•Purchaser/owner must ensure that product is

installed according to these instructions.

Purchaser/owner must not alter or modify the

product.

•Operator and bystanders should never position

any part of body under or on the path of any

portion of this product or the load being supported

or moved.

•Do not allow children to play on or around this

product or the load being supported, or moved.

•Do not use winch to move humans.

•Never exceed the maximum rated capacity.

Refer to stamped markings on winch to obtain

rated capacity.

▪ Capacity is based on direct line pull on third layer

of the strap on the drum. Capacity is reduced as

strap builds up on the drum.

•Never stand along side winch or guide the strap

with your hands.

•Never operate with slippery, wet, or oily hands and

always maintain a firm grip on the winch handle.

▪ Do not attempt to stop a winch by grabbing the

handle while in motion.

•Always maintain a minimum of three layers of

strap on the drum.

•A loud clicking sound from the ratchet must be

heard when pulling the load. If properly engaged

and loud clicking sound is not heard, do not use

and replace ratchet components immediately.

•Never release the crank handle unless the ratchet

plunger/pawl is fully engaged and the load is

supported.

• Winch will not hold the load when load is being

let out.

•Winch is designed for manual operation only and

the load rating is based on an intermittent duty

cycle.

•Excessive force in turning winch handle may

indicate overload. Fulton brand winches will

require a max of 45 lbs of handle force to pull

rated load.

•If you cannot crank the winch with one hand you

are potentially overloading the winch.

•Winches are not designed to secure boats to trail-

ers while towing. Boat tie downs must be used

for this purpose.

•Periodically check mounting hardware for proper

torque and tighten if necessary.

▪ Do not use cable or rope.

•Always replace bent, broken, or worn parts before

using this product.

•On two-speed winches, make sure that the ratchet

plunger is properly engaged and holding the load

before attempting to change gears.

Failure to follow these warnings and instructions may result

in property damage, serious bodily injury, and/or death.

WARNING

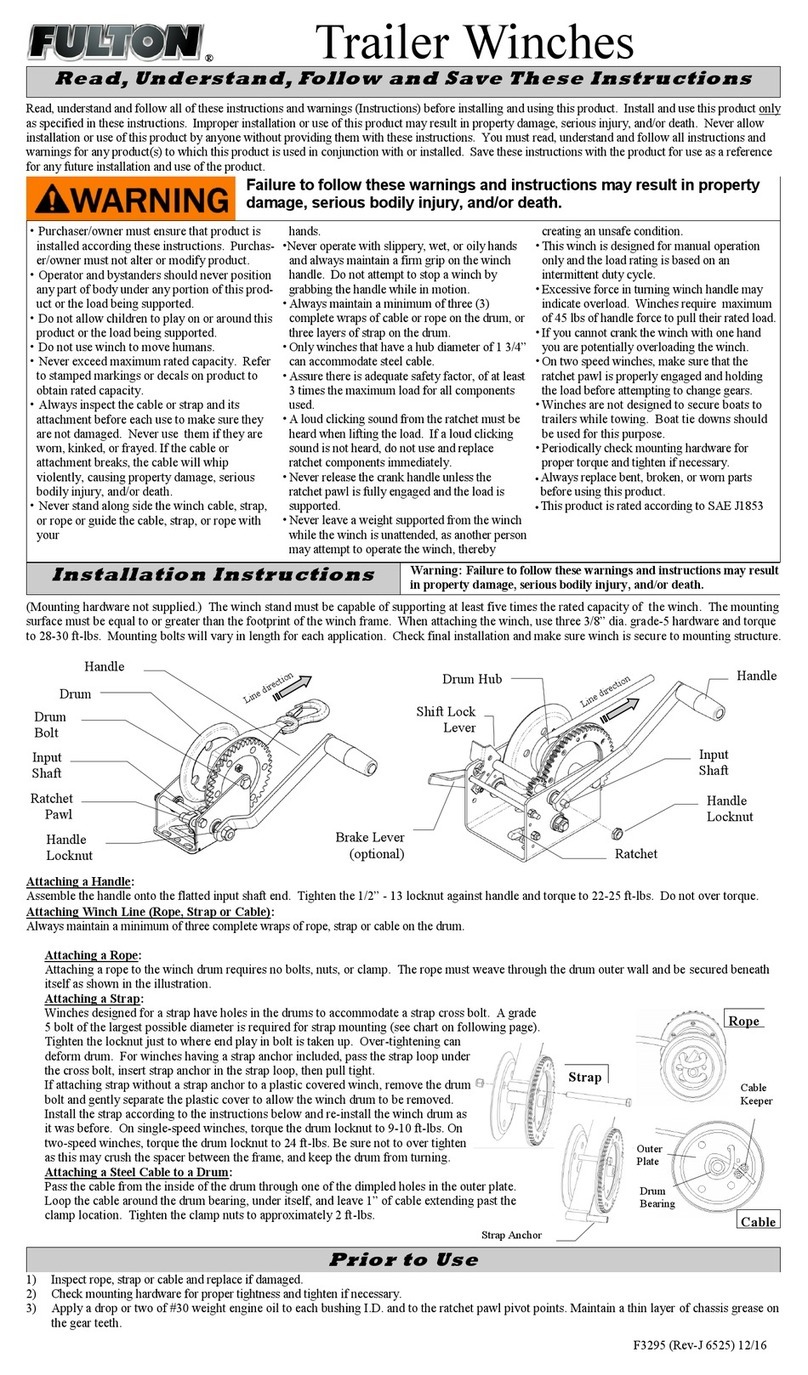

The mounting surface must be equal to or greater than the footprint of the winch frame. When attaching the trailer winch, always use three (3) 3/8” dia.

grade-5 carriage bolts/lock nuts and torque to 28-30 ft-lbs. Check final installation and make sure winch is secure to mounting structure.

Installation Instructions

Warning: Failure to follow all installation instructions could result in

winch failure.

Read, understand and follow all of these instructions and warnings (Instructions) before installing and using this product. Install and use this product only

as specified in these instructions. Improper installation or use of this product may result in property damage, serious injury, and/or death. Never allow

installation or use of this product by anyone without providing them with these instructions. You must read, understand and follow all instructions and

warnings for any product(s) to which this product is used in conjunction with or installed. Save these instructions with the product for use as a reference

for any future installation and use of the product.

Installing Handle Roller Assembly:

Assemble handle assembly as shown and torque locknut to 20-25 ft-lbs., using a 9/16” socket.

Adjustable Handle (6” to 9” and Right or Left Hand Drive):

This handle can be mounted not only in different length configurations, but also in a right or left hand orientation. In order to switch to a right or left hand

drive first remove the bolt and washers from each side of the drive shaft. Push the hex shaft 1/2”-3/4” through to the other side. Do not try to remove the

shaft completely in order to keep the internal gears and bushings inline. Place the handle bolt and washers on the handle side and torque to 22-25 ft-lbs.

Then repeat for the opposite side of the shaft. Do not over torque.

Attaching Winch Strap:

Use strap anchor provided with winch as pictured above. Pass the strap loop under the cross bolt or through the center hub slot, insert strap anchor in the

strap loop, then pull tight. Always maintain a minimum of three complete wraps of strap on the drum.

Strap

Installation

Prior to Use

-Inspect strap and replace if damaged.

-Check mounting hardware for proper tightness and re-torque if necessary.

-Gears, ratchet contact points and shaft bushings must be kept lubricated with a thin oil or grease.

Winch

Mounting

Read, Understand, Follow and Save These Instructions

Trailer Winch

Handle

Bolt

Adjustable

Winch Handle

Lock Washer

Small Flat Washer

Large Flat Washer

Cap

Bolt

Lock Washer

Handle

Installation

Handle Roller

Assembly

Cross Bolt

Strap

Loop

Strap

Anchor

Hub

Slot