Page 4

2.2

GENERAL PRECAUTIONS

The operator must only intervene on the unit commands; he or she must not open any panels except for the one which gives

access to the command module.

The installer must only intervene on the connections between the plant and the machine; he or she must not open any machine

panels nor carry out any commands.

The following precautions should be made when approaching or working on the unit:

• Do not wear jewelry, baggy clothes or any other accessory which can get caught up.

• Use appropriate protection (gloves, glasses etc.) when using an open flame (welding) or compressed air.

• If the unit is located in a closed environment, wear hearing protection.

• Before disconnecting, removing tubes, filters, joints or other line parts intercept the connection tubes, empty them until the

pressure reaches that of the atmosphere.

• Do not use your hands to check for possible pressure losses.

• Always use tools which are in good condition; make sure the instructions have been fully understood before usingthem.

• Make sure that any tools, electrical cables or other loose objects have been removed before closing the unit and starting it

up again.

2.3

PRECAUTIONS AGAINST RISKS DUE TO THE REFRIGERANT

Refer to refrigerant safety data sheet.

2.4

PRECAUTIONS AGAINST RESIDUAL RISKS

Prevention from risks due to the command system

• make sure the instructions for use have been understood before carrying out any work on the controlpanel.

• always keep the instruction manual close at hand when working on the control panel.

• start up the unit only after having certified that it is correctly connected to the plant.

• inform the technician promptly of any alarms which appear on the unit.

• do not reset the alarms to manual restart without having first identified the cause and removed it.

2.5

PREVENTION AGAINST RESIDUAL MECHANICAL RISKS

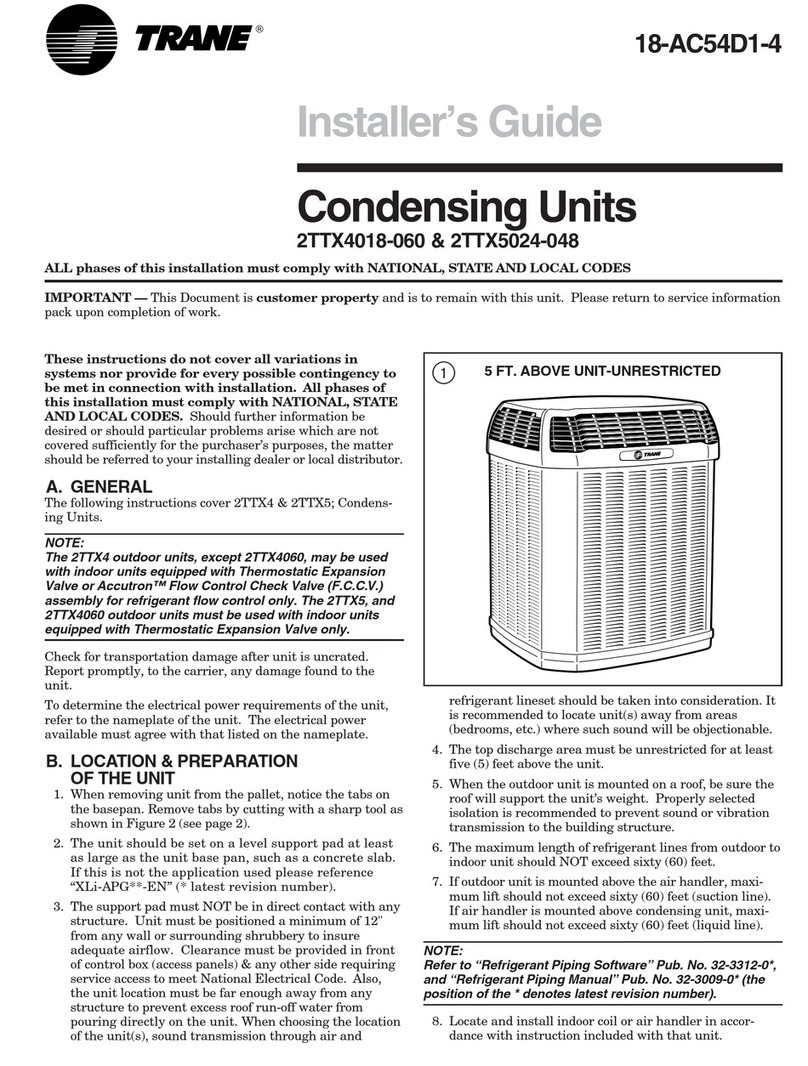

• install the unit in accordance with the provisions of the following manual.

• carry out all the maintenance operations provided for by this manual regularly.

• wear a protective helmet before entering inside the unit.

• before opening a machine panel make sure that it is firmly connected by means of a hinge.

• do not touch the air condensation batteries without having first put on protective gloves.

• do not remove the protections to the moving parts while the unit is running.

• before restarting the unit make sure that the moving part protections are in the correct position.

2.6

PREVENTION AGAINST RESIDUAL ELECTRICAL RISKS

• connect the unit to the mains in accordance with the provisions of this manual.

• carry out all maintenance operations regularly.

• before opening the control panel or access any electrical component installed on the unit disconnect the unit from the mains

by means of the main switch.

• check that the unit has been earthen correctly before starting it up.

• control all the electrical connections and the connection cables paying particular attention to the state of isolation; replace

the cables which are clearly worn or damaged.

• carry out periodic checks of the wiring inside the panel.

• do not use cables with an inappropriate section or flying connections not even for a limited period or in anemergency.

2.7

PREVENTION AGAINST RESIDUAL RISKS OF A DIFFERENT NATURE

• the residual risks due to pressure are mainly coming from a failure of the safety devices. To prevent them it is necessary to

check and replace them when required.

• the RAUS units are equipped with a high pressure safety valve which may relieve high pressure and high

temperature refrigerant in close vicinity of the unit in case of an abnormal overpressure event. In order to prevent

harm to people who might find themselves close to the unit, the installer should convey the escaped refrigerant by

means of piping. The safety valve installed in the unit is equipped with a threaded connection that makes conveying

easier. No safety valve is installed on RAUX units.

If a piping aimed at conveying refrigerant from safety valves, as described above, has not been installed by the installer, in

order to protect from safety devices exhausting it is not allowed to remove the protections while the unit is in operation and to

approach the unit without wearing the right protections. In case of accidental contact with refrigerant due to the safety valves

exhaust it is necessary to follow the above indicated.

• carry out the plant connections to the unit by following the indications reported on the following manual and on the panels of