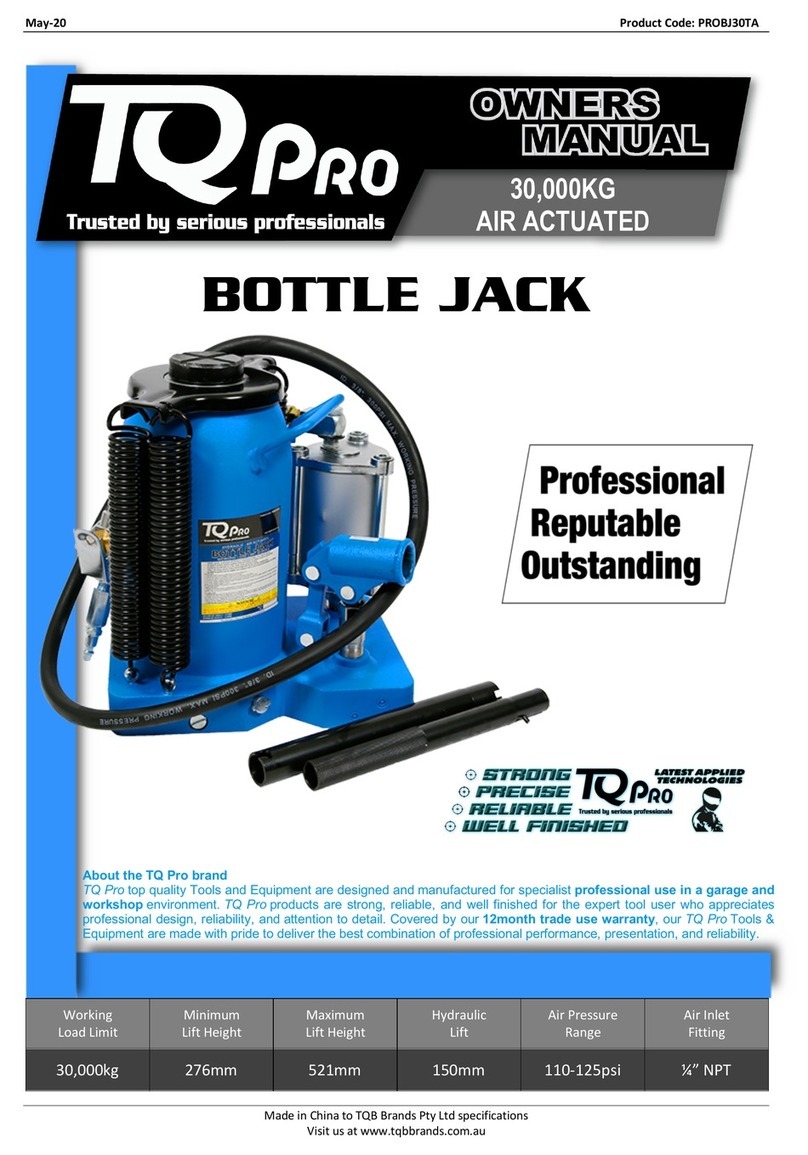

TQB 2906T Operating manual

Other TQB Jack manuals

Popular Jack manuals by other brands

Performance Tool

Performance Tool W1611 owner's manual

Hi-Force

Hi-Force HP110 instruction manual

Hoffmann

Hoffmann EELS904A Installation, operation & maintenance manual

Sealey

Sealey RJAS1500.V2 quick start guide

kincrome

kincrome K12110 Owner's assembly and operating manual

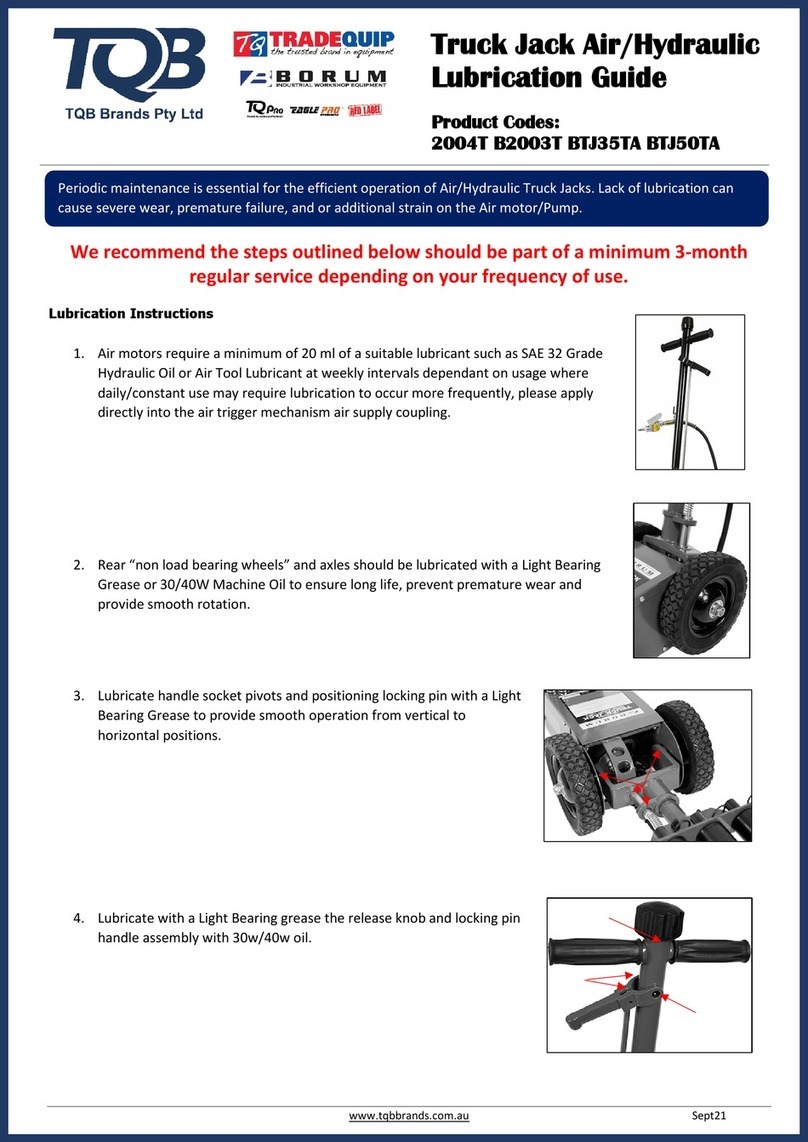

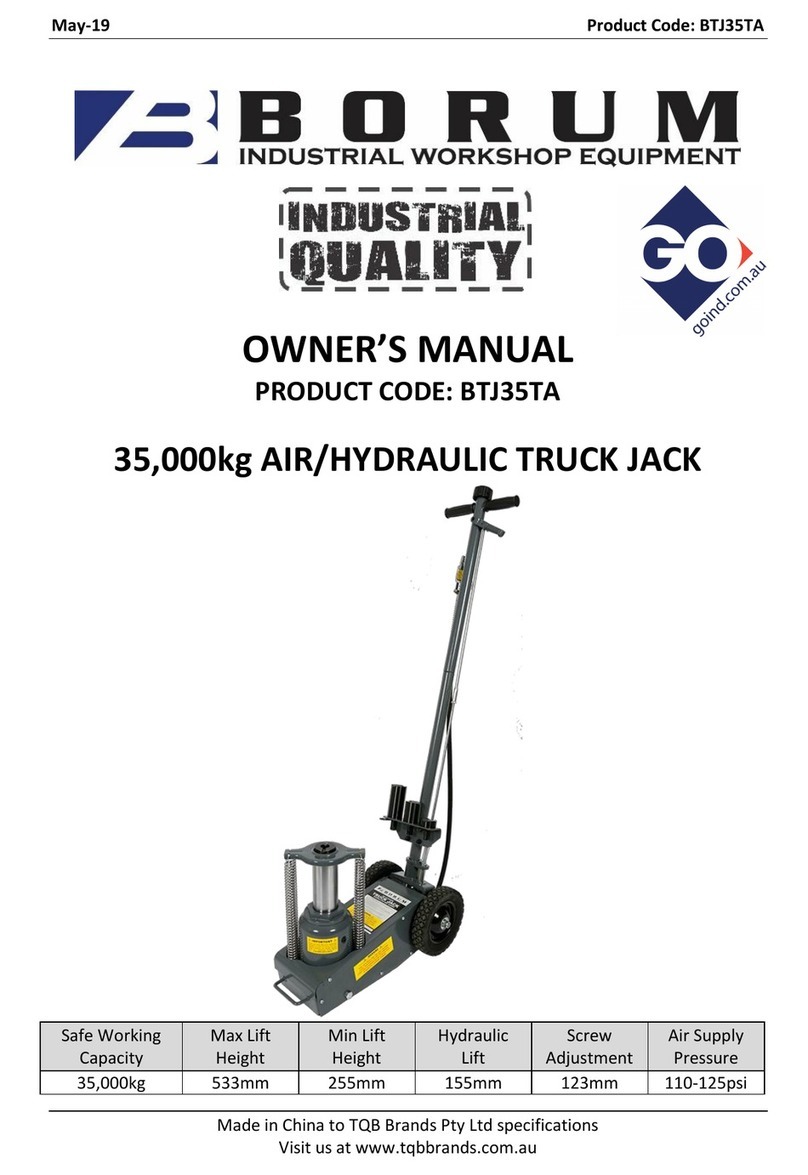

Borum

Borum BTJ35TA owner's manual

MAC TOOLS

MAC TOOLS JSA350LR owner's manual

Chicago Pneumatic

Chicago Pneumatic CP9302 Instruction manual/safety instruction

Tronair

Tronair 02-7802C0111 Operation & service manual

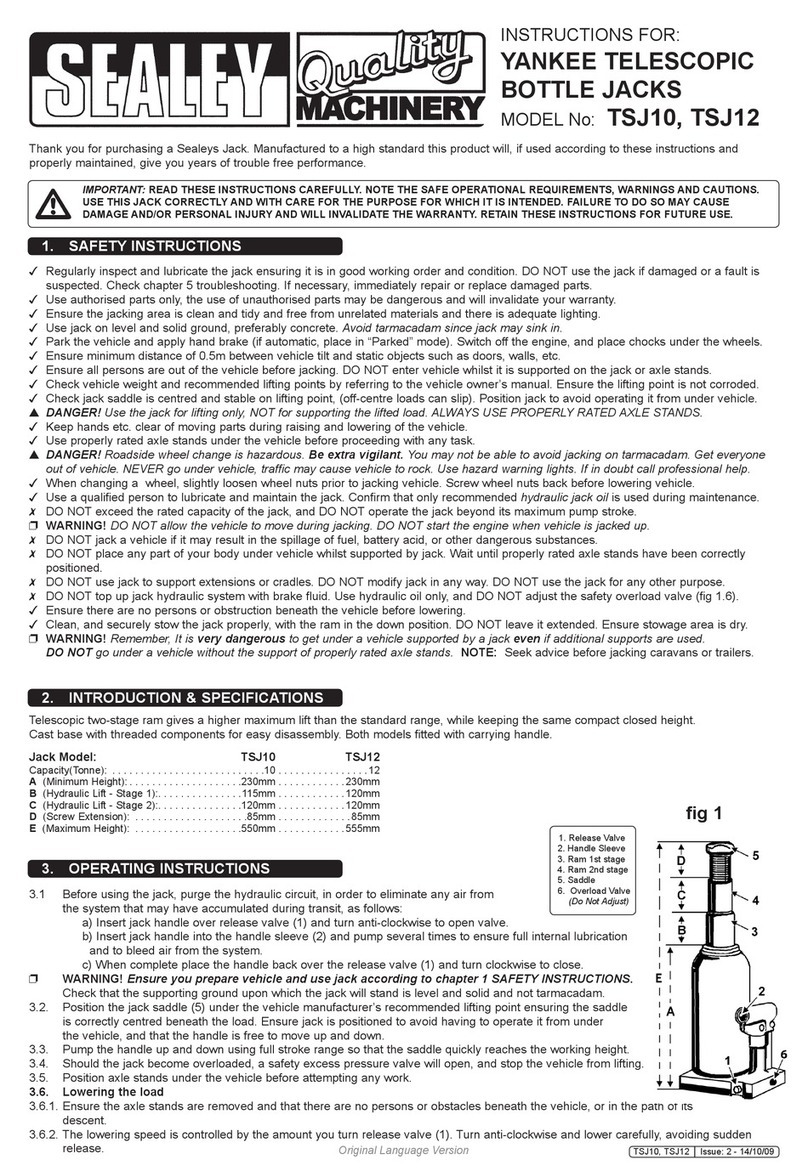

Sealey

Sealey TSJ10 instructions

Sealey

Sealey RJA1800.V2 quick start guide

Omega Lift Equipment

Omega Lift Equipment 18124C Operating instructions & parts manual