TRAXX 5418 User manual

WARNING: when using Electric Tools, basic safety precautions should always be followed to reduce the risk

of fire, electric shock, and personal injury, including the following:

READ AND UNDERSTAND ALL SAFETY WARNINGS AND INSTRUCTIONS, before using the tool!

GROUNDING INSTRUCTIONS (See Fig. 1). This tool should be grounded while in use to protect the operator

from electric shock. The tool is equipped with a 3 conductor cord and 3-prong grounding (A) type plug to fit

the proper grounding (B) type receptacle. The green (or green and yellow) conductor in the cord is the

grounding wire and (A1) is the grounding pin. Never connect the green (or green and yellow) wire to a live

terminal. Type (C) adapter, if approved by Safety Regulations in force, may be used for connecting (A) type

plugs to (D) 2-prong receptacles. The (C1) lug must be connected to a permanent ground by (D1) metal

screw, such as a properly grounded outlet box.

EXTENSION CORD. Make sure your extension cord is in good conditions. When using an extension cord,

be sure to use one heavy enough to carry the tool current. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating. In the Technical Specification is shown the correct size

to use depending on cord length. If in doubt, use the next heavier gage. The smaller the gage number, the

heavier the cord. Use only safety marked 3-wire extension cord that have a 3-prong grounding type plug

and 3-pole receptacle that accepts tool’s plug. Replace damaged cord.

OUTDOOR USE EXTENSION CORD. When tool is used outdoor, use only extension cord intended for use

outdoors and so marked. Replace damaged cord.

ELECTRICAL SUPPLY PLANT. Must be grounded AC single phase, in accordance with all local law

ordinance. It must correspond to the voltage and current rating shown on the tool. Never connect the tool

to DC power source, to an unbalanced 3-phase derivated supply or engine generators.

Do not plug the tool to receptacles that are not properly installed and grounded.

KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

CONSIDER WORK AREA ENVIRONMENT. Do not expose power tools to rain. Do not use power tools in

damp or wet locations. Keep work area well lit.

DO NOT OPERATE the tool near flammable liquids or in gaseous or explosive atmospheres. Switches

normally spark and might ignite fumes.

GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with grounded surfaces. For example: pipes,

radiators, ranges, refrigerator enclosures.

IMPORTANT SAFETY INSTRUCTION

INSTRUCTION MANUAL

TRAXX 5418

Electric Stapler

110-120 V AC

50-60 Hz

KEEP CHILDREN AWAY. All visitors should be kept away from work area. Do not let visitors contact tool or

extension cord.

STORE IDLE TOOLS. When not in use, tools should be stored in dry and high or locked-up place, out of

reach of children.

DO NOT FORCE TOOL. It will do the job better and safer at the rate for which it was intended.

DO NOT EXCEED the maximum average fastener drive rate (stated in the specifications). If the tool over-

heats, leave it to cool down.

USE RIGHT TOOL. Do not force this tool to do the job of a heavy-duty tool (like air-powered fastening

devices). Do not use tool for purpose not intended, for example, do not drive fasteners into impenetrable

materials.

DRESS PROPERLY. Do not wear loose clothing or jewelry. They can be caught in moving parts. Rubber

gloves and non-skid footwear are recommended when working outdoors. Wear protective hair covering to

contain long

hair.

DO NOT ABUSE CORD. Never carry tool by cord or yank it to disconnect from receptacle. Keep cord away

from heat, oil, and sharp edges.

SECURE WORK. Use clamp or a vise to hold work. It is safer than using your hand, it frees both hands to

operate tool.

DO NOT OVERREACH. Keep proper footing and balance at all times. Hold tool firmly to minimize recoil.

MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and safe performance. Follow

servicing instructions. Inspect tool cord periodically and if damaged have replaced or repaired by authorized

service facility. Inspect extension cord periodically and replace if damaged. Keep handle grip dry, clean, and

free from oil and grease.

ALWAYS DISCONNECT THE TOOL AND UNLOAD THE MAGAZINE when not in use, before servicing,

clearing a jammed fastener, moving tool to another location.

NEVER POINT THE TOOL AT YOURSELF OR AT ANYONE ELSE. Point the fastener outlet against the

workpiece when loading and operating.

Always assume the tool contains fastener.

AVOID UNINTENTIONAL STARTING. With plugged-in tool do not rest hand or fingers on the trigger when

not driving fasteners, during loading, unloading, displacements or as a habit. Never play with the tool or the

trigger.

STAY ALERT. Watch what you are doing. Use common sense. Do not operate tool when you are tired.

CHECK DAMAGED PARTS before further use of the tool, check to determine that it operates properly and

performs its intended function. Check for alignment and binding of moving parts, breakage of parts,

tightening of mounting screws. Never use the tool if plastic body, trigger, switch, cord or plug are defective.

CAUTION: ALWAYS WEAR SAFETY GLASSES

To prevent eye injuries, safety glasses with permanently attached side shields must be worn by the

tool operator and everyone in the vicinity of the tool. These glasses must be approved by the Official

Safety Agency for the country the tool is used in, and have the prescribed markings printed or

stamped on them.

DO NOT USE MALFUNCTIONING TOOL or if parts are

missing or damaged.

DO NOT ALTER THE TOOL and the plug in any way.

ALL REPAIRS MUST be performed by authorized service personnel. Only tool

maintenance will be executed by operators as recommended in this manual.

NEVER OPERATE the tool without fasteners or off workpiece. It could cause serious personal injury

or damage the tool especially working in cold areas.

THE WORKPIECE THICKNESS must always exceed fasteners length. Do not drive on top of other fasteners,

with the tool at too steep of an angle or close to the edge of the work surface; the fastener could fly out and

hit someone.

USE ONLY FASTENERS which are specifically recommended by the manufacturer in this manual and on the

tool label.

FOR ANY QUESTIONS or for further safety and technical information, contact the service representative.

EXTENSION CORD: Total length (feet)0-25 26-50 >50

Wire size AWG 14 10 Not Recommended

ELECTRICAL RATING: 10 Amps 110-120 VAC 50-60 Hz single phase, grounded

DRIVING SPEED: max. 3 pcs./sec (instant speed)

DRIVE RATE: max. 20 pcs./min (average working frequency)

MAGAZINE CAPACITY: max. 5 1/8” in.

SAFE: Self interlock trigger against inadvertent drive

UNJAMMING: Removable front plate without tools

FEEDING: From rear side with built-in pusher

TRIGGER: Full hand type

WEIGHT: 2.75 lb.

DIMENSIONS: L = 8 1/16”in. H=75/16” in. W = 2” in.

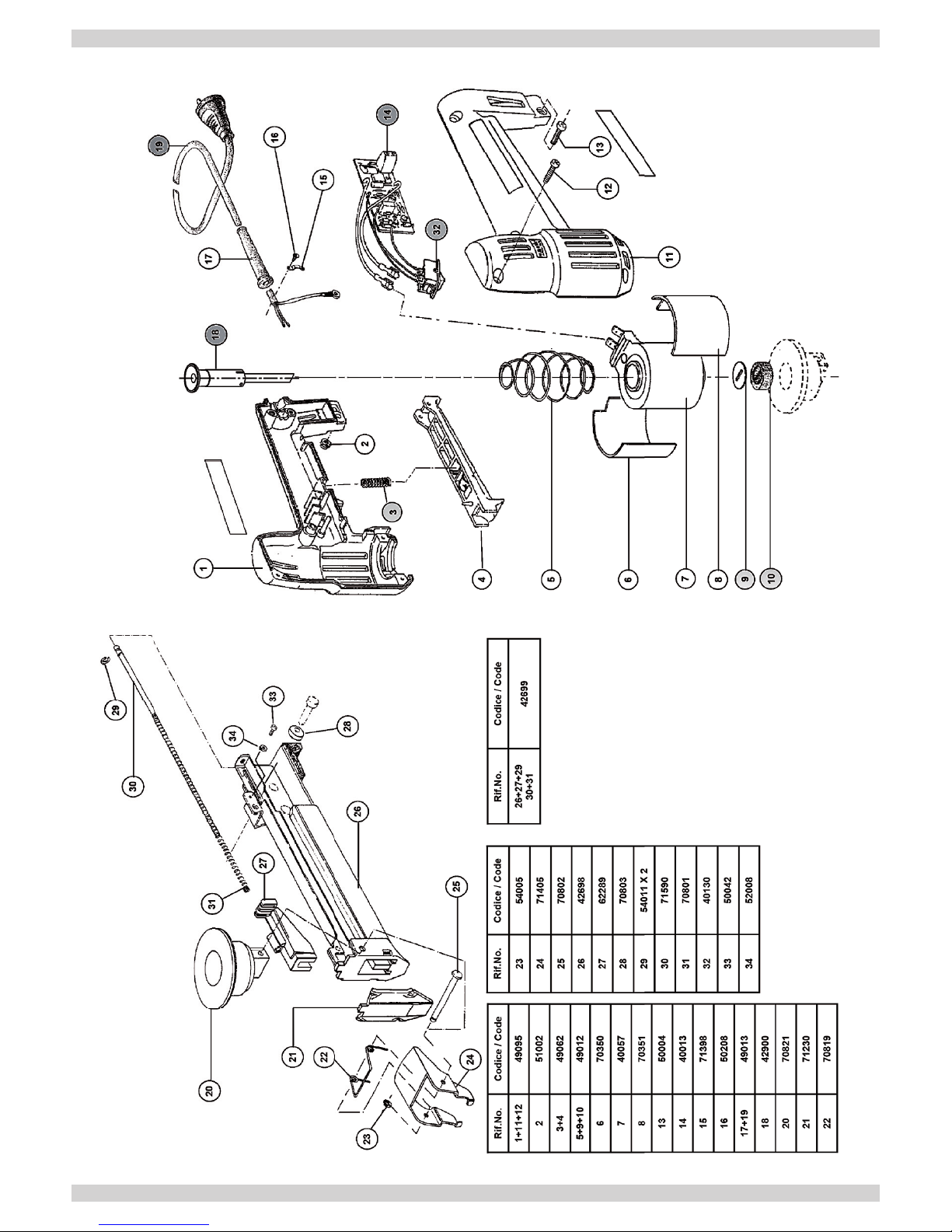

Disconnect the plug from the electrical supply.

Hold the tool firmly as in Fig. 2.

Trigger lock (1) must be in safety position (A).

Pull the pusher lever (2) all the way to the rear and tilt it up to lock position (3).

Insert the fastener strip (4) on rail guide and slide it forward.

Retract the pusher from locked position and tilt it down.

Gently release the pusher forward against the fastener strip (5).

SAVE THESE INSTRUCTIONS

TECHNICAL SPECIFICATIONS

LOADING

Hold the tool firmly against the surface being fastened as in Fig. 3.

With your index finger, push forward the SAFETY lever (1) which is then compressed into trigger cavity.

DO NOT FORCE the safety lever (1) backward: it will break.

Squeeze the trigger (7) to fire.

RELEASE THE TRIGGER completely after each drive.

DO NOT FIRE when empty or on unpierceable surfaces.

ALWAYS UNPLUG after use.

When fastening hard wood, maximum impact force can be achieved by pressing down on the machine with

both hands (6).

Do not drive fasteners on top of one another, or hold the stapler at any extreme angle that could deflect the

fastener off surface and injure someone.

When jamming occurs, do not fire, UNPLUG the tool and UNLOAD the magazine.

As in Fig. 4, press the front plate holder (8) and remove the front plate (9).

As in Fig. 6, use needle nose pliers, or a small pointed probe, to remove any fasteners that have become

lodged in nose area of channel.

It is most important that you DO NOT USE EXCESSIVE FORCE that could bur or bend guides which can

prevent smooth movement of the fastener which could lead to misfiring.

Engage pusher (3) forward to make certain channel is clear and then insert the front plate.

UNPLUG the tool and UNLOAD the magazine. Remove front plate (9)Fig. 4.

Slide the pusher back and forth several times to remove any grit or dirt that may have settled in channel.

Clean the slide area and lubricate the front plate with a drop of light oil, as in Fig. 5.

External cleaning may be done with a damp cloth.

NEVER USE WATER OR SOLVENTS or other liquids in cleaning operations.

NEVER LUBRICATE the internal part of the tool.

Periodically check cable and plug for signs of wear or damage and have replaced by authorized service

facility if necessary.

DO NOT DISASSEMBLE OR ALTER THE TOOL.

All repairs should be performed by authorized service personnel only.

WHEN REQUESTING TECHNICAL OR COMMERCIAL ASSISTANCE give the tool model and fasteners type

code marked on the tool label and stamped on first page of this manual.

REPAIRS

DRIVING FASTENERS

UNJAMMING

MAINTENANCE

Hold the tool firmly against the surface being fastened as in Fig. 3.

1. With your hand push the trigger (7) to fire.

2. For models with safety: with your index finger, push forward the SAFETY lever (1)

which is then compressed into trigger cavity.

DO NOT FORCE the safety lever (1) backward: it will break.

Squeeze the trigger (7) to fire.

RELEASE THE TRIGGER completely after each drive.

DO NOT FIRE when empty or on unpierceable surfaces.

ALWAYS UNPLUG after use.

When fastening hard wood, maximum impact force can be achieved by pressing down on the machine with

both hands (6).

Do not drive fasteners on top of one another, or hold the stapler at any extreme angle that could deflect the

fastener off surface and injure someone.

Fig. 1 Fig. 2

Fig. 3

Fig. 5

Fig. 4

Fig. 6

(OPTIONAL)

READ CAREFULLY BEFORE USING THE TOOL

If warranty terms are not acceptable, return at once unused for refund

LIMITED WARRANTY

•WHAT IS COVERED: this warranty covers any defects in material and workmanship.

•HOW LONG: the duration of this warranty is 180 days from date or purchase.

•WHAT MANUFACTURER WILL DO: during this period, replacements or repairs of tool (at manufacturer's option)

will be made without any cost for parts or labor by an authorized manufacturer service center.

•WHAT IS NOT COVERED: this warranty does not cover damage by accident, misuse, unauthorized repair or

modification, or due to the use of fasteners not recommended by the manufacturer or which do not comply with

the manufacturer quality control specification and/or product performance standards.

•HOW TO GET SERVICE: to obtain repair or replacement under this warranty, the tool must be returned to an

authorized manufacturer service center, AT YOUR EXPENSE, with original purchase receipt, or other positive proof

the tool is within the warranty period.

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTIES. THESE, WHETHER ORAL, WRITTEN, EXPRESS, OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE SHALL NOT APPLY TO THE WARRANTIES EXTENDED WITH THIS TOOL.

Any representations or

promises inconsistent with or in addition to this warranty are unauthorized and shall not be binding upon the

manufacturer.

IN NO EVENT, WHETHER AS A RESULT OF BREACH OF CONTRACT, WARRANTY, TORT (INCLUDING NEGLIGENCE)

OR OTHERWISE, SHALL MANUFACTURER'S LIABILITY TO THE PUCHASER OF THIS TOOL OR ANY LOSS OR

DAMAGE ARISING OUT OF THE BREACH OF WARRANTY, CONTRACT, OR TORT, EXCEED THE PRICE OF THE TOOL

WHICH HAS GIVEN RISE TO THE CLAIM OR LIABILITY.

Magazine

Body

TRAXX 5418 Electric Stapler

REPAIR POLICY

The TRAXX 5418 Electric Carpet Stapler is warranted to be free from defects

in material and workmanship for 6 months from the date of purchase.

This stapler can be sent to TRAXX for repair:

An RMF (Return Merchandise Form) may be obtained on-line at:

www.traxxcorp.com/products/traxx-tools/electric-stapler-5418

An RMF and purchase receipt must accompany all returns.

No pre-approval is required.

Cleaning and testing is included with every repair.

The standard repair charge is $40,

after the warranty period.

Tools under warranty will be repaired and returned to you.

Note: Tools that show excessive damage or

abuse will be returned without repair.

Send tool repair to:

TRAXX Corporation

Tool Repair Center

1201 E. Lexington Ave.

Pomona, CA 91766

Sender is responsible for all shipping costs to TRAXX.

1201 E. Lexington Ave., Pomona, CA 91766 Ph: 909-623-8032 www.traxxcorp.com

Cod. 89045

Table of contents

Popular Power Tools manuals by other brands

Joto

Joto E-HP-JSP-1620 Operator's manual

Makita

Makita 4604D instruction manual

Mapal

Mapal HTC Series Installation and operating instructions

Ingersoll-Rand

Ingersoll-Rand BXR-100H Operation & maintenance manual

Ferm

Ferm HAM1014 Original instructions

woodmizer

woodmizer LX450 Series Safety, Setup, Operation & Maintenance Manual