TRADEair MCFRC103 User manual

DIRECTDRIVECOMPRESSORS

MCFRC100,102A,103,108,109,107,113

MCFRC100,

108

MCFRC102A,

109

MCFRC103

MCFRC107

MCFRC113

--------------------------------------------------------------------------------------------------------------

OperationInstructionofDirectDrive

Oil-LubricatedPistonCompressor

MCFRC100,102A,103,108,109,107and113

Prot

ec

t

y

our

s

e

lf

a

nd

ot

h

e

rs

by

ob

s

e

r

v

ing

a

ll

s

a

f

e

ty

info

r

ma

tion,

w

a

r

n

ing

s

,

a

nd

ca

utio

n

s

.

F

a

ilure

to

c

o

m

p

ly

w

ith

in

s

tru

c

ti

o

ns

c

ould

r

e

s

u

l

t

in

p

e

r

s

o

n

a

l

injuryand/ordamagetoproductorproperty.

Pl

eas

e

r

e

t

a

in

in

s

tru

c

t

i

ons

f

o

r

future

r

e

f

e

r

e

n

ce

.

WARRANTY

TheSupplierwarrantstothe originalpurchaseronly; thispowertooltobefreefromdefects

inmaterialandworkmanship.Subjecttocertainexceptions,theSupplierwillrepairorreplace

anypartonanelectricpowertoolwhich,afterexamination,isdeterminedtobedefectivein

materialorworkmanshipforaperiodofone(1)yearafterthedateofpurchaseunless

otherwisenoted.ReturnofthepowertooltotheRetailer,isrequiredtogetherwiththeproofof

purchaseshouldbeincludedwiththereturnedproduct.Thiswarrantydoesnotapplyto

damagethatisdeterminedtobefromrepairsmadeorattemptedbyanyoneotherthan

authorizedagents,misuse,alterations,abuse,normalwearandtear,lackofmaintenance,or

accidents.Thiswarrantydoesnotincludeitemsconsideredasconsumables.

StatutoryRights

Thiswarrantyisinadditiontoandinnowayaffectsyourstatutoryrights.

SPECIFICATIONS

PartNo. MCFRC100

MCFRC108

MCFRC102A

MCFRC109 MCFRC103 MCFRC107 MCFRC113

Voltage

230V/50HZ 230V/50HZ 230V/50HZ 230V/50HZ 230V/50HZ

Tank

capacity

24Litre 50Litre 100Litre 6Litre 100Litre

RatedSpeed 2850RPM 2850RPM 2850RPM 2850RPM 2850RPM

Current

5.5A 6.5A 6.5A 5.5A 6.5A

Pump

displacement

150L/MIN 206L/MIN 206L/MIN 130L/MIN 315L/MIN

MaxPressure 800kPa/8

Bar

800kPa/8

Bar

800kPa/8

Bar

800kPa/8

Bar

800kPa/8

Bar

Outlet 1x1/4" 1x1/4" 1x1/4" 1x1/4" 1x1/4"

--------------------------------------------------------------------------------------------------------------

GENERALSAFETYINSTRUCTIONS

Beforeattemptingtooperatethiscompressorthefollowingbasicsafetyprecautionsshould

alwaysbetakentoreducetheriskoffire,electricshockandpersonalinjury.Itisimportantto

readtheinstructionmanualtounderstandtheapplication,limitationsandpotentialhazards

associatedwithanytool.Theyaredesignedforthesafetyofyourselfandothers,ensuringa

longandtroublefreeservicelifefromyourmachine.

WorkArea

Workbenchesshouldbekepttidybecauseclutteredbenchesandworkareasinviteaccidents.

Floorsshouldbekeptcleanandfreefromrubbish.Specialcareshouldbetakeniftheflooris

slipperyduetosawdustorwax.

WorkEnvironment

Keeptheworkareawelllit.Donotusecompressorinareaswherethereisariskofexplosion

orfirefromcombustiblematerials,flammableliquids,e.g.,paint,varnish,petroletcor

flammablegasesanddustofanexplosivenature.

GuardAgainstElectricShock

Donotexposeyourcompressortorain,oruseindamporwetlocations.

BewareChildrenandPets

Childrenandpetsshouldbekeptoutoftheworkarea.

Usetherighttool

Selecttherighttoolforthejob.Donotuseatoolforajobforwhichitwasnotdesigned.

Donotforceasmalltooltodothejobofaheavy-dutytool.

PersonalsafetyClothing

Donotwearlooseclothing,jewelleryoranythingthatcouldgetcaughtinmovingmachinery.

Hair

Longhairshouldbetiedbackorcontainedinaprotectivecovering.

EyeProtection

Alwaysuseprotectivesafetygogglesorsafetyglasses.

EarProtection

Earprotectionisadvisedduringperiodsofextendedoperation.

Footwear

Wherethereisariskofheavyobjectsdamagingfeetorifthereisariskofslippingonwetor

slipperyfloorssuitablenon-slipsafetyfootwearshouldbeworn.

--------------------------------------------------------------------------------------------------------------

SecuretheWorkPiece

Whereverpossiblesecuretheworkpieceusingclampsoravice.Itissaferthanusingyour

handandleavesbothhandsfreetocontroltheairtool.

DoNotOver-reach

Donotover-reach,keepproperfootingandmaintainyourbalanceatalltimes.

MaintainToolswithCare

Keepcuttingtoolssharpandcleanforbetterandsaferperformance.Followtheinstructions

forlubricatingandchangingaccessories.Checkthetoolpowercordperiodicallyandif

damagedhaveitreplacedbyanauthorizedservicefacility.Keephandlesdry,cleanandfree

fromoilandgrease.Ensurethatventilationslotsarekeptcleanandfreefromdustatalltimes.

Blockedventilationslotscancauseoverheatinganddamagetothemotor.

StayAlert

Watchwhatyouaredoing,usecommonsense,anddonotoperatetheairtoolwhenyou

aretiredorhavetakenmedicationthatcausesdrowsiness,consumedalcoholordrugs.

GeneralWarningsforcompressors

Donotattempttomodifythecompressorinanyway.

Theuseofanytoolsoraccessoryotherthanthosedesignedforusewith

compressedaircouldresultininjurytotheoperator.

Theoutputpressureofthecompressorshouldbeadjustedtothedesignpressure

oftheairtooloraccessorybeingused.

Alwayscheckthattheoutputofthecompressordoesnotexceedthemaximum

pressureforanyattachedtooloraccessory.

Repairsshouldonlybecarriedoutbyqualifiedpersonsusingoriginalspareparts.

Failuretodosomayresultinconsiderabledangertotheuser.

BreathableAirWarning

Thiscompressor/pumpisnotequippedfor,andshouldnotbeusedtosupplybreathing

qualityairforanyapplicationofairforhumanconsumption.

Overloadprotection.Thiscompressorisfittedwithanoverloadprotectiondevice.Inthe

eventthatthemotorbecomestoohot,athermalprotectiondevicewillcutthemainssupply

tothemotor.Whenthemotortemperaturereturnstonormalthemainssupplywillbe

restoredautomatically.

ExtensionCordsandReels

Ingeneral,itisnotrecommendedtouseanextensionlead.Alongerairlineisrecommended

asvoltagedroponextensionleadsmayleadtomotordamageandwillvoidwarranty.Ifan

extensioncordmustbeused,forlengthsupto5metres,anapproved15ampratedcordmust

beused.

--------------------------------------------------------------------------------------------------------------

DoNotAbusethePowerCord

Neveryankorpullonthepowercordtodisconnectitfromthemainssupplysocket.Never

carryordragyourcompressorbyitspowercord.Keepthepowercordawayfromheat,oil,

solventsandsharpedges.Ifthepowercordbecomesdamagedhaveitreplacedbyan

authorizedservicefacility.

CheckDamagedParts

Beforeusingthecompressoritshouldbecarefullycheckedtodeterminethatitwilloperate

properlyandperformitsintendedfunction.Checkforthecorrectalignmentofmovingparts

ensuringtheydonotbind.Checkforbrokenormissingpartsandhavethemreplacedor

repairedatanauthorizedservicecentre.Checkanyotherconditionthatmayaffectthe

operationofthecompressor.Aguardoranyotherpartofthecompressorthatisdamaged

shouldbeproperlyrepairedorreplacedbyanauthorizedservicecentre.

DisconnectCompressor

Ensurethatthecompressorisdisconnectedfromthemainssupplyandthetankisempty

whennotinuse,beforeservicing,lubricatingormakingadjustmentstoairlines,andwhen

changingaccessoriessuchasblades,bits,nailsandcuttersonairtools.

AvoidUnintentionalStarting

EnsurethattheswitchisintheOFFpositionbeforepluggingthecompressorintothe

mainssupply

TurningthecompressorONandOFF

Usetheredknobontopofthepressureswitchtoturntheunitonandoff.Pulltheknobup

toturnthecompressoronandpushtheknobintoturnitoff.Turningtheunitonandofffrom

themainssupplyonlywillresultindamagetothemotorandvoidwarrantyasthepressure

switchhasanadditionalfunctiontopurgetheairtrappedinthedeliverypipewhenthe

motoristurnedoff.Thisminimisestheloadonthemotorwhenitisnextstarted.

--------------------------------------------------------------------------------------------------------------

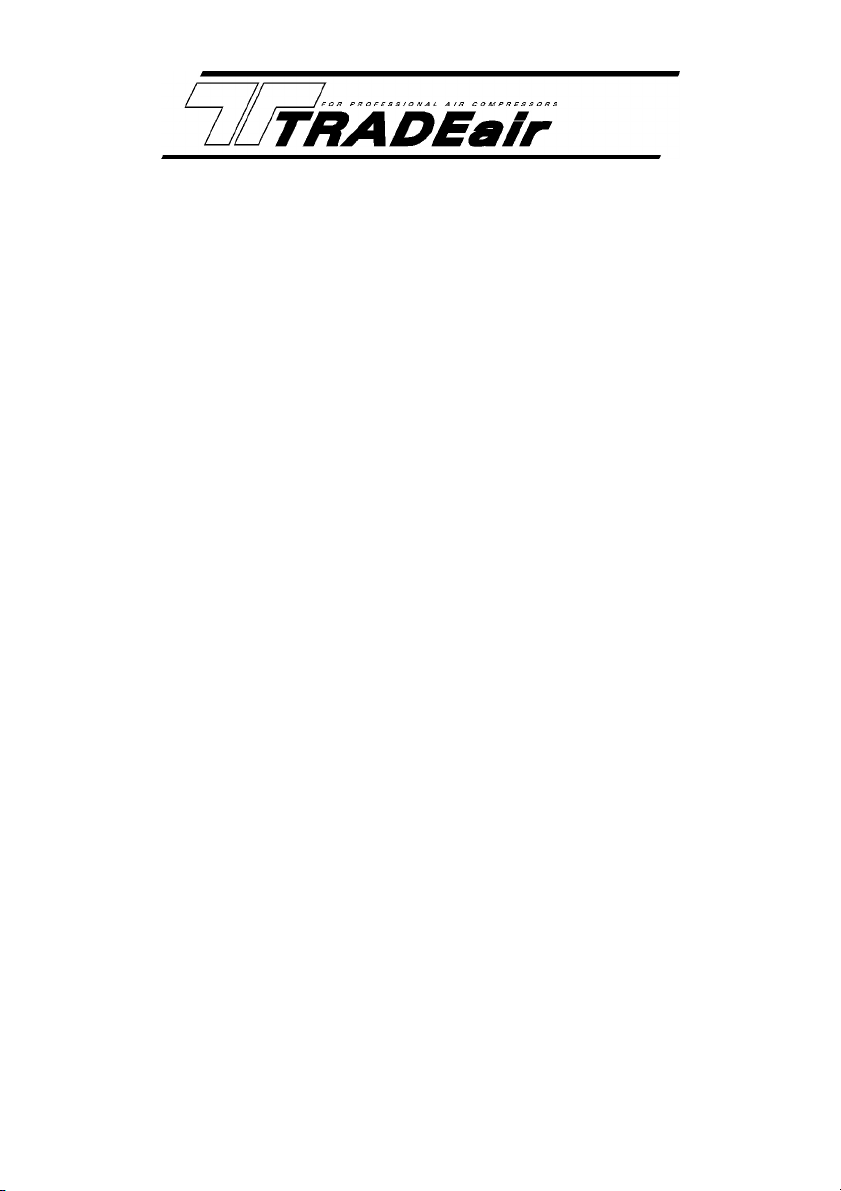

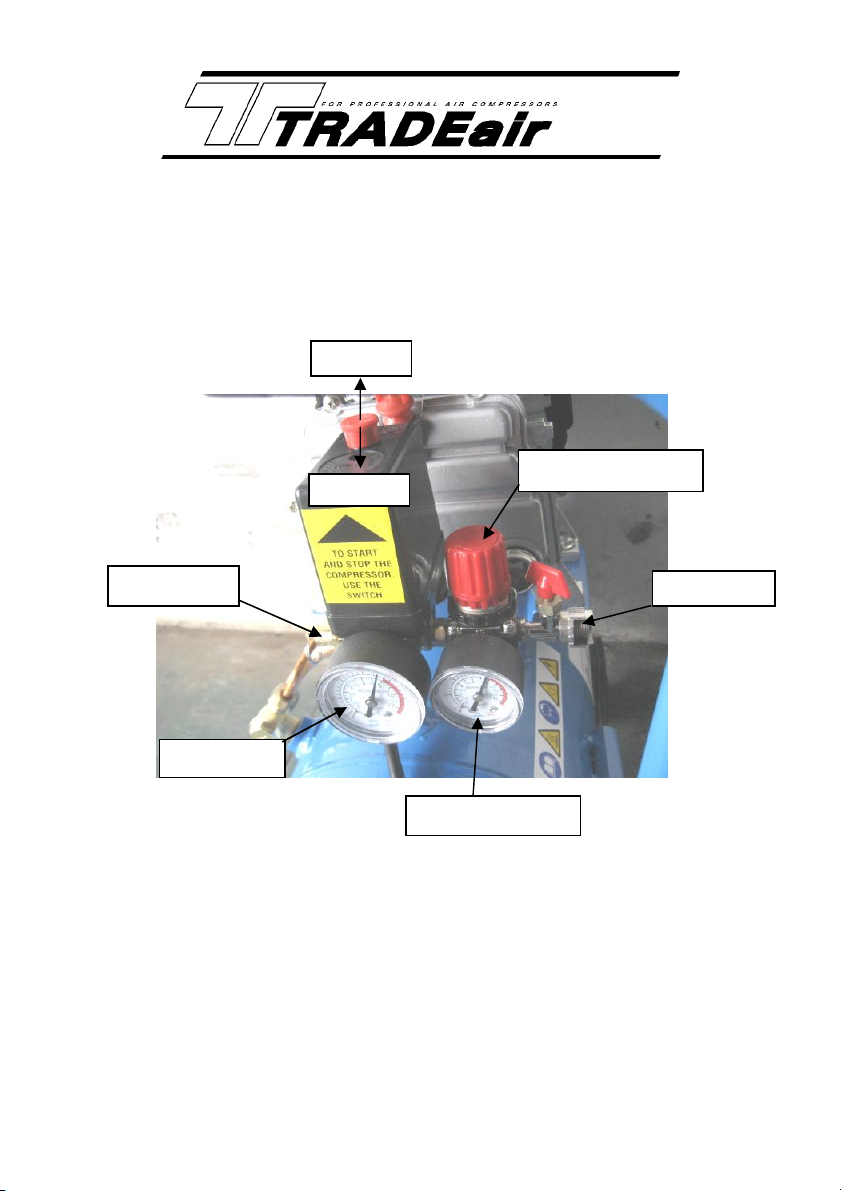

GENERALVIEWANDMAINCOMPONENTS

1. MainCompressor

2. PressureSwitch

3. OutletValve

4. PressureRegulator

5. PressureGauge

6. Non-ReturnValve

7. DrainCock

8. Wheel

9. DischargePipe

10. AirTank

11. SafetyValve

12. FanCover

Note: Fittingsmaydifferfromthoseshownabove.

11

2

4

3

5

6

7

8

9

10

12

1

--------------------------------------------------------------------------------------------------------------

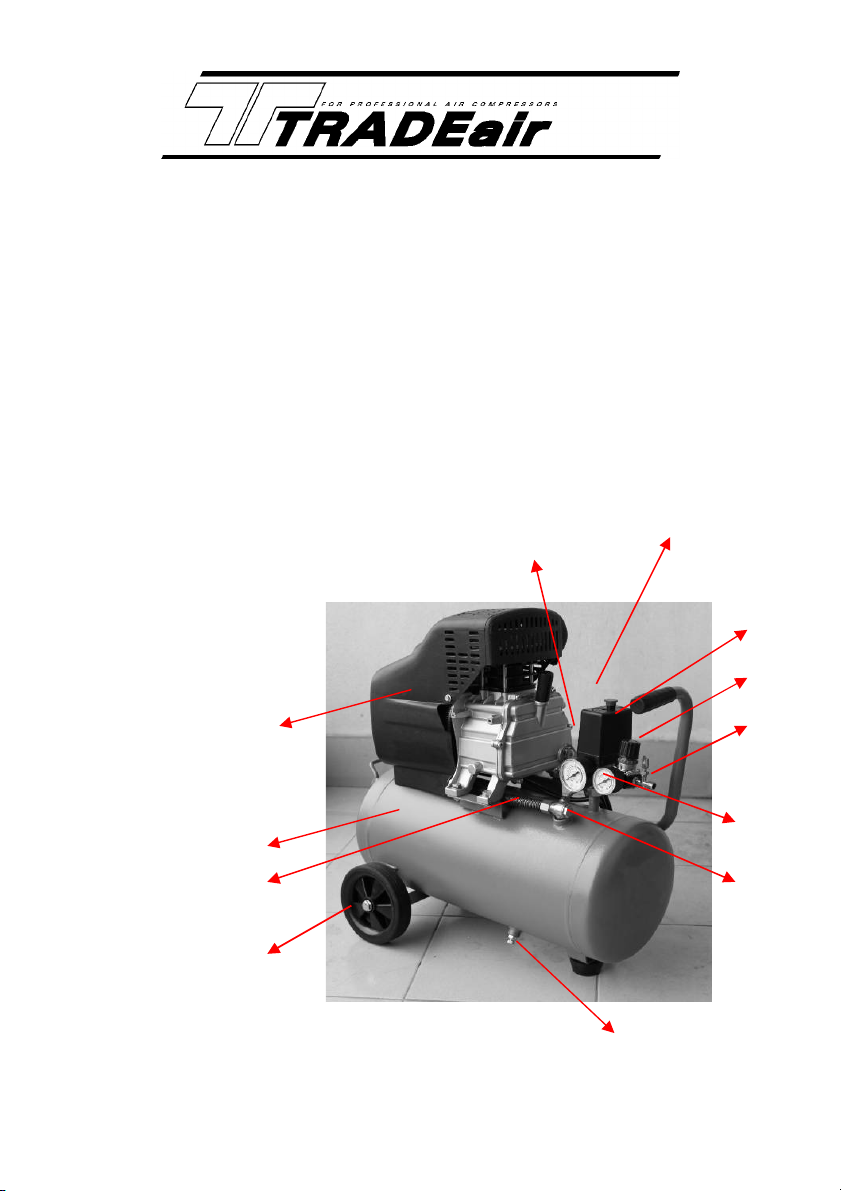

ASSEMBLY

Thisaircompressorrequiressomeminorassemblebeforeitcanbeused.

Locatetheaccessorypack.Itshouldcontain:

1. Wheelsandaxleset

2. Rubberstopper

3. AirFilter

4. OilBreatherplug

5. Abottleofoil

Fitthewheelstotheunitusingtheaxle

kitprovidedandinserttherubberstopperintothe

spigotonthebottomofthetank.

Fittheairfiltertocylinderheadofthecompressor.

Locatetheplasticdustplugintheoilbreatherholeandremoveittoexposetheoil

breatherhole.

Oilbreatherhole

--------------------------------------------------------------------------------------------------------------

OilWarning: Thisunitisshippedwithoilinthecompressorpump. Oilmustbe

addedtotheunitpriortooperating.

Usuallychecktheoillevelinthepump.Pleasefilltheoilfromtheoilbreather

holeuntiltheoilreachestheredmarkonthesightglass

Checkthatthesmallholeinthetopofthebreatherpipeisclearandtheninsertitinto

theoilfillerhole.

NOTE:Theoilmustbechangedafterthefirst10hrsofoperationthenevery20hrs

thereafter.

Recommendcompressoroil:UseSAE30fortemperaturesover10 anduseSAE10below10 .

--------------------------------------------------------------------------------------------------------------

INITIALSTARTUP

Ensuretheunitisstableinawell-ventilateddryposition.

Ensurethatthedrainvalveisclosedandallairoutletsareclosed.

Connectthepowerleadtothemains.

Startthecompressorbypullingontheredknob.

Checkforairleaks

Note: Outputfittingsmaydifferfromthoseshown

Warning:Usetheredknobtoturntheunitonandoff,notthemainsswitch.Turningtheuniton

andofffromthemainsonlywillresultindamagetothemotor

Turn

on

Turn

off

Tankgauge

Regulatorgauge

Pressureregulator

Air

outlet

Safetyvalve

--------------------------------------------------------------------------------------------------------------

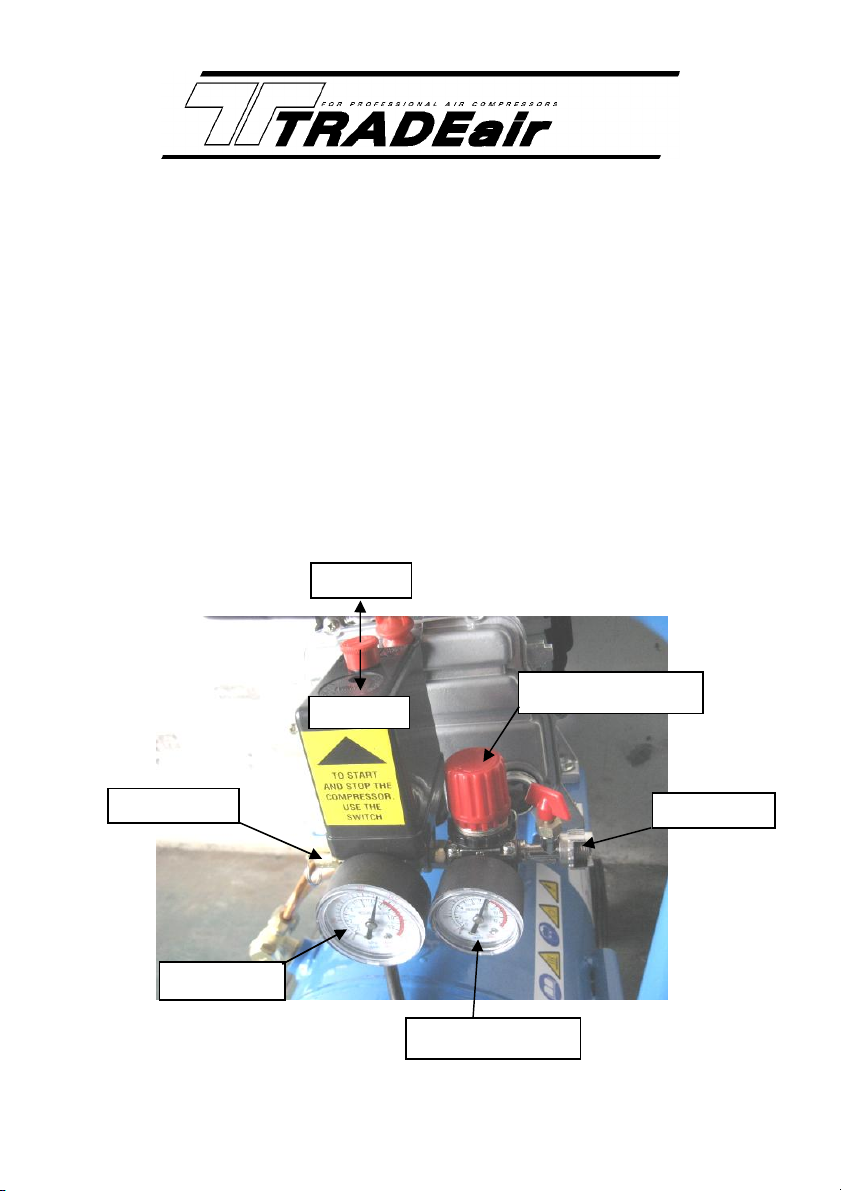

OPERATION

Thepressureinthetankiscontrolledbytheactionofthepressureswitchlocatedunderthe

pressureswitchcover

Whenthesetmaximumpressureisreachedthepressureswitchactivatesandthemotoris

turnedoff.Thepressurewillthendecreaseastheairisuseduntilthesetminimumis

reachedafterwhichthepressureswitchturnsthemotoronagain.

Theoperatorofthecompressorshouldbewellawarethatduringuseofthecompressorthe

motorwillcycle(startandstop)undertheinfluenceoftherisingorfallingpressureinthetank

andthemotorwillstartwithoutanywarning.

Themaximumandminimumpressuresarefactorysetandshouldnotbealtered.

Youcanutilizeeitherthedirectoutletand/ortheregulatedoutlet. Thepressureofthe

regulatedoutletcanbechangedbyturningthecontrolknob.Rotatetheknobclockwiseto

increasepressureandanti-clockwisetodecrease

Note: Outputfittingsmaydifferfromthoseshown

Turn

on

Turn

off

Tankgauge

Regulatorgauge

Pressureregulator

Air

outlet

Safety

valve

--------------------------------------------------------------------------------------------------------------

MAINTENANCE

Warning: Beforemaintenanceoperation,stoptheaircompressor,disconnecttheunit

fromthemainssupplyanddischargeallairintheairtank.

Daily

1

.

Chec

k

o

i

l

l

eve

l

b

e

f

or

e

ea

c

h

u

s

e

.

2.Drainthecondensationfromtheairreceiver.

3.Checkforairleaks.

Weekly

1.Removeairfilterelementandcleanorreplaceasrequired.

Monthly

1.Inspectnon-returnvalve(cleanorreplaceasrequired)

Caution: ensurethatairthetankisemptyforthisoperation.

2.Manuallytestthesafetyvalvebypullingthering.

ThreeMonthly

1.ChangeOil

2.Tightencylinderheadbolts.

3.Cleanandcheckvalveassembly,replacegaskets/valvesifwornordamaged.

RecommendcompressoroiluseSAE30fortemperaturesover10 anduseSAE10

below10 .

--------------------------------------------------------------------------------------------------------------

T

R

O

UB

L

E

S

A

N

D

R

E

M

E

D

I

E

S

Trouble Possiblecauses

Remedies

Motorunabletorun

orrunningslow

Faultinline,orvoltageinsufficient

⑵Powerwiretoothinortoolong

⑶Faultinpressureswitch

⑷Faultinmotor

⑸Stickingofmaincompressor

⑹Theinnerthermalprotectoronmotorcutoff

Checktheline

⑵Replacethewire

⑶Repairorreplace

⑷Repairorreplace

⑸Checkandrepair

⑹Compressorworkstoohard,turnoff

thepowerandwaitfor10-15minutesto

cooldownmotorandrestart.

Stickingofmain

compressor

Movingpartsburntduetoinsufficientoil

⑵Movingpartsdamaged,orstuckbyforeignbody

Checkcrankshaft,bearing,connecting

rod,piston,pistonring,etc.andreplace

ifnecessary

Excessivevibration

orabnormalnoise

Connectingpartloose

⑵Foreignbodygotintomaincompressor

⑶Pistonknockingvalveseat

⑷Movingpartsseriouslyworn

Checkandretighten

⑵Checkandcleanaway

⑶Replacewiththickerpapergasket

⑷Repairorreplace

Pressureinsufficient

ordischarge

capacitydecreased

Motorrunningtooslow

⑵Airfilterchokedup

⑶Leakageofsafetyvalve

⑷Leakageofdischargepipe

⑸Sealinggasketdamaged

⑹Valveplatedamaged,carbonbuilduporstuck

⑺Pistonringandcylinderwornordamaged

Checkandremedy

⑵Cleanorreplacethecartridge

⑶Checkandadjust

⑷Checkandrepair

⑸Checkandreplace

⑹Replaceandclean

⑺Repairorreplace

Excessiveoil

consumption

Oilleveltoohigh

⑵Breathpipechokedup

⑶Pistonringandcylinderwornordamaged

Keepthelevelwithinsetrange

⑵Checkandclean

⑶Repairorreplace

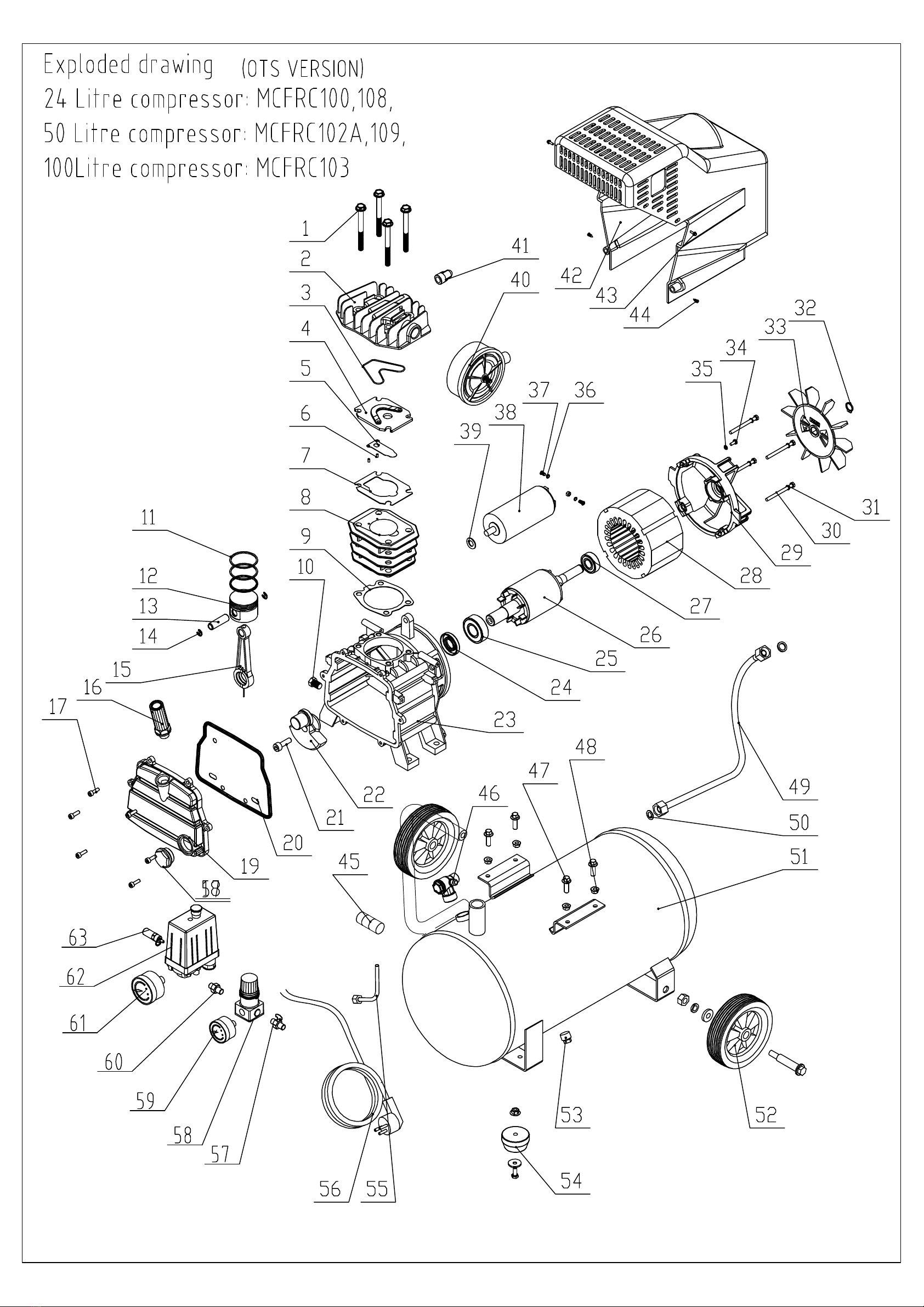

PARTLISTOFDIRECTDRIVECOMPRESSOR

24L:MCFRC100,108;50L:MCFRC102A,109;100L:MCFRC103

OTSVERSION:10TH,MARCH,2012

NO. NAME QTY NO. NAME QTY

1BoltM8 105 4 30 Springwasher5 4

2Cylinderhead 1 31 BoltM5 95 4

3ORing 1 32 CirclipΦ14 1

4Valveplate 1 33 MotorFan 1

5Inletvalve 1 34 ScrewM4 10 1

6Locating pinΦ36 2 35 Toothwasher4 1

7Valvegasket δ0.8 1 36 ScrewM3 6 2

8A Cylinder Φ42forMCFRC100,108 1 37 Springwasher3 2

8B Cylinder Φ48forMCFRC102A,109,103 1 38A Capacitor15UFforMCFRC100,108 1

9 Cylindergasket δ0.8 1 38B Capacitor30UFforMCFRC102A,109,103 1

10 BoltM12 15 1 39 Toothwasher8 1

11A Pistonring Φ42forMCFRC100,108 1 40 Airfilter 1

11B Pistonring Φ48forMCFRC102A,109,103 1 41 Right-angleconnecterRp3/8 1

12A Piston Φ42forMCFRC100,108 1 42 Fan cover 1

12B Piston Φ48forMCFRC102A,109,103 1 43 ScrewM5 10 2

13A PistonPinforMCFRC100,108 1 44 ScrewST3.4 16 2

13B PistonPinforMCFRC102A,109,103 1 45 Handle Grip 1

14 Circlip Φ12 2 46 One-wayvalve 1

15A Connecting rodforMCFRC100,108 1 47 BoltM8 25 4

15B Connecting rodforMCFRC102A,109,103 1 48 NutM8 4

16 Breathpipe 1 49 DischargePipe 1

17 ScrewM5 14 6 50 Dischargegasket 2

18 Oil levelerM27 1.5 1 51 Tank36liter1

19 Crankcasecover 1 52A 4.5" wheelkitsforMCFRC100,108 2

20 Rubbergasket 1 52B 6"wheelkitsforMCFRC102A,109 2

21 ScrewM8 22-left 1 52C 8"wheelkitsforMCFRC103 2

22A Crank17.5mmforMCFRC100,108 1 53 DrainValve 1

22B Crank20mmforMCFRC102A,109,103 1 54 Rubberfootkit 2

23 Crankcase 1 55 Releasepipe 1

24 Sealingring20 40 7 1 56 southafricaPowercord 1

25 Bearing6204-2RZ 1 57 1/4" need valvewithnut 1

26A RotorforMCFRC100,108 1 58 1/4"-1/4"miniregulator 1

26B RotorforMCFRC102A,109,103 1 59 40mmreargauge 2

27 Bearing6202-2RZ 1 60 1/4" -1/4"connector 2

28A statorforMCFRC100,108 1 61 50mmreargauge

28B statorforMCFRC102A,109,103 1 62 8Bar4way1/4"pressureswitch 1

29 Motorbracket 1 63 1/4",8Barsafetyvalve 1

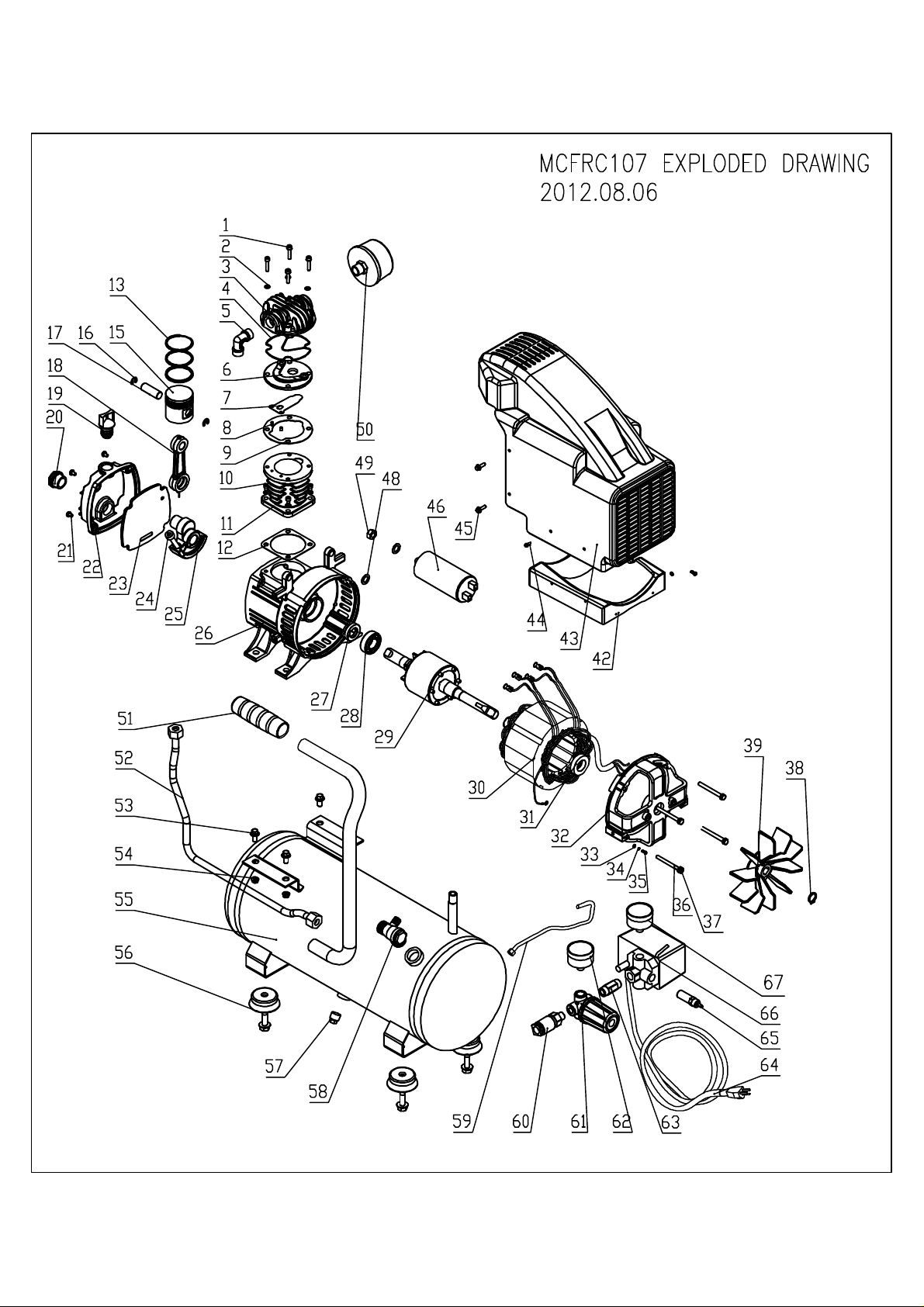

MCFRC107PARTLIST

NO.Name Unit QTY NO.Name Unit QTY

1 BoltM6 35 PC 4 34SpringWasher4 PC 1

2 SpringWasher6 PC 8 35ScrewM4 8PC 1

3 Cylinderhead PC 1 36SpringWasher5 PC 4

4 CylinderHeadSealing PC 1 37BoltM5 80 PC 4

5 E-BowConnector PC 1 38Clip Φ14 PC 1

6 ValvePlate SET 1 39Fan PC 1

7 InletValve PC 1 42PlasticBottomcover PC 1

8 Valvepin PC 2 43Fan cover PC 1

9 ValveGasket PC 1 44ScrewM4 8PC 4

10HelxBoltM6 20 PC 4 45BoltM5 16 PC 4

11Cylinder PC 1 46Capacitor PC 1

12CylinderGasket PC 1 48ToothWasher8 PC 1

13Piston RingSet SET 1 49Nut M8 PC 1

15Piston PC 1 50AirFilter PC 1

16HoleClip Φ12 PC 2 51HandelGrip PC 1

17Piston Pin PC 1 52DischargePipe SET 1

18ConnectRod PC 1 53BoltM8 30 PC 4

19OilBreather PC 1 54Nut M8 PC 4

20OilLeveler PC 1 55PressureTank6LT PC 1

21BoltM5 16 PC 4 56Pad SET 4

22CrankcaseCover PC 1 57DrainValve PC 1

23CrankcaseSealing PC 1 58CheckValve SET 1

24MoltM10forCrank PCS 1 59ReleasePipe SET 1

25Crank PC 1 60OutletValve PC 1

26Crankcase PC 1 61Regulator PC 1

27OilSealing PC 1 62PressureGuage40 PC 1

28Bearing 6003-2RS PC 1 63ConnectorR1/4 PC 1

29Motor PC 1 64Powercord PC 1

30Stator SET 1 65SaftyValve PC 1

31Bearing 6202-2RS PC 1 66PressureSwitch PC 1

32MotorBracket PC 1 67PressureGuage50 PC 1

33ToothWasher4 PC 1

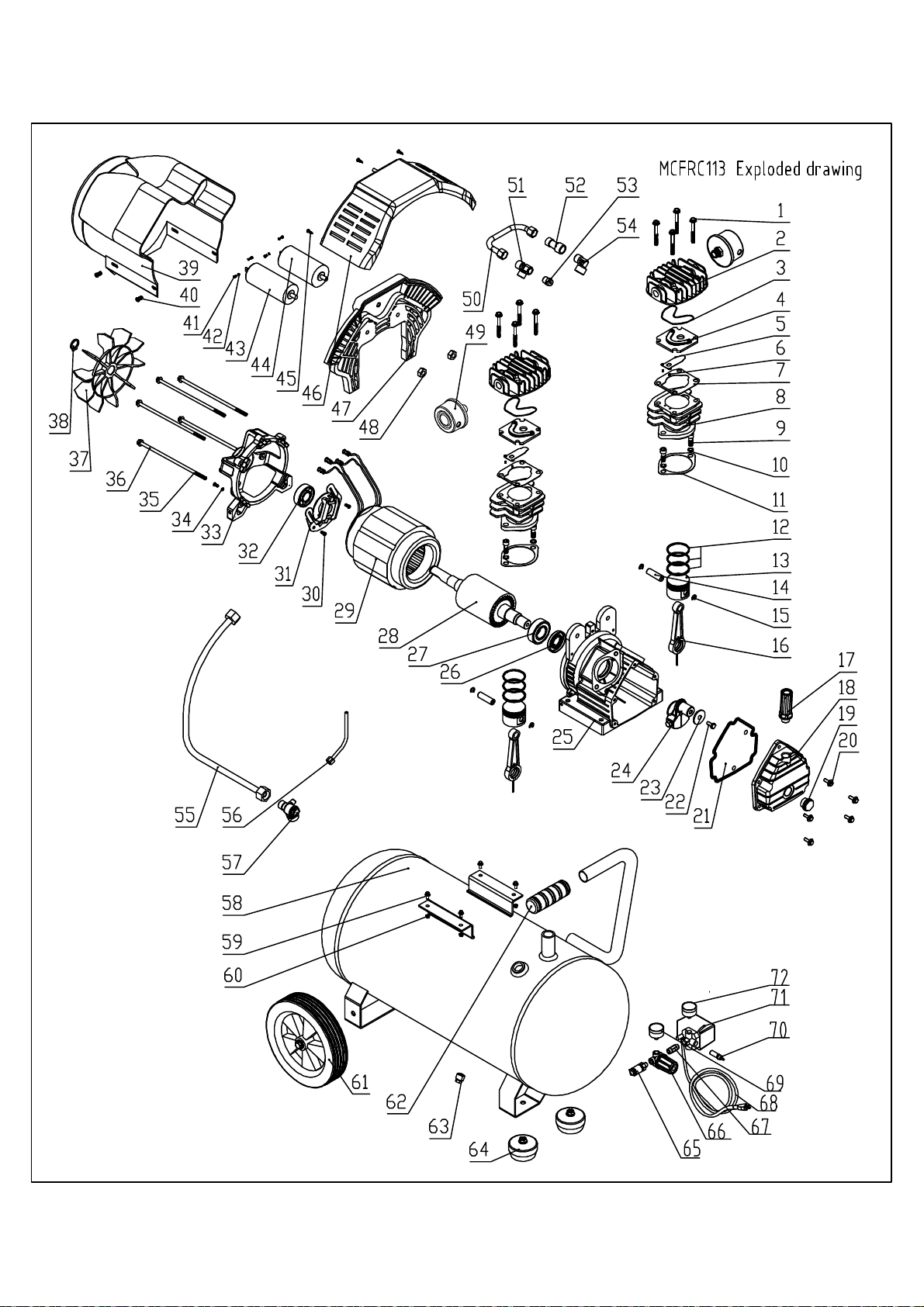

MCFRC113

PART

LIST

NO Part Unit Qty NO Part Unit Qty

1BoltM8x40 PC 8 37 fan PC 1

2cylinderhead PC 2 38 circlip20 PC 1

3ORing PC 2 39 Maincover PC 1

4

valve

plate

subassembly SET 2 40 Srew M5x14 PC 4

5valveslice δ0.3 PC 2 41 Srew M3x6 PC 4

6locatingpin3×6PC 4 42 Springwasher3 PC 4

7valvegasket δ0.8 PC 2 43 StartingcapacitancePC 1

8cylinder 42( 47) PC 2 44 Running capacitancePC 1

9boltM8x25 PC 4 45 Srew ST3.9x15 PC 3

10 SpringWasher 8 PC 4 46 Head cover PC 1

11 cylindergasket δ0.8 PC 2 47 Coversupport PC 1

12 pistonring 42( 47) SET 2 48 nut8 PC 2

13 piston 42( 47) PC 2 49 Airfilter SET 2

14

piston

pin

12×35(38.5) PC 2 50 Connectpipe SET 1

15 circlip 14 PC 4 51 Tree-wayconnectorA PC 1

16 connectingrod PC 2 52 Tree-wayconnectorB PC 1

17 breathpip SET 1 53 Leakvalve PC 1

18 crankcasecover PC 1 54 right-angleconnector PC 1

19 oil leveler SET 1 55 DischargePipe PC 1

20 boltM5x16 PC 5 56 releasepipe SET 1

21 rubbergasket PC 1 57 check valve PC 1

22 screwM8×20 PC 1 58 Tank PC 1

23 enlargewasher8 PC 1 59 BoltM8x40 PC 4

24 crank PC 1 60 nut8 PC 4

25 crankcase PC 1 61 wheelassembly SET 2

26 sealingring24×47×8 PC 1 62 handlegrip PC 1

27 brearing 6205 PC 1 63 drainvalve SET 1

28 rotor SET 1 64 footpadassembly SET 2

29 stator SET 1 65 OutletValve SET 1

30 screwM4×10 PC 2 66 Regulator PC 1

31 CentrifugalswitchL22 SET 1 67 ConectorR1/4 PC 1

32 brearing 6204 PC 1 68 Power cord 3G1.5mm2 PC 1

33 motorbracket PC 1 69 Pressure Guage 40mm PC 1

34 ToothWahser 4 PC 1 70 Safetyvalve1/4" 9Bar PC 1

35 spring washer6 PC 4 71 Pressure switch8Bar PC 1

Distributed

by

L>ool

&MachineryDistributorsLimited

6

KyalamiRd,Westmead3610,P.O.Box15313,Westmead3608,

Telephone:031-7176800,Fax:031-7176868

This manual suits for next models

6

Table of contents

Other TRADEair Air Compressor manuals