problem is corrected.

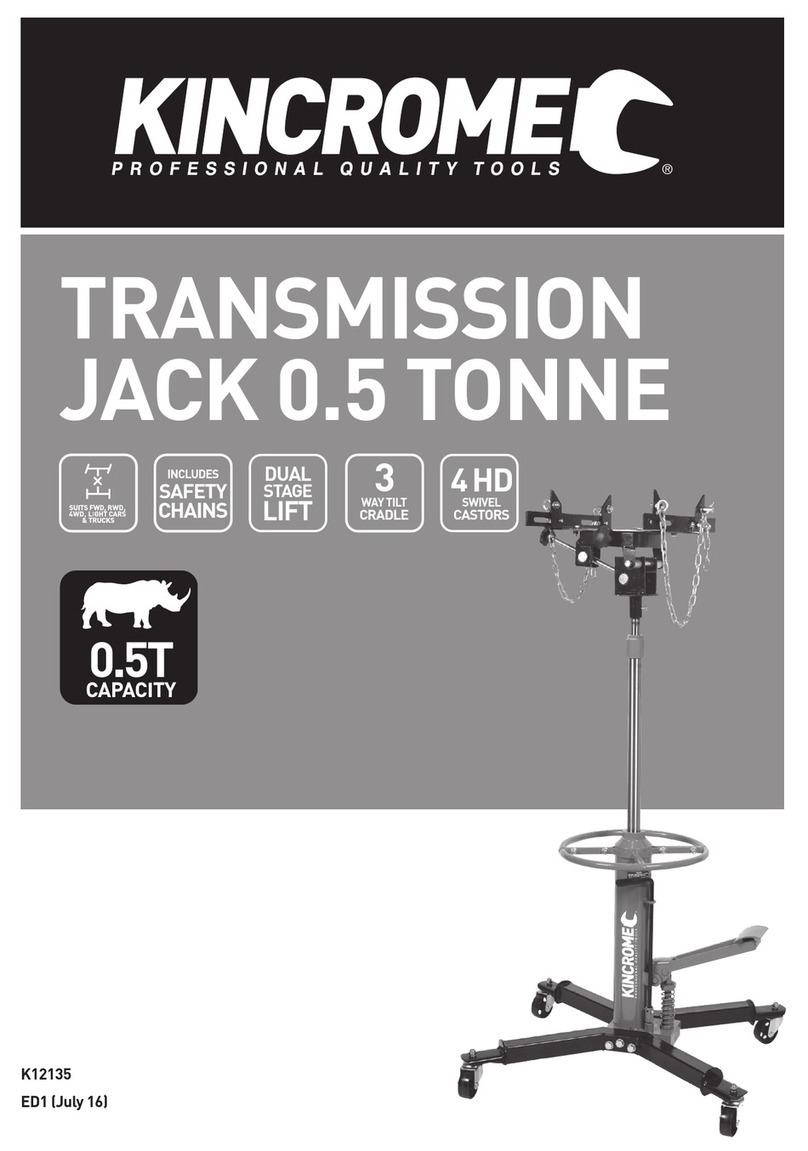

2.) Consult vehicle owner’s manual for safety precautions, Transmission weight, and location of support

areas on transmission. The working load limit of the transmission jack is 600 kg. NEVER EXCEED

WORKING LOAD LIMIT OF TRANSMISSION JACK.

3.) Clear children and others from work area before commencing work. Another adult should be nearby for

extra safety and assistance but must be clear of vehicle as it is worked on.

4.) Clear obstructions from work area. Working in tight or cluttered work areas is dangerous.

5.) Be sure transmission jack and vehicle are on solid, level ground such as paved or concrete driveway or

garage floor so the jack is free to roll. Uneven or sloped surfaces create hazardous working conditions

and dangerously impeded the function of the jack.

6.) With vehicle in proper position, set vehicle’s parking brake or emergency brake and put gearshift in park

(manual transmissions should be placed in lowest gear). TURN VEHICLE IGNITION OFFAND TO THE

“LOCK”POSITION making sure steering wheel locks.

7.) Chock all wheels of vehicle to prevent vehicle rolling. Using wedge-shaped blocks that tyre cannot roll

over, position one chock tight against the tyre in both forward and reverse rolling paths.

8.) Plan location of transmission jack beneath vehicle, making sure transmission jack will be contacting only

the transmission area of vehicle. Consult vehicle owner’s manual for recommended areas.

Using Transmission Jack

Lifting a transmission, gearbox, or differential using a transmission jack can be dangerous. This

transmission jack is designed and intended for use by properly trained and experienced personnel only.

If you are not familiar with the proper and safe operation of a transmission jack, do not use until proper

training and knowledge have been obtained.

Follow all instructions and precautions below.

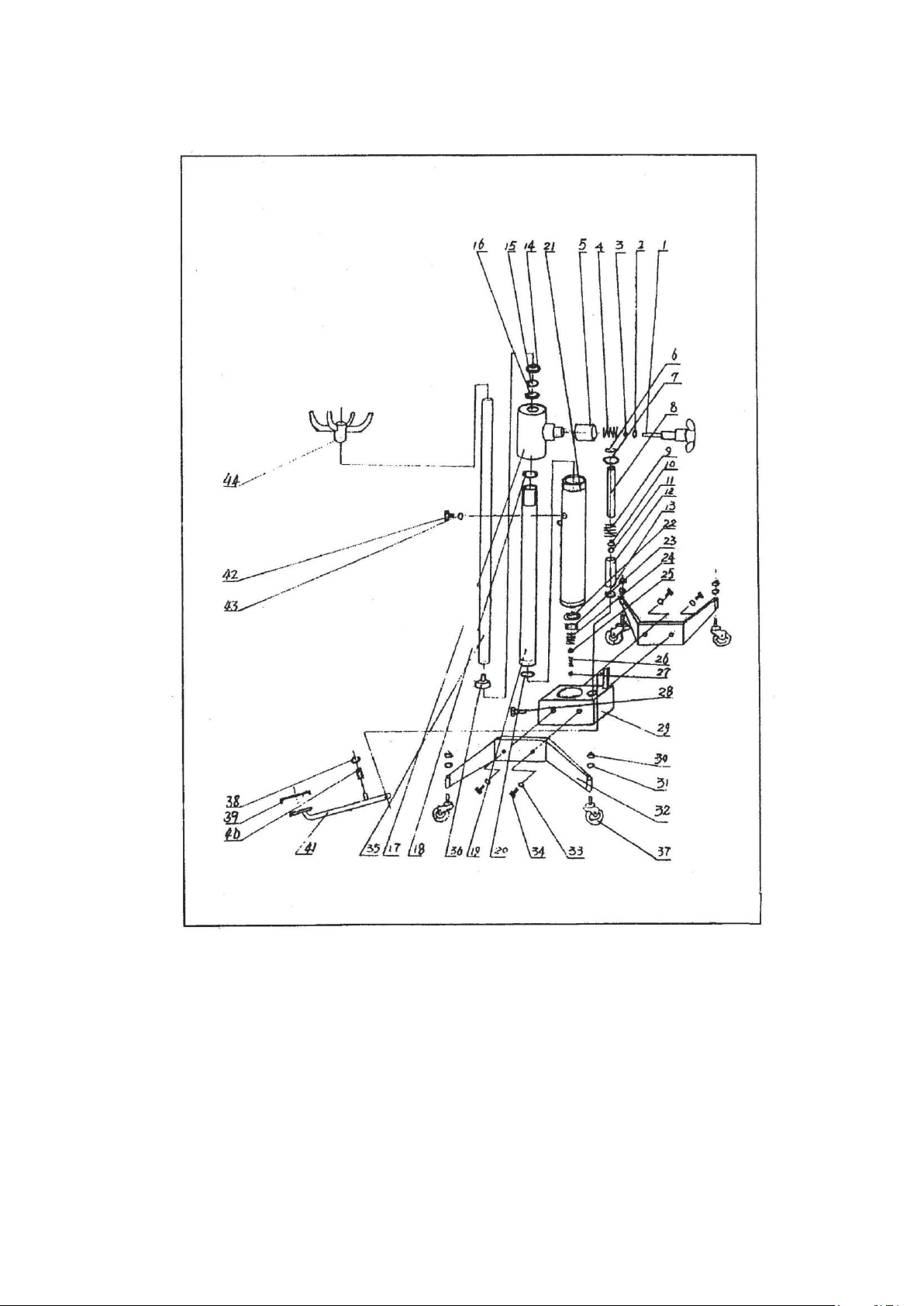

1.) With lifting arm completely lowered, roll jack into position beneath the transmission of the vehicle.

2.) Twist release valve completely clockwise to close release valve. Slowly pump foot pedal until

transmission fork just begins to contact support area on underside of transmission.

3.) Inspect position of transmission fork making sure it is centered and properly engaging the transmission.

4.) Pump handle again until transmission fork is firm against the transmission.

5.) Ensure Transmission is securely attached to the transmission fork, the load may slip or fall if not securely

restrained.

6.) Undo transmission from vehicle

7.) Undo release valve, very slowly turn counter clockwise. Slowly and smoothly lower transmission

excessive speed or jerky motion can cause the transmission to slip leading to property damage or

personal injury.