TRANSDUCERS direct TD1 Series User manual

®

®

Introducing the TD1, 2, 3 Series

Melt Pressure Transducers.

me

SERIES: TD1-Rigid Stem

FEATURES

• Industry Standard Housing

• Standard 3.33mV/V , 6pin Bendix Connector

• 6” Stem (standard) , 18” Flex (standard) (TD2M)

• 0.5% combined error

• Ranges from 3000-20,000psi

• 750ºF (400ºC) Rating, Standard 15-5 SS Tip

• 660°F (350°C) Rating, Standard I5-5 SS Tip (Oil Fill)

• Thermocouple Type J (TD3M)

SERIES: TD2-Stem/Flex

SERIES: TD3-Stem/Flex with Thermocouple

TD1, TD2, TD3 OPTIONS

• Connectors : 8pin, 6pin-SCREW

• 12” Stem, 30” Flex (TD2M)

• Outputs : 4-20mA, 0-10VDC

• 80% Output Cal

®

®

REV: 10.14

cations may change without notice. The information we supply is believed to be accurate and reliable as of this printing. However, we assume no responsibility for its use. While we

provide application assistance personally, through our literature and the Transducers Direct web site, it is up to the customer to determine the suitability of the product in the application.

ORDERING

SPECIFICATIONS

Mechanical

Ranges 3000, 5000, 7500

10,000, 15,000, 20,000 psi

Accuracy +/- 0.5% (mercury), 1.5% (oil)

Repeatability +/-0.2% Of Full Scale

Overload Capability 2x Full Scale

Mounting Torque 150 Inch-lbs MIN 500 Inch-lbs MAX

Temperature E ects

Maximum Diaphragm Temp 750°F(400° C), [660° F (350° C) Oil Fill]

Maximum Housing Temp 250º F (121º C)

Zero Shift Of Electronics 1% / 100º F

Electrical

Measuring Sensor Output 3.33 Mv/v (optional 4-20ma and 0-10 vdc)

Supply Voltage

Insulation Resistance 1000 megohms @ 50 VDC

Zero & Span (Transmitter) ± 15%

Internal Shunt Calibration 80% ± 0.2% Of Full Scale

Series

TD2M

TD1M= RIGID STEM

TD2M= STEM FLEX

TD3M= STEM FLEX T/C

TD1O= Rigid Stem (Oil Fill)

TD2O= Stem/Flex (Oil Fill)

TD3O= Stem/Flex w/TC (Oil Fill)

Output

3

3= 3.33mV/V

4= 4-20mA

1= 0-10VDC

Pressure

5M

M= PSI x1000

3M

5M

7.5M

10M

15M

20M

Accuracy

5

5= 0.5%

Stem

6

6= 6”

12= 12”

Flex

18

18= 18”

30= 30”

Thread

U

U= 1/2” x 20

M= M18 x 1.5

Connector

6B

6B= 6 PIN Bendix

6T= 6 PIN Threaded

8T= 8 PIN Threaded

8C=8 PIN Threaded

(Barber Colman)

Diaphragm

T

T= 15-5 stainless steel

*Contact factor

T

Oil Fill Temperature Drift

(thermal expansion)

Up to 125 psi @ 250° F (121° C), Up to 250 psi @ 500° F (260° C)

Standard Fill Mercury (M), optional oil fill (O)

®

®

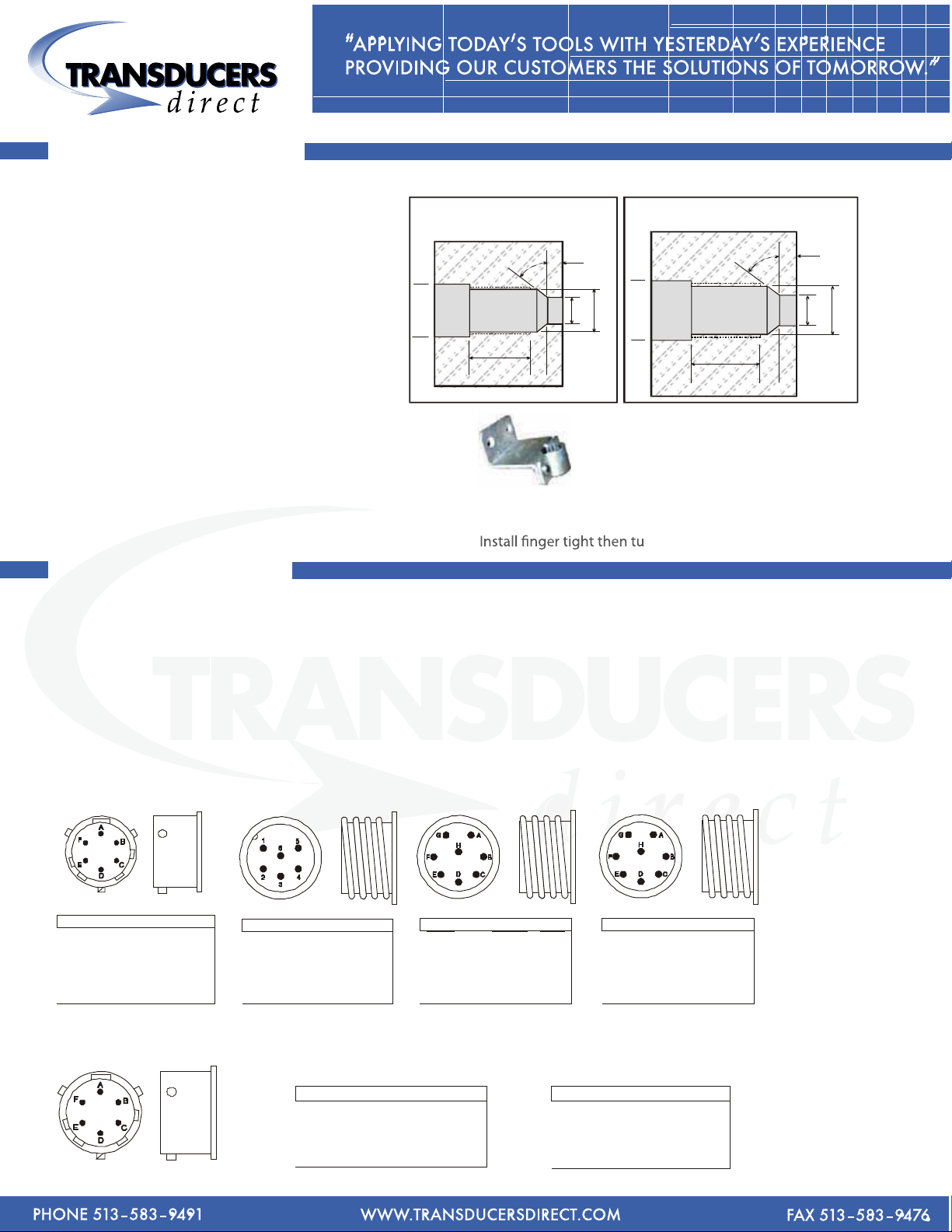

MECHANICAL INSTALLATION

1. MOUNTING HOLE

All holes must be concentric within 0.002”

AVAILABLE DRILL KITS : Page 4

2. PROTECTIVE CAP

Leave cap on until installation - FRAGILE tip

3. LUBRICATE THREADS with EITHER :

1. NEVERSEEZ by BOSTIK

2. C5A by FELRO

3. MOLYKOTE by DOW CORNING

4. CLEAN HOLE OF ALL PLASTIC MATERIALS

Any residue can damage tip on installation.

AVAILABLE CLEAN KITS : Page 4

5. TRANSDUCER HOUSING (Max Temp - 160ºF)

Install in low vibration area.

MOUNTING BRACKET: TDMP-MTG-BRACKET

6. MOUNTING TORQUE

MIN 150inch-lbs MAX 500inch-lbs

rn 1/4 TURN with wrench

1/2 -20 U N F- 2B

M 1 8 x 1 .5

0. 515 ( 13 .1)

m in

0 .7 8 7 (2 0 )

m in

0 .1 7

( 4 .3 )

m a x

0.1 6

(4)

ma x

0 .314

0 .312

( 7.9 8)

7 .92

0 .4 0 1

0 .3 9 9

(1 0 .1 9 )

1 0 . 1 3

0 .458

0 .452

( 11 .6 5)

11. 47

0 .6 3 8

0 .6 3 4

( 1 6 .2 1 )

1 6 . 1 0

0 .2 15

( 5. 46 )

M IN

0 . 2 4 2

(6 .1 5 )

M I N

0.7 5 (19)

m in T HR E A D

1 .0 0 ( 2 5 . 4 )

m i n T H R E A D

45

O

4 5

O

1/2-20 UNF-2B

(S TAN D A R D )

M 18 x 1.5

ip

Install finge

6 PIN BAYONET 6 PIN SCREW 8 PIN SCREW

8 PIN SCREW

(Barber Colman)

LE AD

S IG N A L +

E X C I TAT I ON -

C A L IB R A T IO N

C A L IB R A T IO N

S IG N A L -

E X C I TAT I ON +

C O LO R

R E D

B LA C K

W H IT E

G R E E N

B LU E

O R A N G E

6 PIN

A

B

C

D

E

F

LEA D

SIGNAL +

SIGNAL -

EXCITATION - GREEN

CALIBRATION BLUE

CALIBRATION ORANGE

EXCITATION +

COL O R

RED

BLACK

WHITE

6 PI N

1

2

3

4

5

6

LEA D

E X C ITA T IO N +

S IGN A L +

E X C ITA T IO N -

S IGN A L -

C A L IB R A T IO N

C A L IB R A T IO N

N O T U S ED

N O T U S ED

CO LOR

W H IT E

R E D

G R E E N

B LAC K

B L U E

O R A N G E

8 PIN

A

B

C

D

E

F

G

H

LEA D

E X C ITA T IO N +

S IGN A L +

E X C ITA T IO N -

C A L IB R A T IO N

C A L IB R A T IO N

N O T U S ED

N O T U S ED

S IGN A L -

CO LOR

W H IT E

R E D

B LAC K

G R E E N

B L U E

ORANGE

8 PIN

A

B

C

D

E

F

G

H

6 PIN BAYONET

4-20mA OUTPUT VOLTAGE OUTPUT

0-10VDC

TRANSMITTER - 4-20mA or VOLTAGE

L E A D

S IG N A L +

E X CITAT IO N -

CA L IB R ATIO N

CA L IB R ATIO N

S IG N A L -

E X CITAT IO N +

C O LO R

RE D

B LA C K

W HIT E

G RE E N

B LU E

O RA NG E

6 P IN

A

B

C

D

E

F

L E A D

S UP P LY /S IG NA L +

S UP P LY /S IG NA L

N/A

N/A

CA L IB R ATIO N

CA L IB R ATIO N

-

C O L O R

RE D

B LA C K

W HIT E

G R E E N

B LU E

O R A N G E

6 P IN

A

B

C

D

E

F

ELECTRICAL INSTALLATION

1. WIRING DIAGRAM

Depending on connector below :

2. CABLE+GROUND (26AWG, 6WIRE, SHIELD)

Shield may have to be connected to ground in a

high noise environment. Do not connect to meter.

3. ZERO ADJUSTMENT

To compensate for pressure drift caused by temp changes.

At operating temperature with no pressure on transducer,

adjust the pressure indicating device to read “0”

4. SPAN ADJUSTMENT

To calibrate readout device to transducer.

Press “CALIBRATE” and adjust reading to read 80% SPAN.

TRANSDUCER - 3.33 mV/V

TRANSDUCER - 3.33 mV/V

®

®

T HR E A D C L E A NE R

T IP C L E A NE R

T HR E A D G A UG E

GENERAL OPERATIONAL GUIDES

1. START UP

Before starting the extruder drive, ensure that the extruder is at operational temperature and plastic at tip is molten.

A cold start can literally rip o the fragile diaphragm.

2. REMOVAL

Only remove transducer when barrel is at operational temperature and zero pressure.

Always clean hole of all solids before re-installing.

Check hole dimensions with thread gauge of cleaning kit to ensure proper hole. Hole size at tip can reduce over time.

Always remove transducer before cleaning inside barrel with abrasive cleaner or wire brush.

3. CLEANING TIP

Clean tip lightly with a dry cloth while tip is still hot.

Do not use any sharp tools (screwdriver, chisel, knife, wire brush etc.)

29/64 P IL O T DR IL L

B O T TO M T A P

1/2-2 0U NF TA P

5/16” R E A ME R

9/32” DR IL L

17/32” DR IL L

TROUBLESHOOTING

1. Indicator Full Scale Check Continuity Of Cables

2. Indicator Unstable Reading Check Continuity Of Cables

3. Indicator Reads Only “0” Perform Calibration.

If Doesn’t Change - Send Instrument In For Anaysis

4. Indicates Wrong Pressure Perform Calibration

If Still Incorrect - Send Transducer In For Analysis

HOLE CLEANING KIT

TDMP-1-CLEANKIT

Kit is used to clean transducer hole before insertion to

prevent diaphragm damage.

HOLE CUTTING KIT

TDMP-1-CUTTINGKIT

All the Drills, Reamers and Taps required to drill a

proper hole for standard transducers (1/2-20UNF).

This manual suits for next models

5

Popular Medical Equipment manuals by other brands

Medifab

Medifab Houdini Harness 13 Installation and user manual

FingerTip

FingerTip Pulse Oximeter quick start guide

KaWe

KaWe Reflexhammer user manual

Olympus

Olympus EVIS EXERA II instructions

Thomashilfen

Thomashilfen ThevoautoActiv user manual

Dräger

Dräger Infinity Acute Care System Evita Infinity... Supplement to the instructions for use