Page 8

COMMANDER SEARCHLIGHT - NETWORK & CONFIGURATION MANUAL

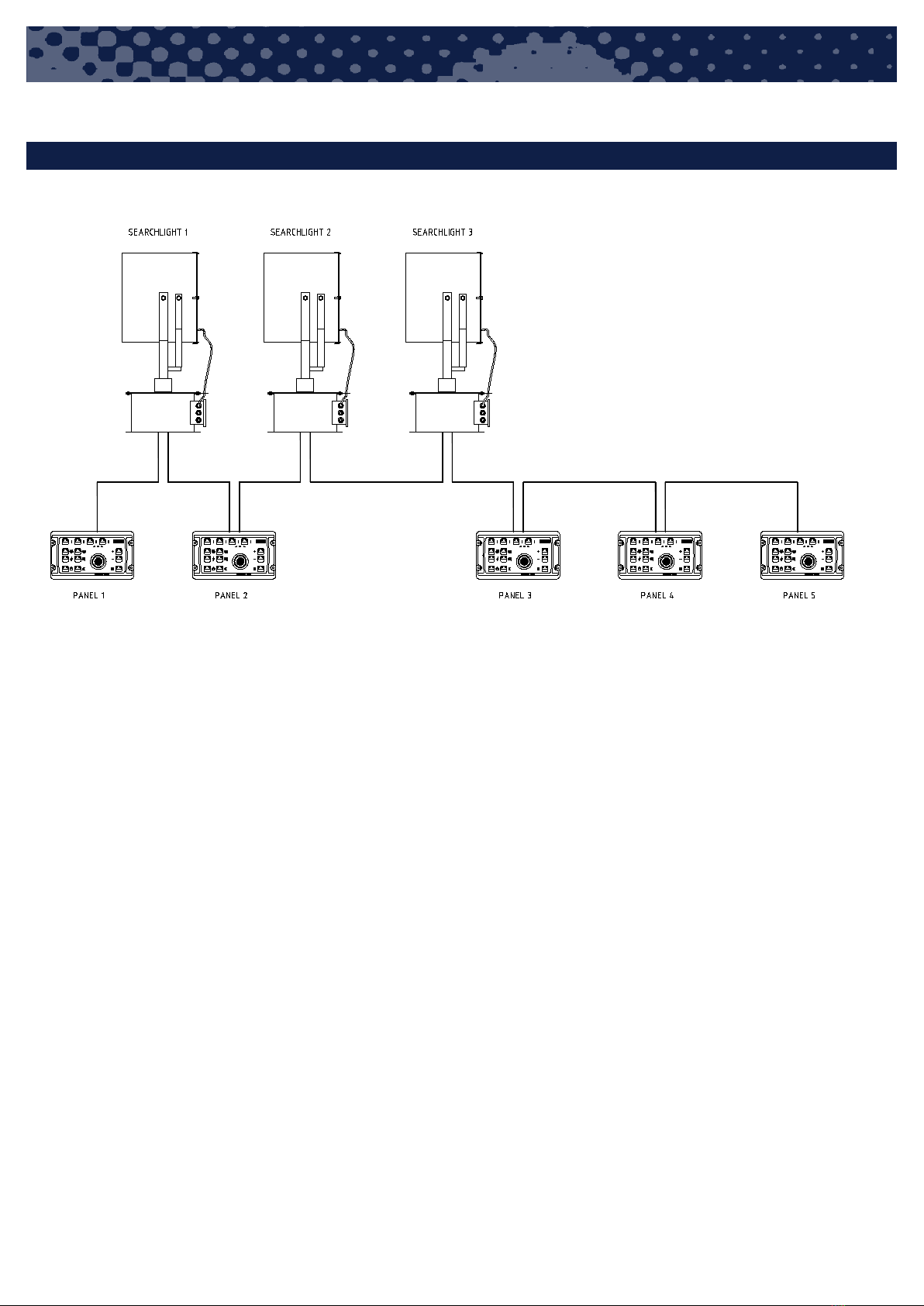

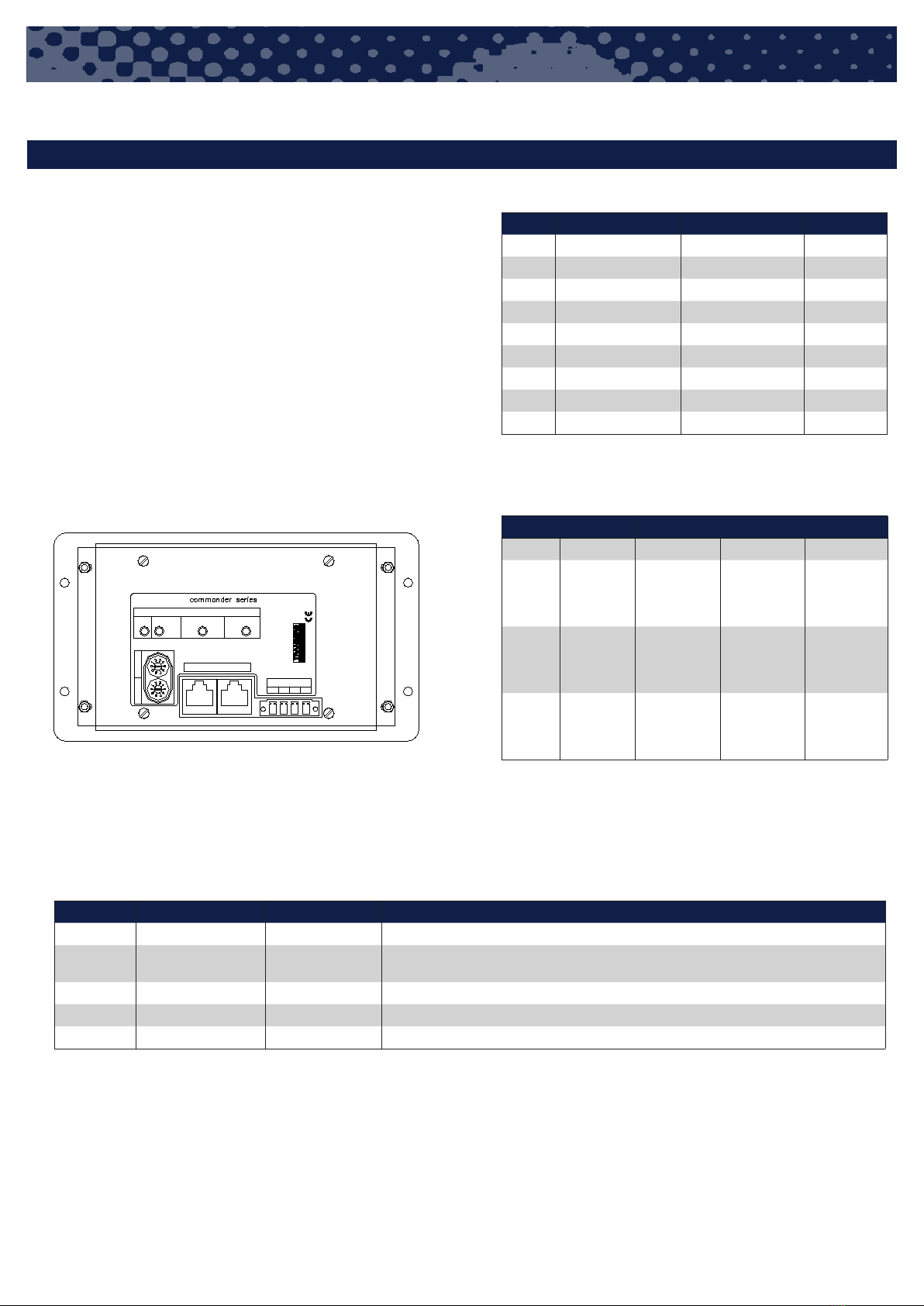

4.1 IDENTIFYING THE MASTER PANEL

For the following special procedures, the master panel need to be

identified.

The master panel can be recognized by the yellow indicator in the

power button. When you turn off power by pressing this button, the

yellow indicator will be continuously lit in the master panel. It will blink

slowly (1 sec. on, 1 sec off) on a slave panel.

4.2 RE-SCAN OF NODES CONNECTED TO THE BUS

If necessary, the master panel can do a bus scan when powered up

using the following procedure:

(Note: Do not operate or use any panels or searchlights during this

procedure. Ensure that all are powered up.)

1. Turn off the master panel using the power button. Release the but-

ton. The backlight will turn off.

2. Press and hold the power button for at least 5 seconds.

3. While holding the power button, press and release the second se-

lect button (marked ‘2/6’ (2613) or ‘B’ (2614) ). (Repeat if neces-

sary, until backlight turns on).

4. The panel backlight will now turn on, and it will start the scanning

of the bus (it takes a couple of seconds).

5. Release the power button.

6. When the scan process is finished, the panel will show which

searchlights are present on the bus by fast flashing the corre-

sponding leds on the select buttons (upper row).

7. Turn on the panel by using the power button as usual.

8. Repeat the procedure if necessary.

4.3 ALTERNATIVE RE-SCAN PROCEDURE

FOR PANELS DELIVERED FROM APRIL 2009 AND ONWARDS:

If necessary, the master panel can do a bus scan when powered up

using the following procedure: A panel can do both this alternate

re-scan procedure as well as the previous procedure (ch. 5.1).

(Note: Do not operate or use any panels or searchlights during this

procedure. Ensure that all are powered up.)

1. Set all panels to standby (“turn off”) by using the on/stdby button.

The backlight will turn off. Locate the master panel (see ch. 3.2),

and turn it on again.

2. Press and hold both speed buttons (‘fast’ and ‘slow’) for at least

5 seconds.

3. On the 2613 and 2614 panels, the indicators in the ‘searchlight

select’ buttons will start flashing in sequence. On the 2612 panels,

the indicators in the speed buttons will flash in sequence. Release

the speed buttons.

4. The sequential flashing will last for a couple of seconds, as long as

the scanning of the bus is performed. When the flashing is finished,

the system is ready for use.

5. Repeat the procedure if necessary.

4.4 RESET OF SEARCHLIGHTS

1. Remove power (230VAC) to the searchlight (motor unit), wait for

approx. 10 sec, and reconnect the power. (It is not necessary to

disconnect the xenon power supply). If several searchlights need

to be reset, repeat this for each searchlight before commencing

to step

2. Do a re-scan from the master panel. Alternatively, remove and re-

apply power (24VDC) to the panels, either all or at least the master

panel. The searchlight will now move to the right and upwards to

find the end positions, and back to center. If necessary, watch the

searchlight at this stage to verify the movement.

4.5 RECALIBRATE END LIMITS ON SEARCHLIGHTS

1. Open the searchlight junction box and set DIP-switch no. 1 to ON.

2. Remove power (230VAC) to the searchlight (motor unit), wait for

approx. 10 sec, and reconnect the power. (It is not necessary to

disconnect the xenon power supply). If several searchlights need

to be reset, repeat this for each searchlight before commencing

to step 3.

3. Do a re-scan from the master panel. Alternatively, remove and re-

apply power (24VDC) to the panels, either all or at least the master

panel. The searchlight will now do a complete movement up – right

– left – center/down to find the end limit positions, and back to

center. If necessary, watch the searchlight at this stage to verify

the movement.

4. Set the DIP-switch no. 1 back to OFF and close the junction box.

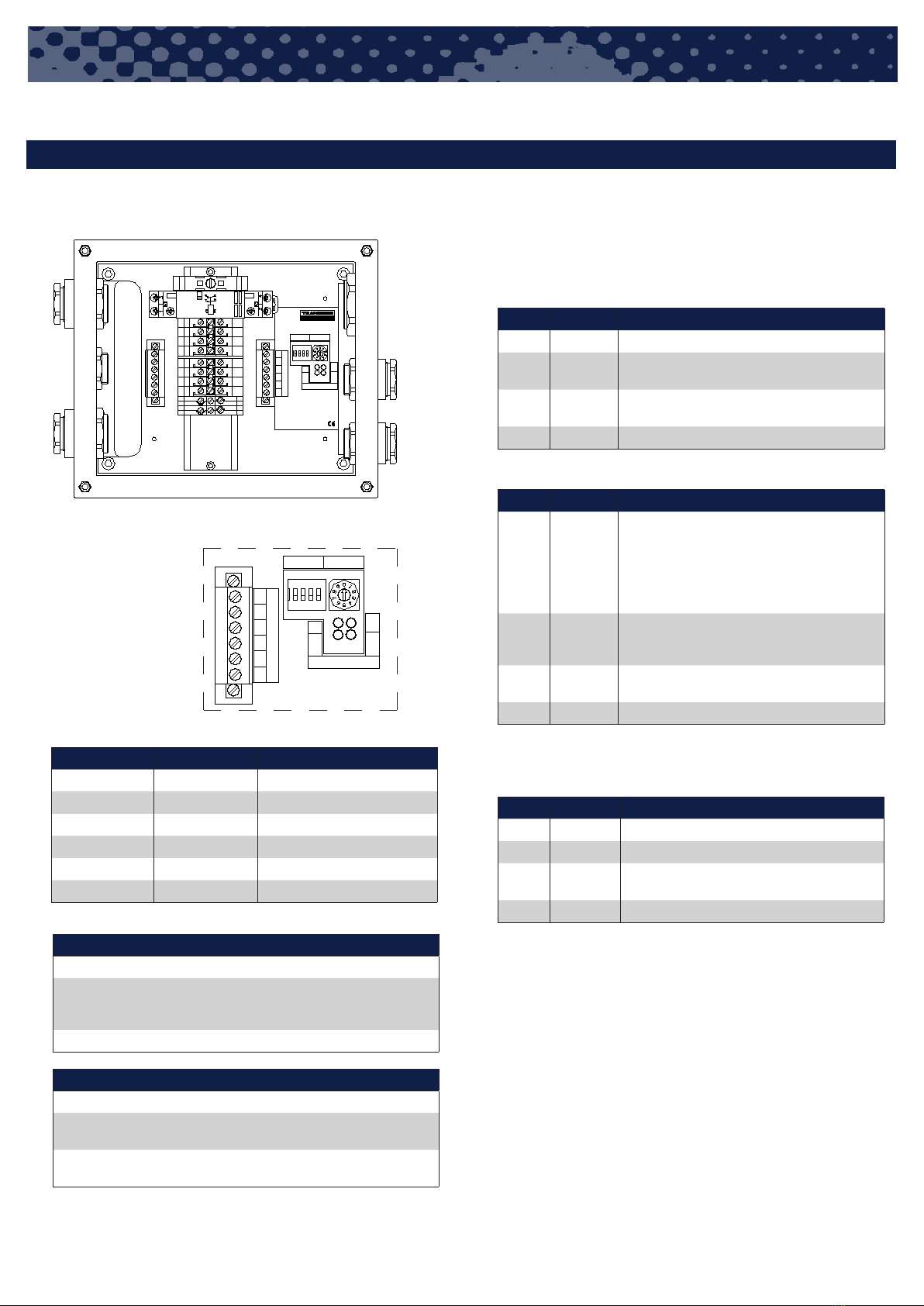

4.6 CHANGING ADDRESS ON A SEARCHLIGHT

PREPARATION:

1. Identify the master panel. Unmount the master pan-

el, so as to get access to the rotary swiches on the rear.

IMPORTANT: Make a note of the settings of the switches

2. Disconnect the power supply to all the searchlights. (Leave the

power supply to the panels connected).

PROCEDURE:

3. Connect the power supply to the searchlight whose

address shall be changed.

4. Turn off the master panel using the power button. Release the but-

ton. The backlight will turn off.

5. Set the rotary switch labeled ”N/A” on the rear, set it to

one lower than the new address of the searchlight (address

minus 1, e.g. set to ‘1’ if the searchlight is to be set to

address ‘2’, i.e. respond to the first press of button ‘2/6’).

6. Press and hold the power button for at least 5 seconds. While

holding the power button, push the button marked ”3/7” (a short

normal push and release). This button can alternatively be pushed

several times, until the panel backlight is lit. When the backligth

is lit, release the power button. The panel will now send a special

message to the searchlight.

7. Check the indicators in the searchlight select buttons (”1/5”, ”2/6”,

”3/7” and ”4/8”). After approx. 5 – 10 sec. one of them will flash

fast (2 times pr. sec) to show the new address of the searchlight.

4 SPECIAL PROCEDURES