ermengineering LRW-130 User manual

Table of contents

Other ermengineering Industrial Equipment manuals

ermengineering

ermengineering SK-270 User manual

ermengineering

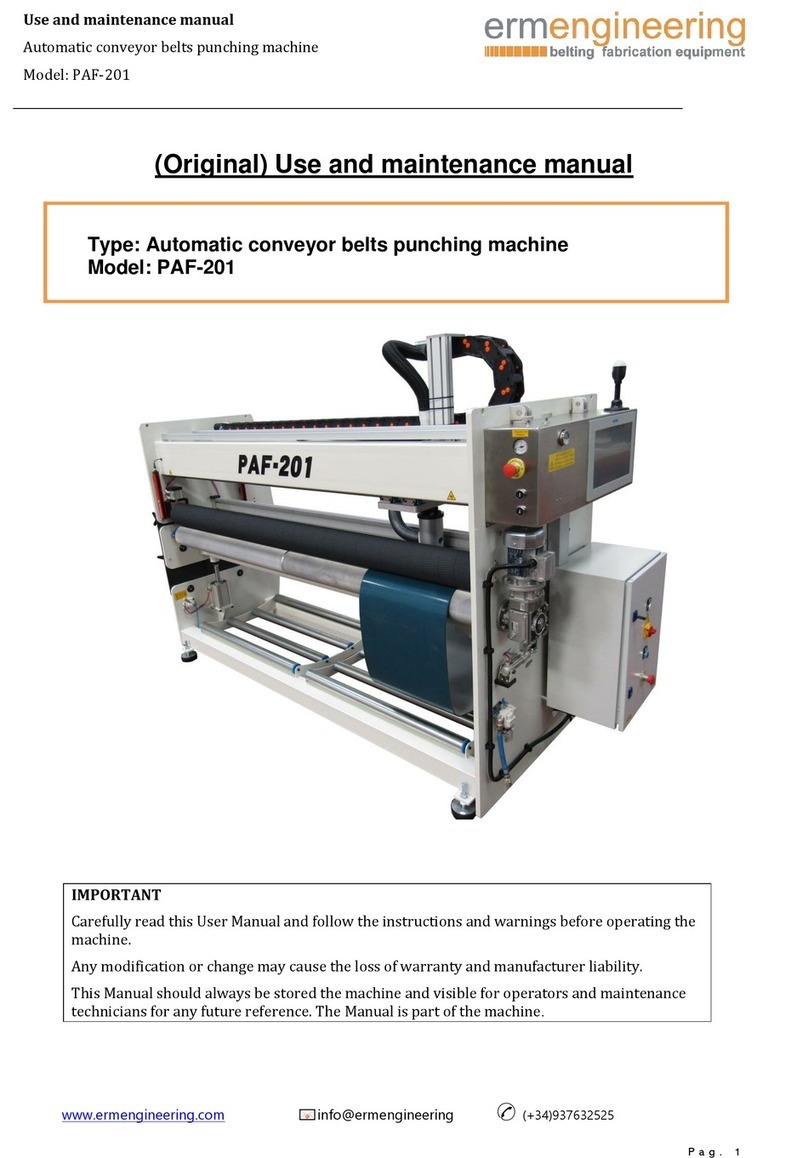

ermengineering PAF-201 User manual

ermengineering

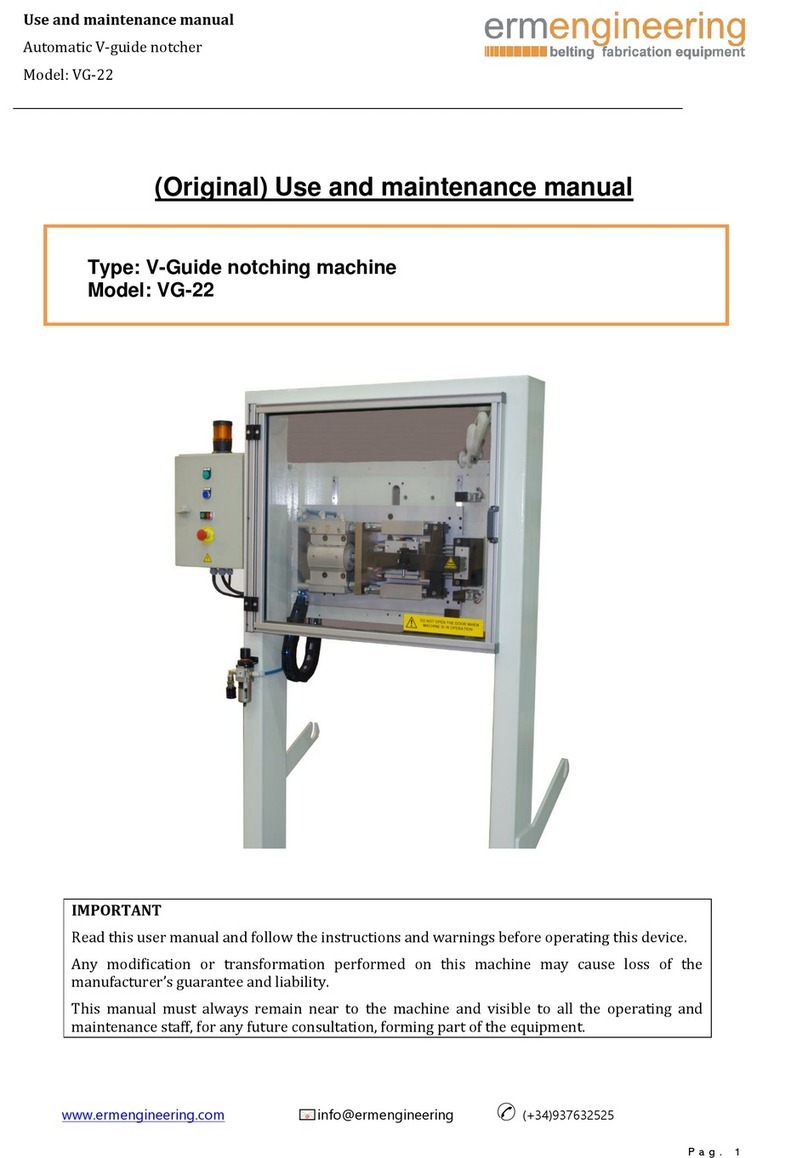

ermengineering VG-22 User manual

ermengineering

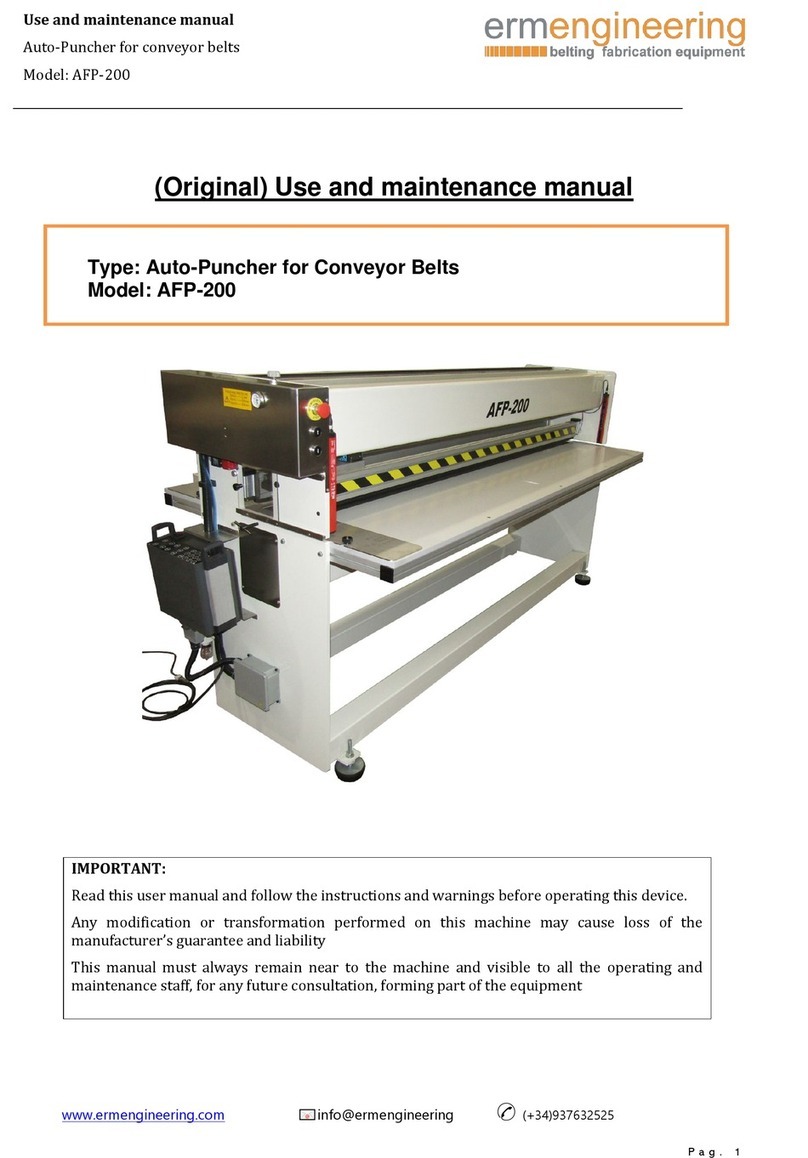

ermengineering AFP-200 User manual

ermengineering

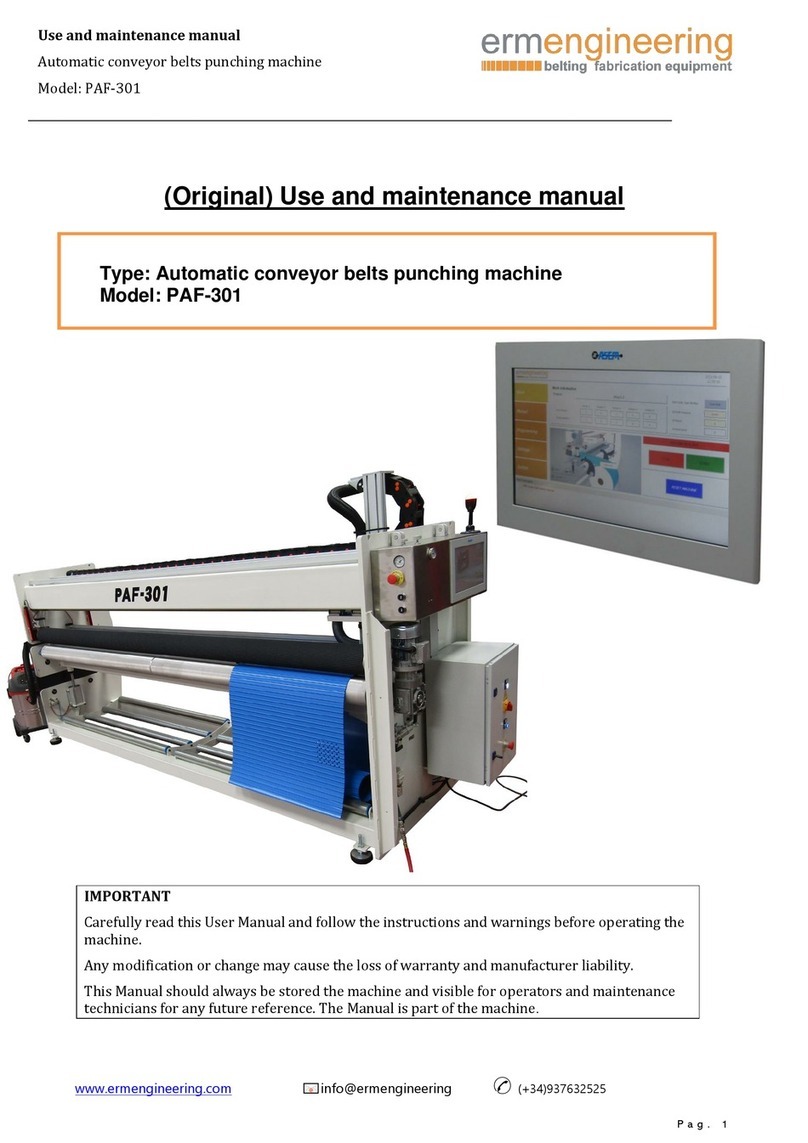

ermengineering PAF-301 User guide

ermengineering

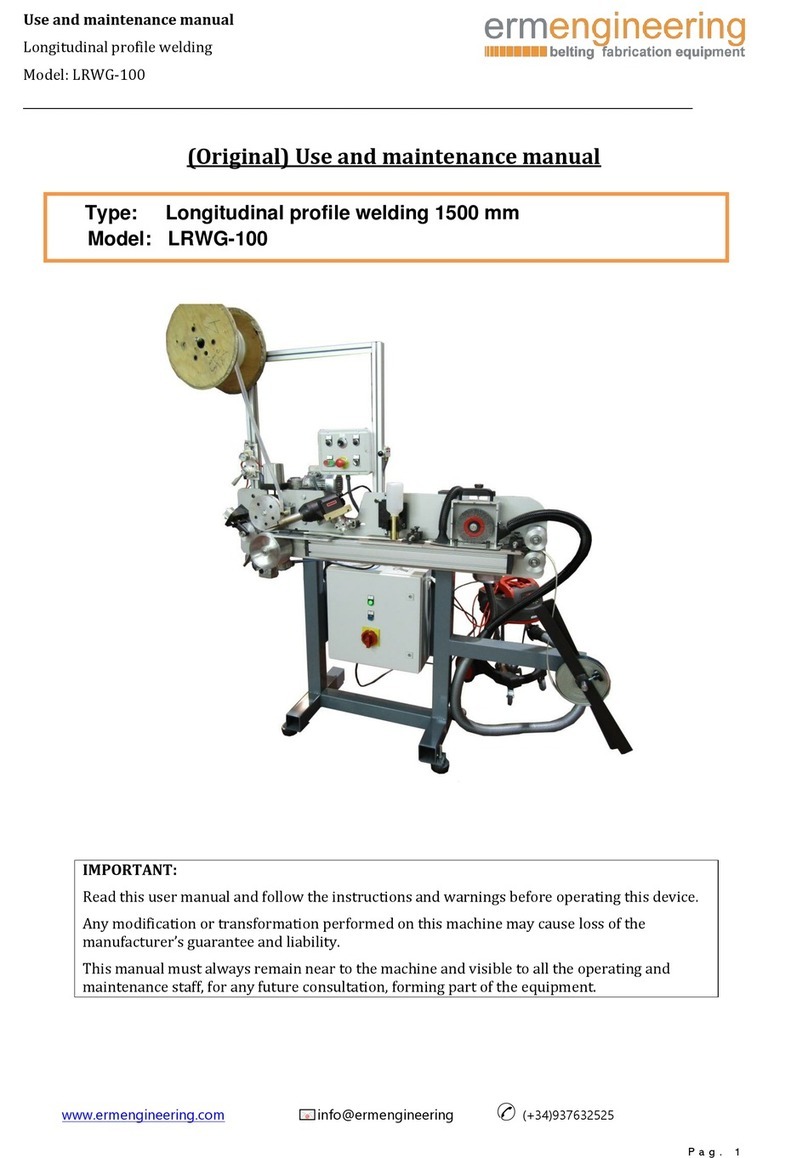

ermengineering LRWG-10 User manual

ermengineering

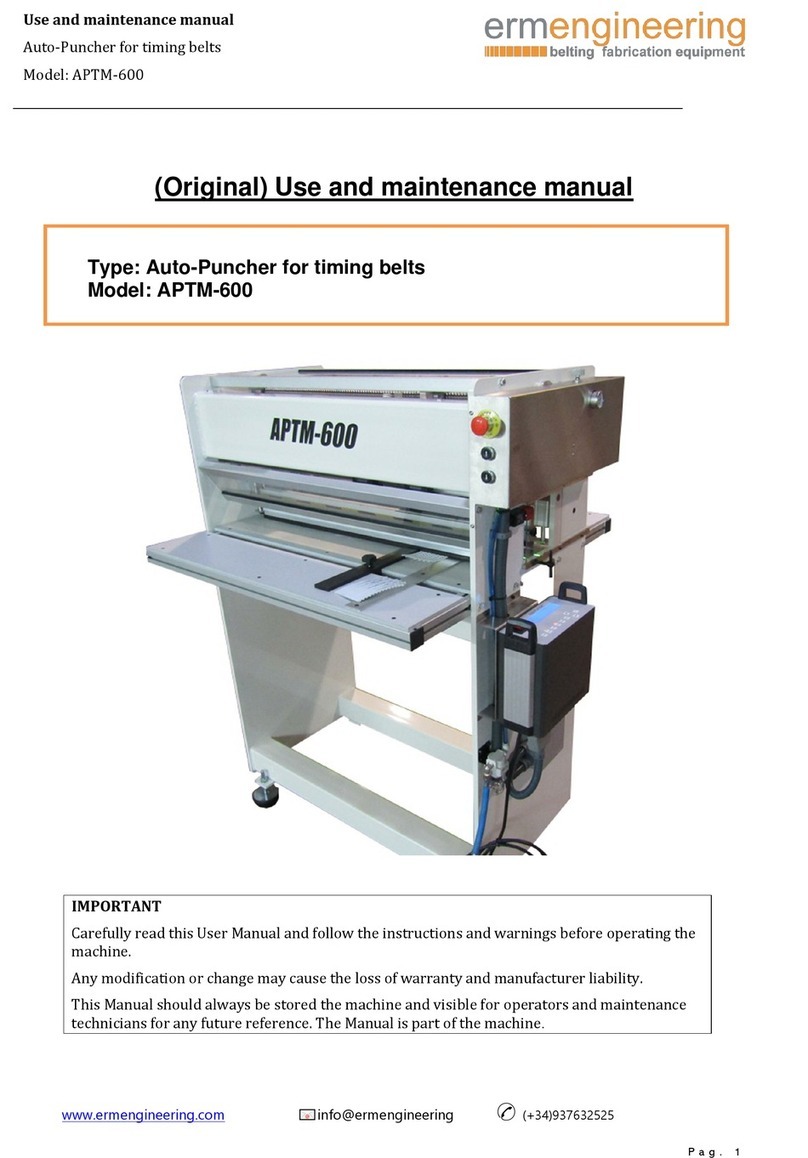

ermengineering APTM-600 User manual

ermengineering

ermengineering SKR-350 User manual

ermengineering

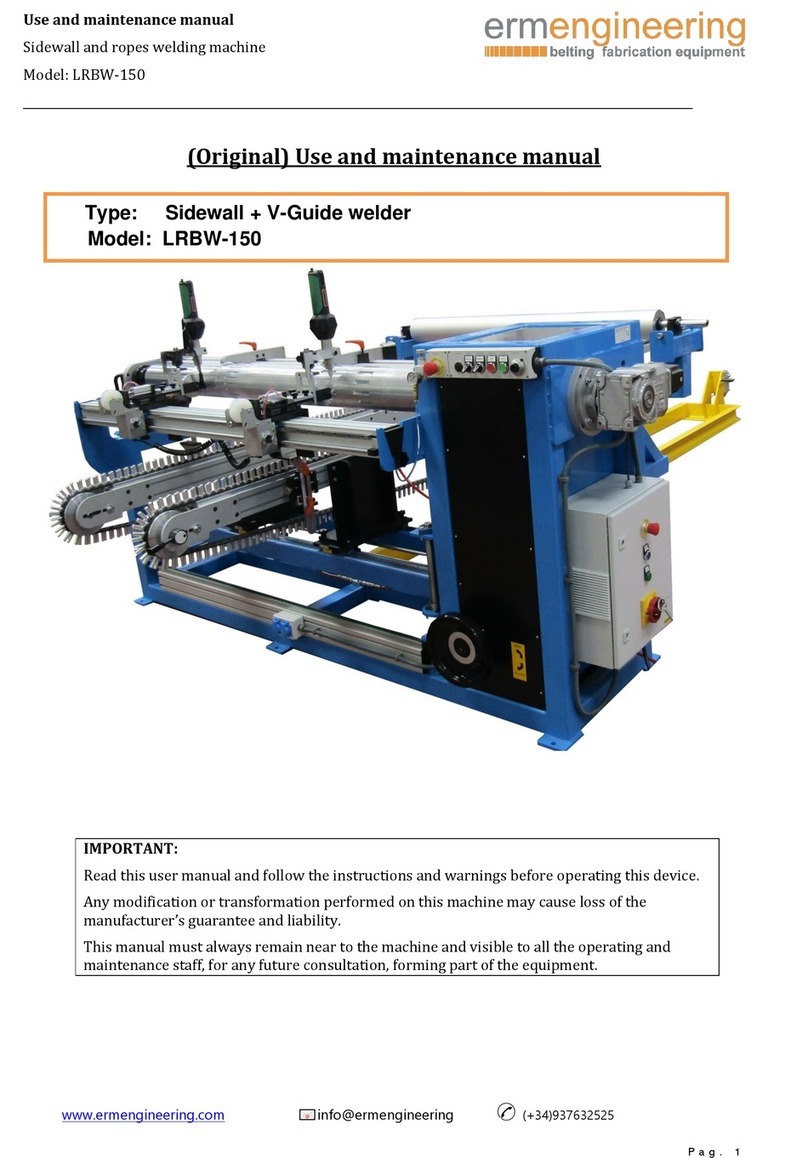

ermengineering LRBW-150 User manual

Popular Industrial Equipment manuals by other brands

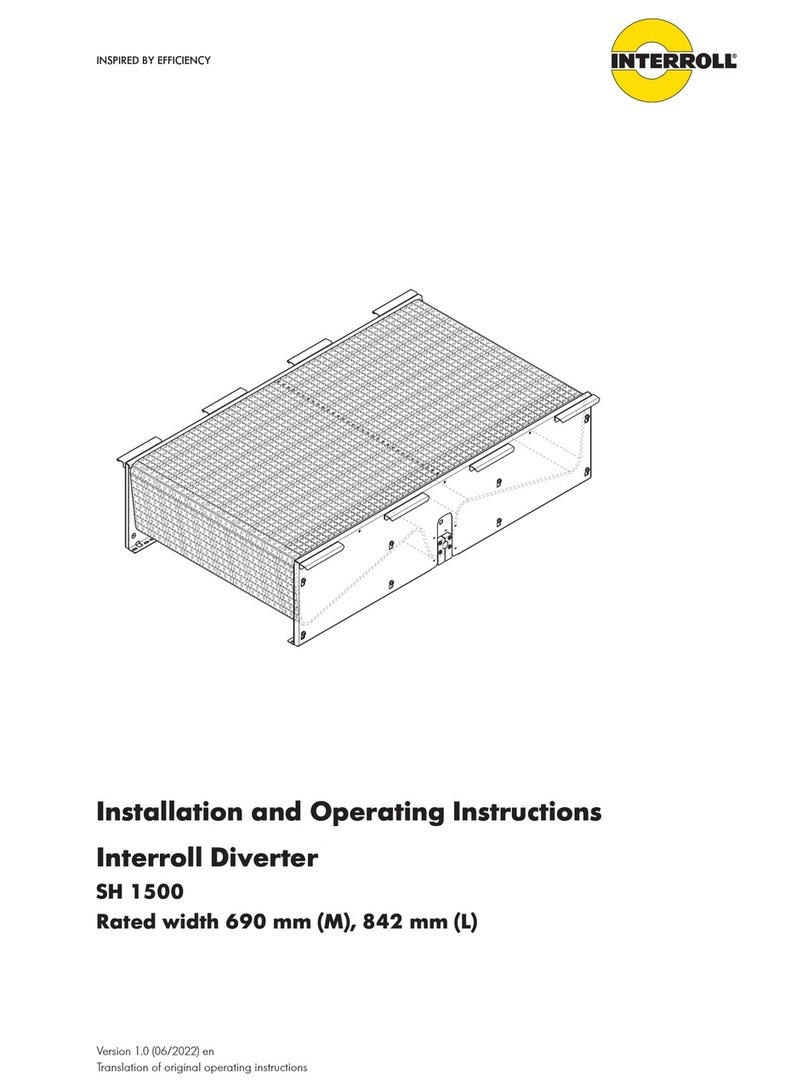

Interroll

Interroll Diverter SH 1500 Installation and operating instructions

Buhler

Buhler SZLH-400b operating instructions

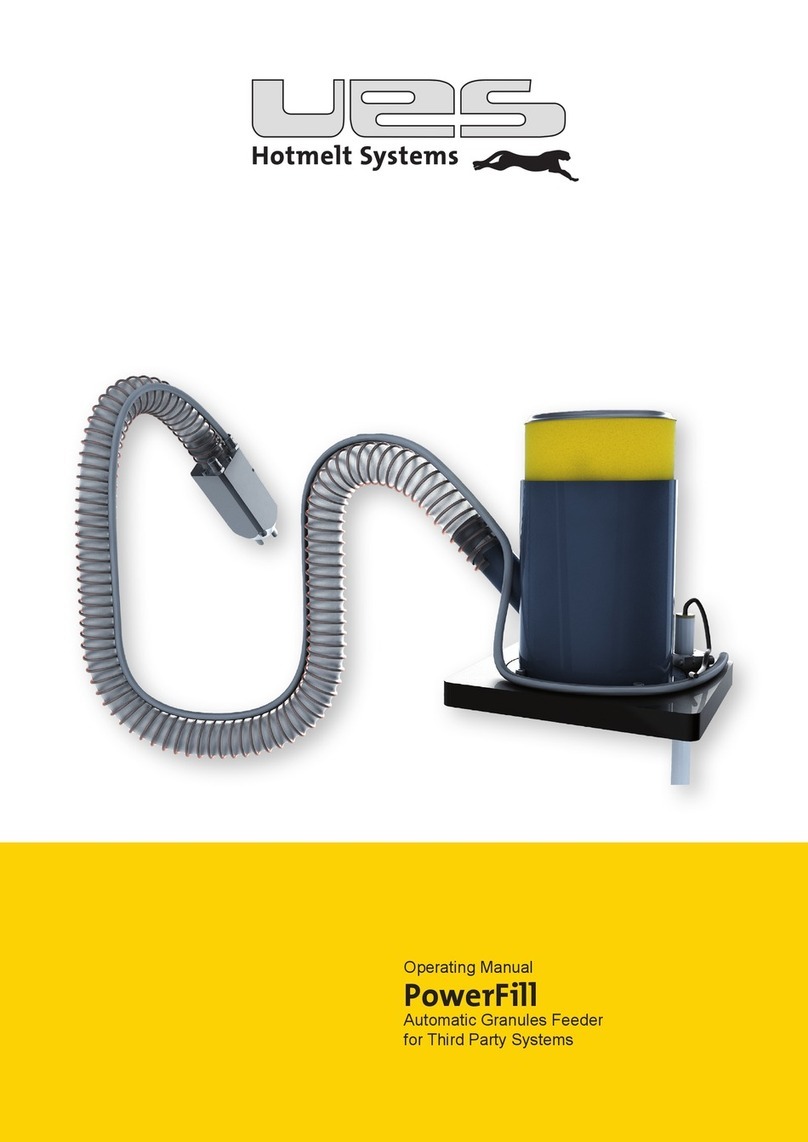

UES

UES PowerFill operating manual

SCHUNK

SCHUNK SPG 100 Assembly and operational manual

ABB

ABB PowerCube PB/F Installation and service instructions

Unitary products group

Unitary products group GY8S Series installation manual

Polysoude

Polysoude MU IV Series user manual

Langmatz

Langmatz EK278 Installation and assembly instructions

Manntek

Manntek SBC operating manual

Stahl

Stahl SolConeX 8573/14 Series operating instructions

WPC

WPC FLEXR Series operating instructions

Mayr

Mayr EAS-NC Lastic-Backlash-free Installation and operational instructions