-10-

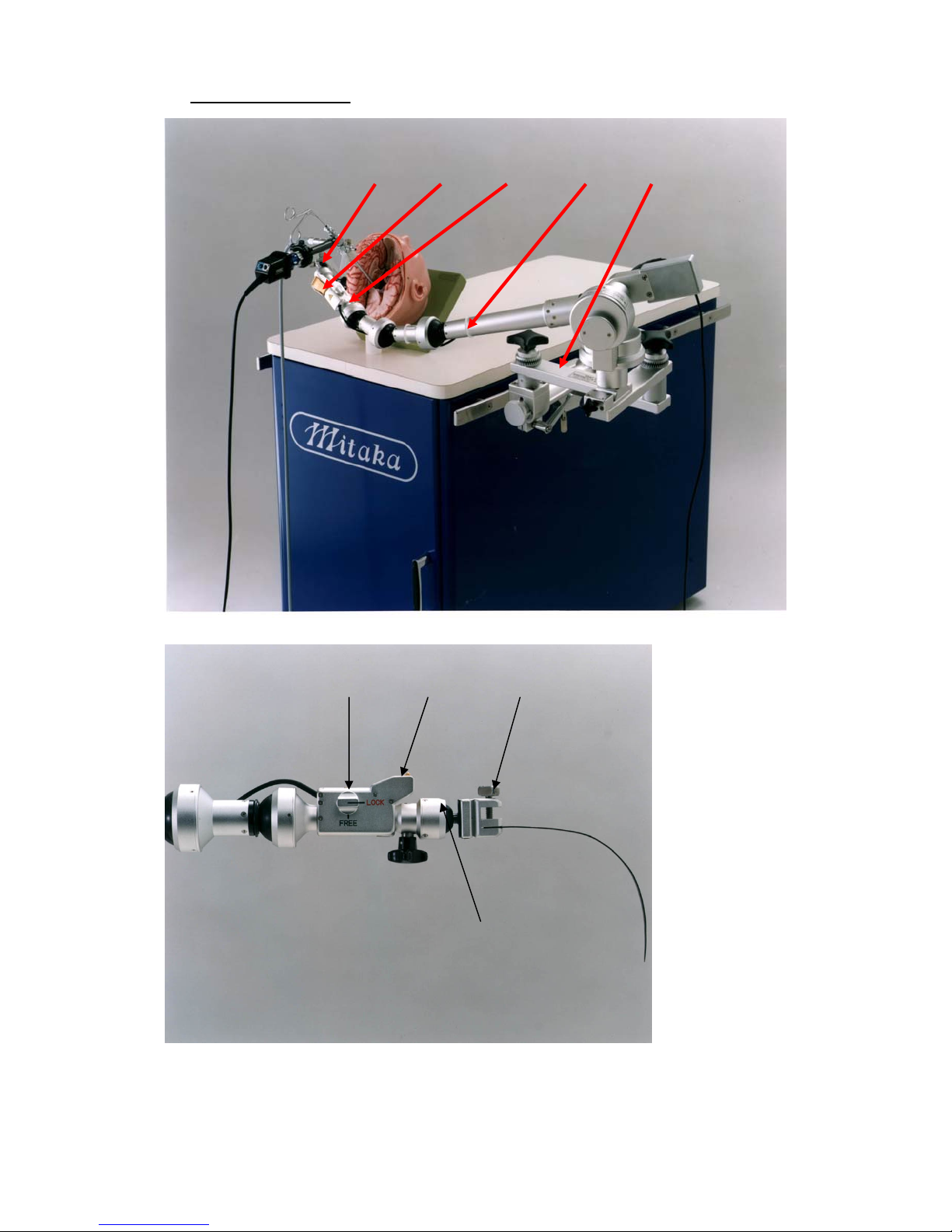

■ Cleaning Instructions for the Endoscope Holder

Caution: Wear protective gloves, clothing, and a face mask for cleaning

of contaminated endoscope holder.

Caution: Hot water (greater than 49 degrees C or 120 degrees F) will

alter organic materials (blood and tissue), making them

difficult to remove.

1. The endoscope holder should be disassembled.

2. Thoroughly rinse all parts to remove all gross debris.

3. Manual cleaning is recommended. However, difficult to reach areas can be

cleaned using an ultrasonic cleaner. It is important to follow the manufacturer’s

instructions for operating the ultrasonic cleaner.

4. Completely immerse the endoscope holder in a neutral pH enzymatic cleaning

solution (e.g., Enzol, Metrizyme or equivalent per manufacturer’s instructions)

and distilled water. Use water that is less than 49 degrees C or 120 degrees F to

clean the endoscope holder; blood and tissue will become difficult to remove

using hot water. Mitaka does not recommend the use of detergents alone, as they

contain high concentrations of surfactants which can leave a film on the

endoscope holder.

5. Remove any residual blood, protein material and contaminants from the

endoscope holder with brushes, sponges, soft cloths or a cotton cloth applicator.

6. Clean the inside of the sheaths and outer tubes with the appropriate size cleaning

brushes.

7. Cleaning brushes should be cleaned and subjected to high level disinfectant or

sterilization daily.

8. Triple rinse the endoscope holder with distilled water for a minimum of one

minute for each rinse. The rinse water should be discarded at the end of each

rinse, as it will be contaminated with the cleaning solution. Thorough rinsing of

the endoscope holder is necessary for removing any debris or detergent which

could interfere with sterilization.

9. Dry the endoscope holder with a lint-free soft cloth or filtered compressed air.