60 Hz, to 50 °C

Overcharge

4x on startup1.5x for 60 s,

repeatable every 60 min.

Environmental temperature

From -25 °C to +100 °C, with current reduction from 60 °C (1,3 % / °C)

Mounting altitude

1000 m, with current reduction from 4000 m (6 % / 1000 m)

Relative air humidity

15 ... 85 %, condensation non allowed

Storage temperature

From -25 °C to +70 °C

Protection

IP20

Acceptance test

Compliant CE

Non industrial environment

EN61800-3

complies with radio shielding

Allowable length of the cable between the drive and motor up to 50 m

Non industrial environment

EN61800-3

complies with radio shielding

Allowable length of the cable between the drive and motor up to 100 m

Code Module Type Rated

current [A]

Total current

loss [W]

Current

contact

[mA]

Weight

[kg]

Connecting cables

[mm

2

]

AT6009 L50 A 7 9 16,5 1 up to 4 mm

2

flex.

Bolt PE M5

AT6010 L75/L85 A 16 20 18,3 1,4 up to 4 mm

2

flex.

Bolt PE M5

AT6011 L85 A 30 21 24,2 1,7 Bolt PE M5

AT6012 L85/L125 A 42 30 25,8 2,5 Bolt PE M6

AT6013L125 A 55 30 25,8 2,9 Bolt PE M6

Ground stud M5

up to 10 mm

2

flex.

up to 10 mm

2

flex.

up to 25 mm

2

flex.

DS2020

L-MAS2-E-161

20

Other manuals for DS2020

1

Other Moog Servo Drive manuals

Moog

Moog MSD C2 User manual

Moog

Moog MSD User manual

Moog

Moog MSD Servo Drive Reference guide

Moog

Moog MSD G393-004 User manual

Moog

Moog MSD User manual

Moog

Moog D633-A Series User manual

Moog

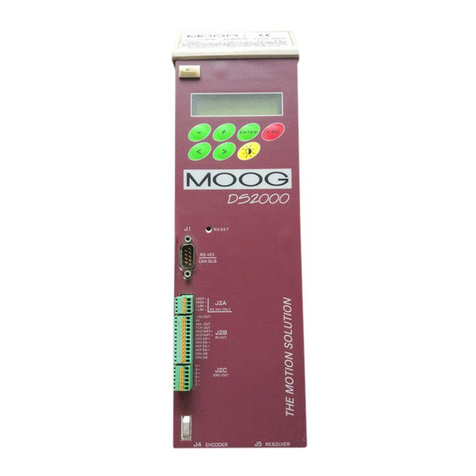

Moog DS2000 User manual

Moog

Moog G400 Series User manual

Moog

Moog DS2020 Installation manual

Moog

Moog T200 User manual