4.2. BLEEDING

Note: BEFOREEACHUSEORIFJACKPERFORMANCEDECREASES,checkforexcessiveairandproperhydraulicuidlevelinJack.

If Jack appears not to be working properly, it may be necessary to purge its hydraulic system of excessive air as follows:

4.2.1. Loosen the Fill Screw.

4.2.2. Twist the Handle counter-clockwise to open the Valve.

4.2.3. Checkuidleveland,ifnecessary,topoffaccordingtoAddingHydraulicFluidbelow.

4.2.4. Twist the Handle clockwise to close the Valve, then pump the Handle quickly several times.

4.2.5. Replace Fill Screw.

IMPORTANT: After bleeding the Jack, test the Jack for proper operation prior to its actual use

4.2.6. If, after bleeding, the Jack does not appear to be working properly, DO NOTuseituntilrepairedbyaqualiedservicetechnician.

5. OPERATION

5.1. ATTACHING THE HANDLE

5.1.1. Attach the Upper Handle to the Lower Handle.

5.1.2. Loosen the Set Screw and insert the assembled Handle into the

Handle Socket.

5.1.3. Tighten the set screw.

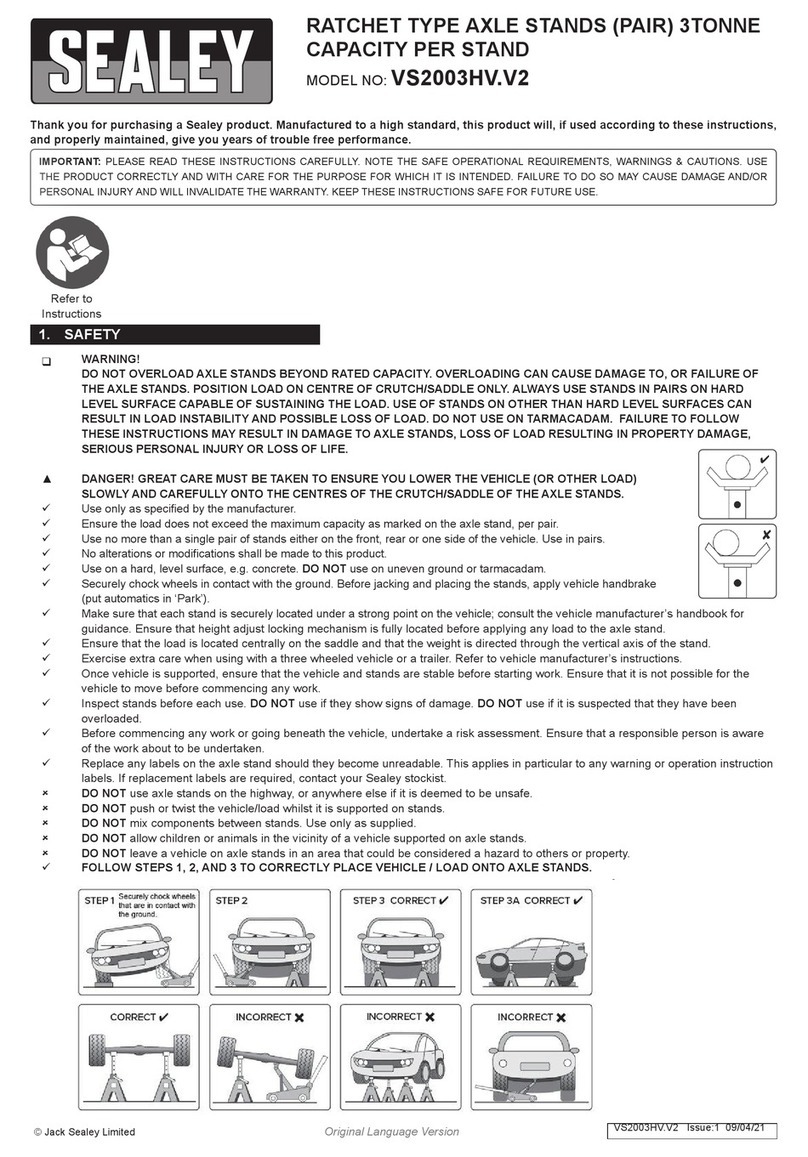

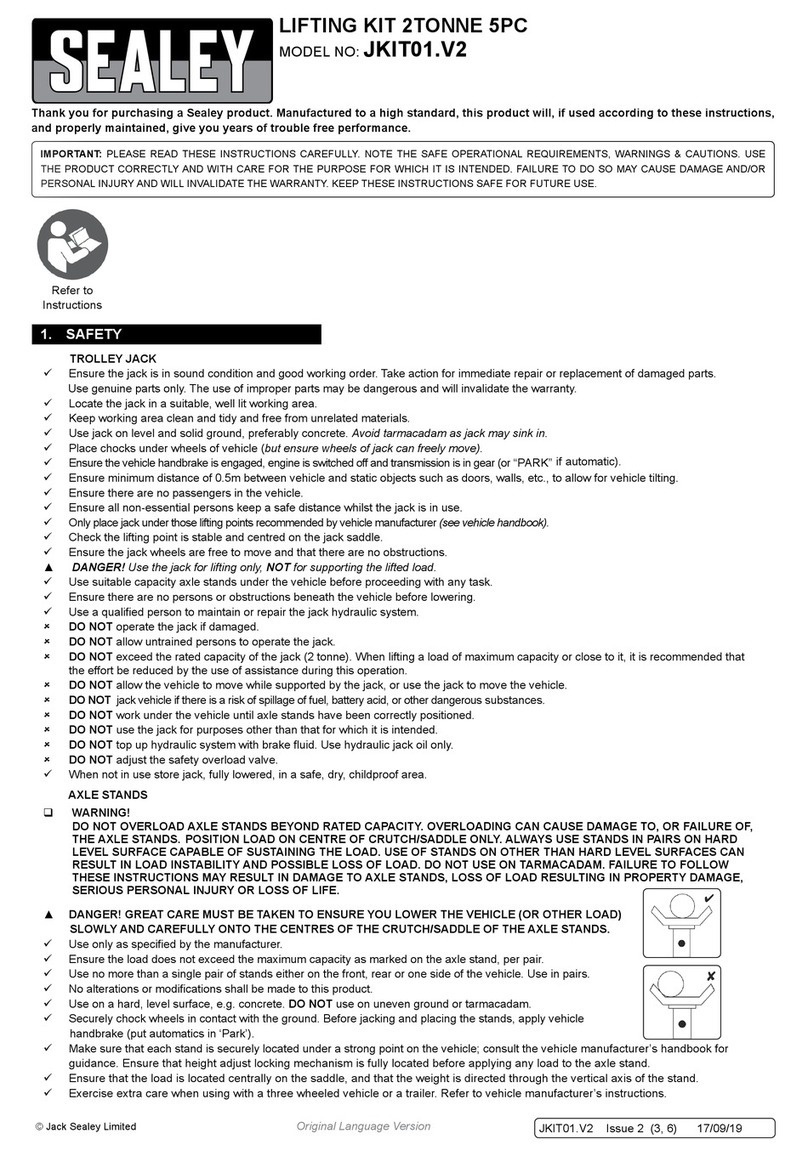

5.2. LIFTING

5.2.1. Parkvehicleonaat,level,solid,surfacesafelyawayfrom

oncomingtrafc.Turnoffthevehicle’sengine.Placethe

vehicle’stransmissionin“PARK”(ifautomatic)orinitslowest

gear(ifmanual).Setthevehicle’semergencybrake.Then

chock the wheels that are not being lifted.

5.2.2. Slowly twist the Handle counter-clockwise to lower the Jack.

OncetheJackisfullylowered,twisttheHandlermlyclockwise.

5.2.3. CarefullypositiontheJack’sSaddleunderthe

vehiclemanufacturer’srecommendedliftingpoint.(Seevehicle

manufacturer’sowner’smanualforlocationofframelifting

point.)

5.2.4. Pump the Handle until the top of the Saddle has nearly reached

thevehicle’sliftingpoint.PositiontheSaddledirectlyunderthe

vehicle’sliftingpoint.

5.2.5. To lift the vehicle, pump the Handle. Use smooth, full strokes.

5.2.6. Select matching jack stands (sold separately) of appropriate

capacity. Set the jack stands to the same height according to the

manufacturer’sinstructions,makingsuretheylocksecurelyinto

position.

5.2.7. Positionthejackstands’saddlesunderthevehicle

manufacturer’srecommendedsupportpoints.

WARNING! Ensure that the vehicle support points are fully

seated in the saddles of both jack stands. Use a matched pair of

jack stands per vehicle to support one end only.

5.2.8. Slowly twist the Handle counter-clockwise to lower the vehicle

ontothejackstands’saddles.

5.2.9. Once the vehicle is fully seated on the jack stands, continue

slowly lowering the Jack until it is completely lowered.

5.2.10. Remove the Jack and store safely out of the way.

5.3. LOWERING

5.3.1. Carefully remove all tools, parts, etc., from under the vehicle.

5.3.2. PositiontheJack’sSaddleundertheliftingpoint.TurntheHandlermlyclockwiseandraisevehiclehighenoughtoclearthejack

stands.

5.3.3. Carefully remove the jack stands.

5.3.4. Slowly turn the Handle counter-clockwise to lower the vehicle onto the ground.

5.3.5. LowertheJackcompletely.StoretheJackindoorsoutofchildren’sreach.

6. MAINTENANCE

WARNING: TO PREVENT SERIOUS INJURY FROM TOOL FAILURE: DO NOT use damaged equipment. If abnormal noise or

vibration occurs, have the problem corrected before further use.

6.1. Before each use, inspect the general condition of the Jack. Check for:

• Loosehardware,

• Misalignmentorbindingofmovingparts,

• Crackedorbrokenparts,

• Anyconditionthatmayaffectitssafeoperation.

6.2. Before each use, thoroughly test the Jack for proper operation prior to its actual use. If the Jack appears not to be working

properly, follow Bleeding instructions on page 4.

6.3. Atleastonceeverythreeyears,changethehydraulicuid:

A. With the Jack fully lowered, remove the Fill Screw.

B. TiptheJackovertoallowtheoldhydraulicuidtodrainoutcompletely.Disposeoftheoldhydraulicuidinaccordancewithlocal

regulations.

C. WiththeJackupright,completelylltheHydraulicUnitwithhighgradehydraulicuiduntiltheuidis1/4″belowthetopoftheFill

Port.

D. Turn the Handle counter-clockwise to open the Release Valve.

E. Pump the Handle up and down quickly several times to purge air from the system.

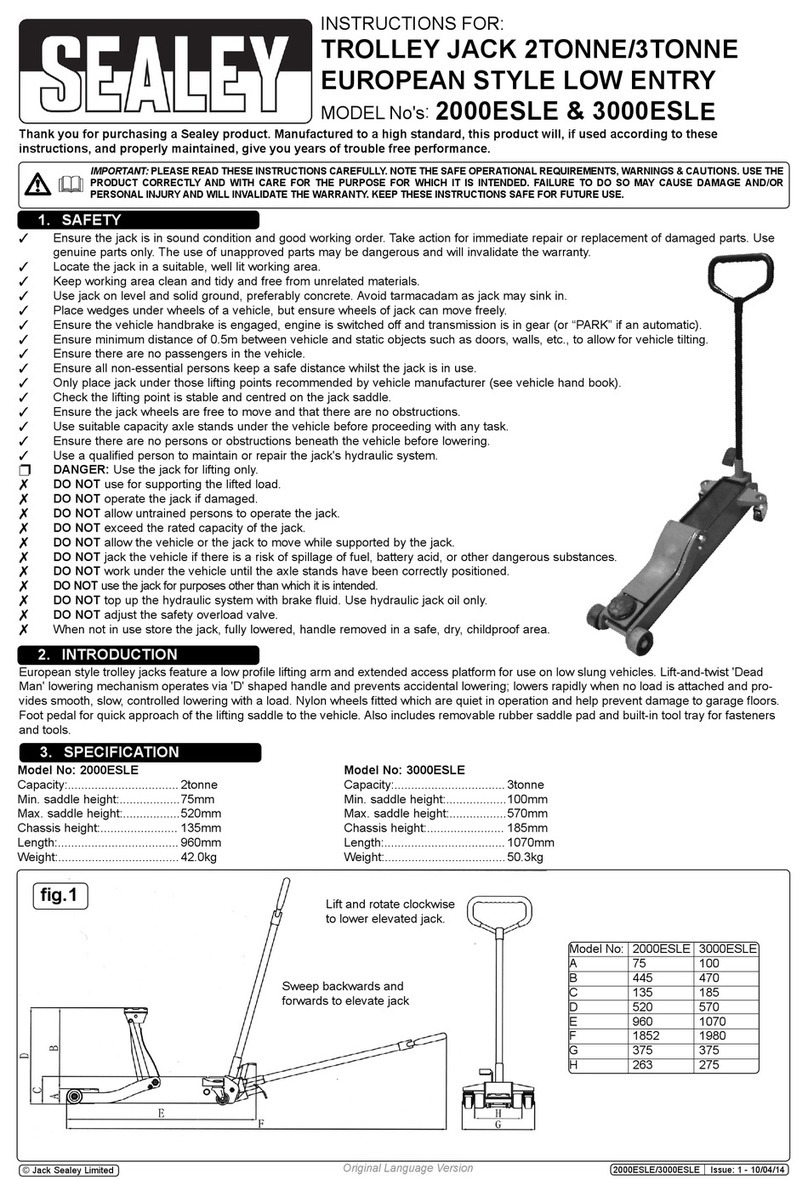

g.1

g.2

RJAS1500.V2 Issue 1 09/10/18

Original Language Version

© Jack Sealey Limited