Trejon OPTIMAL Control Eco Specification sheet

Instructions for use

and maintenance

OPTIMAL Control Eco

Supplement to the sand spreader manual

TREJON FÖRSÄLJNINGS AB

Företagsvägen 9

SE-911 35 VÄNNÄSBY

SWEDEN

Tel: + 46 (0)935 39 900

Fax: + 46 (0)935 39 919

Webb: trejon.se

Edition: 2016-09

Note!

Read instructions before use

Operating manual OPTIMAL Control Eco (2112)

2

Breddningsving

en monteras på

insidan av

maskinen

Table of contents

Introduction .................................................................................................................... 6

Description of handset OPTIMAL Control Eco ............................................................. 9

Generally ....................................................................................................................... 9

Display......................................................................................................................... 10

Description of menu set - user: .................................................................................. 11

Concluding remarks:.................................................................................................. 11

Features and switches on the handset...................................................................... 12

Outputs ............................................................................................................ 13

Other technical specifications ................................................................................... 13

Functions..................................................................................................................... 13

Setting of spread rate................................................................................................. 13

Setting the spreading width........................................................................................ 14

Emptying function ...................................................................................................... 14

Appendix 1 Menu items............................................................................................. 15

Appendix 2 Cable connection................................................................................... 15

Operating manual OPTIMAL Control Eco (2112)

3

Breddningsving

en monteras på

insidan av

maskinen

SAFETY SYMBOLS

Note! This warning symbol is used throughout this instruction manual to call attention to safety

precautions that you, your employees or any other people that may come near the implement

must read and understand. Failure to follow these instructions may result in serious injury or

even death.

This symbol means:

WARNING!

CAUTION!

YOUR SAFETY IS

ENDANGERED!

A word of advice

Pay special attention to the words WARNING!, CAUTION! and NOTE! in the safety instructions.

The words have been chosen from of the following:

WARNING! This safety sign is used to identify potential hazards that can lead to serious injury

or even death. These hazards include situations that may occur when the safety equipment

and/or the safety shields are removed. Signal words can also be used to alert about dangerous

use.

CAUTION! Failure to observe this warning sign could result in light personal injuries. The sign is

also used to indicate that the disregarding of these instructions may cause damage to the

implement.

Operating manual OPTIMAL Control Eco (2112)

4

Breddningsving

en monteras på

insidan av

maskinen

Dear Customer,

You have made a good choice. We congratulate you to your selection of OPTIMAL-product that

offers quality and performance with reliable service.

By reading the manual and following its recommendations you will ensure the long and effective

use of the equipment.

We have produced this manual for you to get a good understanding of the functioning of the

equipment and what safety and maintenance instructions to follow when working with it.

If any question should arise when using the equipment or when reading this manual, you are

welcome to contact us for further information.

TREJON AB

Företagsvägen 9

SE-911 35 Vännäsby

Sweden

Tel: + 46 (0)935 39 900

Fax: + 46 (0)935 39 919

Website: www.trejon.se

Operating manual OPTIMAL Control Eco (2112)

5

Breddningsving

en monteras på

insidan av

maskinen

Honoured retailer,

In order for the guarantee to be valid and to fulfil all legal requirements, we ask you to fill out the

guarantee form together with the customer and register at trejon.se

The guarantee is valid from the day the equipment is handed over to the customer.

Delivery checklist:

Check for damages caused in transporting. Inform the transporting company.

Check that all packing material has been taken away. Dispose packing material in an

environmentally friendly way

Check if delivery is complete with help from machine order/packing list.

Check that the machine is lubricated, see section “Service and maintenance”.

Check that chain has right tension, see section “Service and maintenance”.

Check that all screws are properly tightened, see section “Service and maintenance”.

Make a function test

Having gone through and explained to the customer, with the help of the manual, the

startup, use and maintenance of the equipment and it’s accessories.

Fill out the guarantee form with the customer and register at trejon.se

It can be found as an attachment to this manual and as a copy on the last page.

Instruction manual given to the customer.

Enter the serialnumber of the equipment to the

right.

S/N:

Operating manual OPTIMAL Control Eco (2112)

6

Breddningsving

en monteras på

insidan av

maskinen

Introduction

This manual for the handset OPTIMAL Control Eco (Option) is a supplement to

sand spreader ordinary operating manual.

The manual contains a description of the functions used in the daily practice of handset

OPTIMAL Control Eco.

The manual is prepared with the goal, to give the user the opportunity to use the functions in the

control fully.

The control is designed for use in accordance with the above described application. Any other

use of control is associated with significant risk and deprives the supplier from responsibility.

The steering delivered from Trejon are in compliance with applicable European

directives for electronic control entries when used with machines covered by the

Machinery Directive. Trejon is responsible for the control unit together with sand

spreader, but it does not include the carrying machine.

Operating manual OPTIMAL Control Eco (2112)

7

Breddningsving

en monteras på

insidan av

maskinen

Mounting instruction

This pictures will show the correctmounting to the spreader

Dissmount the steelplate for the hose clamp

Bolt the new support on the hose clamp with the exsiting bolt.

Operating manual OPTIMAL Control Eco (2112)

8

Breddningsving

en monteras på

insidan av

maskinen

Mount the contact to the support.

Mount the two Hirschman contacts to the coils for the valves with rubber seals and screws.

Operating manual OPTIMAL Control Eco (2112)

9

Breddningsving

en monteras på

insidan av

maskinen

Description of handset OPTIMAL Control Eco

Below is an overview of the handset, with description of the display, buttons and

switches.

Generally

This document contains basic description of the features at steering Optimal Control Eco.

Superior machine and product description

During normal operation of the machine, set the desired spreading width and dosage on the

control pad, and spread manually started and stopped via a toggle switch.

6 digit display with Backlight Control

Function buttons

Switches for machine control

LED that lit in work mode

Operating manual OPTIMAL Control Eco (2112)

10

Breddningsving

en monteras på

insidan av

maskinen

Display

Type: 6 digit display with Backlight Control.

Views : The following information is displayed

#

Information

Unit

Symbol

Comments

1

Spreading width

PWM

(%)

-

0 –100 (5% increments)

2

Spread amount

PWM

(%)

-

0 –100 (5% increments)

3

Menu messages for easy

maneuvering of the setting

See the function

description

Standard display :

The figure below shows the information that is seen in the standard display along with some

symbols.

Spreading width

PWM %

Feeding auger

(spread amount)

PWM %

Operating manual OPTIMAL Control Eco (2112)

11

Breddningsving

en monteras på

insidan av

maskinen

Description of menu set - user:

Below is menu set up for user described. This can be activated by pressing the "Enter" key for 2

seconds when the default display is shown.

Figure 1: Example of deactivating the emptying function (Empty tank OFF).

Figure 2: Example of setting the display backlight (backLight on).

Use the "Up Arrow" and "Arrow Down" to scroll through the menus. If you wish to change a

value so kept the "Enter" button depressed (2 seconds) and when a value is flashing, it can be

changed. The value can then be changed with the "Up Arrow" and "Arrow Down". Press "Enter"

to accept or "Esc" to cancel the entry. Press "Esc" to go back one step in menu or to completely

exit the setup menu

Concluding remarks:

See the earlier section "Description of handset Optimal Control Eco" for a picture on the

handset, including the placement of the display, toggle switch, buttons and LEDs.

All push buttons and toggle switch is fitted with symbols indicating functions.

The display has backlight, which turns off automatically if it is not registered keystrokes during 1

hour. The backlight can be switched off entirely.

Operating manual OPTIMAL Control Eco (2112)

12

Breddningsving

en monteras på

insidan av

maskinen

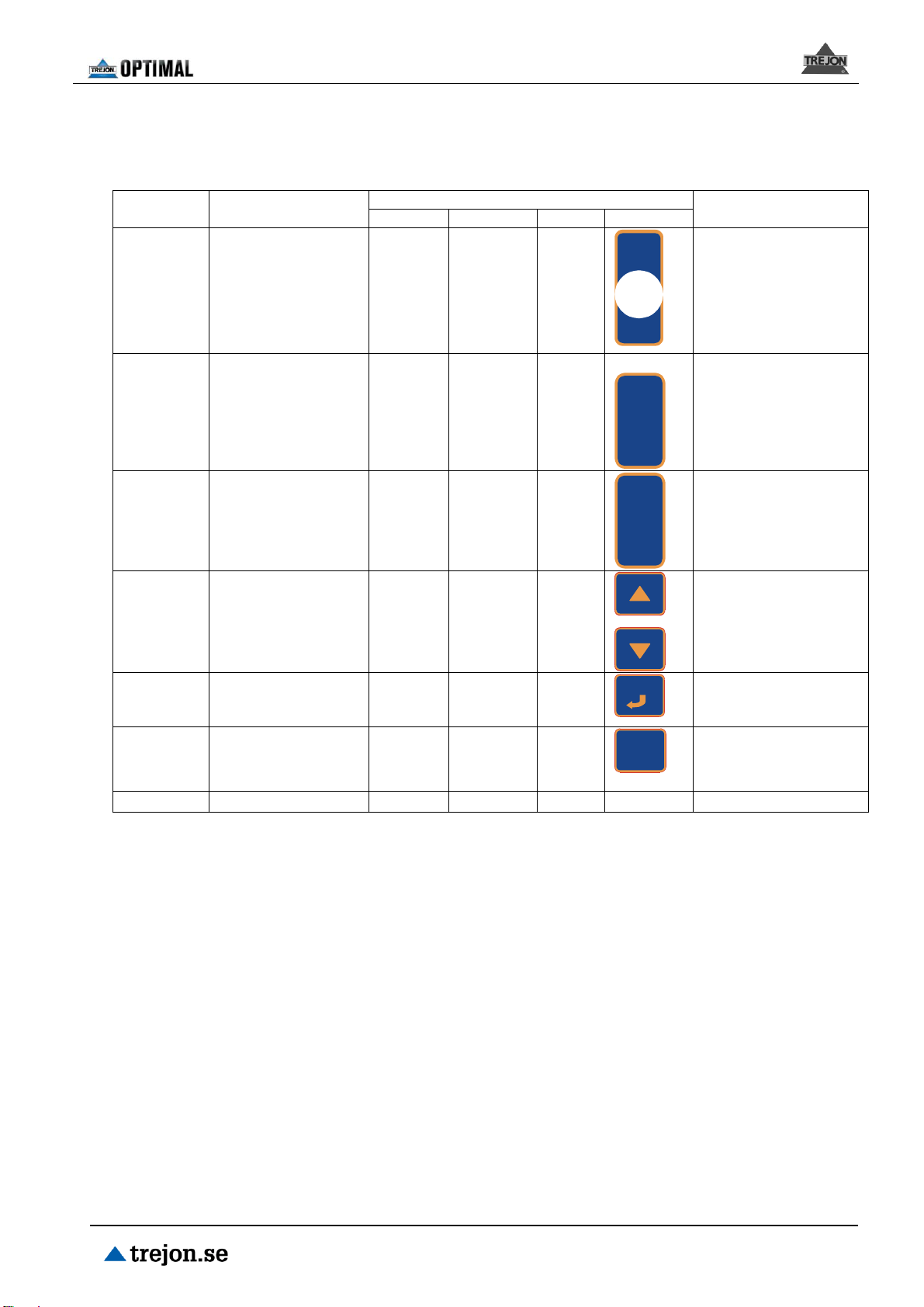

Features and switches on the handset

Description of the function of the handset

Name

Function/

description

Switch

Requirements /

Comments

Type

Direction

Placer.

Symbol

Spreader

activation

Start and stop of

spreader

Switch

(on LED)

Up/down

*

S T A R T

S T O P

Starts and stops the

signal to the hydraulic

motors and thus the

auger and spreader

disc rotation.

LED lights up when

activated.

Spread

amount

Setting of spread

amount

Switch

Up/down

*

-

G R / M ²

+

Adjustment step by

spreading quantity

( = 5 %)

Spreading

width

Setting of spreading

width

Switch

Up/down

*

+

M

-

Adjustment step by

spreading width

( = 5 %)

Adjustment

buttons

Change of the input

values and Info in

the standard display

with menu shifts

Push-

button

-

*

Enter

Switch to sub-

menus and approval

of an input

Push-

button

-

*

MENU

Esc

"Go" back a step in

menus and undo

input.

Push-

button

-

*

ESC

Operating manual OPTIMAL Control Eco (2112)

13

Breddningsving

en monteras på

insidan av

maskinen

Outputs

Description

Output

type

Cabling

Cable

type

Number

of wires

Length

(m)

Anslutningstyp

Terminal

1

Control signal to a

Proportionally flow

valve (feeding auger)

PWM

Soft

2

0,5

Xx

2

Control signal to a

Proportionally flow

valve (spreading

disc)

PWM

Soft

2

0,5

Xx

Other technical specifications

The handset is protected against splashing water acc. IP 65

The overall controller includes handset, cables and hydraulic valves.

The cable from the handset to power is 2 * 1.0 mm2 (length: 2 m) with BOSCH contact.

The cable from the handset to the 7-pin trailer plug is 7 * 0.75 mm2 (length: 6 m)

Power supply: 12 V DC (min. 9 V DC and max. 28 V DC)

Fuse: T16 Amp, 250 Volt

Max load: Long term: 7.0 Ampere

<2 minutes: 15.0 Ampere

Functions

Setting of spread rate

•User Interface

Setting made by activation of the specified toggle switch to the right of the handset.

Each time you press up / down regulated application rate. Held toggle switch up /

down regulated the amount as long as the toggle switch is held in position.

•Conditions

▪Setting the spread rate can not be undertaken when the menu setting is

enabled.

▪When the upper / lower limit of the spread rate is reached, a sound alarm is

given (single beep) for each additional print and values will remain at the set

level.

Operating manual OPTIMAL Control Eco (2112)

14

Breddningsving

en monteras på

insidan av

maskinen

Setting the spreading width

•User interface

The setting is undertaken in the activation of the specified toggle switch on the right

side of the handset. Each time you press up / down toggle switch the spreading width

is regulated. Held toggle switch up / down the spreading width is regulated as long as

the toggle switch is held in position.

•Conditions

▪Setting the spreading width can not be undertaken when the menu setting is

enabled.

▪When the upper / lower limit of the spread rate is reached, a sound alarm is

given (single beep) for each additional print and values will remain at the set

level.

Emptying function

•Description

The function starts and carry on emptying of the container remaining content.

•User interface

Activation of emptying function is done via the user menu. When activated, the LED

flashes.

The function is deactivated by pressing buttons ESC or MENU

•Conditions

▪Emptying function can only be activated when dosing is stopped:

Start/stop switch in position ”stop”.

Operating manual OPTIMAL Control Eco (2112)

15

Breddningsving

en monteras på

insidan av

maskinen

Appendix 1 Menu items

User menu

Screen

display

Function

Value

Et

Empty tank

on/OFF

bL

Display back Light on/OFF

on/OFF

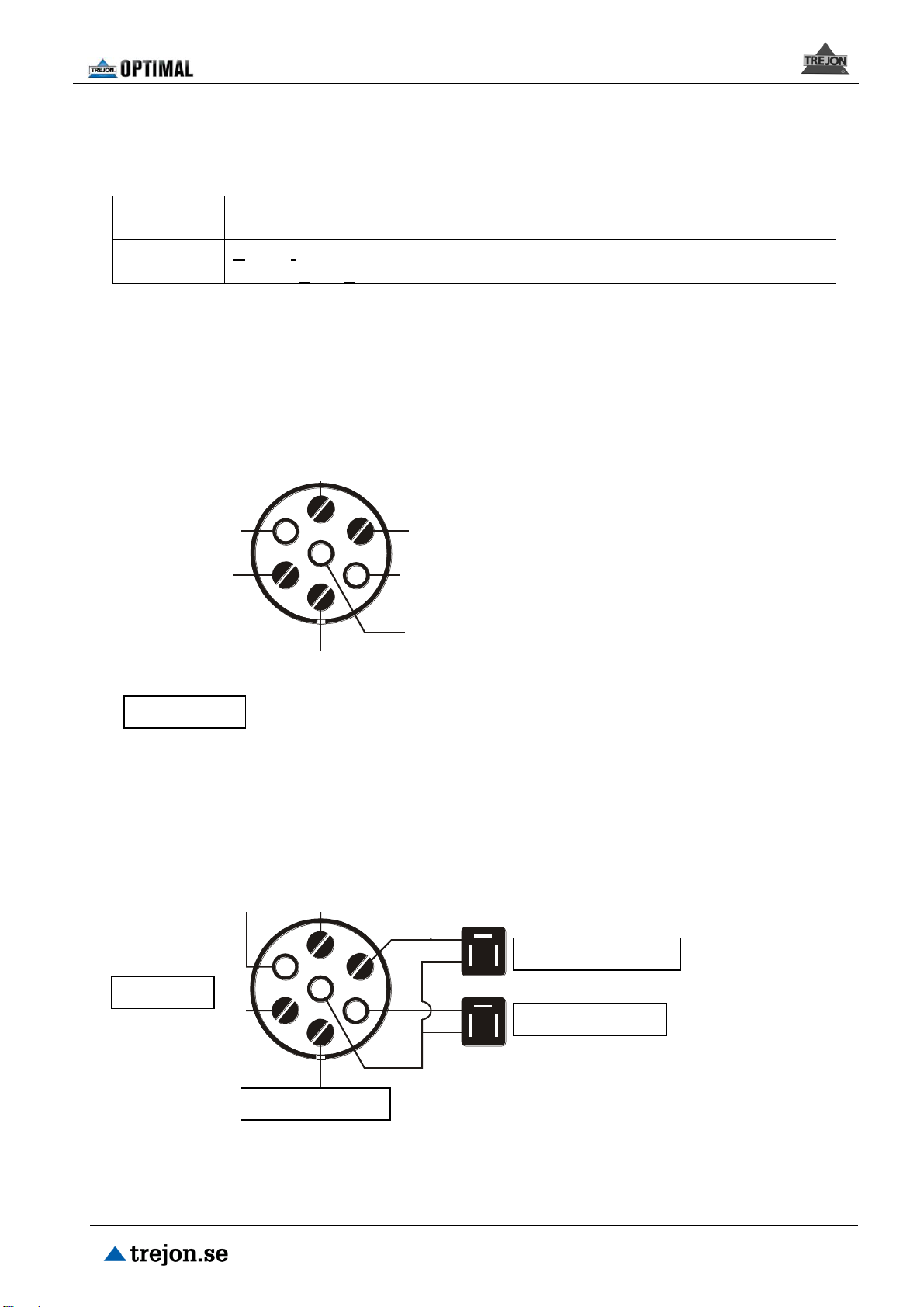

Appendix 2 Cable connection

12

3

4

5

67

12

3

4

5

67

Master ventil (MOSFET)

Master ventil

Spredetallerken (MOSFET)

Spredetallerken

Ingen forb.

Ingen forb.

Dos. Snegl (MOSFET)

Dos. Snegl

+12 V

BLÅ

GUL

BRUN

HVID

RØD

GRØN SORT

+12 V

Skod (Relæ)

Skod

- 0 V

- 0 V

Relä

Spreader disc

Auger

Skod

Spreader disc

Auger

Machine

Handset

No connection

No connection

Yellow

White

Green

Red

Operating manual OPTIMAL Control Eco (2112)

16

Breddningsving

en monteras på

insidan av

maskinen

TREJON AB reserves the right to change or to improve shown models using technical or

commercial reasons, without demands to carry out the same improvements on equipment

already delivered. Pictures in the manual do not necessarily show the equipment as delivered.

Technical data, weights and measures are without obligation. Reservation for faults.

© 2016 Trejon AB, Sweden

Copying, translation and excerpts are only permitted with a written permit from TREJON AB,

Företagsvägen 9, SE –911 35 Vännäsby.

All rights reserved.

TREJON FÖRSÄLJNINGS AB

Företagsvägen 9

SE-911 35 VÄNNÄSBY

SWEDEN

Tel: + 46 (0)935 39 900

Fax: + 46 (0)935 39 919

Webb: trejon.se

Table of contents

Other Trejon Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Amazone

Amazone Cayena 6001 operating manual

DALBO

DALBO CULTILIFT 300 manual

Metalcraft

Metalcraft SCAG GIANT-VAC TL20W-29BV Operator's manual

Blue Diamond

Blue Diamond MINI V-BLADE Operation and maintenance manual

woodmizer

woodmizer Sawmill Safety, Operation, Maintenance & Parts Manual

DALBO

DALBO Levelflex 2000 manual

Avantco

Avantco A21385 Operator's manual for Attachment

Tube-Line

Tube-Line TLR 5000X2 Operator's manual

DALBO

DALBO MEGAROLL 2130 manual

Blue Diamond

Blue Diamond PICKUP BROOM 2 Series Operation and maintenance manual

Midwest

Midwest Mid-Tech Legacy 2000 user guide

Midwest

Midwest Crophawk Draper Platform Operator's manual