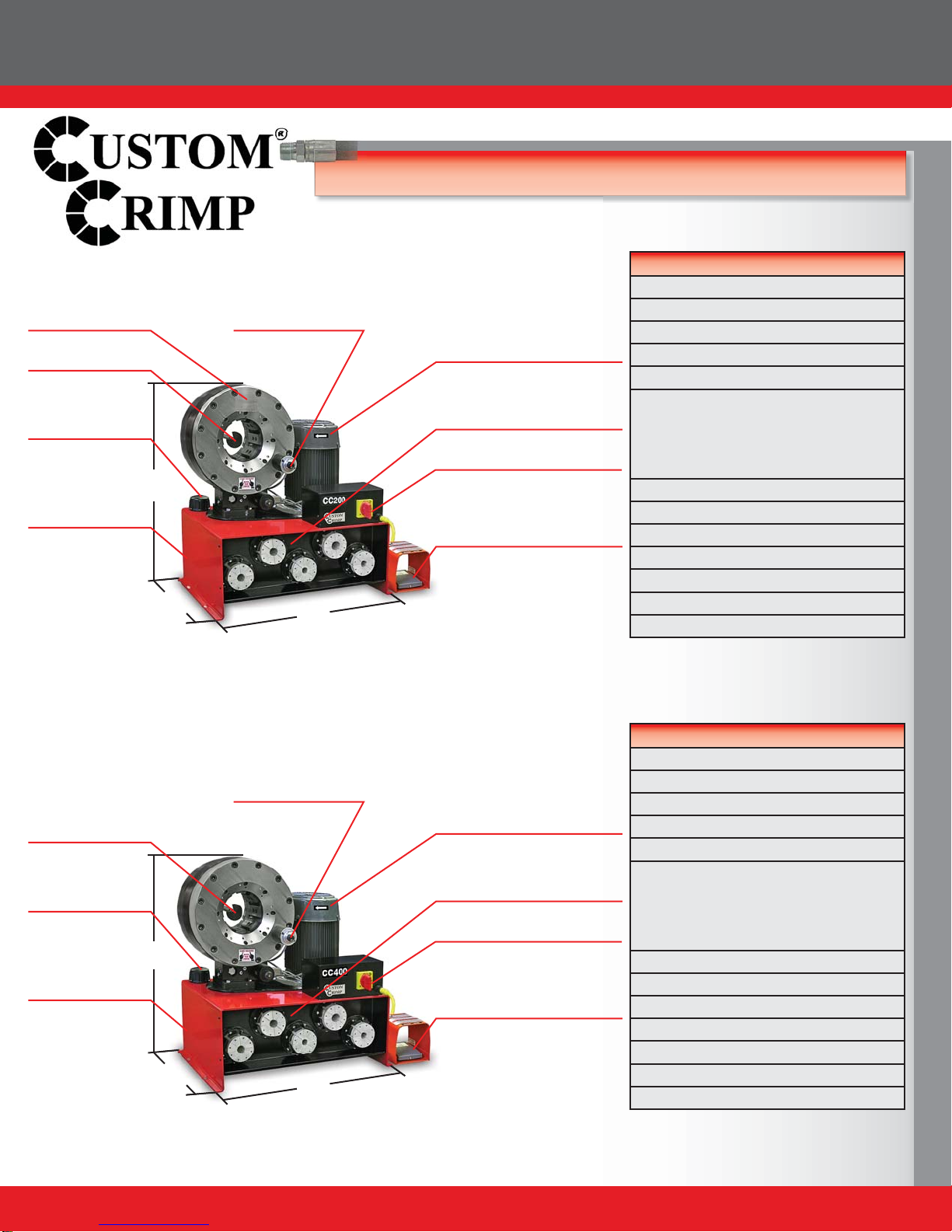

CC200 / CC400 General Production Hose Crimper

4

COMPONENT PARTS & TECHNICAL DATA

Notch for clearance

of 90° fittings Metric Micrometer

Style Adjustment

Manual Back Stop

The Foot Switch permits dies

to be “jogged” into position

and keeps both hands free

The 5 HP motor delivers the

power needed to get the job

done quickly

29"

20"

Small Footprint for

minimum use of space

32"

Technical Data

340 Ton

Max 2SP: 2-½", 4SP: 2-½", 6SP: 2-½"

Max Industrial: 3"

L: 20" x W: 29" x H: 32"

Weight: 635 lbs

Power: 5HP / 230V / 3Phase (Standard)

5HP / 440V / 3Phase (Optional)

5HP / 230 / 1Phase (Optional)

1HP / 12VDC (Optional)

1HP / 24VDC (Optional)

Die series: 99S / 130S

Adjustability: Metric

Opening w/o dies: 160mm / 6.30"

Master die inside diameter: 130mm / 5.12"

Master die travel: 38mm / 1.5"

Reservoir capacity: 8 US Gallons

Oil type: ISO 46 Hydraulic Oil

Built-in die storage panel

keeps frequently used die

sets readily available

Power Switch

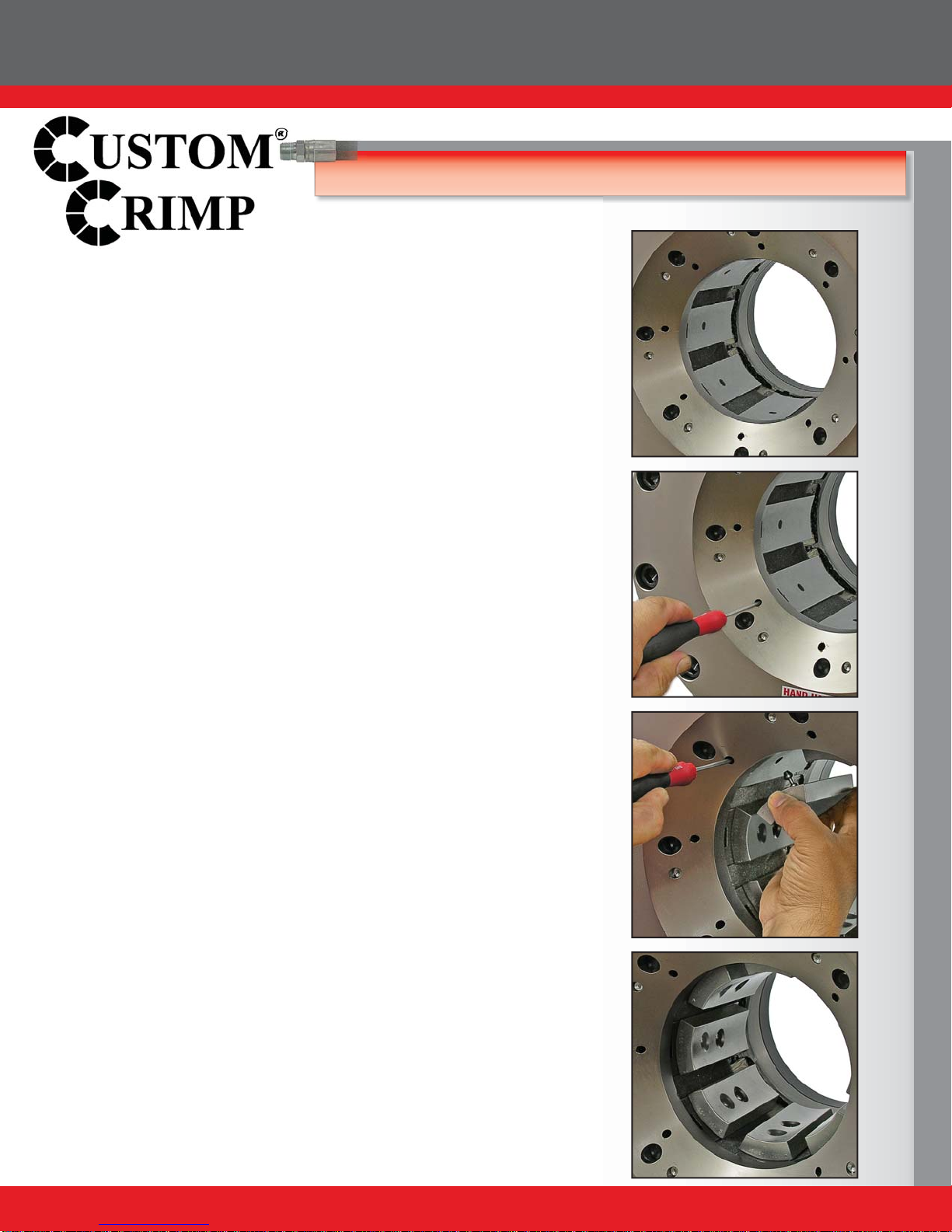

Metric Micrometer

Style Adjustment

Manual Back Stop

CC200 Hydraulic Hose Crimper

CC400 Hydraulic Hose Crimper

The Foot Switch permits dies

to be “jogged” into position

and keeps both hands free

The 5 HP motor delivers the

power needed to get the job

done quickly

29"

20"

Small Footprint for

minimum use of space

32"

Built-in die storage panel

keeps frequently used die

sets readily available

Power Switch

Technical Data

265 Ton

Max 2SP: 2", 4SP: 2", 6SP: 1-½"

Max Industrial: 4"

L: 20" x W: 29" x H: 32"

Weight: 660 lbs

Power: 5HP / 230V / 3Phase (Standard)

5HP / 440V / 3Phase (Optional)

5HP / 230 / 1Phase (Optional)

1HP / 12VDC (Optional)

1HP / 24VDC (Optional)

Die series: 99S / 145S

Adjustability: Metric

Opening w/o dies: 182mm / 7.17"

Master die inside diameter: 145mm / 5.71"

Master die travel: 60mm / 2.4"

Reservoir capacity: 8 US Gallons

Oil type: ISO 46 Hydraulic Oil

Oil Filler Cap

Reservoir

Oil Filler Cap

Reservoir