Unit Mounted 2 or 4 Pipe

Fan Coil Thermostat, 3 Speed

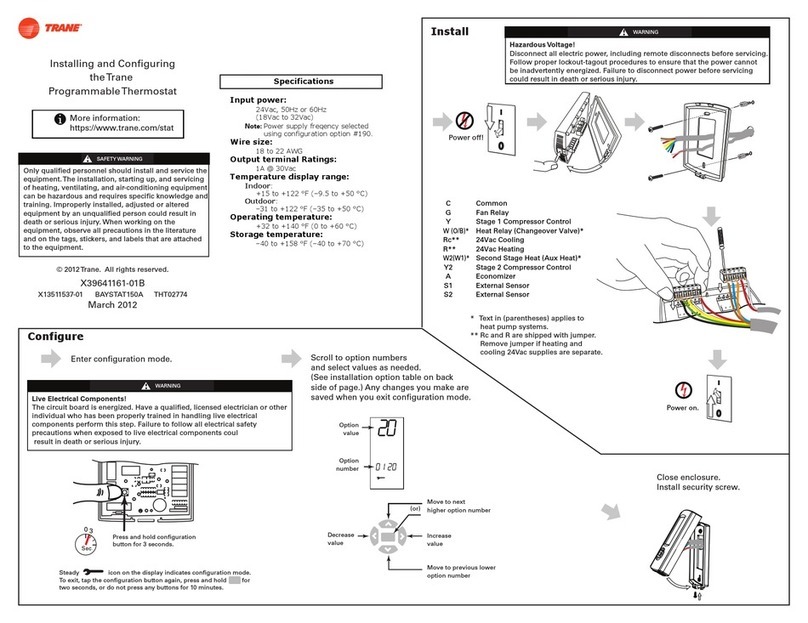

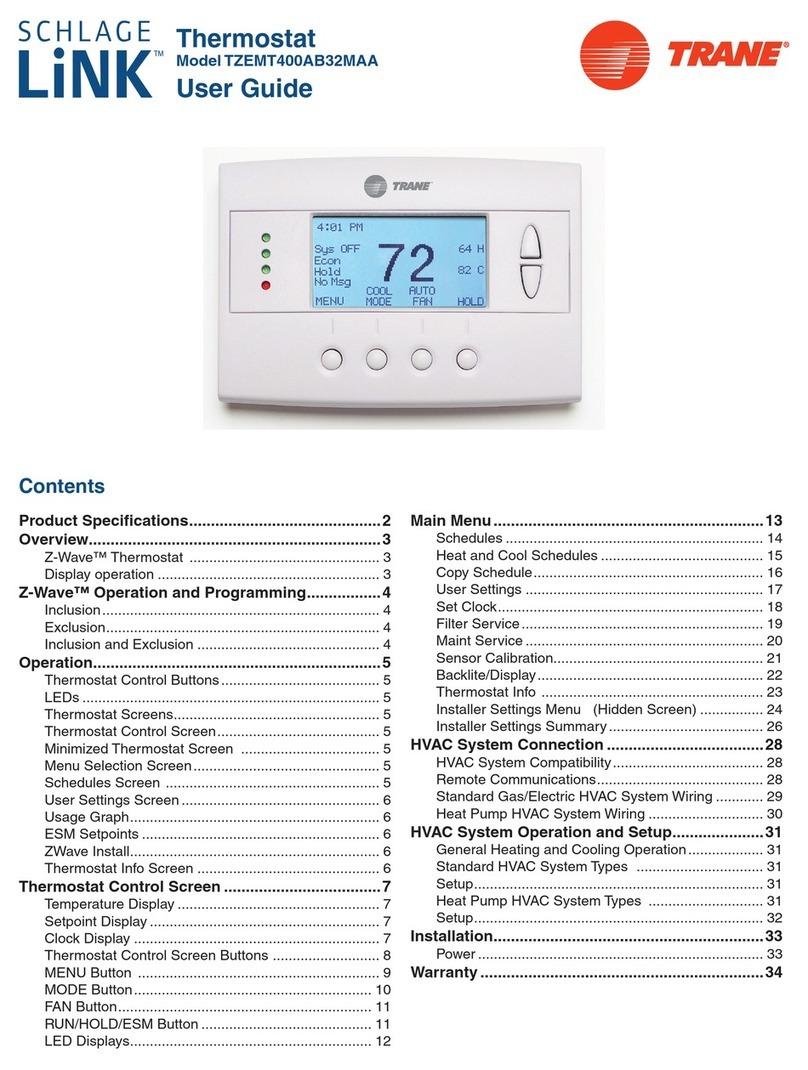

Configuration Mode

The conguration mode is used to set the thermostat to match your heating/cooling system.

To congure the thermostat, perform the following steps:

1. Verify the thermostat is in the OFF mode. Press the SYS button until off mode displays.

2. Press the CONFIG button for 5 seconds while the thermostat is in OFF mode.

Press the up or down button to change settings within each screen.

Press the CONFIG button to advance to the next screen.

Note: Pressing the

SYS

button will return you to the previous screen.

To exit conguration mode, press the CONFIG switch for 5 seconds.

FAN

SYS

CONFIG

Down

button

Up

button

2 – Temperature Scale

This thermostat can function in Fahrenheit or Celsius.

F = Fahrenheit (Default)

C = Celsius

3 – Valve Type

This thermostat operates with Normally Open or Normally Closed valves. Select the correct valve

type for your system.

no = Normally Open (Default)

nc = Normally Closed

Configuration Mode Settings

1 – System

Select the type of operation you require.

1. Heat Only is for a system with only heating.

2. Cool Only is for a system with only cooling.

3. 2-Pipe Manual Changeover is for a 2 pipe system that handles both heating and cooling. The user

selects whether the system will be set to heating or set to cooling.

4. 2-Pipe Seasonal Changeover is for a 2 pipe system that handles both heating and cooling. The

thermostat selects whether the system will be set to heat or set to cool based on the pipe sensor

temperature. (Default)

5. 2-Pipe Manual Changeover with Auxiliary is for a 2 pipe system that handles both heating and

cooling. The user selects whether the system will be set to heat or set to cool. If set to heat and the

pipe sensor indicates there is not heat, the auxiliary output will be turned on.

6. 4-Pipe Manual Changeover is for a 4 pipe system. The user selects whether the system will be set

to heat, cool or off.

7. 4-Pipe Auto Changeover is for a 4 pipe system. The user selects whether the system will be set to

heat, cool, heat & cool or off.

4 – N/A

5 – N/A

• 2-pipe systems

• 4-pipe systems

• Pipe sensor compatible

•Congurable

•Largedisplaywithbacklight

• Selectable Fahrenheit or

Celsius

• Relay outputs (minimum

voltagedropinthermostat)

•Remotesensing

6 – Pipe Sensor (Y/N) (for 2 pipe system only)

Select whether you are using a pipe sensor to monitor the pipe temperature.

n = No Pipe Sensor Connected

y = Pipe Sensor Connected (Default)

7–PipeSensorCooling

Pipe temperature below this setting is considered to be cooling. If pipe sensor temperature is

above this selected temperature for more than the Pipe Sensor Delay Time the cool valve will be

turned off.

Changes setting between 50ºF and 65ºF (10.0ºC and 18.5ºC) Default: 60

8–PipeSensorHeating

Pipe temperature above this setting is considered to be heating. If pipe sensor temperature is

below this selected temperature for more than the Pipe Sensor Delay Time the heat valve will be

turned off.

Changes setting between 70ºF and 90ºF (21.0ºC and 32.0ºC) Default: 80

Auto Changeover

18-30 VAC

Hardwired

3518-7064

Proper Field Wiring and Grounding Required!

Failure to follow code could result in death or serious injury. All eld wiring MUST be performed by qualied

personnel. Improperly installed and grounded eld wiring poses FIRE and ELECTROCUTION hazards. To avoid

these hazards, you MUST follow requirements for eld wiring installation and grounding as described in NEC

and your local/state electrical codes.

WARNING

Personal Protective Equipment Required!

Installing/servicing this unit could result in exposure to electrical, mechanical and chemical hazards. Before

installing/servicing this unit, technicians MUST put on all Personal Protective Equipment (PPE) recommended

for the work being undertaken. ALWAYS refer to appropriate MSDS sheets and OSHA guidelines for proper PPE.

When working with or around hazardous chemicals, ALWAYS refer to the appropriate MSDS sheets and OSHA

guidelines for information on allowable personal exposure levels, proper respiratory protection and handling

recommendations. If there is a risk of arc or ash, technicians MUST put on all necessary Personal Protective

Equipment (PPE) in accordance with NFPA70E for arc/ash protection PRIOR to servicing the unit. Failure to

follow recommendations could result in death or serious injury.

WARNING

Follow EHS Policies!

Failure to follow instructions below could result in death or serious injury.

All Trane personnel must follow the company’s Environmental, Health and Safety (EHS) policies when

performing work such as hot work, electrical, fall protection, lockout/tagout, refrigerant handling, etc. Where

local regulations are more stringent than these policies, those regulations supersede these policies.

Non-Trane personnel should always follow local regulations.

WARNING

Warnings, Cautions, and Notices

Read this manual thoroughly before operating or servicing this unit. Safety advisories

appear throughout this manual as required. Your personal safety and the proper operation

of this machine depend upon the strict observance of these precautions.

• This thermostat is for 18-30 VAC applications only; do not use on voltages over 30 VAC

• Use this thermostat only as described in this manual

Installation Guide

ACC-SVN223B-EN

©2020 TRANE

AUGUST 2020

Onlyqualiedpersonnelshouldinstallandservicetheequipment.Theinstallation,starting

up,andservicingofheating,ventilating,andair-conditioningequipmentcanbehazardous

andrequiresspecicknowledgeandtraining.Improperlyinstalled,adjustedoraltered

equipmentbyanunqualiedpersoncouldresultindeathorseriousinjury.Whenworkin9

ontheequipment,observeallprecautionsintheliteratureandonthetags,stickers,and

labelsthatareattachedtotheequipment.

SAFETY WARNING

The two types of advisories are dened as follows:

WARNING Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a situation that could result in equipment or

property-damage only accidents.

NOTICE

Important Environmental Concerns

Scientic research has shown that certain man-made chemicals can affect the earth’s

naturally occurring stratospheric ozone layer when released to the atmosphere. In

particular, several of the identied chemicals that may affect the ozone layer are

refrigerants that contain Chlorine, Fluorine and Carbon (CFCs) and those containing

Hydrogen, Chlorine, Fluorine and Carbon (HCFCs). Not all refrigerants containing these

compounds have the same potential impact to the environment. Trane advocates the

responsible handling of all refrigerants-including industry replacements for CFCs such as

HCFCs and HFCs.

Important Responsible Refrigerant Practices

Trane believes that responsible refrigerant practices are important to the environment, our

customers, and the air conditioning industry. All technicians who handle refrigerants must

be certied according to local rules. For the USA, the Federal Clean Air Act (Section 608)

sets forth the requirements for handling, reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these service procedures. In addition, some

states or municipalities may have additional requirements that must also be adhered to for

responsible management of refrigerants. Know the applicable laws and follow them.

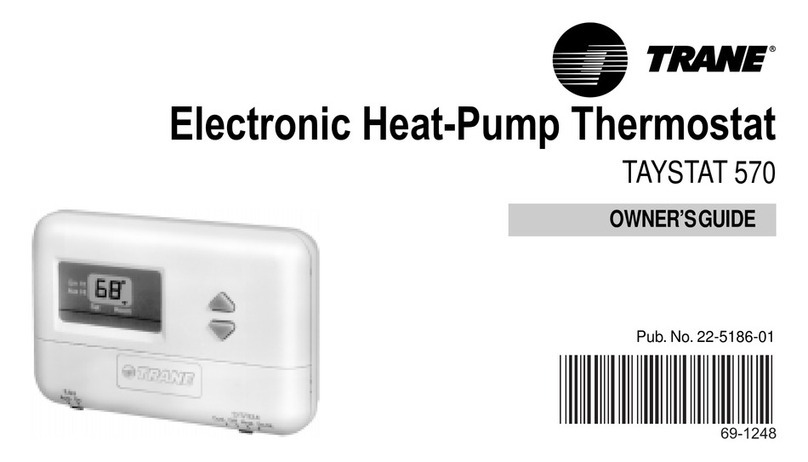

Wiring Diagrams

System 1

Heat Only

Remote Sensor

Pipe Sensor

Fan High

Heat

Fan Low

(Optional)

Purple

Yellow

Gray Gray

Orange/White

Red/White

Blue/White Blue/White Blue/WhiteBlue/White

Red

White

Black

24

VAC

Fan Medium

System 2

Cool Only

Remote Sensor

Pipe Sensor

Fan High

Cool

Fan Low

(Optional)

Purple

Blue

Yellow

Orange/White

Red/White

White

Black

24

VAC

Fan Medium

System 3

2-PipeManualChangeover

Remote Sensor

Pipe Sensor

Fan High

Heat/Cool

Fan Low

(Optional)

Purple

Yellow

Gray

Orange/White

Red/White

Red

White

Black

24

VAC

Fan Medium

System 4

2-PipeSeasonalChangeover

Remote Sensor

Pipe Sensor

Fan High

Heat/Cool

Fan Low

(Required)

Purple

Yellow

Gray

Orange/White

Red/White

Red

White

Black

24

VAC

Fan Medium

System 5

2-PipeManualChangeover

with Auxiliary

Remote Sensor

Pipe Sensor

Fan High

Auxiliary

Heat/Cool

Fan Low

(Required)

Purple

Yellow

Gray

Orange/White

Red/White

Blue

Red

White

Black

24

VAC

Fan Medium

System 7

4-PipeAutoChangeover

Fan High

Cool

Heat

Fan Low

Purple

Yellow

Gray

Blue

Red

White

Black

24

VAC

Fan Medium

System 6

4-PipeManualChangeover

Fan High

Cool

Heat

Fan Low

Remote Sensor

Purple

Yellow

Gray

Blue/WhiteBlue/White

Red/White

Blue/White

Red/White

Blue

Red

White

Black

24

VAC

Fan Medium

C

W1

Y1

GH

GL

PS

SC

RS

R

GM

C

W1

Y1

GH

GL

PS

SC

RS

R

GM

C

W1

Y1

GH

GL

PS

SC

RS

R

GM

C

W1

Y1

GH

GL

PS

SC

RS

R

GM

C

W1

Y1

GH

GL

PS

SC

RS

R

GM

C

W1

Y1

GH

GL

PS

SC

RS

R

GM

C

W1

Y1

GH

GL

PS

SC

RS

R

GM

Remote Sensor

Wire Designator

Descriptions

R – 24 VAC Hot Black

C – 24 VAC Common White

W1 – Heat Red

Y1 – Cool Blue

GH – Fan High Purple

G M – Fan Medium Yellow

GL – Fan Low Gray

PS – Pipe Sensor (optional) Orange/White

RS – Remote Sensor Red/White

SC – Sensor Common Blue/White

Specifications

Electricalrating: 18-30 VAC, 2 amp maximum per output

Temperaturecontrolrange:45°F to 90°F (7°C to 32°C)

Accuracy: ± 1°F (± 0.5°C)

Timing: Backlight Operation: 10 seconds

Terminations: R, C, W1, Y1,GH, GM, GL, PS, RS, SC

Package Contents/Tools Required

Packageincludes: 3518-7065 thermostat on base, thermostat

cover, screws and wall anchors, Installation

guide.

Tools required for installation: Drill with 3/16” bit, hammer,

screwdriver

Icon Descriptions

Heating operation

icon

Cooling operation

icon

COOLHEAT

Fan

Auto

Fan

operation

icon

9–PipeSensorDelayTime

This is the time that the valve will be open to verify the pipe temperature before the valve is turned

off. This gives time for circulation through the system.

Changes setting between 0 and 5 minutes at 1 minute intervals Default: 5