Trans-Cal SSD120-N-RS5 Quick start guide

Trans-Cal Industries, Inc.

Model SSD120-(XX)N-RS5

&

Model SSD120-(XX)NE-RS5

(Includes Mod. 1 Data)

All Solid-State

Altitude Encoder/Digitizer

Owner/Installation Manual

FAA TSO-C88a Approved

EASA ETSO-C88a Approved

Trans-Cal Industries, Inc.

Van Nuys Airport

16141 Cohasset Street

Van Nuys, CA 91406-2908

(818) 787-1221 (800) 423-2913 fax (818) 787-8916

www.trans-cal.com

22 June 2012 Document Number: 882204 Rev. C

Page 2 of 57

Copyright

This document may not be reproduced, transmitted, or copied in any form without the prior written consent of

Trans-Cal Industries, Inc. The data contained herein is subject to change without notice. Trans-Cal Industries

hereby grants permission to download one copy of this manual and any subsequent revision, provided that

electronic or printed copy contains this complete copyright notice. Trans-Cal Industries explicitly prohibits any

unauthorized commercial distribution of this manual or any revision thereto.

Limitations Please Note:

It is the responsibility of the installer of this equipment, within a specified type or class of aircraft, to determine that

the aircraft operating conditions are within TSO or ETSO standards. DO-160E lightning induced transient

susceptibility tests were not conducted on this device and it is the responsibility of the installing agency to

substantiate compliance with FAR25.1316. Advisory Circular AC20-136A provides guidance related to the

protection of aircraft electrical systems from the effects of lightning.

© 2012 by Trans-Cal Industries, Inc.

16141 Cohasset Street

Van Nuys, CA 91406

818/787-1221

800/423-2913 x400 Tech Support

FAX 818/787-8916

E-Mail: support@trans-cal.com

www.trans-cal.com

What’s in the Box:

Qty. Part Number Description

1 ea. SSD120-(XX)N-RS5 Altitude Digitizer with five RS232 Outputs

1 ea. 882204 Owner/Installation Manual

1 ea. DA-15S 15 Pin D-Subminiature Mating Connector - Receptacle

2 ea. 600016 15 Pin Connector Back Shell

1 ea. DA-15P 15 Pin D-Subminiature Mating Connector - Plug

1 ea. 600019 1/8-27 NPT Nylon tube fitting

1 ea. 600020 ¼” Tube Polypropylene tee fitting

1 ea. 103024 1/8-27NPT Nylon Plug

History of Revision

Revision Date Description

A 3/2009 Production release.

B 2/2010 Corrected §6.5.

C 6/2012

Updated copyright data, added KXP 755 data, corrected Century Fight Systems pin data,

and ECP calibration data.

Page 3 of 57

Table of Contents

Abbreviations, Acronyms and Symbols ........................................................................................................ 5

Section 1.0 Introduction ................................................................................................................................ 6

1.1 Scope......................................................................................................................................................................6

1.2 Equipment Description............................................................................................................................................6

1.3 General Specifications ............................................................................................................................................6

1.3.1 Operating Altitude.........................................................................................................................................6

1.3.2 Accuracy .......................................................................................................................................................7

1.3.3 Mechanical Characteristics...........................................................................................................................7

1.3.4 Environmental...............................................................................................................................................7

1.3.5 Over Range ..................................................................................................................................................7

1.4 Parallel ICAO Altitude Data Port Specifications......................................................................................................7

1.5 Serial Altitude Data Port Specifications ..................................................................................................................7

1.6 Serial Port Altitude Data Resolution .......................................................................................................................8

1.7 Serial Communication Format ................................................................................................................................8

1.8 Serial Communication Protocol ..............................................................................................................................8

1.8.1 UPS Aviation Technologies/Garmin AT/IIMorrow Nav. Devices. .................................................................8

1.8.2 Trimble Garmin Navigation Devices Protocol...............................................................................................8

1.8.3 Northstar Navigation Devices Protocol.........................................................................................................9

1.8.4 Magellan Navigation Devices Protocol.........................................................................................................9

1.8.5 ARNAV Systems Protocol ............................................................................................................................9

1.8.6 UPS AT 618 Loran Devices Protocol (IIMorrow)..........................................................................................9

1.8.7 One-Foot Resolution Protocol ....................................................................................................................10

Section 2.0 Operation ................................................................................................................................. 11

2.1 General .................................................................................................................................................................11

2.2 Operating Instructions...........................................................................................................................................11

Section 3.0 Installation................................................................................................................................ 12

3.1 Mechanical Installation..........................................................................................................................................12

3.2 Electrical Installation .............................................................................................................................................12

3.3 Serial Altitude Data Port Test Equipment .............................................................................................................13

3.4 Parallel ICAO Altitude Data Port Test Equipment ................................................................................................13

Section 4.0 Calibration and Configuration .................................................................................................. 14

4.1 Calibration Overview.............................................................................................................................................14

4.2 Required Equipment Span Adjust.........................................................................................................................15

4.3 Required Equipment Dynamic Calibration............................................................................................................15

4.4 Span Adjust Procedure.........................................................................................................................................15

Figure 1 Altitude Digitizer Correspondence................................................................................................................17

4.5 Dynamic Calibration Adjustment Procedure using the ECP-100 .........................................................................18

Figure 2 Dynamic Calibration Set-Up Using the ECP-100 .........................................................................................19

4.6 Hyper Terminal Set-Up on the IBM Compatible PC .............................................................................................20

4.7 Serial Port Software Configuration .......................................................................................................................21

4.8 Serial Port One-Foot Resolution Configuration ....................................................................................................22

4.9 Dynamic Calibration Adjustment Procedure .........................................................................................................23

4.10 Serial Port Software Configuration Using the ECP-100 .....................................................................................25

Figure 3 Serial Port Configuration Using the ECP-100 ..............................................................................................26

4.11 Configuration and Calibration Command List.....................................................................................................27

4.12 Error Correction Table ........................................................................................................................................28

Section 5.0 Tables I through X Digitizer Interconnection............................................................................ 29

Table I Bendix/King.....................................................................................................................................................29

Bendix/King (Honeywell) KT 73 Transponder with Serial Altitude Data Input ............................................................30

Table II Cessna, Narco, Microair ................................................................................................................................31

Table III Garmin ..........................................................................................................................................................32

Table IV Garmin..........................................................................................................................................................33

Table V Edo-Air, Genave, Collins, Radair ..................................................................................................................34

Table VI Bendix, Wicox, UPS AT................................................................................................................................35

Table VII Becker, Terra, Trig.......................................................................................................................................36

Table VIII Honeywell ...................................................................................................................................................37

Page 4 of 57

Tables IX and X Serial Data Connector and Protocol Selection.................................................................................38

Section 6.0 GPS/MFD & Miscellaneous Connection Data ......................................................................... 39

6.1 UPS Aviation Technologies (IIMorrow).................................................................................................................39

6.2 Trimble ..................................................................................................................................................................40

6.3 Garmin International .............................................................................................................................................41

6.4 ARNAV Systems, Inc. ...........................................................................................................................................42

6.5 Century Flight Systems.........................................................................................................................................43

Section 7.0 Instructions for Continued Airworthiness ................................................................................. 44

Section 8.0 Adapter Plate Ordering Information......................................................................................... 44

Section 9.0 Frequently Asked Questions.................................................................................................... 45

Section 10.0 Known Compatibility Issues................................................................................................... 48

10.1 Honeywell KT 73 Transponder with Serial Altitude Data Input...........................................................................48

10.2 Narco AT5A, AT6A, AT-50 and AT-50A Installations and SSD120-(XX)N Mod.1 .............................................48

10.3 “Mod. 1” Installations...........................................................................................................................................48

10.4 King KT-75 ..........................................................................................................................................................48

10.5 S-Tec (Collins) TDR950......................................................................................................................................48

10.6 Trans-Cal SSD120-(XX)N Backwards Compatibility ..........................................................................................48

10.7 SSD120-(XX)N-RS5 Compatibility to Competitor’s Products .............................................................................49

Wiring Harness Diagram Part Number 881404 .......................................................................................... 50

Span Adjust Block Diagram ........................................................................................................................ 51

Dynamic Calibration Block Diagram ........................................................................................................... 52

Figure 2 Temperature vs. Warm-up Time................................................................................................... 53

Outline Drawing .......................................................................................................................................... 54

Environmental Qualification Form............................................................................................................... 55

Part Number Builder ................................................................................................................................... 56

Manufacturer Direct Warranty..................................................................................................................... 57

Page 5 of 57

Abbreviations, Acronyms and Symbols

A Amperes

AC Advisory Circular

ARINC Aeronautical Radio Incorporated

ASCII American Standard for Coded Information Interchange

ATCRBS Air Traffic Control Radar Beacon System

bps Bits per second.

C

R Carriage Return

EASA European Aviation Safety Agency

EEPROM Electronically Erasable Read Only Memory

EIA Electronic Industries Association

ETSO European Technical Standard Order

FAA Federal Aviation Administration

FAR Federal Aviation Regulation

ft. Distance in feet.

GPS Global Positioning System

Hz Hertz

ICAO International Civil Aviation Organization

I.F.F. Identification Friend or Foe

In. Hg. Inches of Mercury

Kbps Kilobits per Second

KHz Kilohertz

L

F Line Feed

LSB Least Significant Bit

mA Milliamperes

max. Maximum

MB Millibar

MHz Megahertz

MFD Multi-Function Display

MSL Mean Sea Level

min. Minimum

ms Time in milliseconds.

MSB Most Significant Bit

mW Milliwatt

NIST National Institute of Standards and Technology

oz Ounce

psi Pounds per Square Inch

RAM Random Access Memory

RS Recommended Standard

RTCA RTCA Inc. (Radio Technical Commission for Aeronautics)

SAE Society of Automotive Engineers

sec. Time in seconds.

SSR Secondary Surveillance Radar

TCI Trans-Cal Industries, Inc.

TIA Telecommunication Industries Association

TSO Technical Standard Order

Vdc Volts Direct Current

VSI Vertical Speed Indicator

W Watt

ΩElectrical resistance measured in Ohms.

ºC Temperature in degrees centigrade.

± Plus or minus.

§ Section

Page 6 of 57

Section 1.0 Introduction

1.1 Scope

This manual provides detailed installation, calibration and operating instructions for Trans-

Cal Industries’ Model SSD120-(XX)N-RS5 and SSD120-(XX)NE-RS51series of altitude

encoder/digitizer.

1.2 Equipment Description

Approved under FAA TSO-C88a and EASA ETSO-C88a the Model SSD120-(XX)N-RS5

and SSD120-(XX)NE-RS5 is an all solid-state electronic device which, when connected to

an aircraft’s static and electrical system, converts pressure altitude information into parallel

and serial digital data.

The parallel digital altitude data protocol is set forth in the ICAO International Standard for

SSR Pressure Altitude Transmission. In accordance with U.S. National Standards for

Common System Component Characteristics for the I.F.F. Mark X (SIF)/Air Traffic Control

Radar Beacon System SIF/ATCRBS.

The serial altitude data is provided on (5) five asynchronous RS232 outputs which are

divided into two groups. Group A consists of TxD1, TxD2 and TxD3. Group B consists of

TxD4 and TxD5. The serial data protocol is selectable for each output group and may be

used to provide pressure altitude data to transponders, GPS or other on board navigation

devices. Refer to Table IX, Table X and §4.6 &§4.7.

1.3 General Specifications

This equipment has been tested and will utilize power in accordance with MIL-STD-704E

for 28 Vdc systems.

Operating Voltage:

Model SSD120-(XX)N-RS5

Model SSD120-(XX)NE-RS5 2

+12 to 30 Vdc

+12 to 30 Vdc

Operating Current all models: 0.26Amps at 14Vdc

0.28 Amps at 28Vdc

Operating Temperature:

Model SSD120-(XX)N-RS5

Model SSD120-(XX)NE-RS5

-20°to +70°C (-4° to +158°F)

-55°to +70°C (-67° to +158°F)

Storage Temperature (non-operating)

all models:

-65°to +85°C (-85° to +185°F)

Warm-up time: 0 Seconds at +20°C (+68°F) and higher. See

Figure 2 for low temp warm-up times.

Weight: 5.1 oz. (6 oz. with tray)

1.3.1 Operating Altitude

Model Operating Altitude

SSD120-30N( )-RS5 -1000 to +30,000 feet.

SSD120-35N( )-RS5 -1000 to +35,000 feet.

SSD120-42N( )-RS5 -1000 to +42,000 feet.

1SSD120-(XX)NE-RS5 Extended operating temperature range: -55°to +70°C. Operate low temperature (-55 C) at +28Vdc.

2Longer warm-up times will be experienced when operated at +12 Vdc.

Page 7 of 57

1.3.2 Accuracy

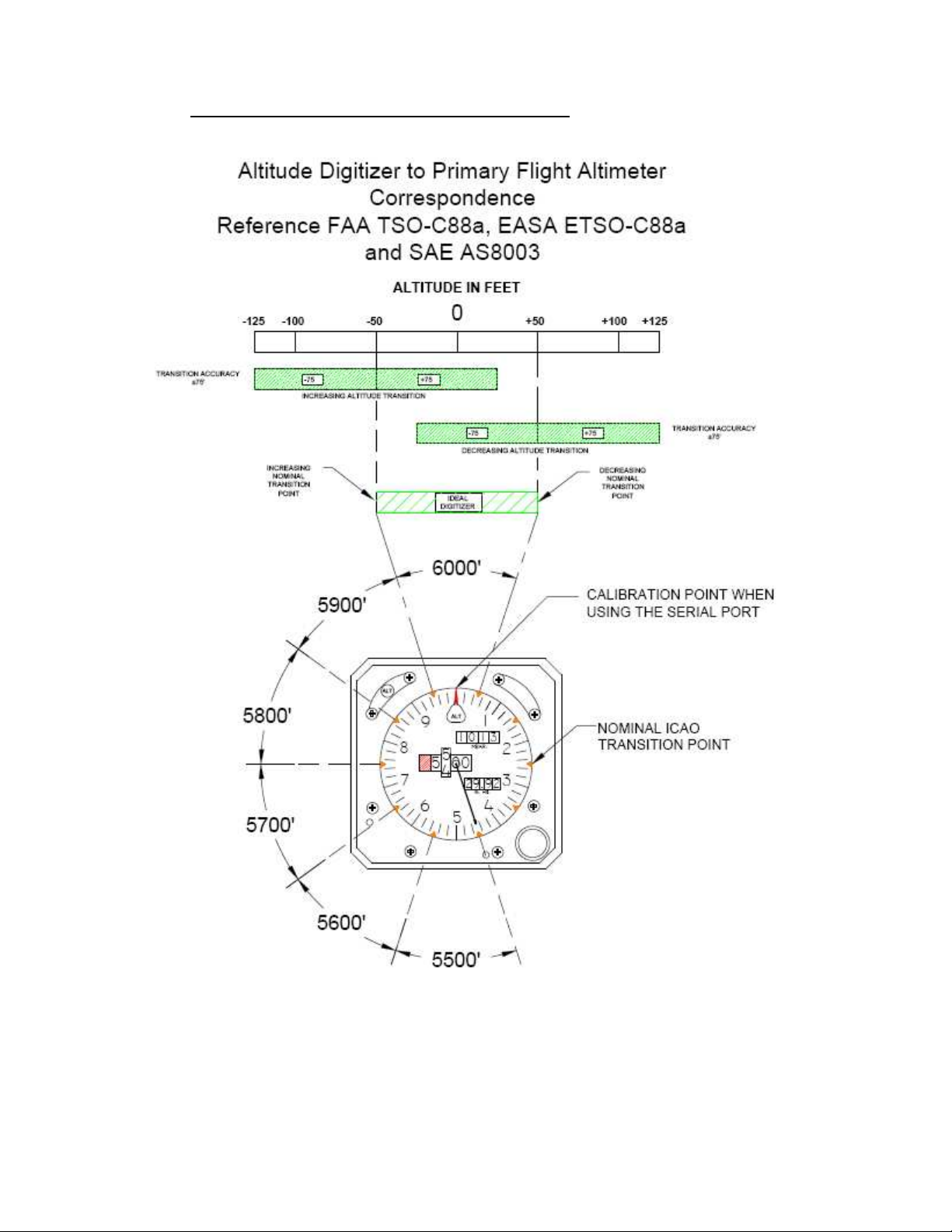

Digitizer accuracy is ±50 feet from -1000 to +30,000 feet, and ±75 feet from

30,100 to +42,000 feet, when measured from the altitude transition points of the

ICAO code and referenced to 29.92 In. Hg. (1013 MB.) See Figure 1 and §4.0.

1.3.3 Mechanical Characteristics

Model Number Dimensions Weight

Model SSD120-30N( )-RS5 See Outline Drawing 5.1 oz.

Model SSD120-35N( )-RS5 See Outline Drawing 5.1 oz.

Model SSD120-42N( )-RS5 See Outline Drawing 5.1 oz.

Mounting tray adds 1 oz. To the weights listed above

1.3.4 Environmental

All model SSD120-(XX)N( )-RS5 digitizers have been designed and tested to meet

the requirements of TSO-C88a and ETSO-C88a, This device is tested in

accordance with RTCA Document DO160E, dated December 2004 Environmental

Category: D1BAB[(SM)(UF)]XXXXXXZBBB(BC)TTBXXXAX. See Environmental

Qualification form for specific test information.

1.3.5 Over Range

The SSD120-(XX)N( )-RS5 series of altitude digitizers will not be damaged when

operated beyond their specified maximum altitude up to 100,000 feet MSL,

(0.1581psi) or over pressured to –5721 feet (18psi) maximum.

1.4 Parallel ICAO Altitude Data Port Specifications

Code Format: In accordance with U.S. National Standard for Common System Component

Characteristics for the IFF Mark X (SIF) Air Traffic Control Radar Beacon System,

SIF/ATCRBS.

Driver Description: The parallel altitude data output is provided by the “uncommitted”

collectors of a transistor array and must be “pulled-up” through a resistive load by

the transponder.

Pull-Up Voltage: +3 to 40Vdc.

Maximum Sink Current: 50 mA.

Maximum Cable Length: 4000 ft. (1219 meters)

Input Signal Requirement: Pin 6 (strobe or signal common) must be either grounded or

connected to the transponder.

1.5 Serial Altitude Data Port Specifications

Electrical Format: Conforming to the TIA/EIA RS-232C standard.

Logic Levels: “0”, +9 Vdc. Logic “1”, -9 Vdc.

Driver Output Maximum Voltage: ±25 Vdc.

Driver Load Impedance: 3KΩtyp.

The RS232E standard recommends one receiver per serial port.

Maximum Cable Length: 50 Feet. (15.24 meters)

Code Format: ASCII

Communication System: Simplex

Transmission Method: Asynchronous. (Talk only.)

Baud Rate: Selectable, 1200 bps to 9600 bps.

Transmission Rate: 2/sec.

Page 8 of 57

1.6 Serial Port Altitude Data Resolution

The default resolution of the altitude digitizer serial data is 100 feet. To enable 10-foot

resolution, connect pin 2 of the DA-15S D-Subminiature connector to ground (see Table

VIII.) The serial port resolution may also be configured via software, see §4.6. See §4.7 for

one-foot resolution.

1.7 Serial Communication Format

Model SSD120-(XX)N( )-RS5 carries out serial communication asynchronously with the

“Start/Stop” system. The specifics of the format, ie. the number of data bits, baud rate etc.,

is determined by the protocol selected. The default protocol is 1200bps, 8 data bits, 1 stop

bit and no parity.

1.8 Serial Communication Protocol

Refer to Table IX & Xand §4.6 &§4.7 & §4.10

Protocol is user selectable by grounding or leaving open pin 9 or pin 10 of the DA-15S

serial data D-Subminiature receptacle, or by selecting protocols via software see §4.6.

1.8.1 UPS Aviation Technologies/Garmin AT/IIMorrow Nav. Devices.

Leaving pin 9 and 10 of the DA-15S serial data receptacle open results in a protocol

compatible with UPS Aviation Technologies’ (IIMorrow) Navigation devices. The Digitizer

will send a seventeen byte message beginning with # AL, then a space followed by five

altitude bytes; the letter “T” and the sensor temperature, two checksum bytes and a

carriage return. (1200bps, 8 data bits, 1 stop bit, no parity). The following is an example of

the serial message for UPS AT (Garmin AT) (IIMorrow) devices.

Message Definition

#AL +00800T+25D8

C

RPressure Altitude 800 feet

1.8.2 Trimble Garmin Navigation Devices Protocol

Grounding pin 10 of the DA-15S serial data receptacle results in a protocol compatible with

some navigation devices manufactured by Trimble and Garmin. The Digitizer will send a

ten-byte message. The message begins with ALT followed by a space and five altitude

bytes; concluding with a carriage return. (9600bps, 8 data bits, 1 stop bit, no parity). The

following are examples of serial messages for Trimble or Garmin devices:

Message Definition

ALT -9900

C

RDigitizer disabled.

ALT 10500

C

RPressure Altitude 10,500 feet

Page 9 of 57

1.8.3 Northstar Navigation Devices Protocol

Grounding pin 9 of the DA-15S serial data receptacle results in a protocol compatible with

some navigation devices manufactured by Northstar and Garmin. The Digitizer will send a

10-byte message. The message begins with ALT followed by a space and five altitude

bytes; concluding with a carriage return. (2400bps, 8 data bits, 1 stop bit, no parity.) The

following are examples of serial messages for these devices:

Message Definition

ALT 02500

C

RPressure Altitude 2500 feet.

ALT -2500

C

RDigitizer disabled.

1.8.4 Magellan Navigation Devices Protocol

Grounding both pins 9 and 10 of the DA-15S serial data receptacle results in a protocol

compatible with some navigation devices manufactured by Magellan. The Digitizer sends a

seventeen-byte message beginning with $MGL, followed by a +/- sign and five altitude

digits, then T+25, a checksum and concludes with a carriage return. (1200bps, 7 data bits,

1 stop bit, even parity.) The following is an example of a serial message for Magellan

devices:

Message Definition

$MGL+02500T+25D6

C

RPressure Altitude 2500 feet.

1.8.5 ARNAV Systems Protocol

Leaving pins 9 and 10 of the DA-15S serial data receptacle open, the ARNAV Systems

protocol MUST be software selected see §4.6 for protocol selection details. Once selected,

the Digitizer will send a 24-byte message. Beginning with a $PASHS followed by a comma

and ALT, then a +/- sign followed by five altitude digits (in meters,) then an asterisk and a

checksum followed by a carriage return and a line feed. (9600bps, 8 data bits, 1 stop bit,

no parity.) The following is an example of an ARNAV serial altitude message:

Message Definition

STX$PASHS,ALT,+00033*1B

C

R

L

FETX Pressure Altitude 33 meters.

1.8.6 UPS AT 618 Loran Devices Protocol (IIMorrow)

Leaving pins 9 and 10 of the DA-15S serial data receptacle open, the UPS AT 618 Loran

devices protocol MUST be software selected see §4.6 for protocol selection details. Once

selected, the Digitizer will send a seventeen byte message beginning with # AL, then a

space followed by five altitude bytes; the letter “T” and the number “25”; two checksum

bytes and a carriage return. (1200bps, 7 data bits, 1 stop bit, odd parity). The following is

an example of an UPS AT 618 Loran serial altitude message:

Message Definition

#AL +00800T+25D8

C

RPressure Altitude 800 feet

1.8.7 One-Foot Resolution Protocol

Leaving pins 9 and 10 of the DA-15S serial data receptacle open, the one-foot resolution

protocol MUST be software selected see §4.8 for protocol selection details. Once selected,

the Digitizer will send a seventeen byte message beginning with RMS, then a space

followed by a sign, five altitude bytes; the letter “T” and the temperature sign; the number

“55”; two checksum bytes and a carriage return. (9600bps, 8 data bits, 1 stop bit, no

parity). The following is an example of the one-foot resolution altitude message:

Message Definition

RMS +00859T+55C2

C

RPressure Altitude 859 feet

This message is transmitted on TxD4 (pin 14) and TxD5 (Pin 15) ONLY!

The remaining serial ports TxD1 (pin 6), TxD2 (Pin 8) and TxD3 (pin 12) will transmit the

protocol assigned via software or via the jumpers on the serial data receptacle DA-15S.

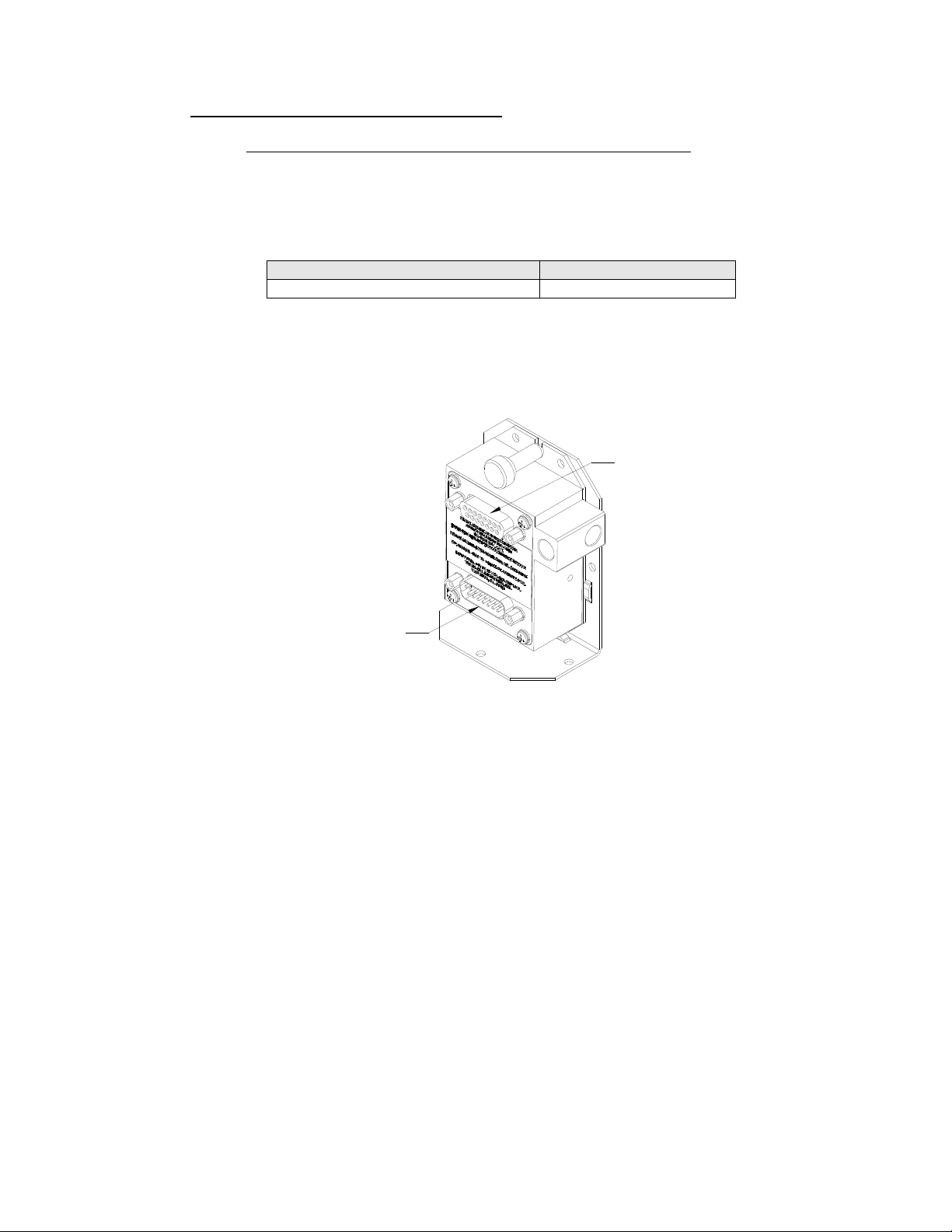

SERI AL DATA

RECEPTACLE DA-15S

PARALLEL DATA AND POWER

CONNECTOR DA-15P

Page 10 of 57

Section 2.0 Operation

2.1 General

The SSD-120(XX)N( )-RS5 series of altitude digitizers are designed to be mounted within a

pressurized or non-pressurized, but temperature controlled area within aircraft operating up

to 42,000 feet MSL. Usually remotely located, the digitizer is fully automatic in operation.

The parallel data output is controlled by the transponder while the serial altitude data is

transmitted asynchronously. (Half duplex, talk only. Full duplex in calibration and

configuration modes only.)

2.2 Operating Instructions

Parallel Data:

Place the transponder in mode “C”, altitude-reporting mode, and apply power to the

transponder and to the digitizer. In some installations the digitizer will automatically be

supplied power when the transponder is energized; in others, power to the digitizer may be

through a separate circuit breaker. If power to the digitizer is provided directly from the

aircraft’s avionics buss, follow the power-up procedures recommended by the transponder

manufacturer. All parallel outputs will be pulled low for a self-test (3 seconds) at power up,

then assume the value for the present input pressure. Note, a short the warm-up time may

affect the actual data enable time. At 0ºC a 30 second period is required before the data

will enable. In some installations, the transponder controls the digitizer by enabling and

disabling its output. In other installations, the digitizer’s output is not controlled by the

transponder and is continuously enabled, (Digitizer pin 6 is grounded.)

Serial Data

The serial communication is fully automatic and transmission begins after the self-test is

complete. Strobing (pin 6) the parallel ICAO altitude data output of the digitizer will not

affect the serial data transmission.

SERI AL DATA

RECEPTACLE DA-15S

PARALLEL DATA AND POWER

CONNECTOR DA-15P

Page 11 of 57

Page 12 of 57

Section 3.0 Installation

3.1 Mechanical Installation

The SSD120-(XX)N( )-RS5 series of digitizer may be mounted in any attitude within

the internal structure of the aircraft. DO NOT mount the digitizer in the direct air stream of

either hot or cold air ducts. The mounting position should allow for a short static pressure

line from the digitizer to the altimeter, access to the digitizer’s adjustments, and ample

room for a service loop for the interconnecting cabling to the transponder. The SSD120-

(XX)N-RS5 is provided with two static port inlets, either or both may be used to connect the

digitizer to the aircraft static system. If only one static port inlet is used, install the 1/8-

27NPT plug included with the connector kit into the unused static port. Apply pipe sealant

(not included) or equal to the plug. Exercise care to prevent excess sealant from plugging

the inlet to the pressure sensor.

On SSD120-(XX)NE-RS5 devices operating below -20ºC, use metal fittings on all

static line connections. The coefficient of thermal expansion for nylon is roughly three times

that of aluminum. Nylon and plastic fittings will leak at low temperatures due to thermal

contraction. Use an appropriate anti-seize compound when mating metal fittings to the

encoder.

To prevent the accumulation of condensation in the digitizer, locate this device away

from the lowest section of the static system, and ensure a proper condensation trap and

system drain is installed and functional.

Use #4-40 or #6-32 machine screws, sheet metal screws, or pop rivets to attach the

digitizer or the mounting tray to the airframe. Secure mating connectors to the digitizer

housing using the #4-40 screws provided. Refer to the outline drawing for mechanical

dimensions.

Adapter plates are available to convert older Trans-Cal and competing digitizer

installations for use with the SSD120-(XX)N(X)-(X) series of altitude digitizers. See

ordering information in §8.0.

3.2 Electrical Installation

Please note, proper solder or crimp techniques should be observed when attaching wires to

the mating connectors. Failure to do so could result in damage, intermittent operation or non-

operation of the digitizer. Shielded cable is recommended for both serial and parallel data

wiring harnesses. Wire and harnesses should be installed in such a way that the weight of

the cable bundle does not exert a force on the connector pins. The digitizer is designed to

operate with either a +14 or 28 Vdc power source. These voltages may be A+ switched

power provided by the transponder or may be provided by the avionics buss. Protect the

Trans-Cal encoder with a ½ amp fuse or circuit breaker.

Parallel Data Connection

The outline drawing provides electrical connector pin/function information. Use this

data when connecting the digitizer to the transponder. In some installations where older

transponders are used, the transponder may not provide an “altitude disable” function. In

this case, an instrument panel mounted switch for this function may be required.

Serial Data Connection (Table IX lists the pin assignments for the serial port receptacle.)

Connect the TxD1 through TxD53 (transmit data) from the 15-pin D-Subminiature

connector to the RxD (receive data) port on the GPS or other navigation devices. All

3The selected serial data protocol is transmitted simultaneously on all outputs, unless assigned separately in two groups via Serial Port

Software Configuration see §4.6.

grounds on the 15 pin D-subminiature connector are internally connected to ground and

may be used to ground protocol pins, as well as provide data ground to the receiving GPS

or other device. Pin 3 (RxD) of the 15-pin serial data connector is used for calibration only.

See Table IX for connector pin assignments and §4.6 through §4.10 for software assigned

protocols. Shielded cable is recommended for both serial and parallel data wiring

harnesses.

3.3 Serial Altitude Data Port Test Equipment

The output of the serial port may, or may not be directly displayed by the GPS or

other device receiving the serial data. There are several ways to test the output of the

serial port:

a) Use a TCI Model ATS-400 Test Set to display the serial altitude data.

b) Connect to an open serial port on a personal computer using serial data

capture software such as PROCOMM™, VERSATERM™, SOFTWARE WEDGE™,

TERMINAL (Windows® 3.x) or HYPERTERMINAL (Windows® 95, 98, 2000 or XP.)

c) Use a dedicated serial data test box such as the BLACK BOX™ RS232

Monitor.

d) Test for serial output using an oscilloscope to view the 9 Vdc square wave

group transmitted about twice a second.

3.4 Parallel ICAO Altitude Data Port Test Equipment

The output of the parallel ICAO altitude data may be monitored by any number of

transponder ramp test sets, which allow display of the ICAO altitude digitizer/encoder code.

The IFR Model ATC-600A Portable Transponder Test Set is one example. Alternatively,

the Trans-Cal Industries’ ATS-400 or EET-200 may be used to display the parallel data.

SERI AL DATA

RECEPTACLE DA-15S

PARALLEL DATA AND POWER

CONNECTOR DA-15P

Page 13 of 57

Page 14 of 57

Section 4.0 Calibration and Configuration

4.1 Calibration Overview

Reference: FAR 91.217; FAA Advisory Circular 43-6B

FAR 91.411; FAR 43-Appendix E and F

FAA TSO-C88a; EASA ETSO-C88a SAE AS8003

This procedure will allow adjustment to the calibration curve of the SSD120-(XX)N-RS5 or

SSD120-(XX)NE-RS5 as an aide in matching the digitizer output to a primary flight

altimeter or NIST traceable pressure standard. The maximum allowed error between the

primary flight altimeter and the altitude digitizer is ±125 feet as required by TSO-C88a and

ETSO-C88a. All Trans-Cal digitizers are calibrated to within ±50 feet of a NIST traceable

pressure standard; however, the error allowed on altimeters at higher altitudes could lead

to a combined error in excess of ±125 feet. When the altitude digitizer is installed in an

aircraft for use as the transponder’s source of mode “C” information the digitizer must be

recalibrated for correspondence to the aircraft’s primary flight altimeter, as required by FAR

91.217 and 91.411. Model SSD120-(XX)N-RS5 and SSD120-(XX)NE-RS5 are designed

to be field calibrated to meet this requirement, as per the procedure described in either

§4.4 or §4.8. The correspondence required for altitude digitizers is fully addressed in SAE

Aerospace Standard AS8003 §3.11. The correspondence described by the SAE standard

requires the digitizer to report altitude within ±125 feet of the primary flight altimeter’s

reading when the pressure datum is set to 29.92 In. Hg., (1013 MB) absolute. The SAE

standard also requires a transition accuracy of ±75 feet of the nominal transition point for

that altitude. A transition is defined as the point at which the digitizer changes from one

altitude to the next, either increasing or decreasing altitude. The nominal transition point of

the ICAO code occurs 50 feet prior to the altitude in question. See Figure 1.

There are two different methods used to change the calibration of this device. The

technician need only perform the method that is best suited for the application in question.

There is no need to perform both methods.The digitizer may be adjusted using two

potentiometers, which affect the span and reference of the pressure transducer. This

device may also be adjusted utilizing an externally addressable EEPROM, which is

configured to accept an alternate error curve entered to the digitizer via an IBM compatible

PC.

The Span Adjust calibration (§4.4) is normally used in applications where only a slight

modification is required to bring the altitude digitizer curve up or down.

The Dynamic Calibration procedure (§4.8) is an alternate method used to match the

altitude digitizer to the primary flight altimeter or NIST standard. It assumes the digitizer

and altimeter are connected as shown in the Dynamic Calibration Block Diagram and

the technician may adjust the input pressure to run the digitizer and primary flight altimeter

to the same altitude and then enter this altitude into an IBM compatible computer, which

will transmit the correction to the digitizer’s EEPROM. This calibration procedure differs

from the Span Adjust procedure in that the adjustments are made at every 1000-foot

interval and the Digitizer is adjusted at the 0 foot mark NOT the ICAO data nominal

transition point.

Page 15 of 57

4.2 Required Equipment Span Adjust

(See span adjust block diagram.)

1. Primary Flight Altimeter.

2. +12 or 28VDC power supply.

3. A pitot-static test set, capable of exercising the altimeter and digitizer over a range of –

1000 feet to the maximum altitude of the digitizer.

4. A ramp checker or test set capable of interrogating the transponder. Optional: ATS-400 or

equal device which will allow the display of the 100 foot resolution parallel altitude data.

4.3 Required Equipment Dynamic Calibration

(See dynamic calibration block diagram.)

1. Primary flight altimeter or NIST traceable pressure standard.

2. +12 to 28VDC power supply.

3. IBM compatible computer with an available serial port, OR Trans-Cal Industries ECP-100

Calibration/Programmer.

4. Software requirement: Windows 98®, Windows 2000® or Windows XP® using Hyper

Terminal Ver. 5.0 by Hilgraeve. (Available as a free download at http://www.hilgraeve.com) Or

equal serial data capture software. See §3.3a. (Windows Vista® is not currently supported by

Hyper Terminal.)

5. A pitot-static test set, capable of exercising the altimeter and digitizer over a range of -1000

feet to the maximum altitude of the digitizer.

6. Optional: ATS-400 or equal device which will allow the display of the 100 foot resolution

parallel altitude data.

4.4 Span Adjust Procedure

1. Connect the pitot-static test equipment to the aircraft’s static line, and connect the transponder

test set per the manufacturer’s recommendations. The digitizer’s two altitude adjustment

potentiometers are identified as L and H, representing low and high altitude. The low

adjustment is closest to the edge of the housing, and the high adjustment is closer to the

center of the housing.

(Note: Changing either potentiometer will affect the other. An adjustment made to correct the low

transition point, will move the high transition point, and require an adjustment of the high

potentiometer.)

2. Apply power to the altitude digitizer/transponder.

3. Set the primary flight altimeter barometric pressure adjustment to 29.92 In. Hg. (1013 MB).

4. Interrogate the transponder with the ramp tester, while observing the digitizer ICAO altitude

code, decrease pressure to the point where the altitude code just makes a transition to the

maximum altitude encoded. Verify that the digitizer is within ±125 feet of the primary flight

altimeter’s reading. If not, adjust the high potentiometer until the digitizer transition point is

Page 16 of 57

within ±30 feet of the nominal transition point. (i.e. while ascending, the digitizer should

transition from 29,900 feet to 30,000 feet at 29,950 feet nominally.)

5. Increase pressure until the digitizer’s output just makes the transition from 100 feet to 0 feet.

Verify that the altitude digitizer reports within ±125 feet of the primary flight altimeter. If not,

adjust the low potentiometer until the transition point is within ±30 feet of the nominal transition

point. (i.e. while descending, the digitizer should transition from +100 to 0 feet at +50 feet

nominally.)

6. Repeat steps (4) and (5) until the ±125 foot tolerance is achieved for both the maximum

calibration altitude and the minimum calibration altitude.

7. Exercise the aircraft’s static system over the operating range of the altitude digitizer and, with

increasing and decreasing pressure, verify at a minimum of ten test points that the altitude

digitizer and primary flight altimeter correspond within the ±125 foot tolerance. Lightly tap the

altimeter before each reading to eliminate friction. If correspondence is not achieved at any test

point, the altimeter may require calibration.

8. Verify that the digitizer’s output is disabled when the transponder is not in mode “C”, or when

the “Altitude Disable” switch is in the off position.

CAUTION: Always refer to the altimeter and VSI manufacturer’s data for maximum rate of climb or

descent, and any special test conditions which must be complied with.

Figure 1 Altitude Digitizer Correspondence

Page 17 of 57

Page 18 of 57

4.5 Dynamic Calibration Adjustment Procedure using the ECP-100

Reference: FAR 91.217; FAA Advisory Circular 43-6B

FAR 91.423; FAR 43-Appendix E and F

FAA TSO-C88a, EASA ETSO-C88a, SAE AS8003

This procedure will allow adjustment to the calibration curve of the SSD120-(XX)N-RS5 or

SSD120-(XX)NE-RS5 using the ECP-100 as an aide in matching the digitizer output to a primary

flight altimeter or NIST traceable pressure standard. This procedure differs significantly from the

Span Adjust Procedure described in §4.4. The Dynamic Calibration Procedure makes

adjustments to the altitude data stored in the digitizer’s EEPROM. The technician may make

adjustments to the digitizer error curve in 1000 foot increments, over the entire operating range

with the single exception of the –1000 foot mark. The technician will make the adjustments at the 0

or whole altitude mark, NOT at the parallel data’s nominal transition point. See Figure 1. The

digitizer will automatically adjust the ICAO parallel altitude data to transition 50 feet prior to the 0

mark. (i.e. the digitizer’s ICAO parallel altitude code will transition from 900 to 1000 feet while the

serial altitude data is transmitting 950 feet.)

1. Connect the digitizer, ECP-100, NIST standard or flight altimeter as shown in the Figure 2

and apply power.

2. Slide the ECP-100 CAL. PROGRAM selector to the leftmost PROGRAM position.

3. Apply power to the altitude digitizer and slide the ECP-100 power switch to the on position.

4. Set the altimeter barometric input to 29.92In.Hg. (1013MB). Adjust the static system

pressure and stabilize at the first altitude to be calibrated. The first possible correction for

Trans-Cal digitizers is at 0 feet. All adjustments to the digitizer calibration curve occur at

1000-foot intervals. Use the ALTITUDE UP and ALTITUDE DOWN buttons to adjust the

ECP-100 to the current pressure altitude prior to pushing the INITIATE PROGRAM

pushbutton.

5. Press the INITIATE PROGRAM pushbutton once. THE ECP-100 will enter a digital

correction into the digitizer’s EEPROM at the current pressure altitude.

6. Adjust the input pressure to the next 1000-foot increment and adjust the ECP-100 to the

next 1000-foot increment and repeat step 5. Continue repeating throughout the operating

range of the altitude digitizer.

7. Exercise the aircraft’s static system over the operating range of the altitude digitizer and,

with increasing and decreasing pressure, verify at a minimum of ten test points that the

altitude digitizer and primary flight altimeter correspond within the ±125 foot tolerance.

Lightly tap the altimeter before each reading to eliminate friction. If correspondence is not

achieved at any test point, the altimeter may require calibration.

8. Verify that the digitizer’s output is disabled when the transponder is not in mode “C”, or

when the “Altitude Disable” switch is in the off position.

NOTE: If an error is entered into the digitizer, adjust the pressure to the correct altitude and re-enter the correction. To

clear ALL the corrections to the digitizer error curve press the ALTITUDE UP PROGRAM pushbutton once. Then

press and hold the ALTITUDE DOWN button for two seconds.

If the digitizer and flight altimeter are within the ±125-foot requirement then no correction is required.

DO NOT adjust the digitizer high and low potentiometers during or after this procedure.

Figure 2 Dynamic Calibration Set-Up Using the ECP-100

Page 19 of 57

4.6 Hyper Terminal Set-Up on the IBM Compatible PC

Boot up the computer and start the serial data capture software such as the Hyper Terminal

program. Hyper Terminal may be located in the Programs section or in the Accessories section

under Communications, and Hyper Terminal will be used for the balance of the examples used in

this manual.

Under the New Connection window:

Choose an icon then select an identifying title such as “Test.”

SelectOK after you have made your choices.

Under the Connect to window:

-Choose Connect Using Com 1 or whatever Com port you have chosen to use.

After your selection click on OK.

Under the Com ? Properties window:

Select the Port Settings tab and set the following:

Bits per second: 9600

Databits: 8

Parity: None

StopBits: 1

FlowControl: None

SelectOK

In the Hyper Terminal window select File then click on Properties.

Under the Com ? Properties window click on the Settings tab.

Set the following:

Function, arrow, ctrl keys to act as Terminal Keys.

Emulation to Auto Detect

UnderASCII Setup

Setthefollowing:

Echo off.

Wrap lines that exceed terminal width.

SelectOK.

The software is now configured for operation.

Note: Past versions (Ver. 5 thru 6) of HyperTerminal have a known issue when communicating with serial

protocols of 7 data bits, 1 stop bit, odd parity. This Windows® program will not correctly auto detect the protocol,

but will display the data when manually configured.

Page 20 of 57

This manual suits for next models

1

Table of contents

Other Trans-Cal Media Converter manuals