+-

1kΩresistor

Controlling the Feather

This route indicator can be wired and controlled in

3 main ways:

1) Using a switch on a control panel

2) Using a switch as fitted on some points

3) From a suitable DCC decoder (eg SC2)

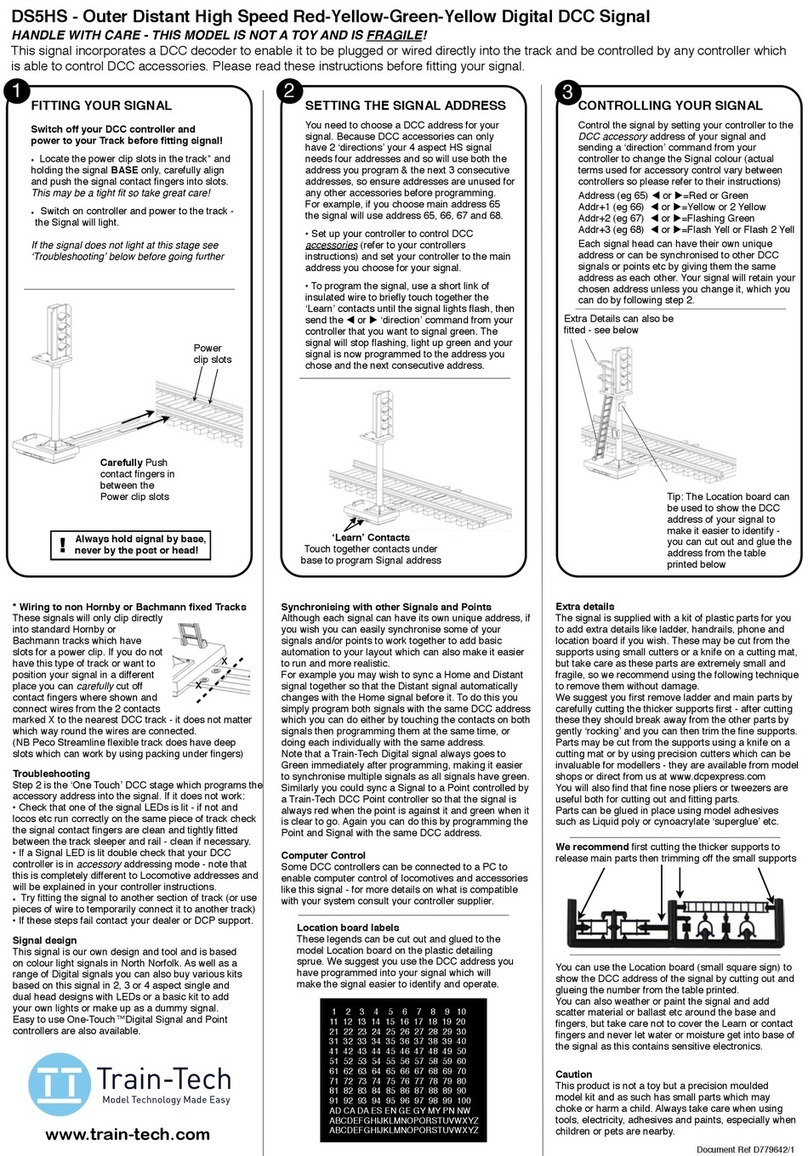

Wiring the Feather

The diagram below shows the 3 components

which go to make up the feather.

However before fitting it together you should

solder your connecting wires onto the feather.

Some types of signal may allow you to pass the

wires inside the signal post as well as the existing

signal connections, though you will need to use

quite fine insulated wire to be able to do this.

Or you can fix the wires down the back of the

signal head and post hidden from view.

All 5 white LEDs are already connected together

in parallel on the PCB so there are just two solder

connections to make, one on the front (+) (where

LEDs are mounted) and one on the rear (-) as

shown below. Note polarity is important with LEDs

and always use a resistor in series to prevent

damage - refer to the Using LEDs advice below.

When soldering the wires onto the PCB contacts

pre-tin the wires first and be careful not to apply

too much solder to keep the connections slim.

LK1 Left Feather add-on kit

CAUTION - ALWAYS SWITCH OFF POWER TO YOUR LAYOUT BEFORE CONNECTING OR DISCONNECTING ANY ACCESSORIES

This kit contains the components to retrospectively add a left feather to an OO/HO gauge colour light signal - reasonable craft skills

including gluing and soldering will be required.

Introduction

Contents

1 Feather circuit board (PCB) with 5 fitted LEDs

1 Front feather cover with light cowls

1 Back feather cover

1 1KΩresistor (Colour: Black Brown Red Gold)

1 Instruction leaflet

You will need

Soldering iron with small tip

Flux cored solder

Plastic Adhesive

Pair of fine wires to connect the feather

Magnifier

Cutting mat

A Feather is a route indicator fitted to the top of

some colour light signals, usually located just

before a point and which lights when a point is

set in the direction of the feather to show the

driver the route he will be taking.

DC, DCC and automatic signals are available in

the Train-Tech range with route indicators

prefitted and wired, but this kit allows a route to

be added retrospectively to Train-Tech or other

makes of signal. Note that reasonable modelling

skills will be required to mount and connect this

route indicator to existing signals.

You can either control the Route indicator using

conventional switches or connect it to a DCC

decoder (eg Train-Tech SC2) to control it from a

Digital controller or computer. You can also

connect the feather to the switch fitted to some

points so that it lights automatically when the

point is in the same direction.

Take extra care when using

tools and adhesives.

-

12-16

V DC

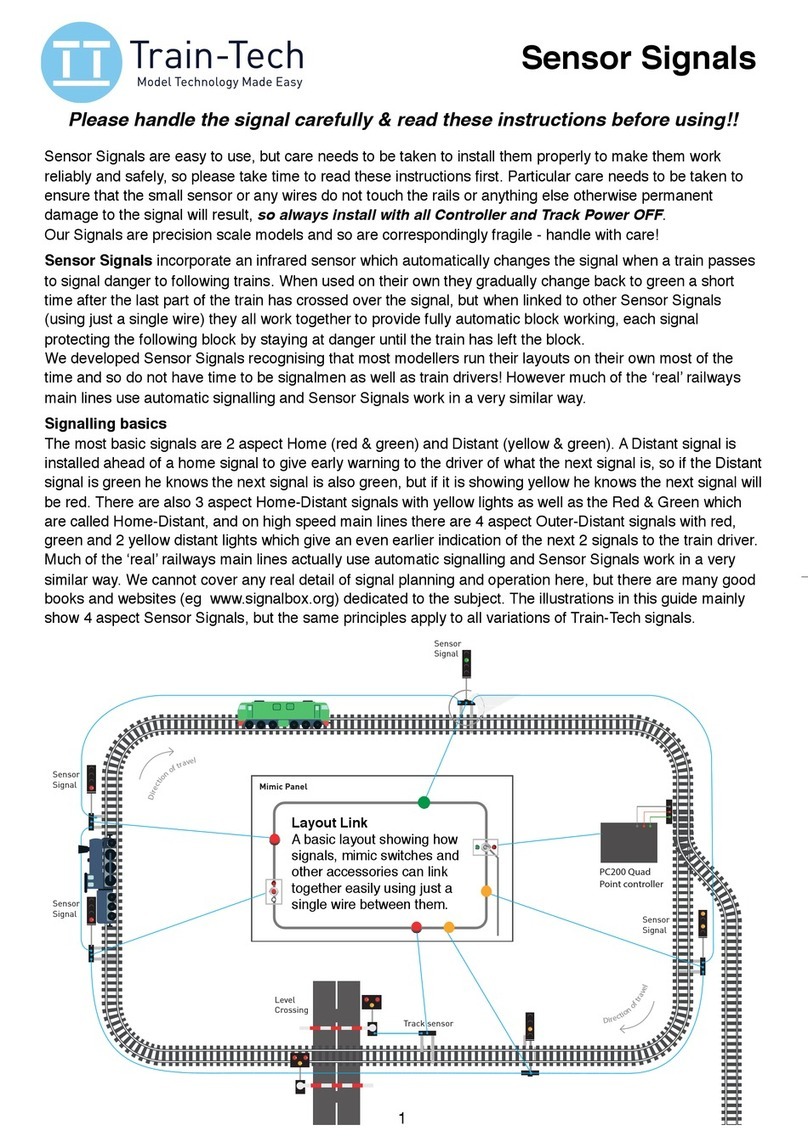

Wiring example for switches

The wiring diagram below shows how to connect a

switch and this example is suitable for either a control

panel switch or a point switch.

©DCP 2018 Document Ref D779679RK

+

Route switch

Before gluing the front and back case together

around the light PCB you can test it using a 12 V

DC supply or a 9 volt battery - do not forget to

use the resistor in series with one of the wires!

Once tested you can trim around the mouldings if

necessary and glue the front and back together

to make the complete feather to mount onto your

signal. The tab fitted to the back cover may be

cut off if not required to fix to the signal.

Cut off

mounting tab

if not required

Feathers are normally located on signals just

before a point so if a point switch is included on

the point motor or you can add a point switch to

the motor (eg Peco PL13) and the advantage is

that the route indicator will light automatically

when the point is in that position.

Remember to always use a resistor when wired to

a DC voltage supply in this way.

Controlling from a DCC decoder

If your layout points are electrically controlled

using DCC, then a decoder can be set up to turn

on the route indicator when the point is set to a

particular direction. Check the decoder

instructions to see if you need to fit a resistor in

series with the LED (note that Train-Tech

decoders have a built in resistor).

Using Signals with Train-Tech DCC controllers

Train Tech manufactures various LED controllers including

the SC1 and SC2 DCC colour light signal controllers which

allow signals with LEDs to quickly and easily connect to

DCC layouts for control by Digital controller or computer.

The SC1 is a dual 2 aspect controller and the SC2 is a 3 or

4 aspect plus route indicator controller.

Like all of our One Touch™DCC products they are quick to

connect needing no resistors or soldering and set up in

seconds with no programming of CV codes.

Assembled Digital Signals with DCC decoders built into the

base are also available which just clip into the track with no

wires or you can connect to the nearest piece of track

using 2 wires.

As well as DCC signals and controllers, Train-Tech also

makes a range of LFX LED lighting controllers which work

on both DC and DCC and offer effects to simulate level

crossings, welding, traffic lights etc - again resistors are

built into all of the LFX units and so LEDs connect directly

to them.

Train-Tech offers packs of various LEDs for modellers and

these come with both instructions and suitable resistors for

using them on a standard DC supply or non Train-Tech

DCC controllers.

See www.train-tech.com for full details of our range or ask

for the latest free Train-Tech brochure.

Using LEDs with model railways

You can use various types of lights for your signal,

but we recommend LEDs as the best choice for

models. LEDs are really useful lights which, unlike

their conventional filament predecessors, are robust,

low power and if used correctly run cool and can

effectively last forever. But there are some important

considerations when using LEDs. Firstly LED stands

for Light Emitting Diode and a diode is an electronic

component which only works in when power is

applied in one specific direction, so they always

need to be fitted the correct way round to work

correctly. Also most standard miniature LEDs a

modeller will use only need a very small amount of

power, so the current flowing through the LED must

be limited and this is usually done by a resistor.

On the usual 12-16 volts DC supply a railway

modeller uses a 1kΩ(one thousand ohms) will limit

the current to around 10-14mA (mA is thousandths

of an amp) which is ideal for most LED’s.

Note you should only ever use LEDs on a DC (direct

current) supply and never an AC (alternating

current) supply because although the LED may

appear to work properly constant reversal of voltage

using AC will eventually damage or shorten its life.

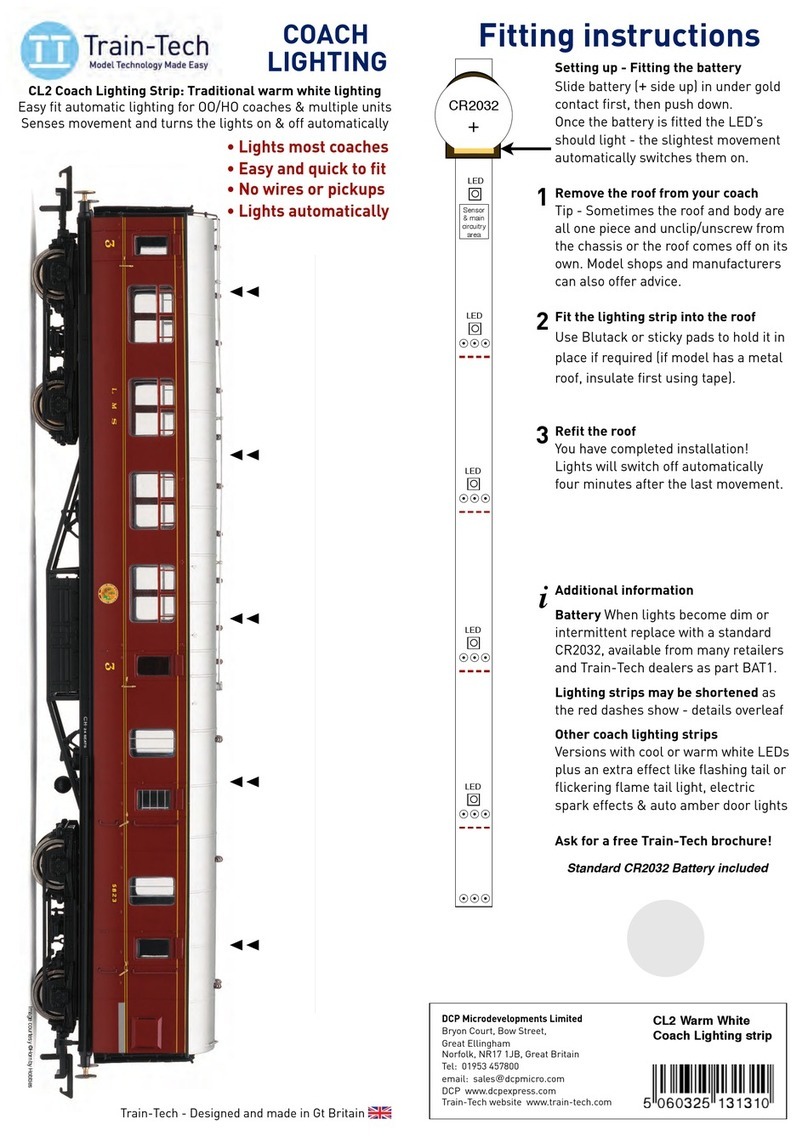

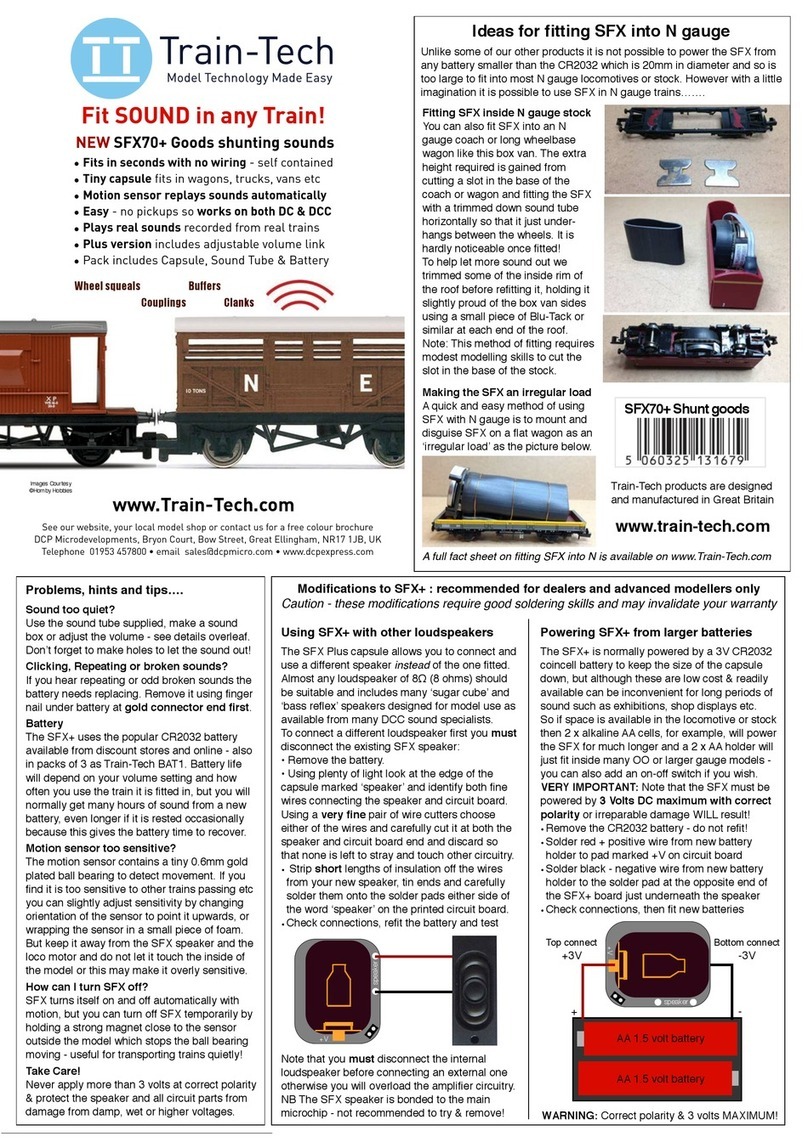

Connecting LEDs

As explained previously LEDs have a polarity and

must be connected the correct way round to light.

The most popular LEDs come in 3mm and 5mm

diameter cases and look similar to this:

The best indication of polarity on this type of LED is

to find the flat side on the round base. This side

usually indicates the negative (Cathode) connection

and the other wire the positive (Anode) connection

to power.

Another really small LED we supply for some Train-

Tech products looks like this:

There are many LEDs available and it is good to

experiment, but check data for specific connection

information as there are no real standards.

FLAT

SIDE

+-

+-

FLAT

SIDE