CGAD-SVN02C-EN 5

General

Data

Table 01 - General Data - CGAD 20-150 TR - 50 or 60 Hz

Notes:

(1) Data based on operational conditions established by standard ARI550/590-03.

(2) MCA values referes to 380 / 60 Hz power supply.

(3) Ratings based on global consumption (compressors and fans).

(4) MCA values referes to 380 / 50 Hz power supply.

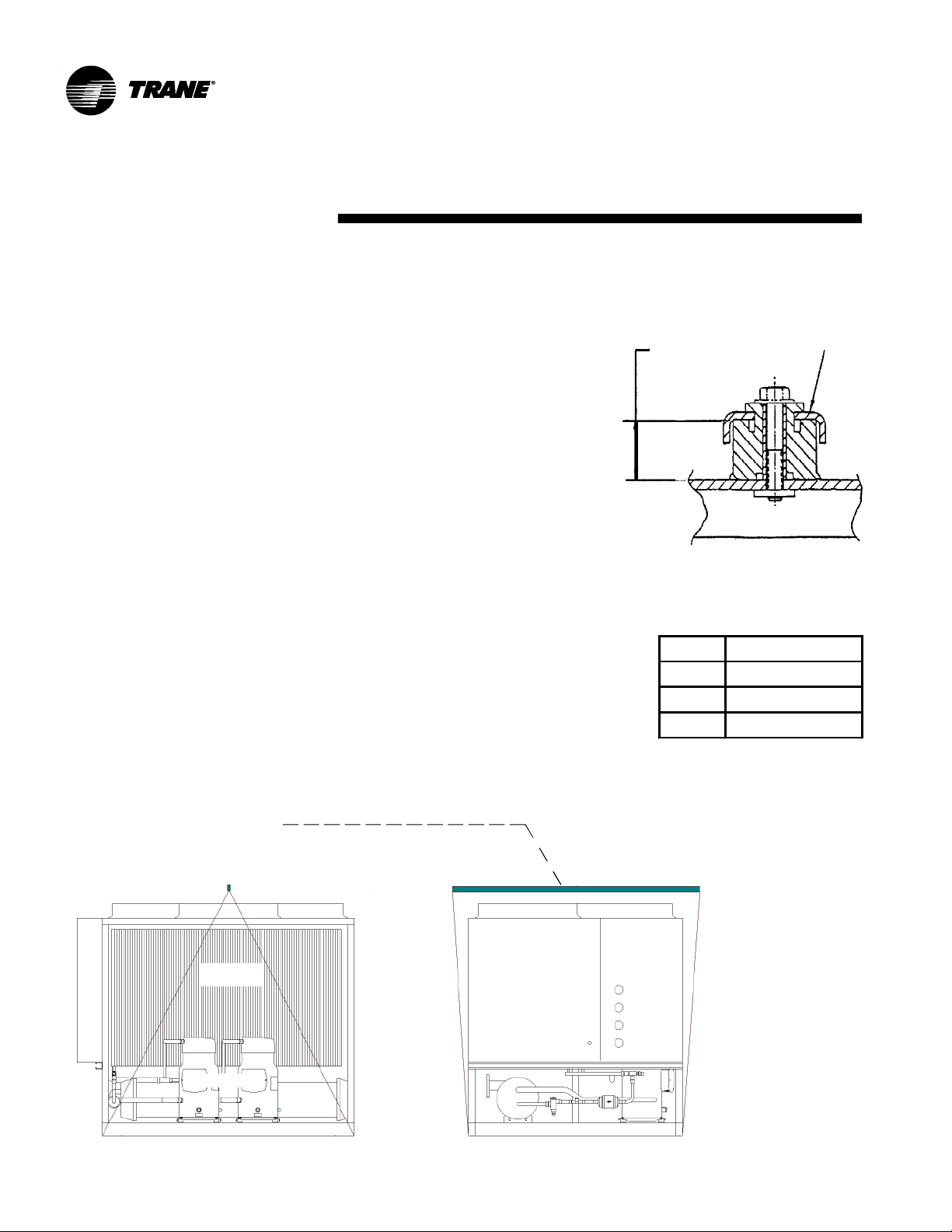

(5) These measurements take into consideration the depth of the electrical frame attached to the equipment.

(6) These measurements of floor space do not take into consideration the base of the electrical frame attached to the equipment.

(7) The adapters for Victaulic connection type are not provided in standard option.

(8) Operating W eight includes refrigerant and water weight.

(9) Shipping Weight includes only refrigerant weight.

M o d e l ( 1 ) C G A D 0 2 0 C G A D 0 2 5 C GA D 0 3 0 C G A D 0 4 0 C G A D 0 5 0 C G A D 0 6 0 C G A D 0 7 0 C G A D 0 8 0 C G A D 0 9 0 C G A D 10 0 C G A D 12 0 C G A D 15 0

C ap acit y To ns 17,9 2 1,4 2 6 ,5 3 6 ,1 4 2 ,8 52,6 6 5,7 76 ,2 8 2 ,6 9 5,3 116 ,8 14 4 ,0

Syst em KW (3 ) 2 0 ,0 2 7,2 3 0 ,7 4 1,3 53 ,9 6 1,6 71,8 8 2 ,2 9 3 ,9 10 6 ,5 13 5,3 156 ,5

N o minal A mp s ( 2 ) A 54 ,0 6 8 ,0 78 ,0 9 7,0 12 3 ,0 14 2 ,0 16 3 ,0 192 ,0 2 10 ,0 2 55,0 2 9 5,0 3 76 ,0

Ef f ic iency ( 3 ) E.E.R . 10 ,8 9 ,4 10 ,4 10 ,5 9 ,5 10 ,2 11,0 11,1 10 ,5 10 ,7 10 ,4 11,0

KW / TR 1,115 1,2 73 1,157 1,14 3 1,2 58 1,171 1,0 9 3 1,0 79 1,13 7 1,118 1,158 1,0 8 7

C ap acit y To ns 15,5 18 ,6 2 3 ,0 3 1,2 3 7,2 4 5,5 56,5 6 5,4 71,2 8 5,2 10 4 ,7 12 8 ,6

Syst em KW (3 ) 16 ,8 2 3 ,0 2 5,8 3 4 ,6 4 5,6 51,8 59 ,9 6 8 ,9 78 ,4 9 5,4 12 1,0 14 0 ,5

N o minal A mp s ( 4 ) A 4 5,0 57,0 6 5,0 8 0 ,0 110 ,0 116 ,0 13 0 ,0 15 0,0 170 ,0 19 0 ,0 2 2 5,0 2 8 4,0

Ef f ic iency ( 3 ) E.E.R . 11,1 9 ,7 10 ,7 10 ,8 9 ,8 10 ,6 11,3 11,4 10 ,9 10 ,7 10 ,4 11,0

KW / TR 1,0 8 6 1,2 3 8 1,12 3 1,10 9 1,2 2 7 1,13 7 1,0 6 0 1,0 53 1,10 2 1,119 1,155 1,0 9 3

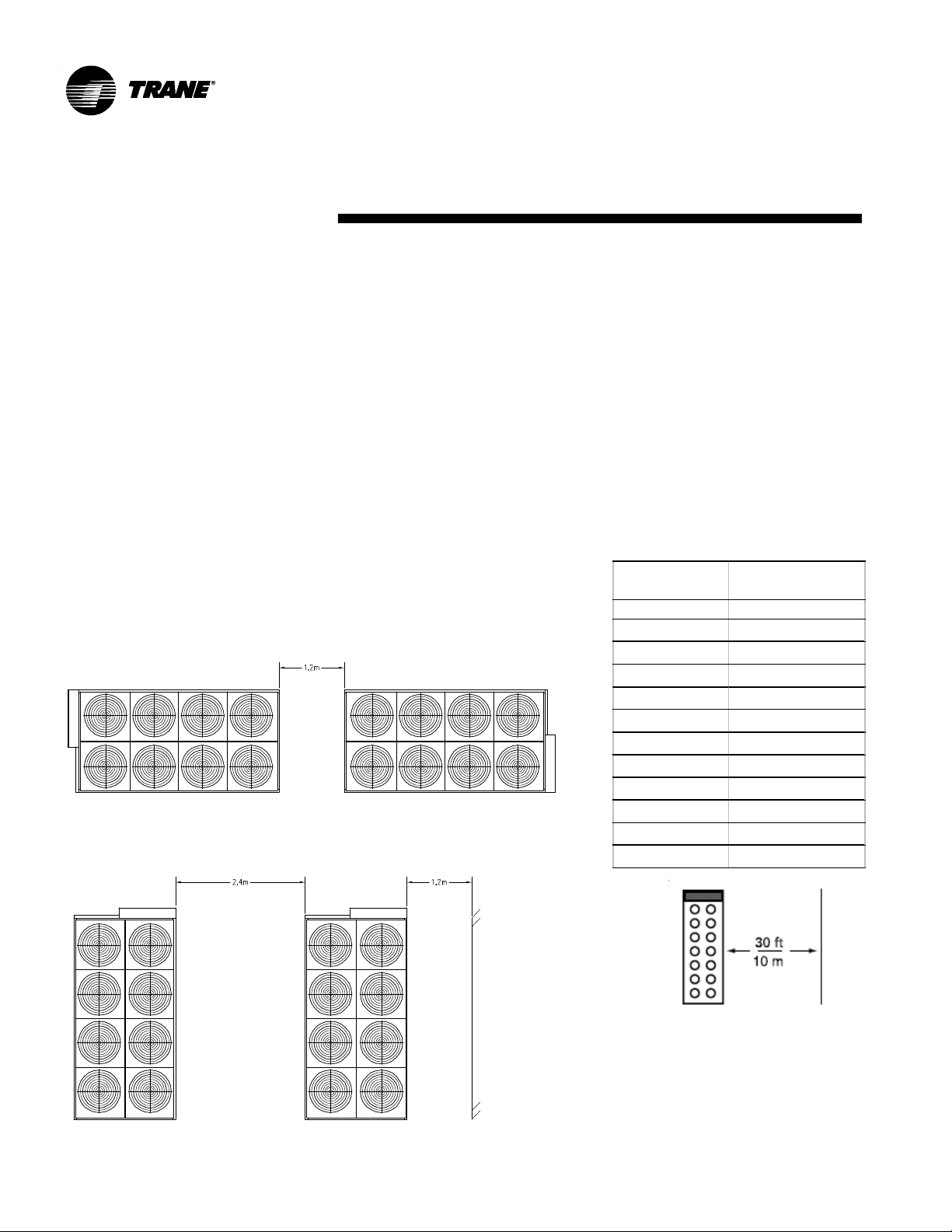

M o d el ( 6) S Z 12 5 S Z 18 5

SZ 12 5 S Z 18 5 S Z 12 5 SZ 18 5

SZ 12 5 S Z 18 5 S Z 18 5

S Z 12 5

S Z 18 5

S Z 12 5 S Z 18 5 SY 3 0 0 SY 2 4 0 SY 3 0 0

Typ e Scro l l Scr o ll Sc ro ll Scr o ll Sc ro ll Scr o ll Scr o ll Scr ol l Scr o ll Scr o ll Scr o ll Scr o ll

Quant it y 2 1 / 1 2 4 2 / 2 4 2 / 4 4 / 2 6 4 6 6

N o minal C ap acit y To ns 10 15/ 10 15/ 15 10 15/ 10 15 15 / 10 15 / 10 15 2 5 2 0 2 5

W at er St o rag e Lit er s 4 4 4 1 6 2 52 79 14 3 151 14 3 12 2 12 2 173 2 77

M i n. w at er f l o w rat e m3/ h 5,5 6 ,8 8 ,2 10 ,9 13 ,6 16 ,4 2 1,8 2 7,3 2 7,3 3 2 ,7 4 0 ,9 4 9 ,1

M ax. wat er f lo w rat e m3/ h 16 ,4 2 0 ,4 2 4 ,5 3 2 ,7 4 0 ,9 4 9 ,1 6 5,4 8 1,8 8 1,8 9 8 ,1 12 2 ,7 14 7,2

Inlet co nnect io n 2 " 2 " 2 1/ 2 " 2 1/ 2 " 3 " 4" 4 " 4 " 4 " 4 " 6 " 6 "

Out let co nnect i on 2 " 2 " 2 1/ 2 " 2 1/ 2 " 3 " 4" 4 " 4 " 4 " 4 " 6 " 6 "

Typ e

N o . o f co ils 2 2 2 4 4 4 4 4 4 4 4 4

T o t al f ac e ar ea m24 ,7 4 ,7 4 ,7 8 ,5 11,0 11,0 14 ,0 14 ,7 14 ,7 13 ,1 16 ,9 19 ,5

Fins p er inches 16 16 14 16 16 16 14 14 14 16 16 16

N o . o f ro ws 2 2 3 2 2 2 3 3 3 3 3 3

2 3 3 4 6 6 6 8 8 6 8 10

D iamet er mm 76 2 76 2 76 2 76 2 76 2 76 2 76 2 76 2 76 2 76 2 762 76 2

A ir f lo w rat e m3/ h 3 2 .6 2 0 4 5.8 70 4 4 .170 6 4 .560 9 5.14 0 9 5.14 0 9 7.6 9 0 12 2 .3 3 0 12 2 .3 3 0 9 8 .118 13 0 .8 2 4 16 3 .53 0

R PM R PM 114 0 114 0 114 0 114 0 114 0 114 0 114 0 114 0 114 0 114 0 114 0 114 0

M o t or p o wer KW 1,12 1,12 1,12 1,12 1,12 1,12 1,12 1,12 1,12 1,12 1,12 1,12

T ransmi ssi o n t yp e D ir ect D ir ect D ir ect Di rect D ir ect D ir ect D ir ect Di r ect Di rect Di rect D i rect D ir ect

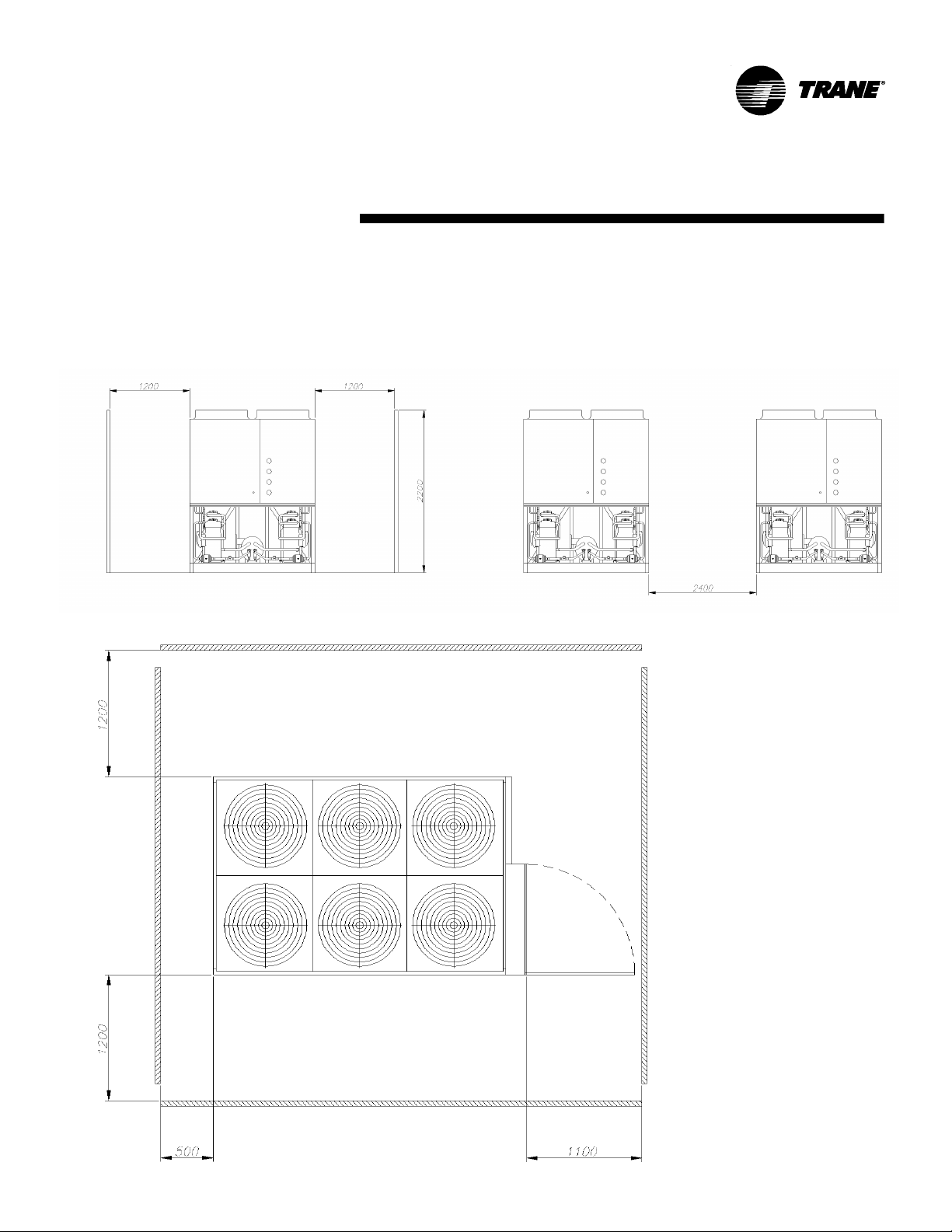

Heig ht mm 18 4 0 ,5 18 4 0 ,5 18 4 0 ,5 2 19 0 ,5 2 19 0 ,5 2 19 0 ,5 2 190 ,5 2 19 0 ,5 2 19 0 ,5 2 3 76 ,0 2 3 76,0 2 3 76 ,0

Lengt h ( 4 ) mm 2 19 5,0 2 19 5,0 2 19 5,0 2 3 8 9 ,0 29 8 9 ,0 2 9 8 9 ,0 3 6 9 5,0 3 9 0 3 ,0 3 9 0 3 ,0 3 4 2 5,0 4 9 4 9 ,0 49 4 9 ,0

W id t h mm 13 50 ,0 170 0 ,0 170 0 ,0 18 8 0 ,0 18 80 ,0 18 8 0 ,0 18 8 0 ,0 18 8 0 ,0 18 8 0 ,0 2 2 4 2 ,0 2 2 4 2 ,0 22 4 2 ,0

Fo o t p ri nt area ( 5 ) m22 ,70 0 3 ,4 0 0 3 ,4 0 0 3 ,9 4 0 5,2 50 5,2 50 6 ,58 0 6 ,9 70 6 ,9 70 7,2 3 7 10 ,6 54 10 ,6 54

R ef rig er ant t yp e St and ard R- 4 0 7C R-4 0 7C R-4 0 7C R- 40 7C R- 4 07C R -4 0 7C R -4 0 7C R -4 0 7C R -4 0 7C R- 40 7C R -4 0 7C R- 4 0 7C

N o . o f circuit s 1 1 1 2 2 2 2 2 2 2 2 2

50 / 10 0 4 0 / 10 0 50 / 100 2 5 / 50 2 0 / 4 0 2 5 / 50 2 9 / 5 7 3 1/ 6 3 3 3 / 6 7 2 5/ 50 17 / 3 3 17/ 3 3

75 / 10 0 70 / 10 0 75 / 10 0 79 / 10 0 8 1/ 10 0 8 3 / 10 0 75/ 10 0 6 7 / 10 0 6 7 / 10 0

Op erat ing w eig ht Kg 13 4 0 14 2 0 14 8 0 1910 22 10 2 500 3 0 0 0 3 2 4 0 3 2 2 0 3 775 4 13 5 4 6 53

Shi p pi ng w eig ht Kg 13 0 0 13 8 0 14 2 0 18 6 0 2 13 0 2 3 6 0 2 8 50 3 10 0 3 10 0 3 6 53 3 9 6 2 4 3 76

C ap acit y st ag es

A luminum f ins, 3 / 8 " - O D co p p er t ub es