8

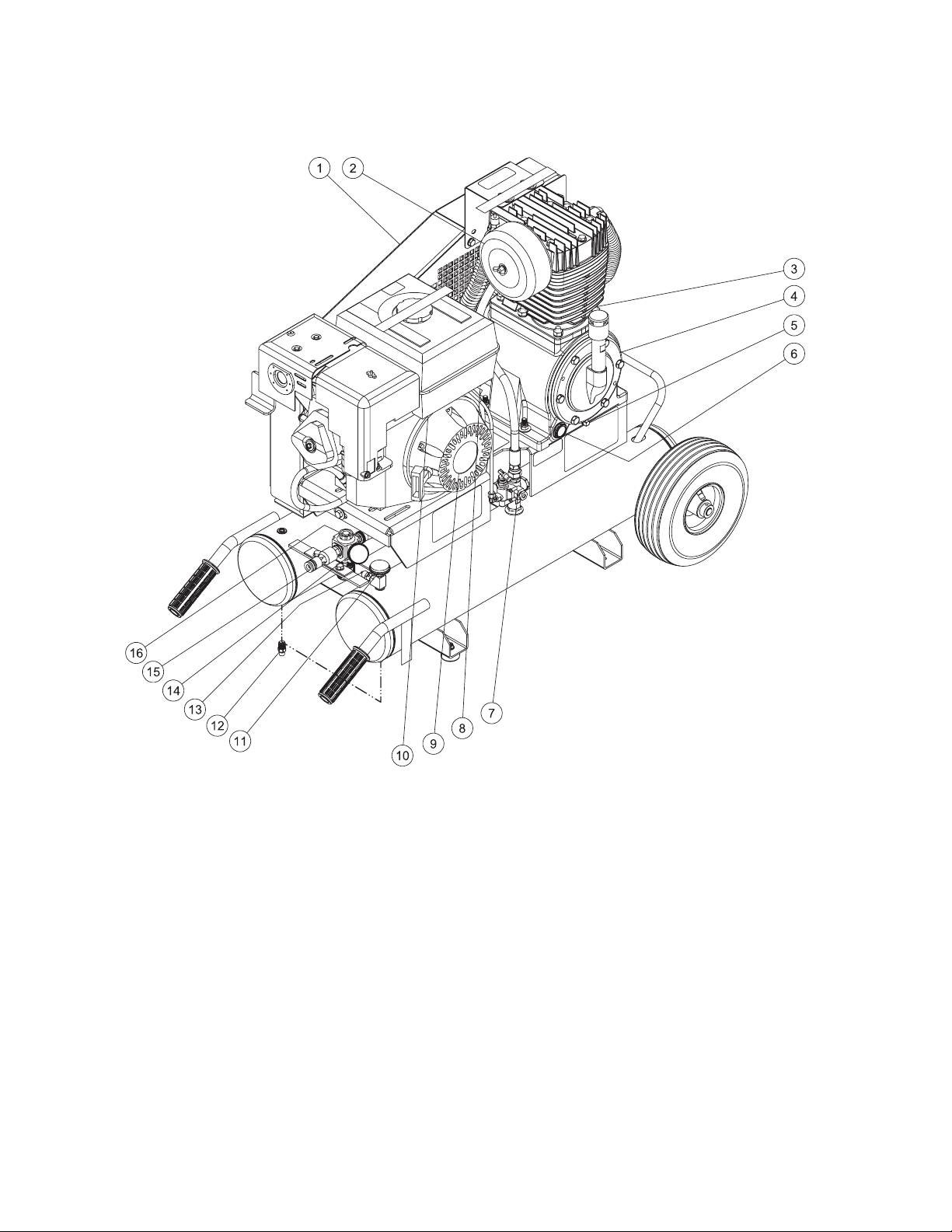

SAFETY RELIEF VALVE: This valve is designed to pre-

vent system failures by relieving pressure from the sys-

tem when the compressed air reaches a predetermined

level. The valve is preset by the manufacturer and

must not be modied in any way. To verify the valve is

working properly, pull on the ring. Air pressure should

escape. When the ring is released, it will reset.

PILOT VALVE: When the toggle is in the upright posi-

tion, all air from the air compressor is vented through

the discharge mufer. This gives an easy start feature.

For normal operation, the toggle is in the 90° position.

AIR INTAKE FILTER: This lter is designed to clean air

coming into the pump. To ensure the pump continu-

ally receives a clean, cool, dry air supply this lter must

always be clean and ventilation opening free from ob-

structions. Replace lter element when necessary.

OIL FILL PORT/VENT: Pour oil into the Oil Fill Port/Vent

when required.

OIL SIGHT GLASS: The Oil Sight Glass displays the oil

level in the pump. The oil level should be at the center

of the Oil Sight Glass. If low, add SAE 30W non-deter-

gent oil.

AIR COMPRESSOR PUMP (Single Stage): To compress

air, the pistons move up and down in the cylinders. On

the downstroke, air is drawn in through the air intake

valves while the exhaust valves remain closed. On the

upstroke, air is compressed, the intake valves close

and compressed air is forced out through the exhaust

valves, into the discharge line, through the pilot valve

and into the air tank.

AIR COMPRESSOR PUMP (Two Stage): A two stage

compressor pump uses two different size cylinders with

the intake valve of the second smaller cylinder linked

to the exhaust valve of the rst larger cylinder. On the

down stroke of the large cylinder, air is drawn through

the intake valve while the exhaust valve remains closed.

On the upstroke, air is compressed, the intake valve

closes and compressed air is forced out through the ex-

haust valve, into the inter cooler and through the intake

valve of the second smaller cylinder on its down stroke.

On the upstroke of the smaller cylinder, the intake valve

closes and the compressed air is compressed a second

time and forced out the exhaust valve into the discharge

line, through the tank check valve and into the air tank.

AIR TANK PRESSURE GAUGE: The air tank pressure

gauge indicates the reserve air pressure in the air tank (s).

PRESSURE REGULATOR: The air pressure coming

from the air tank is controlled by the regulator knob.

Turn the pressure regulation knob clockwise to increase

discharge pressure, and counterclockwise to decrease

discharge pressure.

OUTLET PRESSURE GAUGE: The outlet pressure

gauge indicates the air pressure available at the outlet

side of the regulator. This pressure is controlled by

the regulator and is always less or equal to the air tank

pressure.

AIR TANK DRAIN VALVE: The drain valve is used to

remove moisture from the air tank(s) after the air com-

pressor is shut off.

To open the drain valve, turn the knob coun-

terclockwise.

OIL FILL PORT

OIL SIGHT GLASS