TrailFX W35B User manual

1

ATV / UTV Winch

Owner’s Manual

EnglishFrancaisEspañol

®

1

3

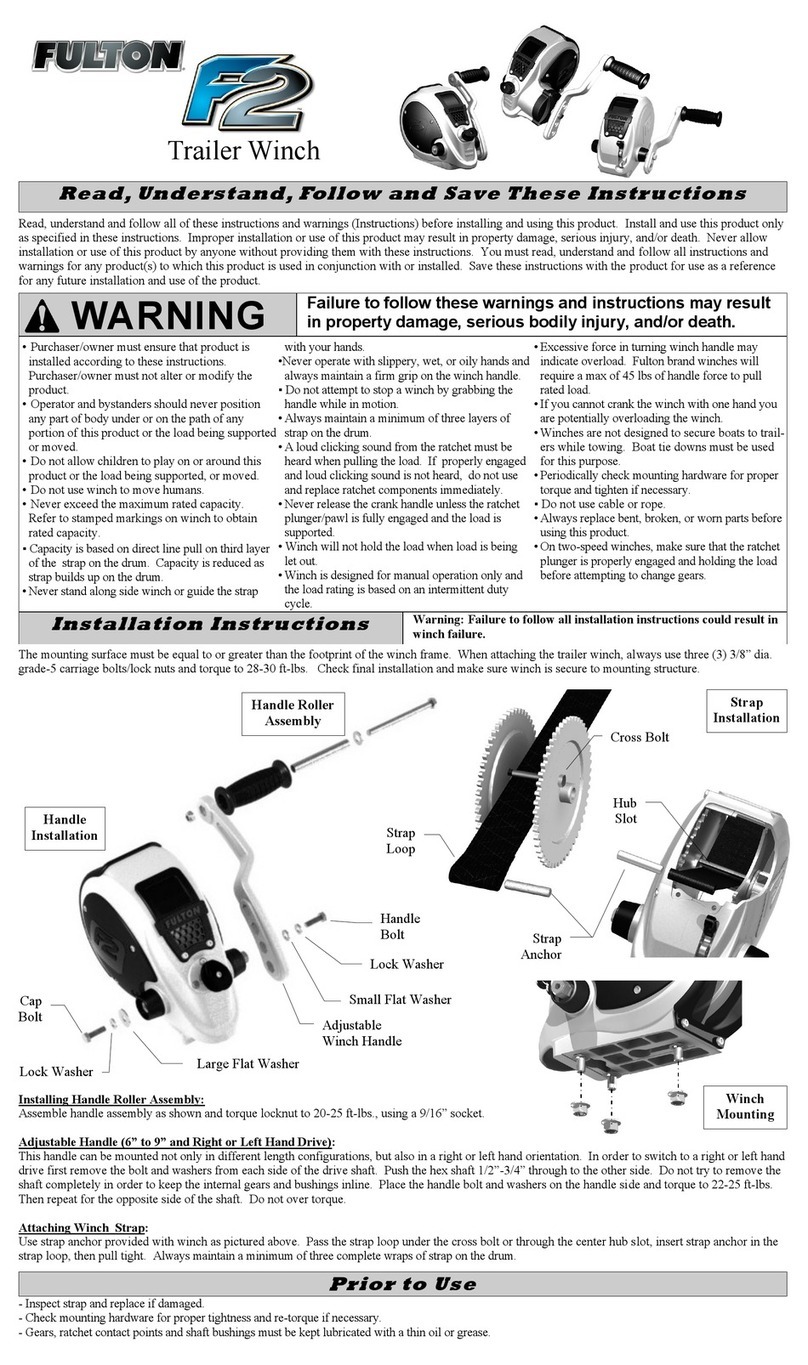

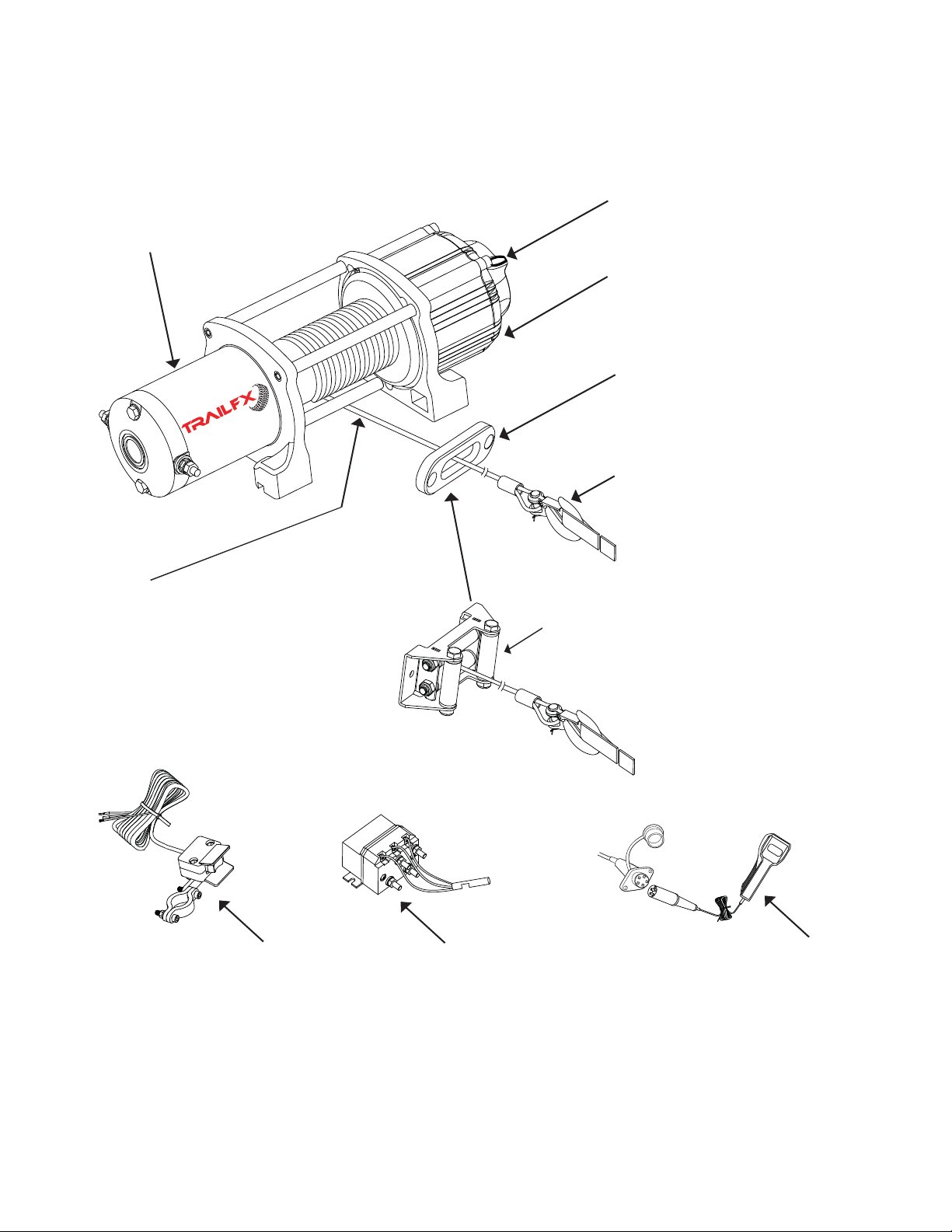

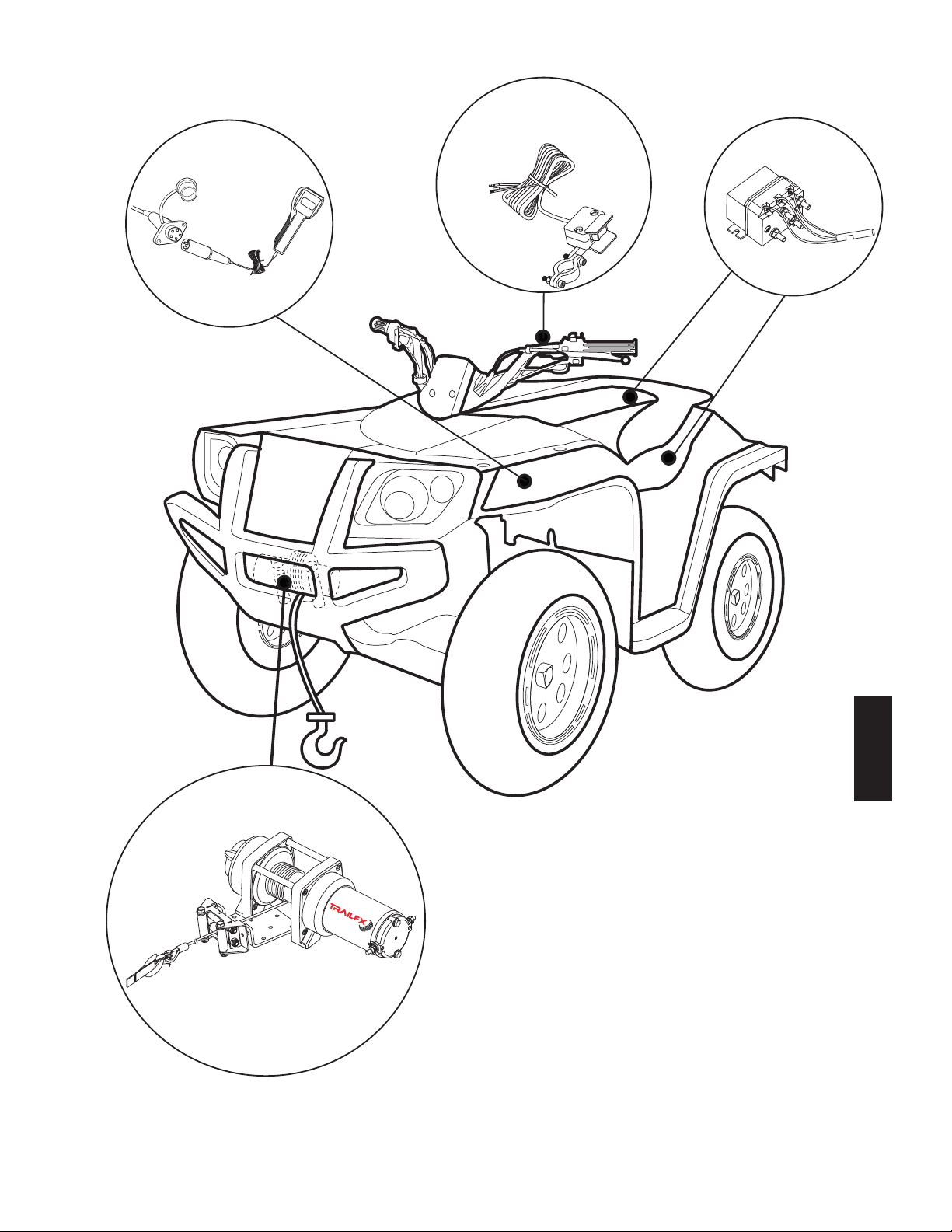

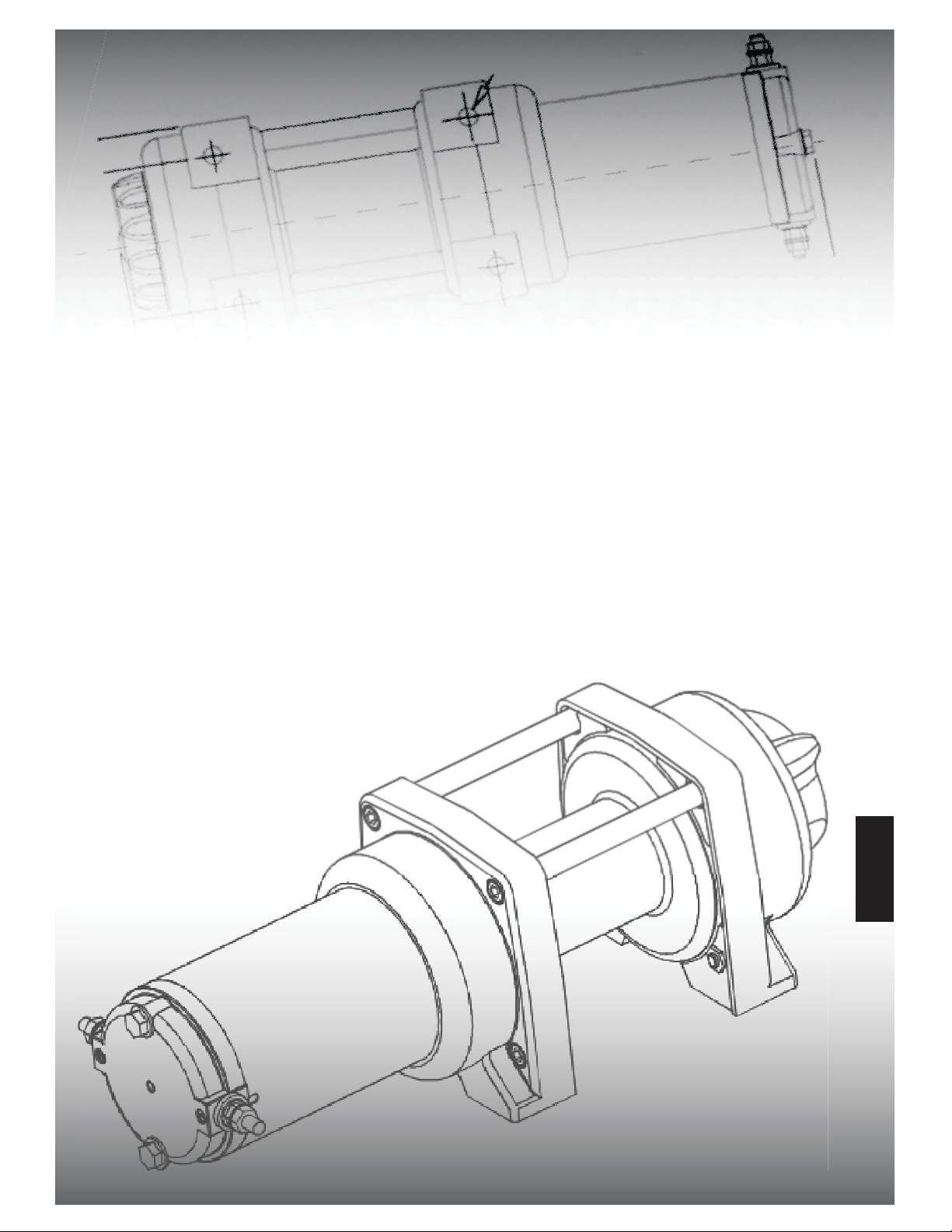

Key Winch Components

Part numbers : W35B and WS35B

Freespool Lever

Motor Housing

Gear Housing

Remote Control

Roller Fairlead ( Applicable for wire rope winch )

Hook

Forged hook designed to safely handle

rated winch load.

Rope

Fairlead

High strength Wire / Synthetic rope

designed to pull rated load safely. Always

remain within the rated load per layer as

specified in this manual and warning label.

Always replace the rope with exactly the

same type, length and rope strength as

specified in this manual.

Houses the series wound 12V

DC motor which drives the gear

system and ultimately driving

the drum.

Engages or Disengages the gear

drive system allowing operator to

pull the rated load or free spool

the rope.

Houses maintenance free 3-stage

planetary gear system that can be

either ‘Engaged’ or ‘Disengaged’ by

the operator.

High quality fairlead for guiding the

winch rope to and from the drum.

High quality roller fairlead for

guiding the winch rope to and

from the drum.

Allows the operator to control

the winch direction from a safe

distance.

Solenoid

Solenoid supplies power to the

motor via mini rocker switch /

remote control switch. Solenoid

meets IP67 for water resistance.

Mini Rocker Switch

Allows the operator to control

the winch direction from ATV

handlebar itself.

OUT IN

English

®

4

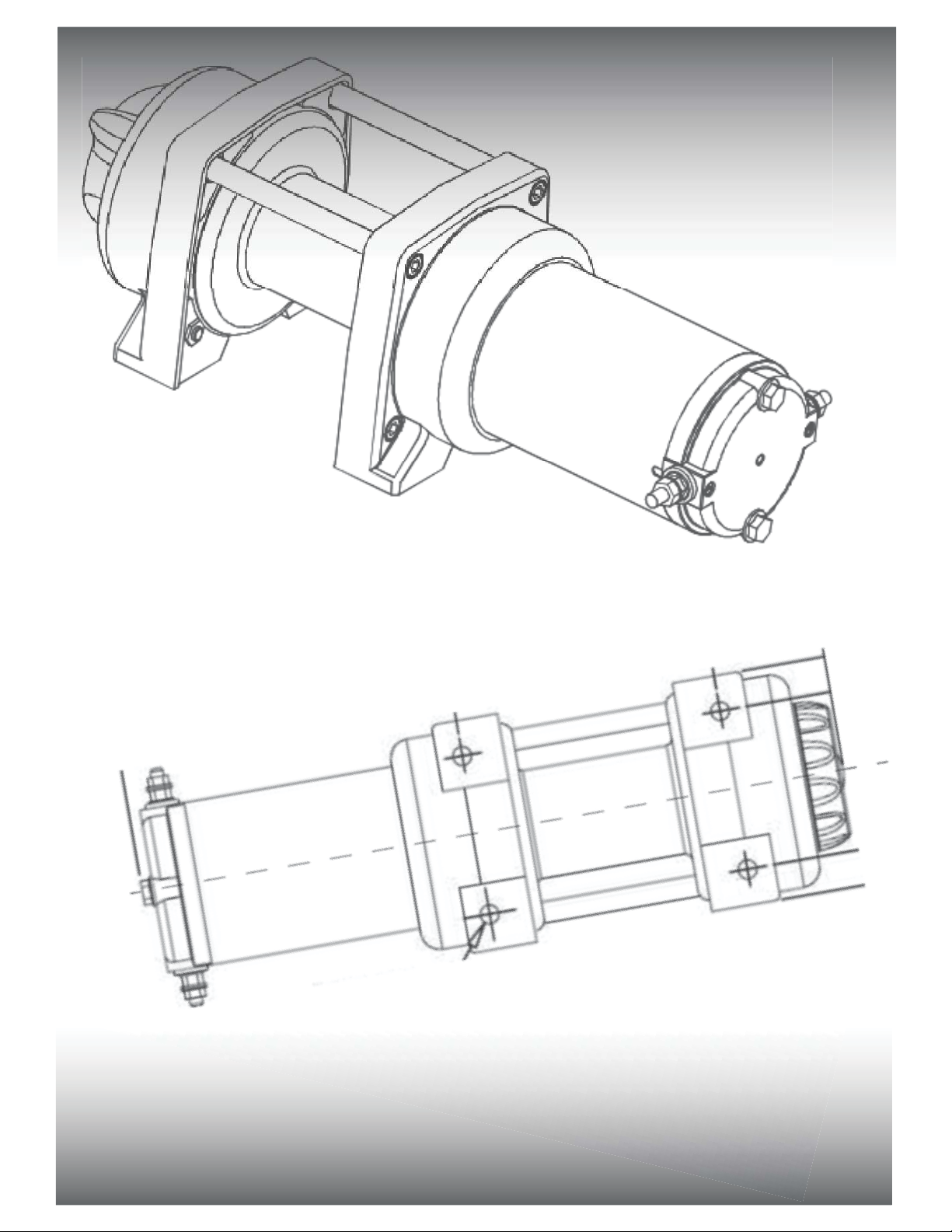

Key Winch Components

Part numbers : W45B and WS45B

Freespool Lever

Motor Housing

Gear Housing

Roller Fairlead ( Applicable for wire rope winch )

Hook

Forged hook designed to safely handle

rated winch load.

Rope

Fairlead

High strength Wire / Synthetic rope

designed to pull rated load safely. Always

remain within the rated load per layer as

specified in this manual and warning label.

Always replace the rope with exactly the

same type, length and rope strength as

specified in this manual.

Houses the series wound 12V

DC motor which drives the gear

system and ultimately driving

the drum.

Engages or Disengages the gear

drive system allowing operator to

pull the rated load or free spool

the rope.

Houses maintenance free 3-stage

planetary gear system that can be

either ‘Engaged’ or ‘Disengaged’ by

the operator.

High quality fairlead for guiding the

winch rope to and from the drum.

High quality roller fairlead for

guiding the winch rope to and

from the drum.

Remote Control

Allows the operator to control

the winch direction from a safe

distance.

OUT IN

Solenoid

Solenoid supplies power to the

motor via mini rocker switch /

remote control switch. Solenoid

meets IP67 for water resistance.

Mini Rocker Switch

Allows the operator to control

the winch direction from ATV

handlebar itself.

®

Safety Precautions

Observe safety precautions for personal safety and the safety of others.

Improper equipment operation may cause personal injur

Never operate this winch if you are under 16 years of age.

Never operate this winch when under the influence of drugs, alcohol or medication.

y and equipment damage.

Read the following carefully before attempting to operate your winch and keep the instructions

for future reference.

1. Dress Properly:

• Do not wear loose clothing or jewelry. They can be caught in moving parts.

• Wear proper winching gloves when handling the winch rope. Do not handle rope with bare hands as

broken strands can cause injuries.

• Non-skid footwear is recommended.

2. Keep a Safe Distance:

• Ensure that all persons stand clear of winch rope and load during winch operation,

1.5 times of the length of the rope is recommended. If a rope pulls loose or breaks under load,

it can lash back and cause serious injury or death.

• Do not step over the rope.

• All visitors and onlookers should be kept away from the work area.

• Keep proper footing and balance at all times.

3. Do Not Abuse Electrical Cables:

• Never carry your winch by the electrical cables or yank it to disconnect it from the receptacle.

• Keep electical cables from heat, oil and sharp edges.

4. Do Not Overwork the Winch:

• If the motor becomes uncomfortably hot to touch, stop and let it cool for a few minutes.

• Shut off power to the winch if the motor stalls.

Do not exceed maximum line pull ratings shown in tables.

Shock loads must not exceed these ratings.

5. Avoid Unintentional Starting:

• Winch clutch should be disengaged when not in use and fully engaged when in use.

6. Check Damaged Parts:

• Before using, you should check your winch carefully. Any part that is damaged should be

properly repaired or replaced. Technical support and replacement parts may be obtained by

contacting customer service as specified on the back cover of the manual or on the warranty card.

7. Repair Your Winch:

• When repairing, use only identical replacement parts or it may cause considerable danger to

the user. Replacement parts may be obtained from customer service as specified in

page number 16.

8. Re-spool the Rope:

• Winching gloves must be worn while re-spooling. It is necessary to maintain a slight load on the rope.

Hold the rope with one hand and the remote control switch with the other. Start as far back and in

the center as you can. Walk up keeping load on the rope as the winch is powered in.

• Do not allow the rope to slip through your hand and do not approach the winch too closely.

• Turn off the winch and repeat the procedure until all the rope is spooled except 3 ft.

• Disconnect the remote control switch and finish spooling in rope by rotating the drum by

hand with clutch disengaged.

• On hidden winches, spool in rope under power but keep hands clear.

5

English

Winch Operation Warnings

Read the following carefully before attempting to operate your winch and keep the instructions for

future reference.

1. The uneven spooling of rope,while pulling a load, is not a problem, unless there is rope stacked

up on one end of the drum. If this happens, reverse the winch to relieve the load and move your

anchor point further to the center of the vehicle. Once complete, you can unspool and rewind for

a more balanced lay of the rope.

2. Store the remote control switch inside your vehicle where it will not get damaged. Inspect it

before you plug in.

4. When ready to begin spooling in, plug in remote control switch or use handle bar rocker switch

with clutch disengaged. Do not engage clutch with motor running.

3. Turn ATV key switch to ON position. Check winch for proper operation. The rope should

spool in and out in the direction indicated on the rocker switch / remote control.

9. After winch use, always prepare your winch for storage. Inspect the installation, rope, rigging,

and accessories for any damage that may have occurred during use. Inspect the winch by

checking the tightness of mounting bolts and checking the winch for any loose

components or fasteners.

10. The solenoid is a primary safety feature in your winch system. It disconnects your winch from the

battery when the ATV is not in use. The solenoid must be correctly installed for the winch

to work properly.

5. Never connect the hook back to the rope as this causes rope damage. Always use a sling or

chain of suitable strength.

6. Observe your winch while winching if possible, standing at a safe distance. Stop the

winching process every meter or so to assure the rope is not pulling up in one corner.

Jamming the rope can break your winch.

7. Ensure "D" rated, or bow shackles are used in conjunction with an approved tree trunk protector

to provide a safe anchor point.

8. When extending the winch rope, ensure that at least five wraps of rope remain on the drum at all

times. Failure to do this could result in the rope parting from the drum under load. Serious

personal injury or property damage may result.

11. All winches are provided with a red marking on the rope which identifies

where (5) rope wraps remain on the winch drum. No recovery should be

attempted beyond this marking or serious injury may occur.

12. Since the maximum line pull is achieved on the first layer of the winch, it is desirable to pull off

as much line as you can for heavy pulls. Doubling or tripling snatch blocks can help. You

must leave at least five wraps minimum on the drum or see red rope NOT exposed!

13. Draping a heavy blanket or similar object over the extended winch rope is recommended as it

will dampen any back lash should a failure occur.

14. Neat, tight spooling avoids rope binding, which is caused when a load is applied and the rope

is pinched between the others. If this happens, alternatively power the winch in and out. Do not

attempt to work a bound rope under load, free by hand.

15. Apply blocks to wheels when vehicles are on an incline.

16. Battery:

• Be sure that the battery is in good condition. Avoid contact with battery acid or other contaminants.

.

a

y:

• Always wear eye protection when working around a battery.

• Have the engine running when using the winch, to avoid rapid degradation of the battery.

6

Solenoid

ATV Winch

Figure: 1

Mini Rocker Switch

To install an ATV winch, you need to mount the winch, solenoid, Handlebar Mini Rocker switch & Remote socket (female

Receiver). Winch & Accessory mounting locations may vary depending on your ATV/UTV Make/Model. Please read the ATV

Winch Kit mounting instructions provided on the next page.

Handled Remote

Control

OUT IN

ATV Winch Kit Mounting:

English

7

®

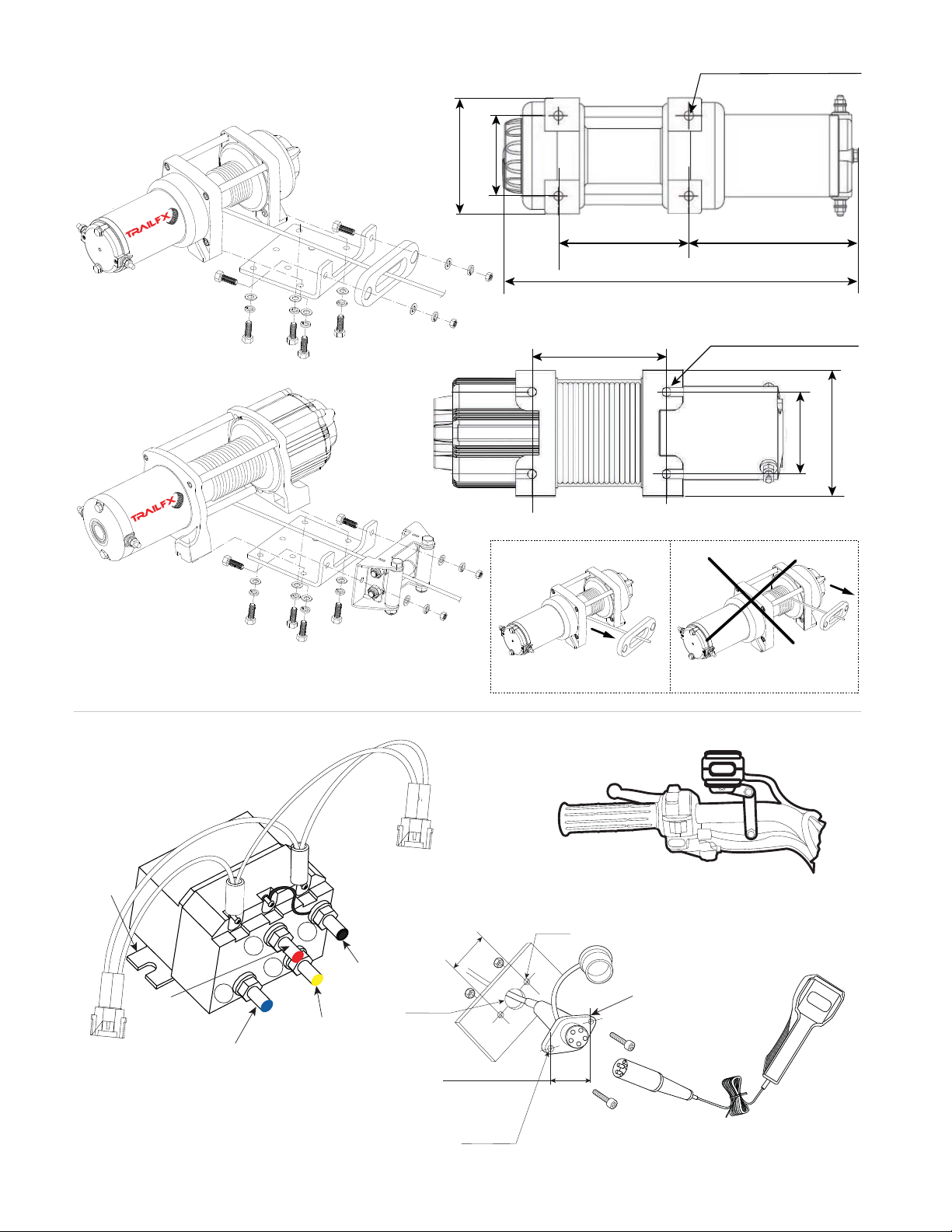

13.35” ( 339 mm )

4.88” ( 124 mm )

1.98” ( 50 mm )

3”( 76 mm )

4.88” ( 124 mm )

4.33” ( 110 mm )

3” ( 76 mm )

6.3” (160 mm )

4 x ø8 mm (Threaded)

4.62” ( 117 mm )

4 x ø8 mm (Threaded)

ø4.5 mm

1.98”(50 mm)

ø4.5 mm

ø19 mm

WINCH MOUNTING

W35B, WS35B

W45B, WS45B

CORRECT INCORRECT

Red

Terminal

Black Terminal

Remote Receiving

Socket

Solenoid Mounting

Blue Terminal

Mounting

Plate

Yellow Terminal

B+

M-

M+

B-

DOWN WIND TOP WIND

Handlebar Mini Rocker Switch

Handheld Remote Control

OUT IN

Figure: 2

Figure: 3

Figure: 4

Figure: 5

8

OUT IN

®

®

Winch Mounting:

1. To secure the winch, always use a flat, secure mounting location at least 3/16 inch (4.8 mm) thick.

2. 5/16-18 x 1 inch grade 5 hexagonal head cap screws and lock washer supplied with TrailFX

ATV/UTV Winch kit.

3. Torque mounting bolts to 12 lbs/ft (1.7 kg-m).

4. Attach roller fairlead / aluminium fairlead to winch mounting plate using 3/8-16 bolts, nuts and washers

5. Attach the clevis Hook to the rope.

6. Put the clutch in freespool position & manually feed cable loop through fairlead.

7. Attach hook to cable loop and re-engage the clutch.

8. Refer to figure No. 2 for the mounting pattern & dimensions.

9. After mounting, rope should be in the under wind direction as shown in the figure 2. Over-winding

the rope may damage the winch and void warranty.

Solenoid Mounting:

1. The solenoid disconnects the winch from the power source (Battery) when ATV is not in use.

2. The solenoid should be mounted on a safe, clean place close enough to the battery.

3. The solenoid can be placed under the seats, in the rear storage box, or as recommended by the ATV

manufacturer.

4. The solenoid should have enough clearance from other metal parts of the ATV to avoid direct contact,

which may lead to solenoid malfunction.

5. Drill mounting holes for the solenoid, however do not mount the solenoid until you attach all the

cables from the battery, handlebar mini rocker switch & remote control.

6. Cable colors should be matched with the contact terminal color codes (M+, M-, B+, B-) as shown in

the figure 3.

Handlebar Mini Rocker Switch Mounting:

1. Using the supplied black coated mounting clamp & screws, mount the mini rocker switch on the

handlebar.

2. A small piece of electrical tape could be used to avoid rotation of mini rocker switch cable after

mounting on the handlebar. (N0TE: It's recommended to mount this mini rocker switch on the left

side of the handlebar).

3. After mounting the mini rocker switch, route the cables to the place where the solenoid is

mounted. Connect the small red lead into the wire that electrifies with the ignition switch “ON”

and not electrifies with the ignition switch “OFF” as shown in the figure No 6. The wire

should only have power when the ATV/UTV key is in the “ON” position (Preferably fuse controlled).

Remote Control Socket Mounting:

1. Select a place to mount the remote control socket (female receiver).

2. Drill 3 holes as per the pattern & dimensions shown in the figure 5 and mount the socket.

3. After mounting the remote socket, route the cables to the place where the solenoid is mounted.

Connect the small red lead into the wire that electrifies with the ignition switch “ON”and not

electrifies with the ignition switch “OFF” as shown in the figure No 6. The wire should only

have power when the ATV/UTV key is in the “ON” position (Preferably fuse controlled).

4. Keep the remote socket closed with the built in cap when not in use.

9

English

OUT IN

Motor

Blue

Yellow

Black

Red

Positive Terminal (+) Positive Terminal (+)

Negative Terminal (-)

Red Terminal

Black Terminal

Solenoid

Blue Terminal

Yellow Terminal

Negative Terminal (-)

Remote

Receiver Socket

Small Red Cable

Handle Bar Mini Rocker Switch

ATV Ignition Key

Handheld

Remote Control

Electrical Connection:

10

B+B-

OUT IN

M+ M-

White Plastic Connector Green &

Black

Small Red Cable

Figure: 6

1. Please refer to Figure 6 while making electrical connections.

2. Connect one end of the “Yellow” cable to the positive (+) Terminal of the winch motor.

3. Connect the other end of the “Yellow” cable to the “Yellow Terminal marked as M+” on the solenoid.

4. Connect one end of the “Blue” cable to the negative (-) Terminal of the winch motor.

5. Connect the other end of the “Blue” cable to the “Blue Terminal marked as M-” on the solenoid.

6. Connect one end of the “Red” cable to the “Red terminal marked as B+” on the solenoid.

7. Connect one end of the “Black” cable to the “Black terminal marked as B-” on the solenoid.

8. There are 2 white plastic connectors provided from the solenoid.

9. Connect any one of the white plastic connectors with the black jacketed cable which is connected

to the handlebar mini rocker switch on the other end.

10. Connect the other white plastic connector with the black jacketed cable which is connected to the

remote receiver socket on the other end.

11. Make sure that the 2 small red cables coming from the handlebar mini rocker switch & handheld

remote control are connected to the ATV Ignition switch as stated under the handlebar mini

rocker switch mounting Instructions & remote control mounting instructions on the previous page.

12. Connect the loose end of the “Red” cable from the red terminal of solenoid to the positive (+) terminal

of the battery.

13. Connect the loose end of the “Black” cable from the black terminal of the solenoid to the negative (-)

terminal of the battery.

14. Make sure that all the cable connections are properly connected with the referred terminals and are

secured, clear of sharp edges & metal objects.

15. Use the provided black color cable / terminal protectors to protect connection points.

16. Use extra electrical insulation tape & cable tie wraps to secure wiring.

Remote

Transmitter

(OPTIONAL)

Wireless

Remote Control

®

11

MUST READ

Winch Operation

Suggestion

The best way to get acquainted with how your winch operates is to make a few test runs before you

actually need to use it. Plan your test in advance. Remember you can hear your winch as well as

Operating

1. Ensure the vehicle is secure by applying the parking brake or chocking the wheels.

3. Recheck all rope rigging before proceeding.

4. Plug in the winch remote control or use the handlebar mini rocker switch. It is recommended

that the winching operation takes place from the driver’s position to ensure safe operation.

5. To commence winching operation, start vehicle engine, place transmission in neutral, maintain

engine speed at idle.

6. Operate the handlebar mini rocker switch / remote control switch to IN or OUT until the vehicle has

been retrieved. Regularly check the winch to ensure rope is winding onto the drum evenly.

7. TrailFX ATV/UTV Winches are designed for intermittent use only. DC powered motor installed on

these winches can operate continuously under load for less than a minute and should be cooled

down for several minutes before operating again.

8. Longer runs will make the motor load heavier, causing the motor to create excessive heat, lower

speed and increase risk of potential winch failure. If the motor becomes uncomfortably hot to

touch, stop and let it cool for a few minutes, before winching again.

1. Never winch with your vehicle in gear. This could damage your vehicle’s transmission.

2. Never wrap the rope around the object and hook onto the rope itself. This can cause damage to

the object being pulled, and kink or fray the rope.

3. Keep hands, clothing, hair and jewelry clear of the drum area and rope when winching.

4. Never use the winch if the rope is frayed, kinked or damaged.

5. Never allow anyone to stand near the rope or in line with the rope behind the winch while it is

under power. If the rope should slip or break, it can suddenly whip back towards the winch,

causing a hazard for anyone in the area. Always stand safely to the side while winding.

6. Do not leave the remote control plugged in when not in use.

EVEN UNDER NO LOAD CONDITION, NEVER OPERATE WINCH FOR MORE THAN 2 TO

3 MINUTES CONTINUOUSLY! LONG DURATION PULLS MAY CREATE EXCESSIVE HEAT

ON THE MOTOR, CAUSING WINCH FAILURE & VOID WARRANTY!

2. Pull out the rope to the desired length and connect to an anchor point. The winch clutch allows

rapid uncoiling of the rope for hooking onto the load or anchor point. The shifter tab located on the

gear housing of the winch operates the clutch as follows:

a) To disengage the clutch, rotate the clutch shifter tab into the “FREESPOOL” position.

Rope may now be free spooled off the drum.

b) To engage the clutch, move the clutch shifter tab into the “ENGAGED” position. The

winch is now ready for pulling.

see it operate. Recognize the sound of a light steady pull, a heavy pull, and sounds caused by load

jerking or shifting. Soon you will gain confidence in operating your winch and its use will become

second nature to you.

English

12

Maintenance

It is highly recommended that the winch be used regularly (once a month). Simply power the rope

out 24 ft., free spool 9 ft. and then power back in. This will keep all components in good working

condition so that the winch can be relied on when needed. Contact your dealer for technical

assistance and repairs.

Trouble Shooting

Symptom Possible Cause Suggested Remedy

Motor does not turn on Switch assembly not

connected properly. Insert switch assembly firmly to the connector.

Loose battery cable. Tighten nuts on cable connectors.

Solenoid malfunctioning.

Tap solenoid to free contact, applying 12 volts to

coil terminal directly. Make an audible clicking when

activating.

Defective rocker switch

assembly. Replace rocker switch assembly.

Defective motor. Check for voltage at armature port with switch

pressed. If voltage is present, replace motor.

Water has entered motor. Drain and dry, run in short bursts without load until

completely dry.

Motor runs too hot. Long period of operation. Let winch cool down periodically.

Motor runs slowly or

without normal power.

Battery runs down. Recharge battery by running vehicle.

Insufficient current or voltage. Clean, tighten or replace the connector.

Motor runs but rope

drum does not turn. Clutch not engaged. Turn clutch into engaged position, if that does

not work, ask a qualified technician to check and repair

Motor runs in one

direction only.

Defective or stuck solenoid. Tap solenoid to free contacts. Repair or replace

solenoid.

Defective rocker switch

assembly. Replace rocker switch assembly.

Replace rope with the same type, exact diameter, length and strength as that of the

existing rope. Use of different type rope will void warranty!

Lubrication

All moving parts in the winch are permanently lubricated with high temperature lithium grease at the

time of assembly. Lubricate wire rope periodically using light penetrating oil. Inspect for broken strands

and replace if necessary. If the rope becomes worn or damaged it must be replaced.

Rope Installation

Unwind the new rope by rolling it along the ground,to prevent kinking. Remove the old rope and

observe the manner in which it is attached to the rope drum flange. Install the new rope in the same

way as the old rope is attached to the rope drum flange.

13

Motor rating based on input power.

Solenoid meets IP67 specification for water resistance.

TrailFX Part No. W35B - Steel Rope WS35B - Synthetic Rope W45B - Steel Rope

Rated Line Pull

Motor

3500lbs (1581kgs)

single-line

3500lbs (1581kgs)

single-line

4500lbs (2045kgs)

single-line

3.8 HP Permanent

magnet motor

3.8 HP Permanent

magnet motor

4.5 HP Permanent

magnet motor 4.5 HP Permanent

magnet motor

Remote Control Mini rocker switch &

handheld remote control

Mini rocker switch &

handheld remote control

Mini rocker switch &

handheld remote control

Mini rocker switch &

handheld remote control

Electrical Control

Gear Train 3 Stage planetary

250A Solenoid 250A Solenoid 250A Solenoid 250A Solenoid

3 Stage planetary 3 Stage planetary

Gear Ratio 136 : 1 136 : 1 166 : 1

Clutch Type Cam activated Cam activated

Braking Action Mechanical brake Mechanical brake

Drum Size

(Diameter X Length) 2.0" X 2.9" 2.0" X 2.9"

Fairlead 4 Way roller fairlead Aluminum fairlead

Cam activated Cam activated

Mechanical brake

2.0" X 2.9"

4 Way roller fairlead

WS45B - Synthetic Rope

4500lbs (2045kgs)

single-line

3 Stage planetary

166 : 1

Mechanical brake

2.0" X 2.9"

Aluminum fairlead

Winch Performance (12V DC) Performance specs are based on first layer of drum.

1000

0

2000

3000

3500

4500

15

11

7

79

138

225

13

10

7

5

71

124

170

227

79

21

15

11

7

21 19 17 20

19

138

225

2

Motor

Current

Amps

Line

Speed

Ft / min

13

10

7

5

17

Line

Speed

Ft / min

Motor

Current

Amps

Line

Speed

Ft / min

Motor

Current

Amps

Line

Speed

Ft / min

Line Pull

(lbs)

Rope

Capacity

(Ft)

Line Pull

by Layer

(lbs)

Rope

Capacity

(Ft)

Line Pull

by Layer

(lbs)

Rope

Capacity

(Ft)

Line Pull

by Layer

(lbs)

Line Pull

(Layer)

1

3

4

3500 8.85 3500 8.85 4500 7.5

2561 19.22 2561 19.22 3673 16.3

2234 31.11 2234 31.11 3102 26.8

1981

44.52

1981 44.52 2685 40

Rope

Capacity

(Ft)

Line Pull

by Layer

(lbs)

4500 7.5

3673 16.3

3102 26.8

2685 40

71

124

170

227

20

Motor

Current

Amps

TrailFX ATV / UTV Winch Specifications

Rope

(Diameter X Length)

3/16" X 50' Steel rope 3/16" X 50'

Synthetic rope

(Dyneema SK75 fibre)

13/64" X 40' Steel rope 15/64" X 40'

Synthetic

rope

(Dyneema SK75 fibre)

3/8” Sq. X 6’ 3/8” Sq. X 6’ 3/8” Sq. X 6’ 3/8” Sq. X 6’

Recommended

Battery

650 CCA

Minimum for winching

650 CCA

Minimum for winching

Battery Lead

Weight

Mounting Pattern

24 lbs 21 lbs

3” X 4.88”

(Universal type)

3” X 4.88”

(Universal type)

3” X 4.88”

(Universal type)

3” X 4.88”

(Universal type)

650 CCA

Minimum for winching

30 lbs

650 CCA

Minimum for winching

26.5 lbs

English

3500lb

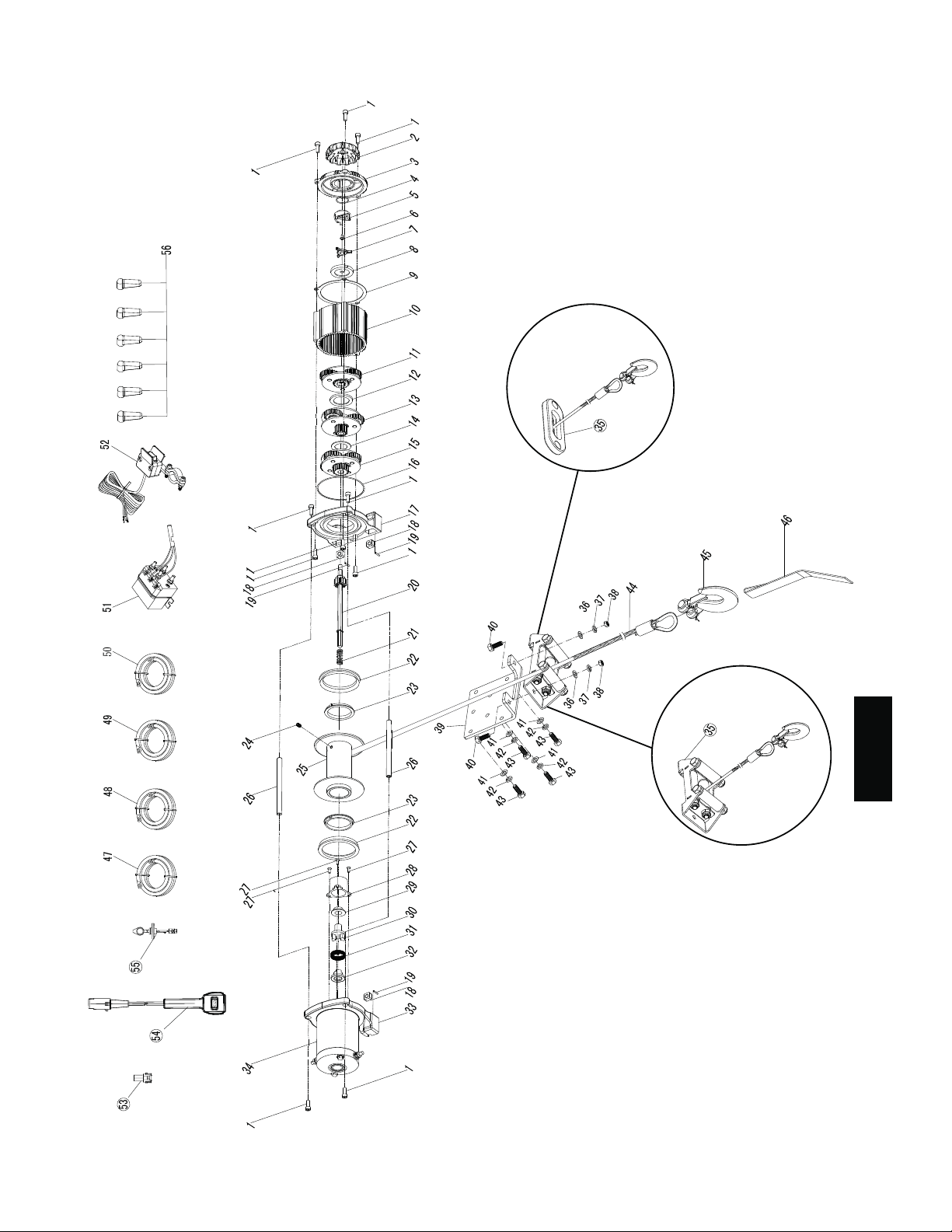

Parts List W35B and WS35B

14

ROLLER FAIRLEAD

APPLICABLE FOR

WIRE ROPE WINCH

ALUMINIUM FAIRLEAD

APPLICABLE FOR SYNTHETIC

ROPE WINCH

4500lb

Parts List W45B and WS45B

15

ROLLER FAIRLEAD

APPLICABLE FOR

WIRE ROPE WINCH

ALUMINIUM FAIRLEAD

APPLICABLE FOR SYNTHETIC

ROPE WINCH

English

Parts List W35B and WS35B

Replacement Parts list

Parts List W45B and WS45B

No. Description Qty

1Socket head screw 4

2Clutch knob

1

3Socket head screw 4

4Gear box

1

5

6

7

Nut

O Ring

Clutch knob base

4

1

1

8

9Screw

Fork pin 1

1

10 2nd stage planetary gear 1

11 Spacer 1

12 3rd stage planetary gear 1

2

2

4

2

13

14 O Ring

Gear box cap

15 Nut

16 Nylon bearing

Seal

Drive shaft

Spring

Screw

Tie bar

Drum

1st stage planetary gear

Screw

Brake caliper

Spring

Brake base

Brake house

Gearbox (motor side)

Motor Assy

Mounting plate

Bolt

Washer

Lock washer

Nut

Wire rope

Hook 1/4

Washer

Lock washer

Bolt

Power lead red

Power lead black

Power lead bule

Power lead yellow

Connector Assy

Control handle

Plug-in components

Solenoid

Mini rocker switch

Brush

Hand strap

Locating ring

Clip

2

1

1

1

1

2

1

1

6

1

1

1

1

1

1

2

1

2

2

2

1

1

4

4

4

1

1

1

1

1

1

1

6

1

6

1

1

1

17

18

19

20

21

22

23

24

25

27

28

29

30

31

32

33

34

35 1

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

26

No. Description Qty

1Socket head screw 10

2Clutch knob

1

3Cover of gear box 1

4O Ring

Screw

Fork pin

1

5

6

7

Clutch knob base 1

1

1

8

9

Inner supporter

Gasket ring 1

1

10 Ring gear 1

11 1st stage planetary gear 1

12 Bulkhead

Bulkhead

1

1

1

1

1

13

14 2nd stage planetary gear

15 3rd stage planetary gear

16 O Ring

Gear box base

Nut

Shaft Assy

Spring

Gasket ring

Nylon bearing

Screw

Drum

Screw

Brake house

Brake caliper

Locating ring

Spring

Brake base

Gear box (motor side)

Motor Assy

Washer

Lock washer

Nut

Mounting plate

Bolt

Washer

Lock washer

Nut

Nylon rope

Hook 1/4

Hand Strap

Power lead red

Power lead black

Power lead bule

Power lead yellow

Mini rocker switch

Solenoid

Plug-in components

Control handle

Tie bar

Elastic pin

1

1

4

4

1

2

2

1

1

3

1

1

1

1

1

1

1

2

2

2

1

2

4

4

4

1

1

1

1

1

1

1

1

1

1

1

2

1

17

18

19

20

21

22

23

24

25

27

28

29

30

31

32

33

34

35

Fairlead - ( Applicable for synth rope )

4

1

4

1

4

1

1

1

1

1

1

1

2

2

4

2

2

1

1

1

1

2

1

1

6

1

1

1

1

1

1

2

1

2

2

2

1

1

4

4

4

1

1

1

1

1

1

1

6

1

6

1

1

1

1

Roller fairlead - ( Applicable for wire rope )

Fairlead - (Applicable for synth rope)

Roller Fairlead-(Applicable for wire rope) 1

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54 Connector Assy

Brush 1

6

55

56

26

- Applicable

WA025

WA026

WA027

WA028

WA029

Part No. Description W35B WS35B WS45B

W45B

Remote control

Solenoid

Handlebar rocker switch

Synthetic rope

Synthetic rope

WA030

WA031

WA032

Wire rope

Wire rope

Roller fairlead

WA033

WA034

WA035

WA036

WA037

Part No. Description W35B WS35B WS45B

W45B

Aluminum hawse, black

Cables set

Mounting plate

Forged hook

Mounting hardware set

WA038

WA039 Motor

Motor

16

Limited Lifetime Warranty For Mechanical Components

Limited One (1) Year Warranty For Electrical Components

Keystone Automotive Operations, Inc. (“Keystone”) warrants the original purchaser that (a) the

mechanical components of any TrailFX winch will be free of defects in material and workmanship

for the lifetime of the winch, and (b) the electrical components will be free of defects in material

and workmanship for a period of one (1) year from the original date of purchase. This Warranty

applies only to the original purchaser of the winch. To obtain any warranty service, you must provide

Keystone with proof of purchase and date of purchase deemed as acceptable to Keystone, such as a

copy of your original purchase receipt. This Warranty does not cover the removal or re-installation of

the winch. Keystone will, at its sole option, repair, replace or refund the purchase price of a defective

winch or component, provided the defective winch or component during the warranty period is

returned, transportation charges prepaid, to Keystone. Attach owner’s name, address, telephone

number, a description of the problem, and a copy of your receipt or original bill of sale bearing the

Keystone serial number of the defective winch and date of purchase.

This Warranty does not apply to (i) to finish, synthetic rope or wire rope; (ii) if the winch has been

damaged by accident, abuse, collision, misuse, modification, misapplication, overloading, improper

installation or improper service; or (iii) any normal wearable part. This Warranty is void if the serial

number has been removed or defaced. Commercial or industrial use or application, or any hoisting

application of the winch voids the Warranty.

THE WARRANTY SET FORTH ABOVE IS THE ONLY WARRANTY. THERE ARE NO OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. ANY IMPLIED WARRANTY WHICH

BY LAW MAY NOT BE EXCLUDED IS LIMITED IN DURATION TO ONE (1) YEAR FROM THE DATE OF

ORIGINAL RETAIL PURCHASE OF THE PRODUCT.

No Keystone dealer, agent, or employee is authorized to make any modification, addition or extension

to this Warranty.

KEYSTONE SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES (INCLUDING, BUT NOT LIMITED TO, LOST PROFITS, DOWN TIME OR LOSS OF USE) UNDER

ANY LEGAL THEORY, EVEN IF KEYSTONE WAS ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Some states do not allow the exclusion of implied warranties of the exclusion or limitation of liability

for incidental or consequential damages or limitations on how long an implied warranty lasts, so the

above limitation or exclusion may not apply to you. This Warranty gives you specific legal rights. You

may also have other rights that vary from state to state.

Keystone reserves the right to change product design without notice. In situations in which Keystone

has changed a product design, Keystone shall have no obligation to upgrade or otherwise modify

previously manufactured products.

To submit a warranty claim or inquiry, or technical support or warranty information contact:

Keystone Automotive Operations, Inc.

44 Tunkhannock Avenue, Exeter, PA 18643

1.866.638.4870 • E-mail: [email protected]

To return product for warranty service contact:

1.866.638.4870 • E-mail: [email protected]

17

English

1

1

Treuil

Manuel d’utilisateur

Francais

1

This manual suits for next models

1

Table of contents

Languages:

Other TrailFX Winch manuals