Tractel Group Dynasafe HF 32 Operating instructions

c.o

I-

...J

>-

I-

.....J

z

-

(!)

>-

dynasafe®

HF

32

universal load cell

I(

It

Iequipment

in

~

accordance with

CE directives

0420001103 -

03/96

®

o

•

operating

and

maintenance

manual

racI8~®

0

0

(0

V

CO

(0

f'oo-

I'-

m

~

...-...

0

"'-"

V

+

~

W

l-

.

0

I-

~

>-

I-

W

LL

~

C/)

C>

z

-

l-

LL

~

0

Z

~

C>

z

-

0:::

W

W

Z

-

C>

z

w

>-

CO

~

W 2

C/)

CONTENTS

GENERAL WARNING 2

INSTALLATION OF HF32 LOAD CELL 3-4-5

OPERATION AND AJUSTMENT OF

HF32 LOAD CELL 6 •

GENERAL WARNING

1 - Reading and

fully

understanding

the

technical

data

sheets

relating

to

this

equipment

is

essential

forthe

best

use

of

this

high

technological

material

that

you

have received.

All

the

technical

data

sheets

are available on

request.

2-

Before

installing

and

operating

Dynasafe®

equipment

it

is

essential

forthe

safe

and

correct

operation

of

the

material

that

this

manual

be read and

fully

understood

and

that

all

the

instructions

be

followed.

This

manual

should

be made available

to

every

operator.

Extra

copies

of

this

manual

will

be

supplied

on

request.

3 - The

installation

and

operation

of

Dynasafe®

equipment

should

only

be

carried

out

in

accordance

with

the

appropriate

health and

safety

at

work

regulations.

4 -

Never

apply

to

the

Dynasafe® a

load

or

an

effort

in

excess

of

the

working

load

limit,

and

never

use

it

for

an

operation

for

which

it

is

not

intended.

5 - TRACTEL

SA

declines

any

responsibility

for

the

consequences

of

dismantling

or

altering

the

machine

by

any

unauthorized

person.

6 - Dynasafe®

equipment

must

not

be used in

explosive

atmospheres.

7 - Dynasafe®

equipment

must

only

be used in a

system

designed

for

lifting

people

after

ensuring

that

the

appropriate

operating

coefficients

have be

used in

accordance

with

the

current

regulations.

8 -

Priorto

the

use

of

Dynasafe®equipment

with

complementary

equipment

relaying

the

signals

to

an

operating

system,

the

user

or

installer

of

this

system

should

carry

out

a

specific

risk

analysis

of

the

operating

functions.

The

appropriate

measures

should

be taken

to

obviate

the

risks

identified.

® ®

~

+

~

W

I-

o

I-

~

>-

I-

W

LL

~

C/)

C>

z

-

l-

LL

~

o

z

~

C>

z

-

0:::

W

w

Z

-

C>

z

w

>-

CO

~

W

C/)

INSTALLATION OF

HF

32 LOAD CELL

M----jfzi_.J:::::I!:::::::::;:--A

Fig. 1

K

-------.......A=~T1

J

--';1:::~J..j

H

__

...J

Components

of

the load cell

A - 2 m connecting cable F - Locking nut

G -Tare

screw

H - Traction part

B -Flat washer

C - Adjusting pin

D -Locking ring I - Safety

washer

E - Load cell body J - Tightening

screw

Procedure for installing load cell

B

C

D

E

K - Tightening bracket

L -Rubber compression pad

M -Wire rope

N -Fixing screws for

circuit-

breaker (Do not touch)

Essential condition: The hook of the lifting system should be free

of

any load.

-Position the adjusting pin as a function of

the

load range and wire rope disameter

(see page 4 and 5).

-Remove the tightening bracket (K).

-Position the load cell on the wire rope near the dead end/fixed point. The connecting cable

should be uppermost.

-Replace the tightening bracket (K) ensuring that it is correctly positioned depending on the

diameter

of

the wire rope. (See page 4 and 5).

-Adjust the tightening screws (J) symetrically (+/- 0.5 kgm) to ensure that there is no risk of

movingthe

load cell outoflinewiththewire rope. Excessivetightening may breakthe bracket.

-Operate the lifting system up

to

the upper limitswitch and ensure thatthe sheaving or bottom

block does notfoul the load cell. (Ifthis happens adjust the upper limit switch so that there is

an appropriate distance between the load cell andthe bottom block. Also checkthatwhen the

bottom block is in the upper position the load cell is not in contact with the overhead crane.

-Wire the connecting cable from the load cell to the control box. Ensure that the cable is

secured.

® ®

3

0

0

(0

V

CO

(0

f'oo-

I'-

m

~

...-...

0

"'-"

V

+

~

W

l-

.

0

I-

~

>-

I-

W

LL

~

C/)

C>

z

-

l-

LL

~

0

Z

~

C>

z

-

0:::

W

W

Z

-

C>

z

w

>-

CO

~

W 4

C/)

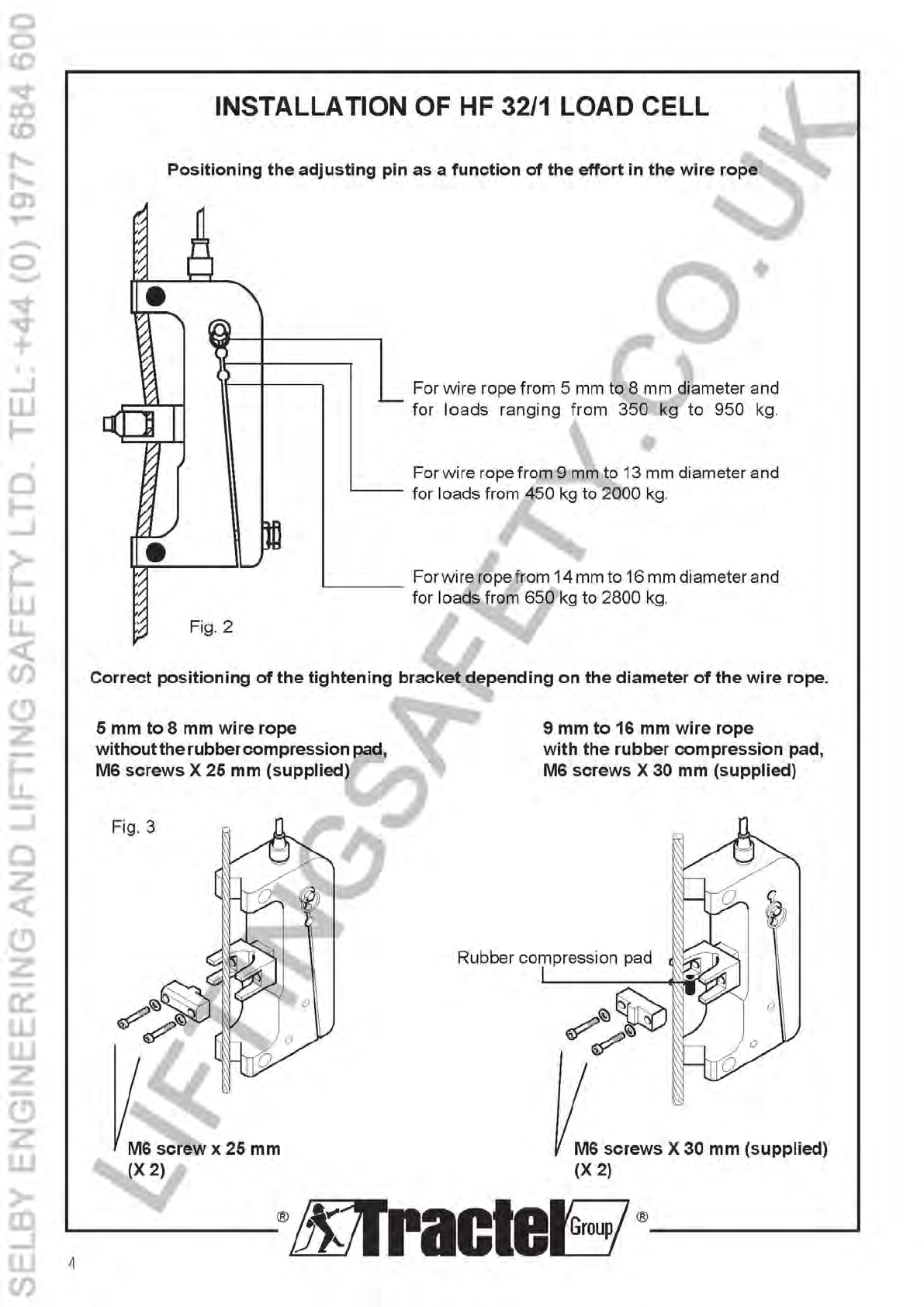

INSTALLATION OF HF 32/1 LOAD CELL

Positioning the adjusting

pin

as a function of the effort

in

the wire rope

•

Fig. 2

For wire rope from 5

mm

to 8 mm diameter and

for

loads

ranging from 350 kg to 950

kg.

Forwire rope from 9

mm

to 13

mm

diameter and

'----

for loads from 450

kg

to 2000

kg.

L.-

___

Forwireropefrom 14

mmto

16

mm

diameterand

for loads from 650

kg

to 2800

kg.

Correct positioning of the tightening bracket depending on the diameter

of

the wire rope.

5

mm

to 8

mm

wire rope

withoutthe

rubber

compression

pad,

M6 screws X 25

mm

(supplied)

Fig. 3

M6 screw x 25

mm

(X2)

®

9

mm

to 16

mm

wire rope

with the rubber compression pad,

M6 screws X 30

mm

(supplied)

Rubber compression pad

M6 screws X 30

mm

(supplied)

(X

2)

®

~

+

~

W

I-

.

o

I-

~

>-

I-

W

LL

~

C/)

C>

z

-

l-

LL

~

o

z

~

C>

z

-

0:::

W

w

Z

-

C>

z

w

>-

CO

~

W

C/)

INSTALLATION OF

HF

32/2 LOAD CELL

Positioning the adjusting pin as a function of the effort

in

the wire rope

Fig. 2

For wire rope 17 mm diameter and for loads

ranging

from

300

kg

to

2500

kg

without

the

rubber

compression

pad

.

For wire rope from 18 mm to 22 mm diameter

and for loads ranging from 500 kg to 4000 kg

with the rubber compression pad.

For wire rope from

23

mm to

26

mm and for

loads ranging from 800 kg to 6000 kg with the

rubber compression pad.

Correct positioning of the tightening bracket depending on the diameter of the wire rope.

17

mm

wire rope

withoutthe

rubber

compression

pad,

M8 screws X 40

mm

(supplied)

Fig. 3

®

18

mm

to 26

mm

wire rope

with the rubber compression pad,

M8 screws X 50

mm

(supplied)

Rubber compression pad

M8 screws X 50

mm

(supplied)

(X

2)

®

5

0

0

(0

V

CO

(0

f'oo-

I'-

m

~

...-...

0

"'-"

V

+

~

W

I-

0

I-

~

>-

I-

W

LL

~

C/)

C>

z

-

l-

LL

~

0

Z

~

C>

z

-

0:::

W

W

Z

-

C>

z

w

>-

CO

~

W 6

C/)

OPERATION AND ADJUSTMENT OF HF32 LOAD CELli

•

Connection layout (brown)

(blue) (black)

lifting

contactor

G

/.rown/blue

=NF (Normally closed)

brown/black =NO (Normally open)

alarm control

voltage

The switching poweris 4 A,220 Vac (0.3A,

250

Vdc). (It is therefore possible to connect in series

in the upper limit switch circuit.)

Adjustment of the safety trip point

Essential conditions: -The load cell must be correctly installed and wired.

-The hook ofthe lifting system should be free of any load.

Equipment required: - A load ("Pm") equivalentto 100% ofthe working load limit

of

the lifting

system.

-An additional load equivalent to

10%

of "Pm".

ACTION EXPLANATION

1 Lift the

two

loads (100%

+ 10% of "Pm") The additional 10 % load represents the overload value permitted

under the European directives.

2

by +/- 10 cm

To adjust the safety

trip

point.

®

Ifan overloadsituation is detectedin

thewire

rope (withoutliftingthe

loads) the preadjustment ofthe load cell in thefactory istoo

low

for

your

lifting system.

Solution:

release the tightening

screw

(G -see

FigA)

one turn at a

time and restart at the beginning of point

1.

Use the tightening

screw

(G).

Warning:

incorrect

adjustment

may

damage

the

circuit-breaker.

Do notforgetto tighten the locking nut (F). The switch is a normally

closed contact(NC),requiring the opening ofthe switch to setoffan

overload condition.

Turn clockwise

to

reduce the value ofthe trip point.

Turn anticlockwise to increase the value of the trip point.

®

Table of contents

Popular Industrial Equipment manuals by other brands

ABB

ABB HT604903 Operation manual

RUD

RUD VCGH-G Safety instruction

Emerson

Emerson Penberthy Installation, operation and maintenance instructions

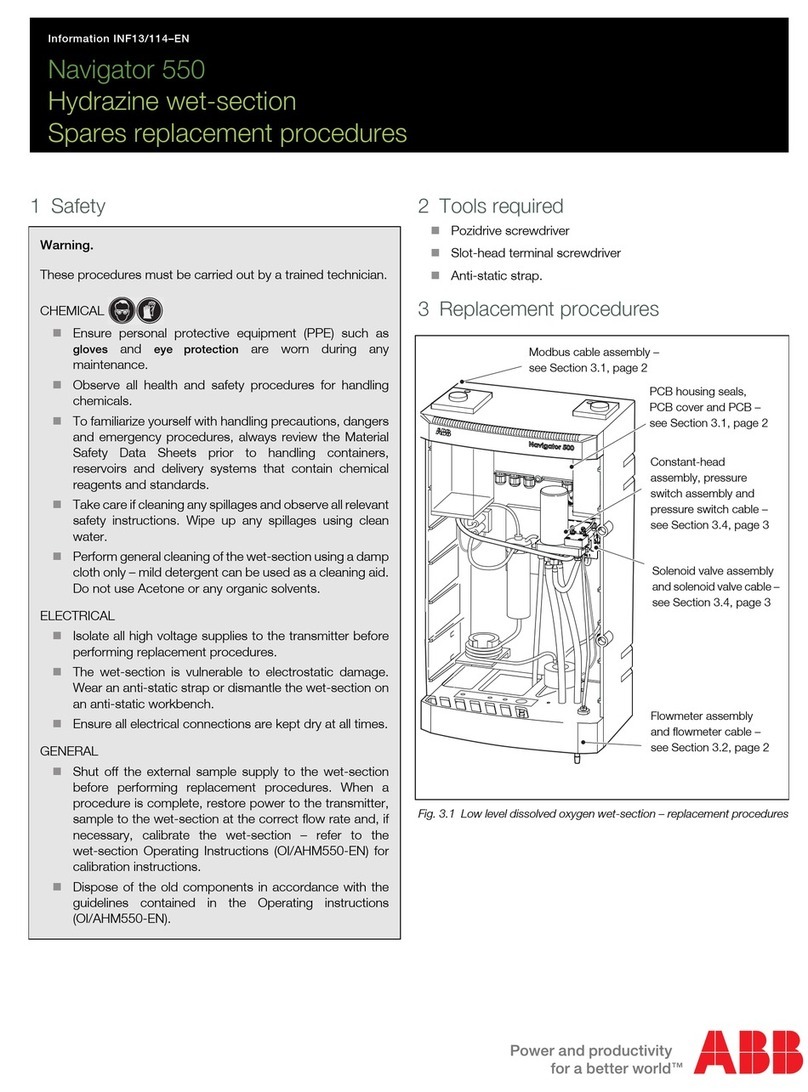

ABB

ABB Navigator 550 Spares Replacement Procedures

ermengineering

ermengineering LRW-130 Use and maintenance manual

schmersal

schmersal AZM201Z-I2-SK-T-1P2PW-DU Operation and assembly instructions