Trademark WEED EATER GTI 15T User manual

IMPORTANT

MANUAL

Do

Not

Throw

Away

TRADEMARK*

A

WARNING:

Read

the

Operator’s

Manual

and

Follow

All

Warnings

and

Safety

Instructions.

Failure

To

Do

So

Can

Result

in

Serious

Injury.

OPERATOR’S

MANUAL

MODEL;

Gxr

15

T

GAS

POWERED

TRIMMER

4;

^CUSTOMER

4

ASSISTANCE

i-800-554-6723

I

SEE

BACK

COVER

FOR

DETAILS!

^

Always

Wear

Eye

Protection

TABLE

OF

CONTENTS

WARNINGS

AND

SAFETY

INSTRUCTIONS

...

3

KNOWYOURUNIT.

5

ASSEMBLY.

6

ACCESSORIES

.

8

FUELING

YOUR

ENGINE.

9

STARTING

YOUR

ENGINE.10

USING

YOUR

TRIMMER.

GENERAL

MAINTENANCE

.15

CUSTOMER

ASSISTANCE

SERVICE...

Back

Cover

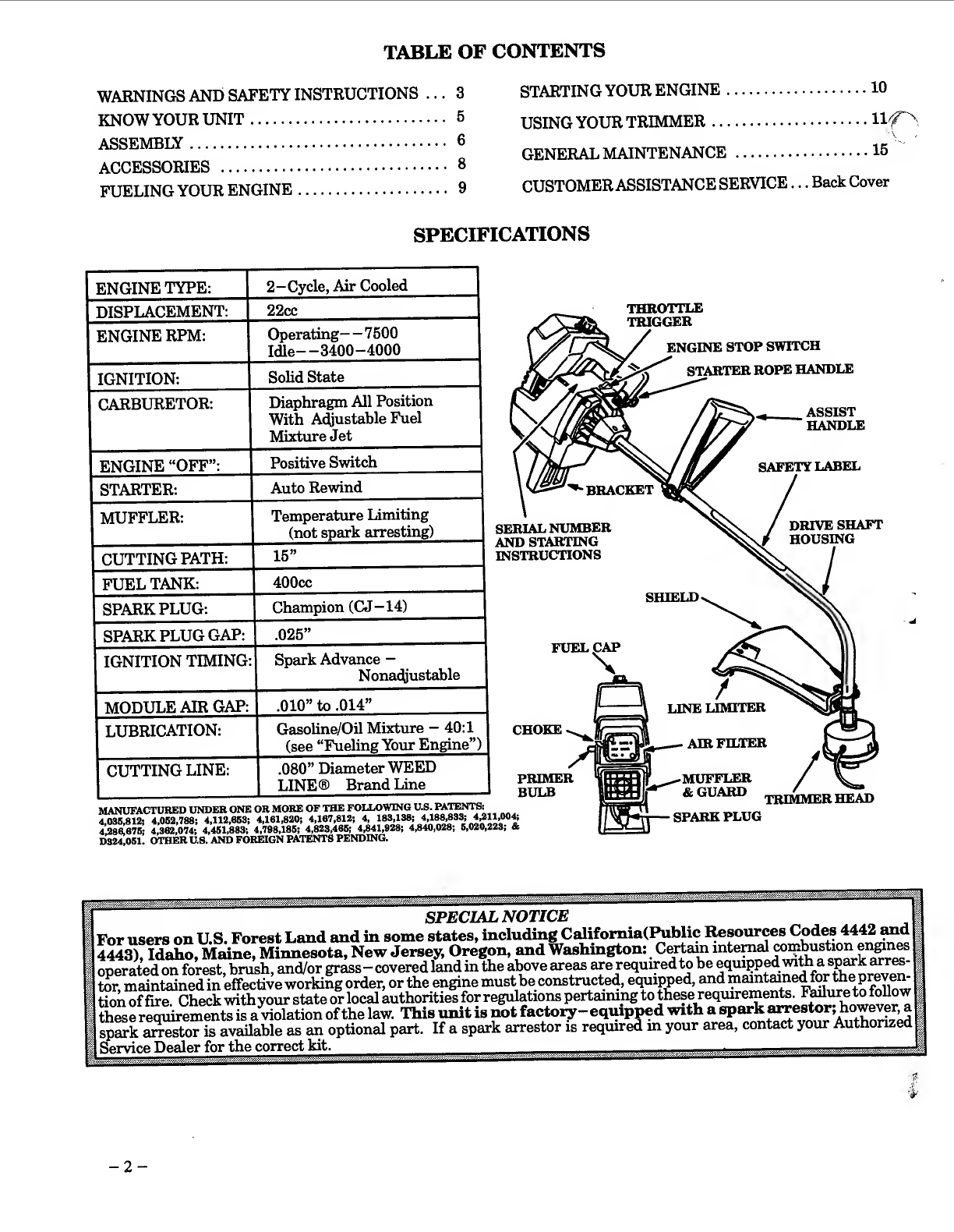

SPECIFICATIONS

ENGINE

TYPE:

DISPLACEMENT:

ENGINE

RPM:

IGNITION:

_

CARBURETOR:

ENGINE

“OFF”:

STARTER:

_

MUFFLER:

CUTTING

PATH:

FUEL

TANK:

SPARKPLUG:

SPARK

PLUG

GAP:

IGNITION

TIMING:

MODULE

AIR

GAP:

LUBRICATION:

|

CUTTING

LINE:

2—Cycle,

Air

Cooled

_

22cc

__

Operating—

7500

Idle—3400-4000

_

Solid

State

_

Diaphragm

All

Position

With

Adjustable

Fuel

M

ixture

Jet

_

Positive

Switch

_

Auto

Rewind

_

Temperature

Limiting

(not

spark

arresting)

_

15”

_

400cc

_

Champion

(CJ-14)

_

.025”

_

Spark

Advance

—

Nonadjustable

.010”

to

.014”

_

Gasoline/Oil

Mixture

-

40:1

(see

“Fueling

Your

Engine”)

.080”

Diameter

WEED

LINE®

Brand

Line_

THROTTLE

TRIGGER

ENGINE

STOP

SWITCH

y

STARTER

ROPE

HANDLE

ASSIST

HANDLE

■

B

RACKET

SERIAL

NUMBER

AND

STARTING

INSTRUCTIONS

SAFETY

LABEL

DRIVE

SHAFT

HOUSING

SHIELD.

FUEL

CAP

CHOKE

PRIMER

BULB

MANUFACTURED

UNDER

ONE

OR

MORE

OF

THE

FOLLOWING

U.S.

PATENTS:

4,03S,912;

4,062,789;

4,112,863;

4,161,820;

4,187,812;

4,

183,138;

4

286.676;

4,362,074;

4,461,983;

4,798,186;

4,823,466;

4,841,929;

4,940,028;

6,020,223;

&

D324,061.

OTHER

U.8.

AND

FOREIGN

PATENTS

PENDING.

/

^

LINE

LIMITER

AIR

FILTER

^

MUu'P'LiEjR

&

GUARD

,

SPARK

PLUG

TRIMMER

HEAD

A

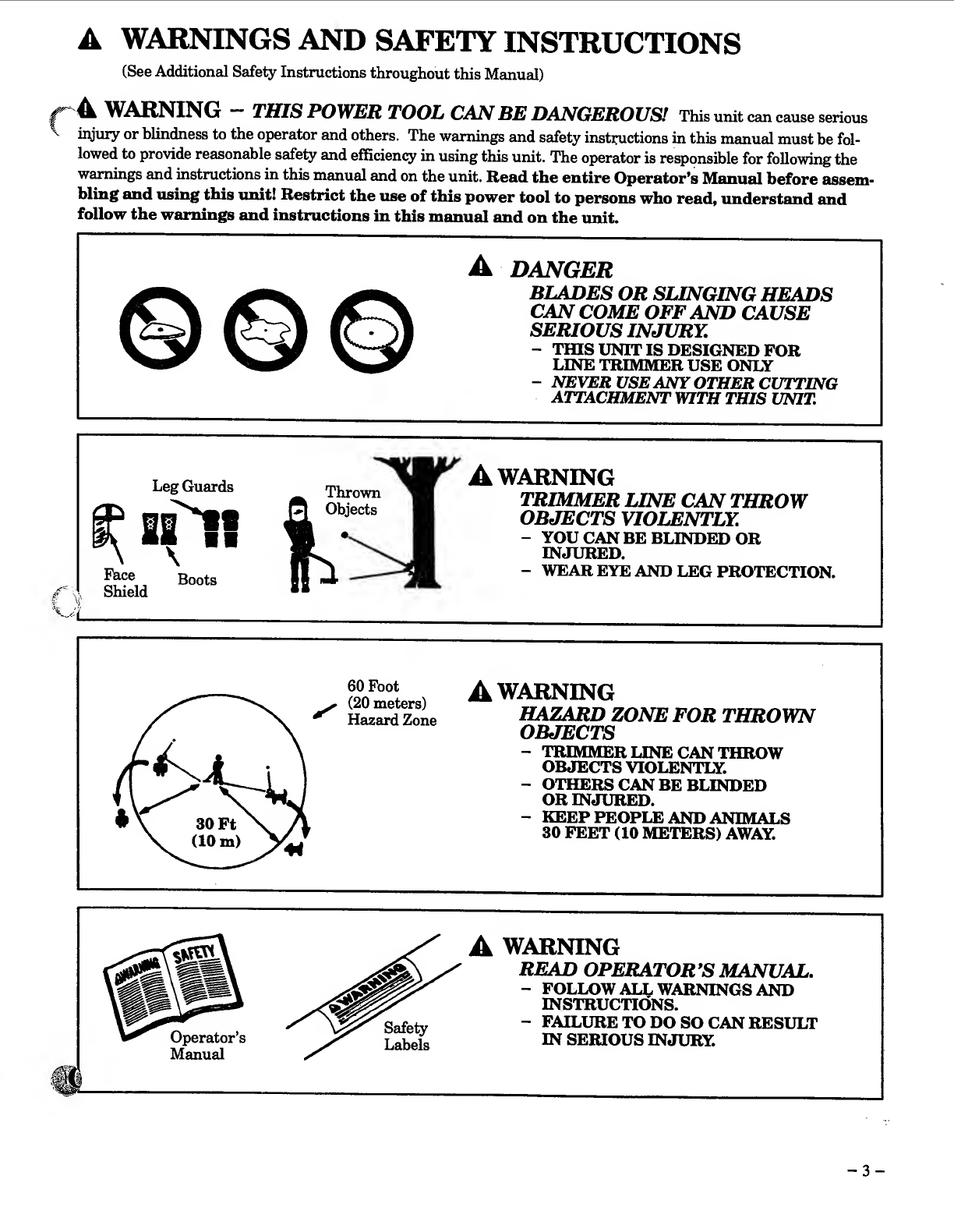

WARNINGS

AND

SAFETY

INSTRUCTIONS

(See

Additional

Safety

Instructions

throughout

this

Manual)

^^ARNING

■

“

THIS

POWER

TOOL

CAN

BE

DANGEROUS!

This

unit

can

cause

serious

injury

or

hhndness

to

the

operator

and

others.

The

warnings

and

safety

instiructions

in

this

manual

must

be

fol¬

lowed

to

provide

reasonable

safety

and

efficiency

in

using

this

unit.

The

operator

is

responsible

for

following

the

warnings

and

instructions

in

this

manual

and

on

the

unit.

Read

the

entire

Operator’s

Manual

before

assem¬

bling

and

using

this

unit!

Restrict

the

use

of

this

power

tool

to

persons

who

read,

understand

and

follow

the

warnings

and

instructions

in

this

manual

and

on

the

unit.

A

DANGER

BLADES

OR

SUNGING

HEADS

CAN

COME

OFF

AND

CAUSE

SERIOUS

INJURY.

-

Tins

UNTTIS

DESIGNED

FOR

LINE

TRIMMER

USE

ONLY

-

NEVER

USE

ANY

OTHER

CUTTING

ATTACHMENT

WITH

THIS

UNIT.

Face

Shield

Leg

Guards

siW

Thrown

Objects

Boots

A

WARNB^G

TRIMMER

LINE

CAN

THROW

OBJECTS

VIOLENTLY.

-

YOU

CAN

BE

BLINDED

OR

INJURED.

-

WEAR

EYE

AND

LEG

PROTECTION.

WARNINGS

AND

SAFETY

INSTRUCTIONS....(Contmued)

A

OPERATOR

SAFETY

•

Always

wear

safety

eye

protection.

•

^ways

wear

long

pants,

boots

and

gloves.

Wear¬

ing

s^ety

leg

guards

is

recommended.

Do

not

go

barefoot

or

wear

sandals,

jewelry,

short

pants,

loose

clothing,

or

clothing

with

loosely

hanging

ties,

straps,

tassels,

etc.;

they

can

be

caught

in

moving

parts.

•

Secure

hair

so

it

is

above

shoulder

length.

•

Do

not

operate

this

unit

when

you

are

tired,

ill,

or

under

the

influence

of

alcohol,

drugs,

or

medica¬

tion.

•

Wear

hearing

protection

if

you

use

this

unit

for

more

than

1—1/2

hours

per

day.

•

Never

start

or

run

the

engine

inside

a

closed

room

or

building.

Breathing

exhaust

fumes

can

kill.

•

Keep

handles

free

of

oil

and

fuel.

A

UNITIMAINTENANCE

SAFETY

•

Look

for

and

replace

damaged

or

loose

parts

be¬

fore

each

use.

Look

for

and

repair

fuel

leaks

before

use.

Keep

the

unit

in

good

working

condition.

•

Replace

trimmer

head

parts

that

are

chipped,

cracked,

broken,

or

damage

in

any

other

way

be¬

fore

using

the

unit.

•

Use

only

.080”

diameter

WEED

EATER®

brand

line.

Never

use

wire,

rope,

string,

etc.

•

Make

sure

the

unit

is

assembled

correctly

as

listed

in

this

manual.

•

Make

carburetor

adjustments

with

the

lower

end

supported

to

prevent

the

trimmer

line

from

con¬

tacting

any

object.

•

Keep

others

away

when

making

carburetor

ad¬

justments.

•

Disconnect

the

spark

plug

before

performing

maintenance

except

carburetor

adjustments.

•

Use

only

genuine

WEED

EATER

accessories

and

replacement

parts

as

recommended

for

this

unit.

A

FUEL

SAFETY

•

Mix

and

pour

fuel

outdoors.

•

Keep

away

from

sparks

or

flames.

•

Use

a

container

approved

for

fuel.

•

Do

not

smoke

or

allow

smoking

near

fuel

or

the

unit

or

while

using

the

unit.

•

Wipe

up

all

fuel

spills

before

starting

engine.

•

Move

at

least

10

feet

(3

meters)

away

from

fueling

site

before

starting

engine.

▲

•

Stop

engine

before

removing

fuel

cap.

v

•

Empty

the

fuel

tank

before

storing

the

unit.

Use

up

fuel

left

in

the

carburetor

by

starting

the

en¬

gine

and

letting

the

engine

run

until

it

stops.

•

Store

unit

and

fuel

in

an

area

where

fuel

vapors

cannot

reach

sparks

or

open

flames

from

water

heaters,

electric

motors

or

switches,

furnaces,

etc.

A

CUTTING

SAFETY

•

Inspect

the

area

to

be

cut

before

each

use.

Remove

objects

(rocks,

broken

glass,

nails,

wire,

string,

etc.)

which

can

be

thrown

or

become

entangled

in

the

trimmer

head.

•

Keep

others

including

children,

animals,

bystand¬

ers

and

helpers

outside

the

60

foot

(20

meter)

Haz¬

ard

Zone.

Stop

the

engine

immediately

if

you

are

approached.

•

Always

keep

the

engine

on

the

right-hand

side

of

your

body.

•

Hold

the

unit

firmly

with

both

hands.

•

Keep

firm

footing

and

balance.

Do

not

over¬

reach.

•

Keep

the

trimmer

head

below

waist

level.

•

Do

not

raise

the

engine

above

your

waist.

•

Keep

all

parts

of

your

body

away

from

trimmer

head

and

muffler

when

engine

is

running.

•

Cut

from

your

left

to

your

right.

•

Use

only

forjobs

explained

in

this

manual

A

TRANSPORTING

AND

STORAGE

•

Stop

the

unit

before

carrying.

•

Keep

the

muffler

away

from

yoim

body.

•

Mow

the

engine

to

cool,

and

secure

the

unit

be¬

fore

storing

or

transporting

in

a

vehicle.

•

Empty

the

fuel

tank

before

storing

or

transport-

ing

the

unit.

Use

up

fuel

left

in

the

carburetor

by

starting

the

engine

and

letting

the

engine

run

un¬

til

it

stops.

•

Store

unit

and

fuel

in

an

area

where

fiiel

vapors

cannot

reach

sparks

or

open

flames

from

water

heaters,

electric

motors

or

switches,

furnaces,

etc.

•

Store

unit

so

line

limiter

cannot

accidentally

cause

injury.

The

unit

can

be

hung

by

the

bracket

below

the

engine

or

by

drive

shaft

housing.

•

Store

the

unit

out

of

the

reach

of

children.

Ifsituatio^

occur

which

are

not

covered

in

this

manual,

use

care

and

good

judgment.

If

you

need

assistance,

contact

your

Authorized

Service

Dealer

or

the

CUSTOMER

ASSISTANCE

HOTLINE,

1

-800

-554-6723.

SAFETY

NOTICE

must

Ytmnitrki*

r*irkQoi«r

_

j

ja*

_

powcr

tools

On

8.

Gontmu&l

snd.

rGgulai*

basis

A.

INTRODUCTION

Your

Trimmer

is

a

versatile

product

developed

for

large

lawns

and

to

make

short

work

of

a

variety

of

lawn

care

tasks

—

trimming,

scalping,

mowing,

and

sweeping.

Special

Features

Include:

•

ComforTouch®

Anti-vibration

Handle

•

All—Position

Carburetor

•

Adjustable

Assist

Handle

•

TAP-N-GO®

Cutting

Head

•

15”

Cutting

Path

B.

UNPACKING

INSTRUCTIONS

1.

After

removing

the

contents

from

the

carton,

check

parts

against

the

Carton

Contents

list.

2.

Examine

the

parts

for

damage.

Do

not

use

damaged

parts.

3.

Notify

your

WEED

EATER

dealer

immediately

if

apart

is

missing

or

damaged.

NOTE:

Your

unit

has

been

shipped

with

a

plastic

shipping

i^ard

over

the

primer

bulb

(see

Specifications”

for

location).

Remove

and

discard

the

plastic

shipping

guard.

NO'l'K;

It

is

normal

to

hear

the

fuel

filter

rattle

in

£m

empty

fuel

tank.

C.

C

ARTON

CONTENTS

1.

Engine

1

2

.

Drive

Shaft

Assembly

w/Safety

Label

1

3.

Trimmer

Head

Shield

1

4.

Line

Trimmer

Head

1

5.

Assist

Handle

1

-

-

Operator’s

Manual

1

—

Loose

Parts

Bag

1

LOOSE

PARTS

BAG

CONTENTS:

6.

Hex

Wrench

(not

shown)

1

7.

3.2

oz.

40:1

Engine

Oil

(not

shown)

1

A.

Screw

2

B.

Screw

2

C.

Screw

1

D.

Dust

Cup

1

E.

Bracket

1

F.

Wing

Nut

1

G.

Flat

Washer

1

H.

Lock

Nut

2

iTflARDWARE

CHART

SHOWN

ACTUAL

SIZE

Refer

to

the

hardware

reference

letters

below

during

assembly.

^TE:

This

Hardware

is

packaged

in

the

Plastic

Bag.

ASSEMBLY

(If

tool

is

received

assembled,

repeat

all

steps

in

this

section

to

be

sure

assembly

is

correct

and

is

ad¬

justed

for

the

operator.)

PREPARATION

This

Manual

is

designed

to

help

you

assemble

the

tool

and

to

provide

its

s^e

operation.

It

is

important

that

you

read

the

entire

manual

to

become

famihar

with

the

tool

before

you

bemn

assembly.

If

you

have

any

questions

or

need

further

assistance,

call

our

CUSTOMER

ASSISTANCE

HOTLINE

at

1-800-554-6723.

1.

Read

your

Operator’s

Manual

2.

Tools

you

will

need:

-

Hex

Wrench

provided

with

the

tool.

-

Adjustable

Wrench

-

Standard

Screwdriver

ASSEMBLY

STEPS

(Refer

to

illustrations)

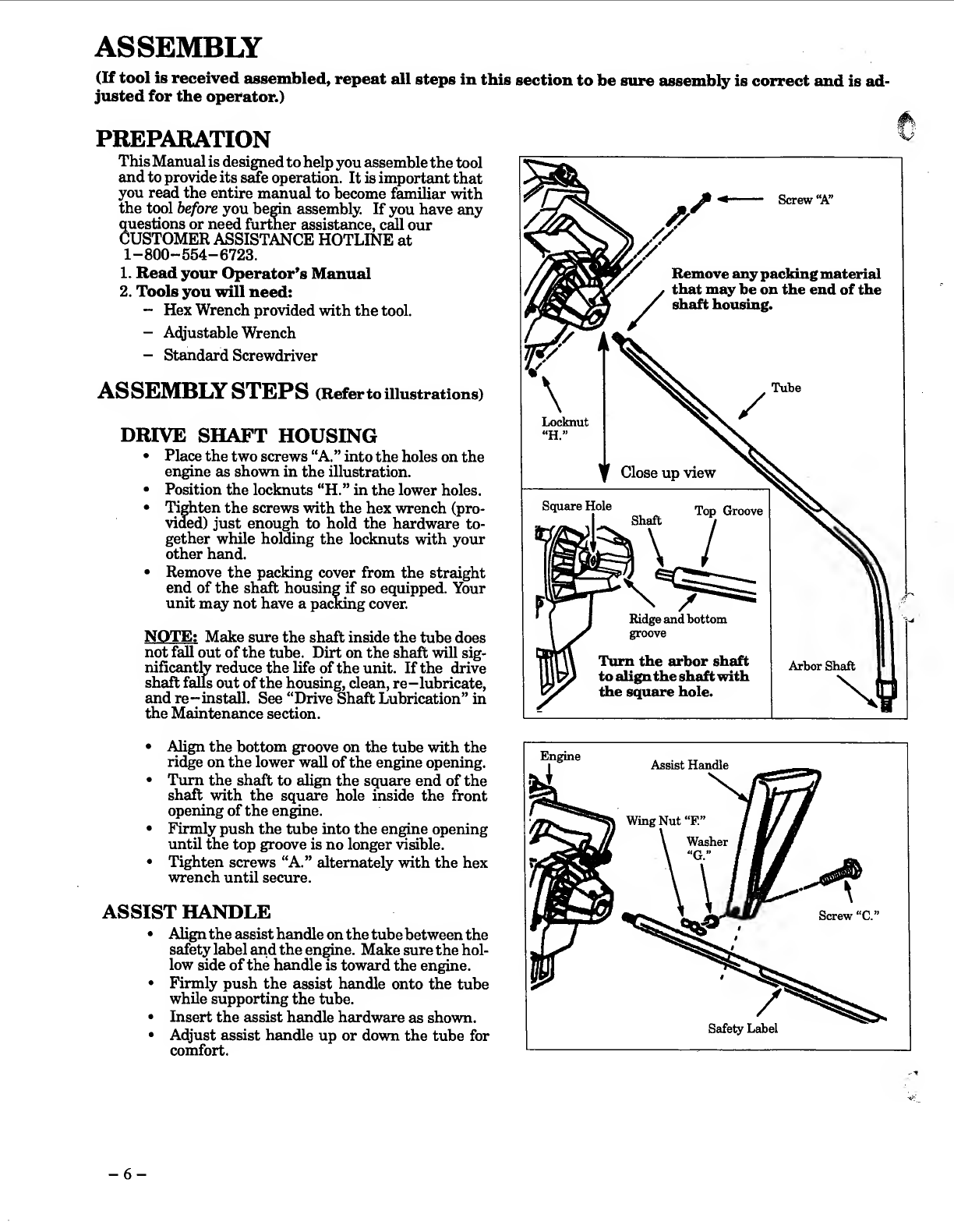

DRIVE

SHAFT

HOUSING

•

Place

the

two

screws

“A.

”

into

the

holes

on

the

engine

as

shown

in

the

illustration.

•

Position

the

locknuts

“H.”

in

the

lower

holes.

•

Tighten

the

screws

with

the

hex

wrench

(pro¬

vided)

just

enough

to

hold

the

hardware

to¬

gether

while

holding

the

locknuts

with

your

other

hand.

•

Remove

the

packing

cover

from

the

straight

end

of

the

shaft

housing

if

so

equipped.

Your

unit

may

not

have

a

pacMng

cover.

NOTE:

Make

srnre

the

shaft

inside

the

tube

does

not

fall

out

of

the

tube.

Dirt

on

the

shaft

will

sig¬

nificantly

reduce

the

life

of

the

unit.

If

the

drive

shaft

falls

out

of

the

housing,

clean,

re-lubricate,

and

re-install.

See

“Drive

Shaft

Lubrication”

in

the

Maintenance

section.

%J

•

Align

the

bottom

groove

on

the

tube

with

the

ridge

on

the

lower

wall

of

the

engine

opening.

•

Turn

the

shaft

to

align

the

square

end

of

the

shaft

with

the

square

hole

inside

the

front

opening

of

the

engine.

•

Firmly

push

the

tube

into

the

engine

opening

until

the

top

groove

is

no

longer

visible.

•

Tighten

screws

“A.”

alternately

with

the

hex

wrench

until

secure.

ASSIST

HANDLE

•

Align

the

assist

handle

on

the

tube

between

the

safety

label

and

the

en^ne.

Make

sure

the

hol¬

low

side

of

the

handle

is

toward

the

engine.

•

Firmly

push

the

assist

handle

onto

the

tube

while

supporting

the

tube.

•

Insert

the

assist

handle

hardware

as

shown.

•

Adjust

assist

handle

up

or

down

the

tube

for

comfort.

-

6

-

TRIMMER

HEAD

•

Place

the

dust

cup

“D.

”

over

the

hex

nut

on

the

bottom

of

the

tube

-

see

illustration.

The

hex

nut

should

fit

completely

inside

the

dust

cup.

•

Hold

the

dust

cup

with

a

wrench

to

keep

the

ar¬

bor

shaft

from

turning.

•

Thread

the

trimmer

head

onto

the

arbor

shaft

against

the

dust

cup

and

hand

tighten

firmly.

NOTE:

Unless

trimmer

head

is

tightened

ade¬

quately,

it

can

unthread

when

engine

is

started

or

stopped.

If

this

situation

occurs,

reinstall

the

trimmer

head

and

tighten

more

securely.

SHIELD

AT

TACHMENT

^

.

AWARNING

The

shield

must

be

properly

installed.

The?

shield

provides

partial

protection

from

the

risk

of

thrown

objects

to

the

operator

and

others

ntir^

is

equipped

with

a

line

limiter

which

cuts

excess

line

to

th

e

proper

length.

AWARNING

^

Do

not

alter

or

remove

the

bracket

tab.

When

in¬

stalled

correctly,

the

bracket

tab

ensures

proper

shield

alignment.

Failure

to

install

the

shield

in

position

shown

in

illustration

can

result

in

seri-

ous

injury

to

the

operator.

CAUTION;

I

The

line

limiter

(on

the

underside

of

the

shield)

is

sharp

and

can

cut

you.

!

•

Match

the

tab

on

bracket

“E.”

with

the

hole

in

?

the

tube.

•

Attach

the

shield

to

the

bracket

with

the

two

screws

“B.”

Tighten

evenly

and

securely.

NOTE

;

Although

a

screwdriver

slot

is

pro¬

vided

in

screws

it

is

easier

to

install

the

screws

with

a

wrench

or

socket.

OPERATING

POSITION

•

Before

starting

the

engine,

stand

as

shown

and

check

for

the

following:

•

Left

arm

fully

extended,

hand

holding

assist

handle.

•

Right

arm

shghtly

bent,

hand

holding

top

handle,

fingers

on

throttle

trigger.

•

Top

handle

below

waist

level.

•

Weight

of

tool

evenly

distributed

between

arms.

•

Without

operator

bending

over,

the

trimmer

head

is

near

and

parallel

to

the

ground

and

easily

contacts

the

material

to

be

cut.

•

A^ust

the

assist

handle

up

or

down

the

drive

shaft

housing

(but

above

the

safety

labels)

to

a

comfortable

position.

•

Rotate

assist

handle

from

left

to

right

to

tilt

the

angle

of

the

trimmer

head

when

cutting

a

large,

sloped

area

such

as

a

ditch

bank.

NOTE

;

It

is

possible

that

a

small

space

will

be

left

between

the

bracket

and

the

shield

when

the

screws

are

fully

tightened.

-

7

-

ACCESSORIES

ITEM

SAFETY

FACE

SfflELD.

SAFETY

GLASSES

.

SAFETY

LEG

GUARDS.

WEED

EATER®

40:1

2-CYCLE

ENGINE

OIL

—3.2

oz.

container

(mix

with

1

gallon

gasoline)

...

—8

oz.

container

(mix

with

2-1/2

gallons

gasoline)

—19.6

oz.

container.

FUEL

CAP

tap-n-g6®

iii

TRIMMER

HE^

!.!!!!!!!!!!!!!!

SPOOL

W/LINE.

NYLON

CUTTING

LINE

—80

Ft.

(.080

Dia.)

Cutting

Line

.

—200

Ft.

(.080

Dia.)

Cutting

Line

.

—400

Ft.

(.080

Dia.)

Cutting

Line

.

FLEX

SHAFT

LUBE.

AIR

FILTER

.

SPARKPLUG.

STOCK

NO.

.

952-701601

.

952-701645

.

952-701600

.

952-030133

.

952-030128

.

952-031138

,.

952-701583

..

952-701618

,.

952-701619

.

952-701534

.

952-701595

.

952-701590

.

952-701570

.

952-701614

..

530-030077

NOTES

-

8

-

FUELING

YOUR

ENGINE

\

FUEL

SAFETY

•

Be

sure

to

read

the

fuel

safety

section

on

page

4

of

this

manual

before

you

begin.

•

If

you

do

not

understand

the

fuel

safety

section

DO

NOT

attempt

to

fuel

your

unit;

seek

help

&om

someone

that

does

under¬

stand

the

fuel

safety

section

or

call

our

Customer

Assistance

Hotline

at

1-800-554-6723.

FUEL

MIXTURE

HOW

MUCH

OIL

TO

USE:

)^ED

EIATER

40:1,

2-cycle

engine

oil

is

sold

in

both

3.2

ounce

and

8

ounce

containers.

When

you

buy

the

3.2

ounce

container,

mix

it

with

1

gallon

of

regular

unleaded

gasoline.

If

you

purchase

the

8

ounce

container,

mix

it

with

2-1/2

gallons

of

regu-

lar

unleaded

gasohne.

Both

of

the

above

mixtures

will

provide

40

parts

gasoline

to

1

part

oil.

Paramount,

Poulan,

or

Poulan

Pro

brand

40:1,

2-cycle

engine

oil

is

also

sold

in

the

same

size

con¬

tainers

and

may

be

mixed

in

the

same

manner.

•

Your

umt

is

powered

by

a

two—qrcle

engine

that

requir^

a

fuel

mixtime

of

regular

unleaded

gaso¬

hne

and

a

high

quality

engine

oil

specially

made

lor

2—cycle,

air

cooled

engines.

*

^^oline

must

be

clean

and

not

over

two

months

I.

CAUTIQMlJ

Too

little

oil

or

incorrect

oil

will

cause

the

engine

to

overheat

and

seize.

•

^ways

mix

the

fuel

thoroughly

in

a

con-

t^er

since

gasoline

and

oil

do

not

readily

com-

if

^

bine.

DO

NOT

USE:

•

AUTOMOTIVE

OIL

•

NMMA

OIL

for

boat

engines

These

oOs

do

not

have

proper

additives

for

2-cycle

air

cooled

engines

and

can

cause

engine

damage.

’

USE

THE

FOLLOWING

OIL:

WHAT

TO

DO

IF

YOU

USE

ANOTHER

BRAND

OF

OIL:

Not

^

air

cooled,

2—cycle

engine

oils

have

the

same

qualities.

If

WEED

EATER,

Paramount,

Poulan,

or

ui

^

Pro

brand

2-cycle

engine

oil

is

not

avail¬

able,

use

a

high

quality

2-cycle

engine

oil

recom¬

mended

for

air

cooled

engines.

Mix

at

a

ratio

of

40:1

by

mixing

3.2

ounces

oil

with

1

gallon

of

gasoline.

40:1

must

be

listed

as

a

suggested

miY

ratio.

HOW

TO

MIX

FUEL

AND

FILL

TANK

•

Pour

the

proper

measure

of

engine

oil

into

an

ap¬

proved,

marked

fuel

container.

Then,

fill

the

container

with

regular

unleaded

gasoline.

NOTE;

If

gasoline

is

already

in

the

container,

add

the

proper

measure

of

2

-

cycle

engine

oil.

Then,

close

the

container

tightly

and

shake

it

momen¬

tarily.

•

WEED

EATER

40:1,

2—cycle

engine

oil

Paraniount,

Poulan,

or

Poulan

Pro

brand

40:1

2-

wcle

engine

oil

is

acceptable

if

mixed

according

to

the

instructions

on

the

container.

40

PARTS

GASOLINE

TO

1

PART

OIL=

1

gallon

gasoline

to

3.2

fl.

oz.

oil

2.5

gallon

gasoline

to

8.0

fl.

oz.

oil

N

OTE;

Do

not

mix

gasoline

and

oil

directly

in

the

fuel

tank.

•

Slowly

remove

the

fuel

cap.

•

Using

a

spout

or

funnel,

fill

the

fuel

tank

with

fuel

mix.

•

Reinstall

the

fuel

cap

securely.

-

9

-

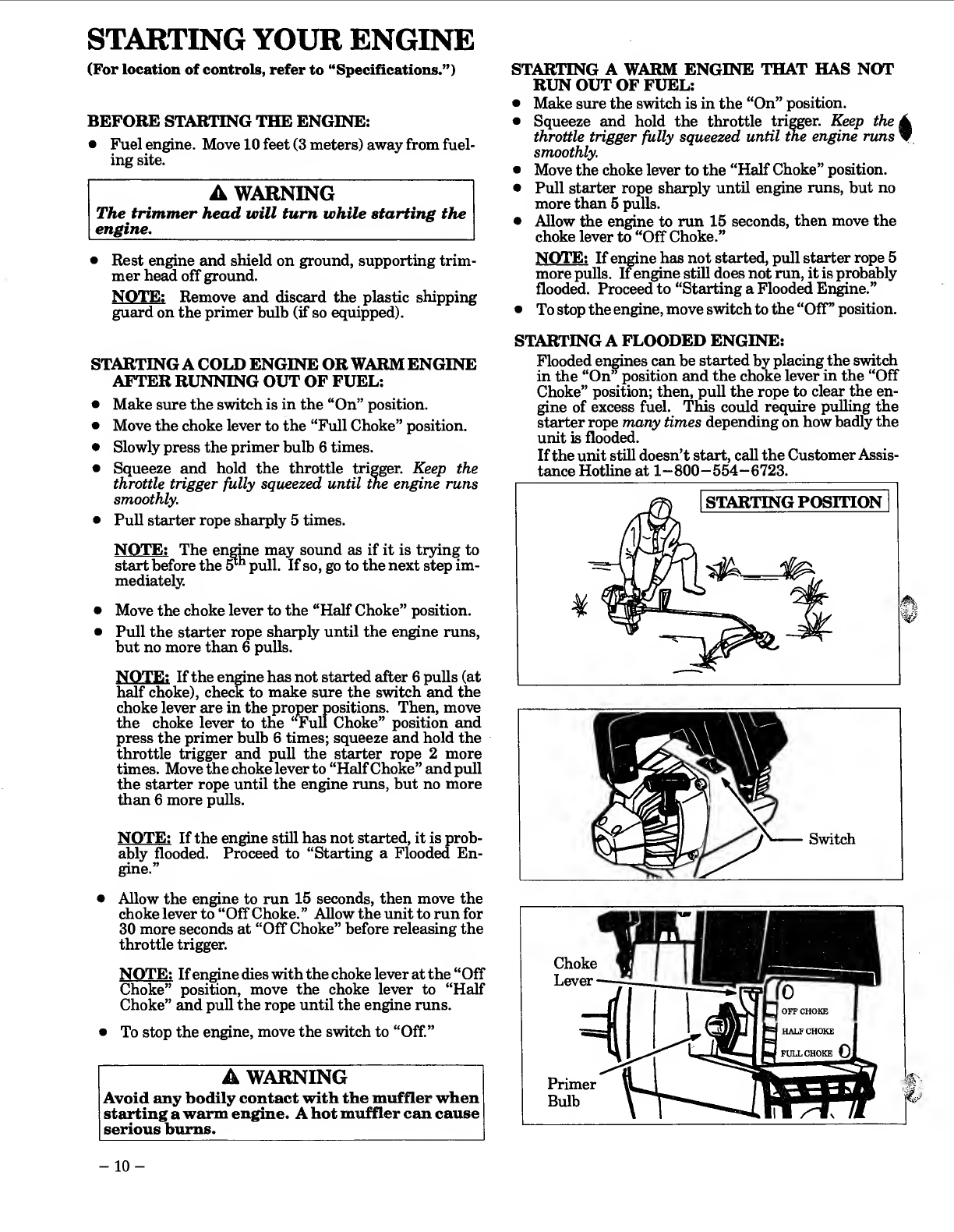

STARTING

YOUR

ENGINE

(For

location

of

controls,

refer

to

“Specifications.”)

BEFORE

STARTING

THE

ENGINE:

•

Fuel

engine.

Move

10

feet

(3

meters)

away

from

fuel¬

ing

site.

A

WARNING

The

trimmer

head

will

turn

while

starting

the

engine.

_

•

Rest

engine

and

shield

on

ground,

supporting

trim¬

mer

head

off

ground.

NOTE:

Remove

and

discard

the

plastic

shipping

guard

on

the

primer

biilb

(if

so

eqmpped).

STARTING

A

COLD

ENGINE

OR

WARM

ENGINE

AFTER

RUNNING

OUT

OF

FUEL:

•

Make

sure

the

switch

is

in

the

“On”

position.

•

Move

the

choke

lever

to

the

“Full

Choke”

position.

•

Slowly

press

the

primer

bulb

6

times.

•

Squeeze

and

hold

the

throttle

trigger.

Keep

the

throttle

trigger

fully

squeezed

until

the

engine

runs

smoothly.

•

Pull

starter

rope

sharply

5

times.

NOTE:

The

enfflne

may

sound

as

if

it

is

trying

to

start

before

the

pull.

If

so,

go

to

the

next

step

im¬

mediately.

•

Move

the

choke

lever

to

the

“Half

Choke”

position.

•

Pull

the

starter

rope

sharply

until

the

engine

runs,

but

no

more

than

6

pulls.

NOTE:

If

the

engine

has

not

started

after

6

pulls

(at

half

choke),

check

to

make

sure

the

switch

and

the

choke

lever

are

in

the

proper

positions.

Then,

move

the

choke

lever

to

the

“Full

Choke”

position

and

press

the

primer

bulb

6

times;

squeeze

and

hold

the

throttle

trigger

and

pull

the

starter

rope

2

more

times.

Move

the

choke

lever

to

“HalfChoke”

and

pull

the

starter

rope

until

the

engine

runs,

but

no

more

than

6

more

pulls.

NOTE:

If

the

engine

still

has

not

started,

it

is

prob¬

ably

flooded.

Proceed

to

“Starting

a

Flooded

En-

gine.

•

Allow

the

engine

to

run

15

seconds,

then

move

the

choke

lever

to

“Off

Choke.”

Allow

the

unit

to

run

for

30

more

seconds

at

“Off

Choke”

before

releasing

the

throttle

trigger.

NOTE:

If

engine

dies

with

the

choke

lever

at

the

“Off

Choke”

position,

move

the

choke

lever

to

“Half

Choke”

and

pull

the

rope

until

the

engine

runs.

•

To

stop

the

engine,

move

the

switch

to

“Off.”

A

WARNING

Avoid

any

bodily

contact

with

the

muffler

when

starting

a

warm

engine.

A

hot

muffler

can

cause

serious

bums.

STARTING

A

WARM

ENGINE

THAT

HAS

NOT

RUN

OUT

OF

FUEL:

•

Make

sure

the

switch

is

in

the

“On”

position.

•

Squeeze

and

hold

the

throttle

tri^er.

Keep

the

^

throttle

trigger

fully

squeezed

until

the

engine

runs

▼

smoothly.

•

Move

the

choke

lever

to

the

“Half

Choke”

position.

•

Pull

starter

rope

sharply

until

engine

runs,

but

no

more

than

5

pulls.

•

Allow

the

engine

to

run

15

seconds,

then

move

the

choke

lever

to

“Off

Choke.”

NOTE:

If

engine

has

not

started,

pull

starter

rope

5

more

pulls.

If

engine

still

does

not

run,

it

is

probably

flooded.

Proceed

to

“Starting

a

Flooded

Engine.”

•

To

stop

the

engine,

move

switch

to

the

“Off”

position.

STARTING

A

FLOODED

ENGINE:

Flooded

engines

can

be

started

by

placing

the

switch

in

the

“On”

position

and

the

choke

lever

in

the

“Off

Choke”

position;

then,

puU

the

rope

to

clear

the

en¬

gine

of

excess

fuel.

This

could

require

pulling

the

starter

rope

many

times

depending

on

how

badly

the

unit

is

flooded.

If

the

unit

still

doesn’t

start,

call

the

Customer

Assis¬

tance

Hotline

at

1—800—554—6723.

-

1

0

-

D.

OPERATING

INSTRUCTIONS

1.

B

ring

the

engine

to

cutting

speed

before

enter¬

ing

the

material

to

be

cut.

a.

Do

not

run

the

engine

at

a

higher

speed

than

necessary.

The

cutting

line

vdll

cut

effi¬

ciently

when

the

engine

is

run

at

less

than

full

throttle.

At

lower

speeds,

there

is

less

engine

noise

and

vibration.

The

cutting

line

will

last

longer

and

will

be

less

likely

to

“weld”

onto

the

spool.

b.

If

trinuner

head

does

not

turn

when

the

en¬

gine

is

in

operation,

make

sure

the

drive

shaft

housing

is

properly

seated

in

the

engine

shroud.

Refer

to

“Assembly—Drive

Shaft

Housing.”

2.

Alwa^

release

the

throttle

trigger

and

al¬

low

the

engine

to

return

to

iffie

speed

when

not

cutting.

3.

To

stop

engine:

a.

Release

the

throttle

trigger.

b.

Move

ignition

switch

to

the

“Off”

position.

USING

YOUR

TRIMMER

LegG^u^s

\

\

-

Face

Boots

Shield

Thrown

Object

1

A

warning-throws

objects

The

rapidly

moving

line

causes

objects

to

be

thrown

violently.

The

shield

will

not

provide

complete

protection

to

the

operator

or

others.

The

operator

must

wear

a

safety

face

shield

or

goggles.

Always

wear

heavy,

long

pants

and

boots.

Keep

others

at

least

30

feet

(10

meters)

away.

A

WARNING

-

HAZARD

ZONE

This

tool

wih

throw

objects

and

cut.

Keep

oth¬

ers

including

children,

animals,

bystand¬

ers

and

helpers

at

least

30

feet

(10

meters)

away

&om

the

operator

and

tool.

Stop

the

engine

if

you

are

approached.

A

WARNING

-

DAMAGED

TRIM¬

MER

HEAD

Trimmer

head

parts

that

are

chipped,

cracked

or

damaged

in

any

other

way

can

fly

apart

and

cause

serious

injury.

Do

not

use.

Replace

damaged

parts

before

using

the

tool.

A.

LINE

TRIMMER

SAFETY

1.

OPERATOR

a.

Always

we^

eye

protection

when

oper-

ating,

servicing,

or

performing

mainte¬

nance

on

yom-

unit.

See

“Accessories.”

b.

Always

wear

heavy,

long

pants,

boots,

and

gloves.

See

“Accessories.

”

Do

not

go

bare¬

foot

or

wear

sandsils,

jewelry,

short

pants,

loose

clothing,

or

clothing

with

loosely

hanging

ties,

straps,

or

tassels;

they

can

be

caught

in

moving

parts.

Secure

hair

so

it

is

above

shoulder

length.

Being

fully

covered

will

help

protect

you

from

pieces

of

toxic

plants

such

as

poison

ivy

thrown

by

the

trimmer

head

which

could

be

more

of

a

hazard

than

touching

the

plant

itself.

c.

Do

not

operate

this

tool

when

you

are

tired,

ill

or

under

the

influence

of

alco¬

hol,

drugs

or

medication.

d.

Do

not

swing

unit

with

such

force

that

you

are

in

danger

of

losing

your

balance.

e.

Never

start

or

run

the

engine

inside

a

closed

room

or

building.

Breathing

exhaust

fumes

can

kill.

f.

Keep

handles

free

of

oil

and

fuel.

2.

TOOL

a.

Inspect

the

entire

tool

before

each

use.

Replace

damaged

parts.

Check

for

fuel

leaks

and

make

sure

aU

fasteners

are

in

place

and

se¬

curely

fastened.

b.

Use

only

.080”

diameter

WEED

LINE

brand

line.

Never

use

wire,

rope,

string,

etc.

c.

Be

sure

the

shield

is

properly

attached.

d.

Make

sure

the

trimmer

head

is

properly

installed

and

securely

fastened.

Refer

to

“Assembly.”

e.

Make

carburetor

adjustments

with

drive

shaft

housing

supported

to

prevent

the

trimmer

line

fl:om

contacting

any

object.

f.

Keep

others

away

when

making

carbure¬

tor

adjustments.

g.

Use

only

genuine

WEED

EATER

accesso¬

ries

or

attachments

as

recommended.

-

11

-

3.

CUTTING

a.

Inspect

the

area

to

be

cut

before

each

use.

Remove

objects

(rocks,

broken

glass,

nails,

wire,

string,

etc.)

which

can

be

thrown

or

become

entangled

in

the

trimmer

head.

b.

Always

keep

the

engine

on

the

right-

hand

side

of

your

body.

c.

Hold

the

tool

firmly

with

both

hands.

d.

Keep

firm

footing

and

balance.

Do

not

over-reach.

e.

Keep

the

trimmer

head

below

waist

level.

B.

TRIMMER

LINE

ADVANCE

•

The

trimmer

line

will

advance

approxi¬

mately

2

inches

each

time

the

bottom

of

the

trimmer

head

is

tapped

on

the

ground

with

the

engine

running

at

hill

throttle.

•

The

most

eHicient

line

length

is

the

maxi¬

mum

length

allowed

by

the

line

limiter.

•

Always

keep

the

shield

in

place

when

the

tool

is

being

operated.

•

To

Advance

Line:

1.

Operate

the

engine

at

full

throttle.

2.

Hold

the

trimmer

head

parallel

to

and

above

the

grassy

area.

3.

Tap

the

bottom

of

the

trimmer

head

hghtly

on

the

ground

one

time.

Approximately

2

inches

of

line

will

be

advanced

with

each

tap.

NOTE:

Always

tap

the

trimmer

head

on

a

grassy

area.

Tapping

on

surfaces

such

as

concrete

or

asphalt

can

cause

excessive

wear

to

the

trim¬

mer

head.

NOTE:

If

the

line

is

worn

down

to

two

inches

or

less,

more

than

one

tap

will

be

re¬

quired

to

obtain

the

most

efficient

line

length.

A

WARNING

Use

only

.080"

ffiameter

WEED

LINE

brand

line.

Other

sizes

of

line

will

not

advance

properly

and

can

cause

serious

injury.

Do

not

use

other

mate¬

rials

such

as

wire,

string,

rope,

etc.

Wire

can

break

off

during

cutting

and

become

a

danger-

ous

missile

that

can

cause

serious

ipjury.

f.

Do

not

raise

the

engine

above

your

waist.

g.

Keep

all

parts

ofyour

body

away

hrom

the

trimmer

line

when

the

engine

is

running.

h.

Keep

all

parts

of

your

body

away

foom

a

hot

muffler.

i.

Use

this

unit

only

for

jobs

explained

in

|

this

manual.

_

A

WARNING

Avoid

any

contact

with

a

hot

muffler.

A

hot

muffler

can

cause

serious

burns.

C.

CUTTING

METHODS

A

WARNING

Use

minimum

speed

and

do

not

crowd

the

line

when

cutting

around

hard

objects

(rock,

gravel,

fence

posts,

etc),

which

can

damage

the

trimmer

head,

become

entangled

in

the

line,

or

be

thrown

causing

a

serious

hazard._

•

The

tip

of

the

line

does

the

cutting.

You

will

achieve

the

best

performance

and

minimum

line

wear

by

not

crowding

line

into

the

cutting

area.

The

right

and

wrong

ways

are

shown

below.

•

The

line

will

easily

remove

grass

and

weeds

from

around

walls,

fences,

trees

and

flower

beds,

hut

it

also

can

cut

the

tender

hark

of

trees

or

shruhs

and

scar

fences.

To

help

avoid

d^age

especially

to

delicate

vegetation

or

trees

with

tender

bark,

shorten

line

to

4-5

inches

and

use

at

less

than

full

throttle.

•

For

trimming

or

scalping,

use

less

than

full

throttle

to

increase

line

life

and

decrease

’

head

wear,

especially:

-

during

light

duty

cutting.

-

near

objects

around

which

the

line

can

wrap

such

as

small

posts,

trees

or

fence

wire.

•

For

mowing

or

sweeping,

use

full

throttle

for

a

good

clean

job._

Tip

of

the

Line

Line

Crowded

Into

Does

The

Cutting

Work

Area

RIGHT

Ground

WRONG

A

WARNING

Always

wear

eye

protection.

Never

lean

over

the

trimmer

head.

Rocks

or

debris

can

ricochet

or

be

thrown

into

eyes

and

face

and

cause

blind¬

ness

or

other

serious

injury.

I

-

1

2

-

1.

TRBMMING

—

Hold

the

bottom

of

the

trimmer

head

about

3

inches

above

the

ground

and

at

an

angle.

Allow

only

the

tip

of

the

line

to

msike

con¬

tact.

Do

not

force

the

trimmer

line

into

the

work

area.

2.

SCALPING

—

The

scalping

technique

removes

unwanted

vegetation.

Hold

the

bottom

of

the

trimmer

head

about

3

inches

above

the

ground

and

at

an

angle.

Allow

the

tip

of

the

line

to

strike

the

ground

around

trees,

posts,

monuments,

etc.

This

technique

increases

line

wear.

3.

MOWING-

Your

trimmer

is

ideal

for

mowing

in

places

conventional

lawn

mowers

cannot

reach.

In

the

mowing

position,

keep

the

line

parallel

to

the

ground.

Avoid

pressing

the

head

into

the

ground

as

this

can

scalp

the

ground

and

damage

the

tool.

4.

SWEEPING

-

The

fanning

action

of

the

rotat¬

ing

line

can

be

used

for

a

quick

and

easy

clean

up.

Keep

the

hne

parallel

to

and

above

the

surfaces

be¬

ing

swept

and

move

the

tool

from

side

to

side.

D.

LINE

REPLACEMENT

•

For

proper

line

feed:

-

Use

only

genuine

WEED

ElATER

pre-

wound

spools

and

.080”

diameter

WEED

LINE

brand

line.

Use

of

other

types

of

spools

or

lines

can

result

in

excessive

breakage,

line

welding

and

improper

line

feed.

—

Pre—wound

spools

offer

the

most

conven¬

ient

method

for

replacing

line

as

well

as

optimum

performance.

*

Always

clean

dirt

and

debris

from

the

spool

and

hub

when

performing

any

type

mainte¬

nance.

1.

Installing

Spool

w/Line

a.

Hold

the

trimmer

head

as

shown.

Press

the

two

lock

tabs

and

remove

the

cover.

b.

Remove

the

spool.

c.

Clean

dirt

and

debris

from

all

parts.

d.

Inspect

all

trimmer

head

parts

for

damage.

Re¬

place

damaged

parts.

A

WARNING

Trimmer

head

parts

that

are

chipped,

cracked

or

damaged

in

any

way

can

fly

apart

and

cause

serious

injury.

Do

not

use.

Replace

damaged

parts

before

using

the

tool.

-

13

-

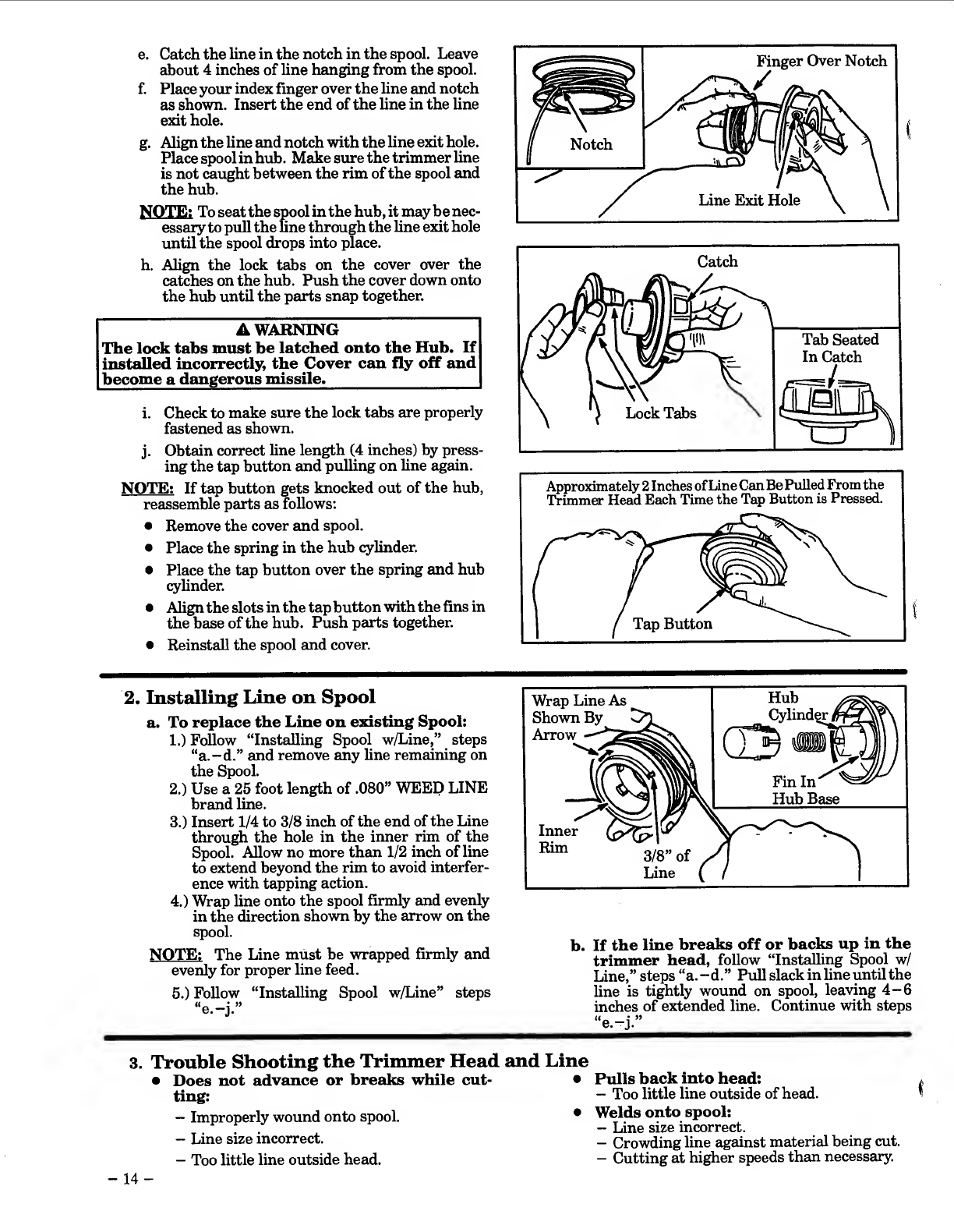

e.

Catch

the

line

in

the

notch

in

the

spool.

Leave

about

4

inches

of

line

hsinging

from

the

spool.

f.

Place

yom:

index

finger

over

the

line

and

notch

as

shown.

Insert

the

end

of

the

line

in

the

line

exit

hole.

g.

Align

the

line

and

notch

with

the

line

exit

hole.

Place

spool

in

hub.

Make

sure

the

trimmer

line

is

not

caught

between

the

rim

of

the

spool

and

the

hub.

NOTE;

To

seat

the

spool

in

the

hub,

it

may

be

nec¬

essary

to

pull

the

fine

through

the

Une

exit

hole

until

the

spool

drops

into

place.

h.

Align

the

lock

tabs

on

the

cover

over

the

catches

on

the

hub.

Push

the

cover

down

onto

the

hub

until

the

parts

snap

together.

A

WARNING

The

lock

tabs

must

be

latched

onto

the

Hub.

If

installed

incorrectly,

the

Cover

can

fly

off

and

become

a

dangerous

missile._

i.

Check

to

meike

sure

the

lock

tabs

are

properly

fastened

as

shown.

j.

Obtain

correct

line

length

(4

inches)

by

press¬

ing

the

tap

button

and

pulling

on

line

again.

NOTE:

If

tap

button

gets

knocked

out

of

the

hub,

reassemble

parts

as

follows;

•

Remove

the

cover

emd

spool.

•

Place

the

spring

in

the

hub

cylinder.

•

Place

the

tap

button

over

the

spring

and

hub

cylinder.

•

Align

the

slots

in

the

tap

button

with

the

fins

in

the

base

of

the

hub.

Push

parts

together.

•

Reinstall

the

spool

and

cover.

Approximately

2

Inches

of

Line

Can

Be

Pulled

From

the

Trimmer

Head

Each

Time

the

Tap

Button

is

Pressed.

2.

Installing

Line

on

Spool

a.

To

replace

the

Line

on

existing

Spool:

1.

)

FoUow

“Installing

Spool

w/Line,”

steps

“a.—d.”

and

remove

any

line

remaining

on

the

Spool.

2.

)

Use

a

25

foot

length

of

.080”

WEED

LINE

brand

line.

3.

)

Insert

1/4

to

3/8

inch

of

the

end

of

the

Line

through

the

hole

in

the

iimer

rim

of

the

Spool.

Allow

no

more

than

1/2

inch

of

line

to

extend

beyond

the

rim

to

avoid

interfer¬

ence

with

tapping

action.

4.

)

Wrap

line

onto

the

spool

firmly

and

evenly

in

the

direction

shown

by

the

arrow

on

the

spool.

NOTE;

The

Line

must

be

wrapped

firmly

and

evenly

for

proper

line

feed.

5.

)

Follow

“Installing

Spool

w/Line”

steps

“e.-j.”

b.

If

the

line

breaks

off

or

backs

up

in

the

trimmer

head,

follow

“Installing

Spool

w/

Line,”

steps

“a.

-d.”

Pull

slack

in

Une

until

the

Une

is

tightly

wound

on

spool,

leaving

4-6

inches

of

extended

Une.

Continue

with

steps

3.

Trouble

Shooting

the

Trimmer

Head

and

Line

•

Does

not

advance

or

breaks

while

cut-

•

ting:

-

Improperly

wound

onto

spool.

•

—

Line

size

incorrect.

-

Too

little

Une

outside

head.

Pulls

back

into

head:

-

Too

little

Une

outside

of

head.

Welds

onto

spool:

-

Line

size

incorrect.

-

Crowding

Une

against

material

being

cut.

-

Cutting

at

higher

speeds

than

necessary.

I

-

14

-

GENERAL

MAINTENANCE

A.

MAINTENANCE

SAFETY

1.

Maintain

unit

according

to

recommended

procedures.

Keep

cutting

fine

at

proper

length.

2.

Disconnect

spark

plug

before

performing

maintenance

except

carburetor

adjustments.

3.

Make

carburetor

adjustments

with

drive

shaft

housing

supported

to

prevent

the

trimmer

line

&om

contacting

any

object.

4.

Keep

others

away

when

making

carburetor

adjustments.

5.

Replace

trimmer

head

parts

that

are

cracked,

chipped

or

damaged

before

using

the

unit.

6.

Use

only

.080”

diameter

WEED

LINE

brand

line.

Never

use

wire,

rope,

string,

etc.

7.

Use

only

genuine

WEED

EATER

replace¬

ment

pails.

Use

of

other

brands

of

replacement

parts

can

cause

damage

to

your

unit

or

injury

to

the

operator

or

others.

Your

warranty

does

not

cover

damage

or

liability

caused

by

the

use

of

ac¬

cessories

and/or

attachments

not

specifically

rec¬

ommended

by

WEED

EATER.

8.

Inspect

the

entire

unit.

Replace

damaged

parts.

Check

for

fuel

leaks

and

make

sure

all

fas¬

teners

are

in

place

and

securely

fastened.

B.

AIR

FILTER

NOTE:

A

dirty

air

filter

decreases

the

fife

and

performance

of

the

engine

and

may

increase

fuel

consumption

and

hEumful

emissions.

1.

C

lean

the

Air

Filter:

•

Always

after

5

tanks

of

fuel

or

5

hours

of

operation,

whichever

is

less.

•

More

frequently,

in

dusty

conditions.

a.

Loosen

the

two

screws

on

the

air

filter

cover

enough

to

remove

the

cover

from

engine.

b.

Remove

the

air

filter

from

the

cover.

c.

Wash

filter

in

soap

and

water.

_

d.

Sque

eze

filter

dry

and

replace

in

cover.

1

CAUTION:

I

Do

not

clean

the

air

filter

in

gaso¬

line

or

any

other

flammable

solvent;

doing

so

may

create

a

fire

hazard

or

produce

harmf^

evaporative

emissions.

e.

Reinstall

the

air

filter

cover,

making

sure

the

choke

exit

slot

is

placed

over

the

choke

lever.

I

CAUTION:

I

Make

sure

the

air

filter

is

fitted

into

the

comers

of

the

cover

to

keep

dust

from

entering

the

engine

and

causing

en¬

gine

damage.

NOTE:

If

replacing

the

air

filter,

see

the

Accessory

List

for

proper

part

number.

C.

DRIVE

SHAFT

LUBRICATION

•

Lubricate

the

Drive

Shaft:

-

After

each

ten

(10)

hours

of

operation.

—

Before

operating

if

the

unit

has

been

stored

for

90

days

or

longer.

•

See

the

Accessory

List

for

flex

shaft

lube

part

number.

A

WARNING

If

the

engine

is

hot,

avoid

touching

the

muffler.

A

hot

muffler

can

cause

serious

bums.

I

CAUTI

ON:

I

Lay

the

drive

shaft

on

a

clean

sur¬

face.

Avoid

laying

the

shaft

on

the

floor,

ground,

or

on

any

other

smrface

that

may

have

dirt

or

debris.

Even

after

wiping

shaft,

grease

residue

can

pick

up

particles

that

can

cause

damage

or

premature

failure.

I

CAUTION:

I

Take

care

to

avoid

ipjuring

yotu*

hands

and

fingers

with

broken

wires

when

checking

for

damage

or

wiping

the

shaft.

A

cloth

will

not

prevent

broken

wires

from

puncturing

or

tearing

your

skin.

•

Use

the

following

procedure:

1.

Loosen

the

“nose

cone”

screws

and

remove

the

drive

shaft

housing

from

the

engine.

2.

Remove

drive

shaft

from

drive

shaft

housing.

3.

Check

the

drive

shaft

for

broken

wires,

twists

or

kinks,

and

replace

if

damage

is

found.

4.

Using

a

clean

cloth,

wipe

the

drive

shaft

thor¬

oughly

to

remove

any

old

grease.

5.

Apply

a

uniform

coat

of

lube

to

the

entire

sur¬

face

of

the

drive

shaft.

6.

Inject

the

remaining

contents

of

the

tube

into

the

top

of

the

drive

shaft

housing.

7.

Replace

drive

shaft

in

the

drive

shaft

housing.

8.

Reassemble

drive

shaft

housing

to

the

engine.

Tighten

screws

securely.

-

1

5

-

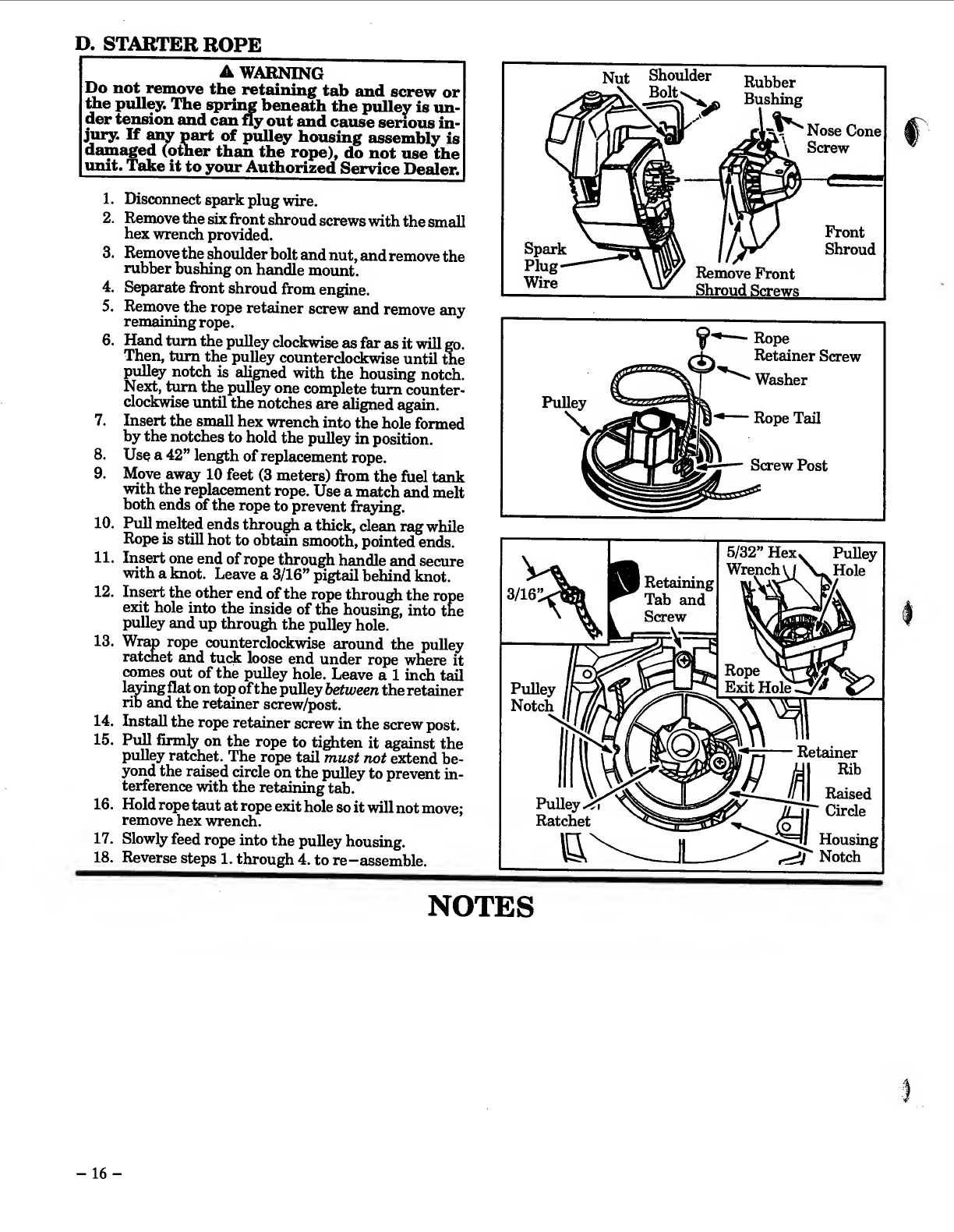

D.

STARTER

ROPE

A

WARNING

Do

not

remove

the

retaining

tab

and

screw

or

the

pulley.

The

sprii^

beneath

the

pulley

is

un¬

der

tension

and

can

fly

out

and

cause

serious

in¬

jury.

If

any

part

of

pulley

housing

assembly

is

damaged

(other

than

the

rope),

do

not

use

the

unit.

Tahe

it

to

your

Authorized

Service

Dealer.

1.

Disconnect

spark

plug

wire.

2.

Remove

the

six

front

shroud

screws

with

the

small

hex

wrench

provided.

3.

Remove

the

shoulder

bolt

and

nut,

and

remove

the

rubber

bushing

on

handle

mount.

4.

Separate

front

shroud

from

engine.

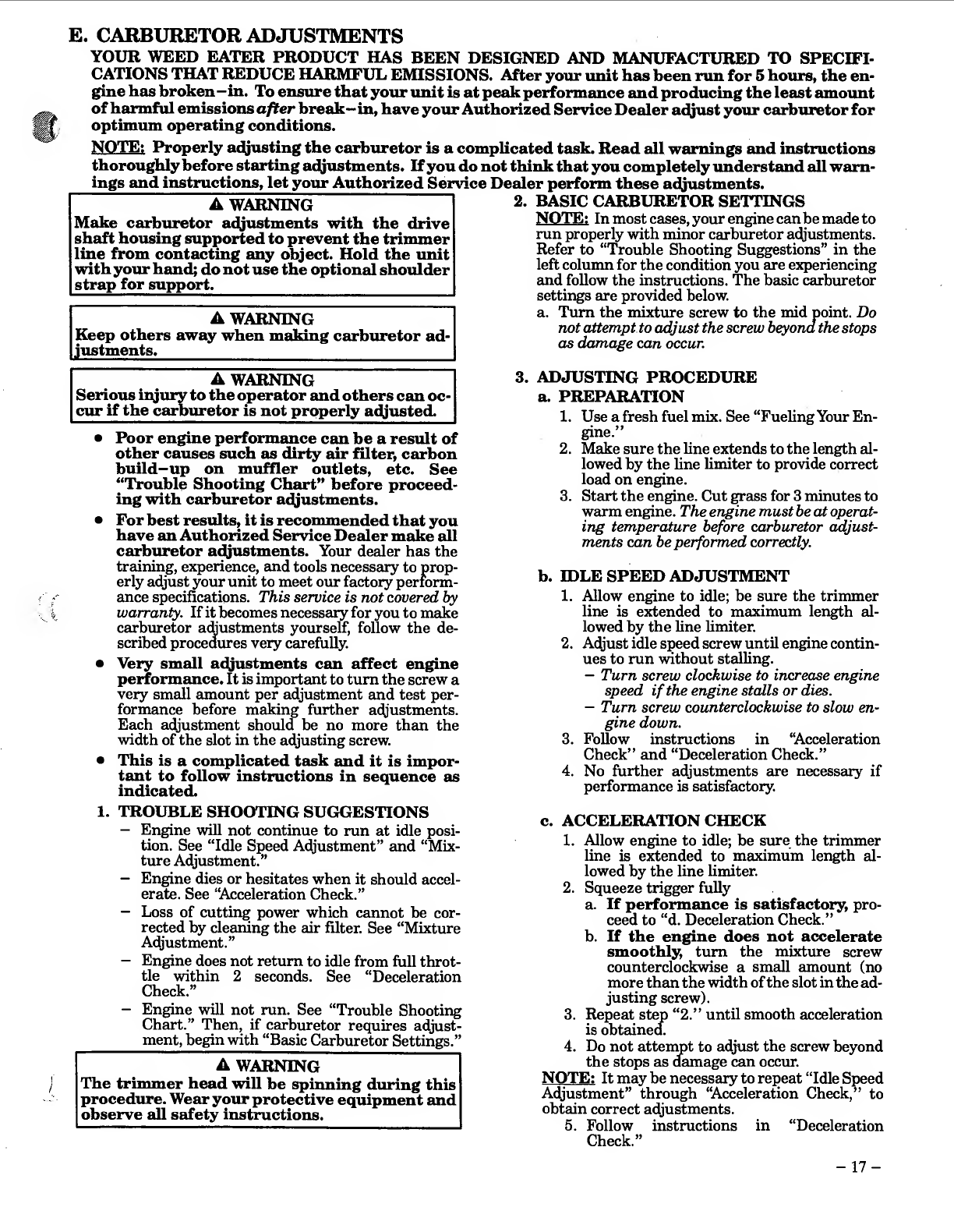

5.

Remove

the

rope

retainer

screw

and

remove

any

remaining

rope.

6.

Hand

turn

the

pulley

clockwise

as

far

as

it

will

go.

Then,

turn

the

pulley

counterclockwise

until

the

pulley

notch

is

aligned

with

the

housing

notch.

Next,

turn

the

pulley

one

complete

turn

counter¬

clockwise

until

the

notches

are

aligned

again.

7.

Insert

the

small

hex

wrench

into

the

hole

formed

by

the

notches

to

hold

the

pulley

in

position.

8.

Use

a

42”

length

of

replacement

rope.

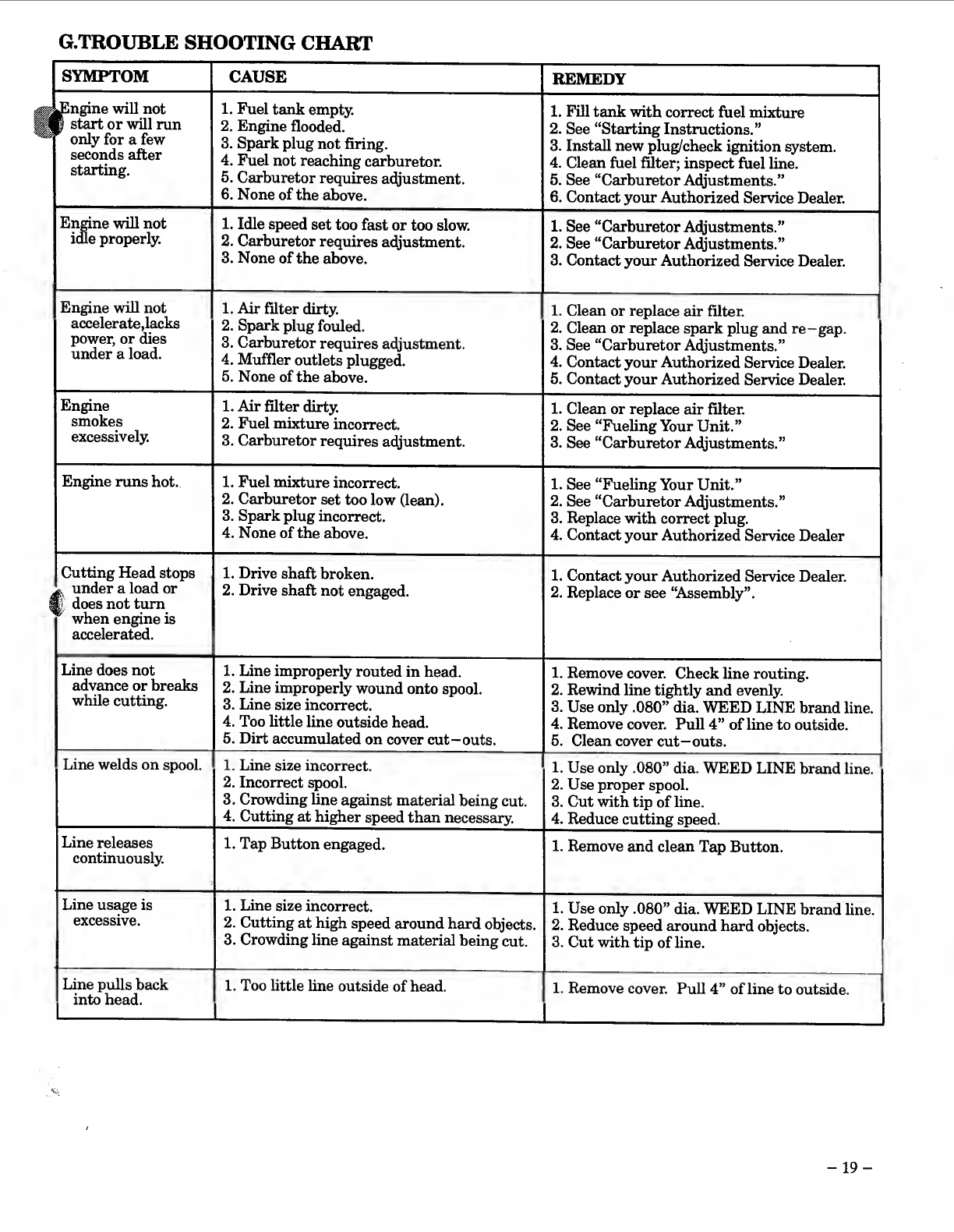

9.

Move

away

10

feet

(3

meters)

from

the

fuel

tank

with

the

repleicement

rope.

Use

a

match

and

melt

both

ends

of

the

rope

to

prevent

fray

ing

10.

Pull

melted

ends

through

a

thick,

clean

reig

while

Rope

is

still

hot

to

obtedn

smooth,

pointed

ends.

11.

Insert

one

end

of

rope

through

handle

and

secure

with

a

knot.

Leave

a

3/16”

pigtail

behind

knot.

12.

Insert

the

other

end

of

the

rope

through

the

rope

exit

hole

into

the

inside

of

the

housing,

into

the

pulley

and

up

through

the

pulley

hole.

13.

Wrap

rope

counterclockwise

around

the

pulley

ratchet

and

tuck

loose

end

under

rope

where

it

comes

out

of

the

pulley

hole.

Leave

a

1

inch

tail

l&^ngflat

on

top

of

the

pulley

between

the

retainer

rib

and

the

retainer

screw/post.

14.

Install

the

rope

retainer

screw

in

the

screw

post.

15.

Pull

firmly

on

the

rope

to

tighten

it

against

the

pulley

ratchet.

The

rope

tail

must

not

extend

be¬

yond

the

reused

circle

on

the

pulley

to

prevent

in¬

terference

with

the

retaining

tab.

16.

Hold

rope

taut

at

rope

exit

hole

so

it

will

not

move;

remove

hex

wrench.

17.

Slowly

feed

rope

into

the

pulley

housing.

18.

Reverse

steps

1.

through

4.

to

re-assemble.

Nut

Shoulder

Bolt

Rubber

Bushing

Nose

Cone

1

Screw

Spark

Plug

Wire

Front

Shroud

Remove

Front

Shroud

Screws

—

Rope

NOTES

i

-

16

-

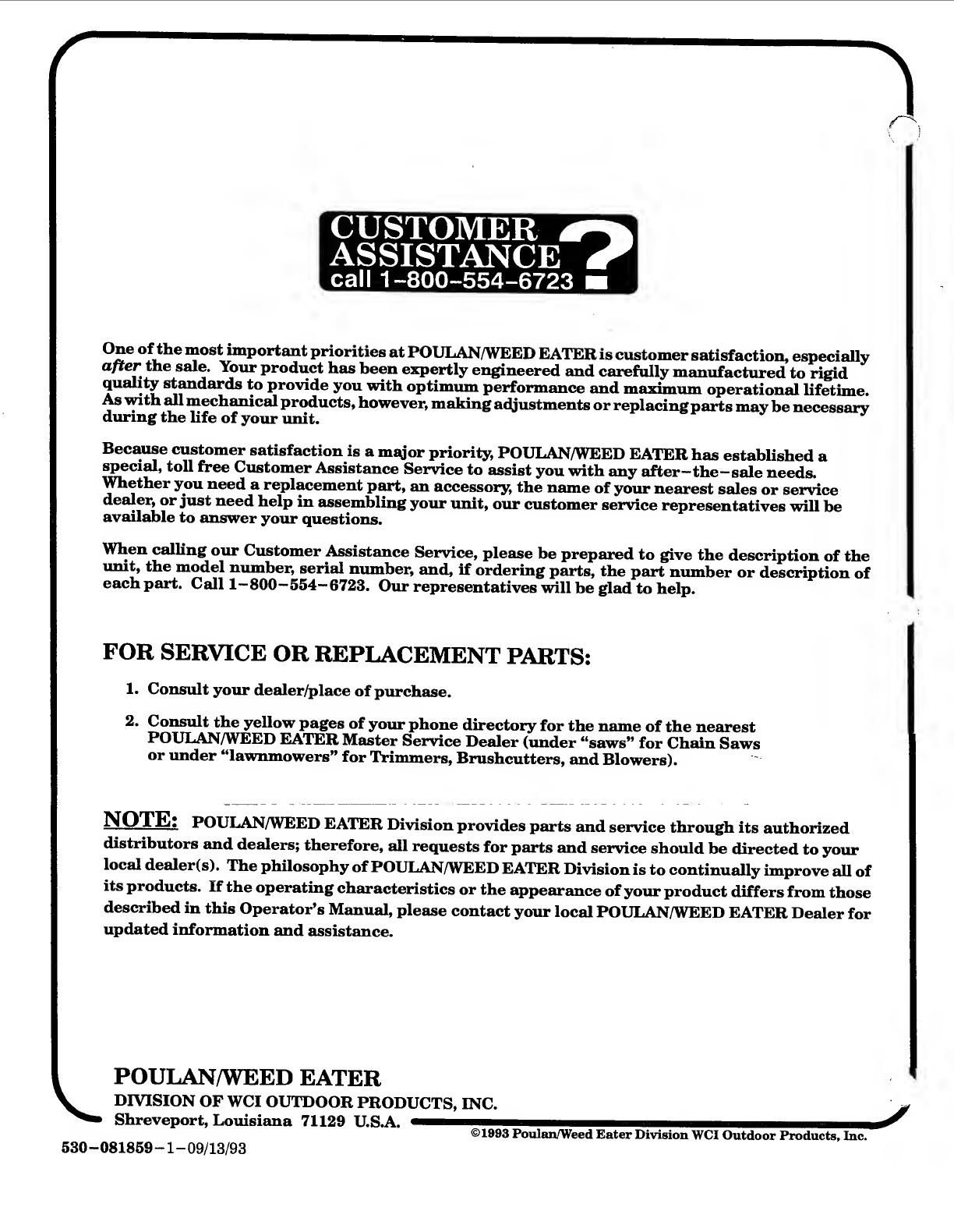

E.

CARBURETOR

ADJUSTMENTS

YOUR

WEED

EATER

PRODUCT

HAS

BEEN

DESIGNED

AND

MANUFACTURED

TO

SPECIFI¬

CATIONS

THAT

REDUCE

HARMFUL

EMISSIONS.

After

your

unit

has

been

run

for

6

hours,

the

en¬

gine

has

broken-in.

To

ensure

that

yoiur

unit

is

at

peak

performance

and

producing

the

least

amount

of

harmful

emissions

after

break-in,

have

your

Authorized

Service

Dealer

adjust

yoiur

carburetor

for

optimum

operating

conditions.

NOTE;

Properly

adjusting

the

carburetor

is

a

complicated

task.

Read

all

warnings

and

instructions

thoroughly

before

starting

adjustments.

If

you

do

not

think

that

you

completely

understand

all

warn¬

ings

and

instructions,

let

your

Authorized

Service

Dealer

perform

these