Table of Contents Section-Page

ii TD02doc072519 Table of Contents

SECTION 1 SAFETY 1-1

1.1 Safety Symbols.......................................................................................1-1

1.2 Safety Instructions..................................................................................1-2

SECTION 2 GENERAL INFORMATION 2-1

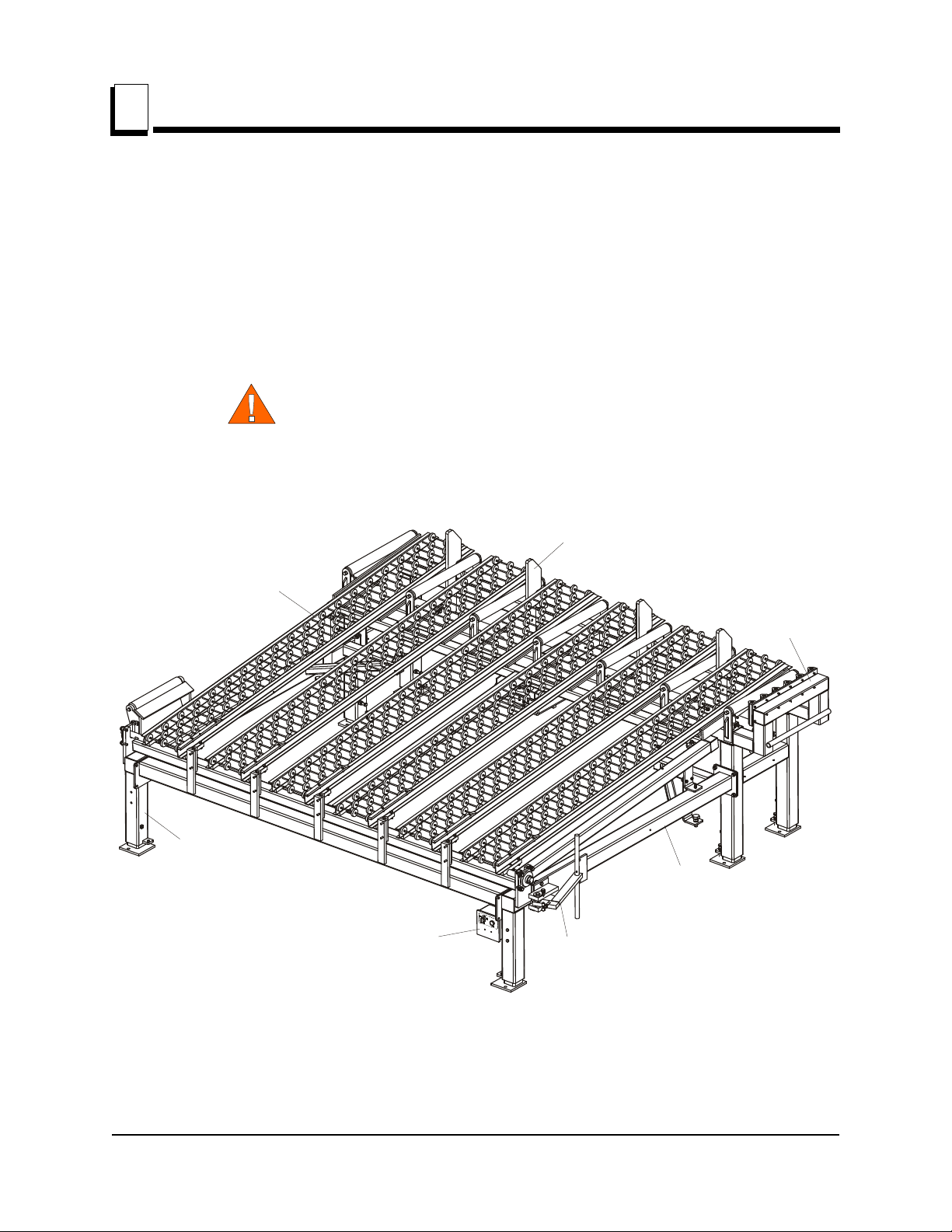

2.1 Transfer Deck Components....................................................................2-1

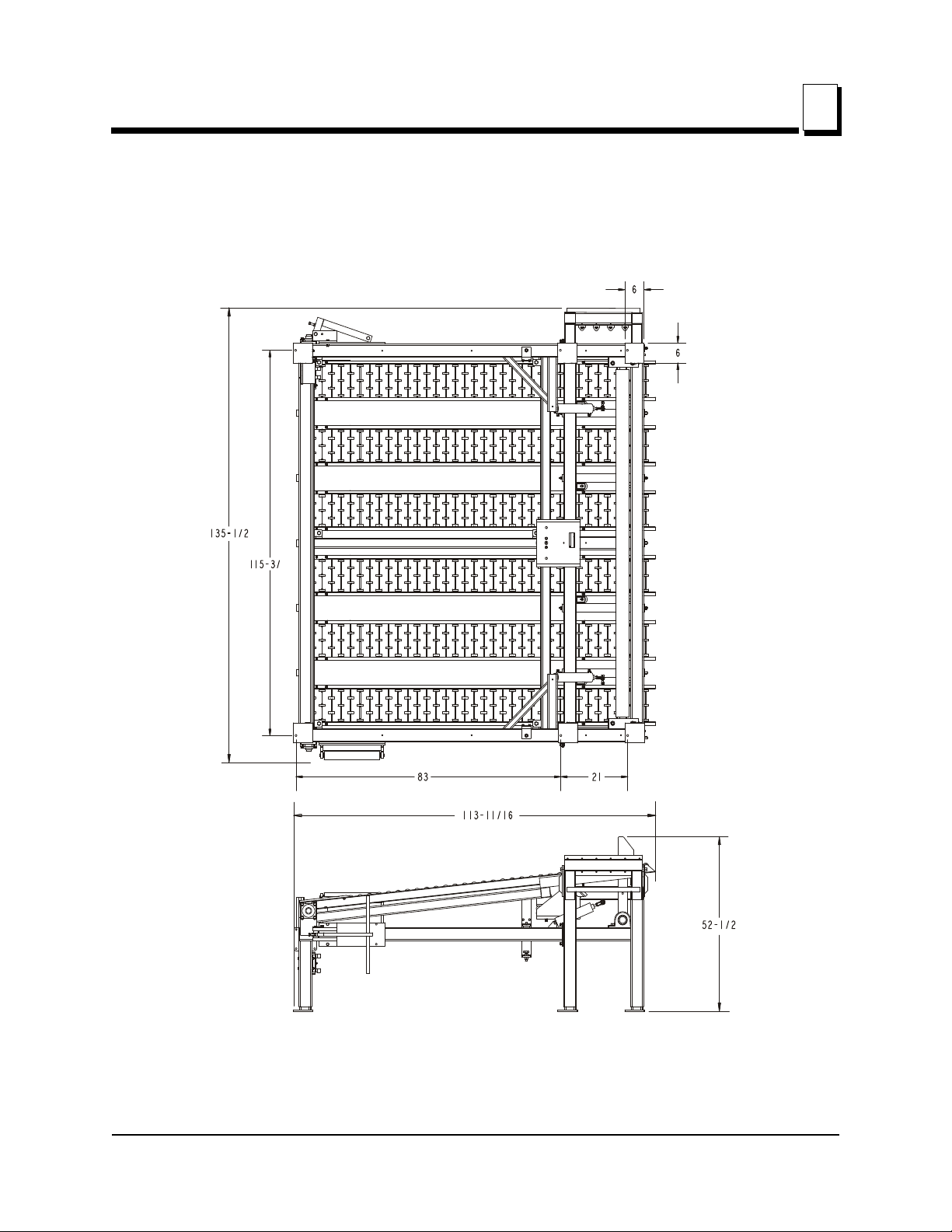

2.2 Overall Dimensions ................................................................................2-2

SECTION 3 INSTALLATION & SETUP 3-1

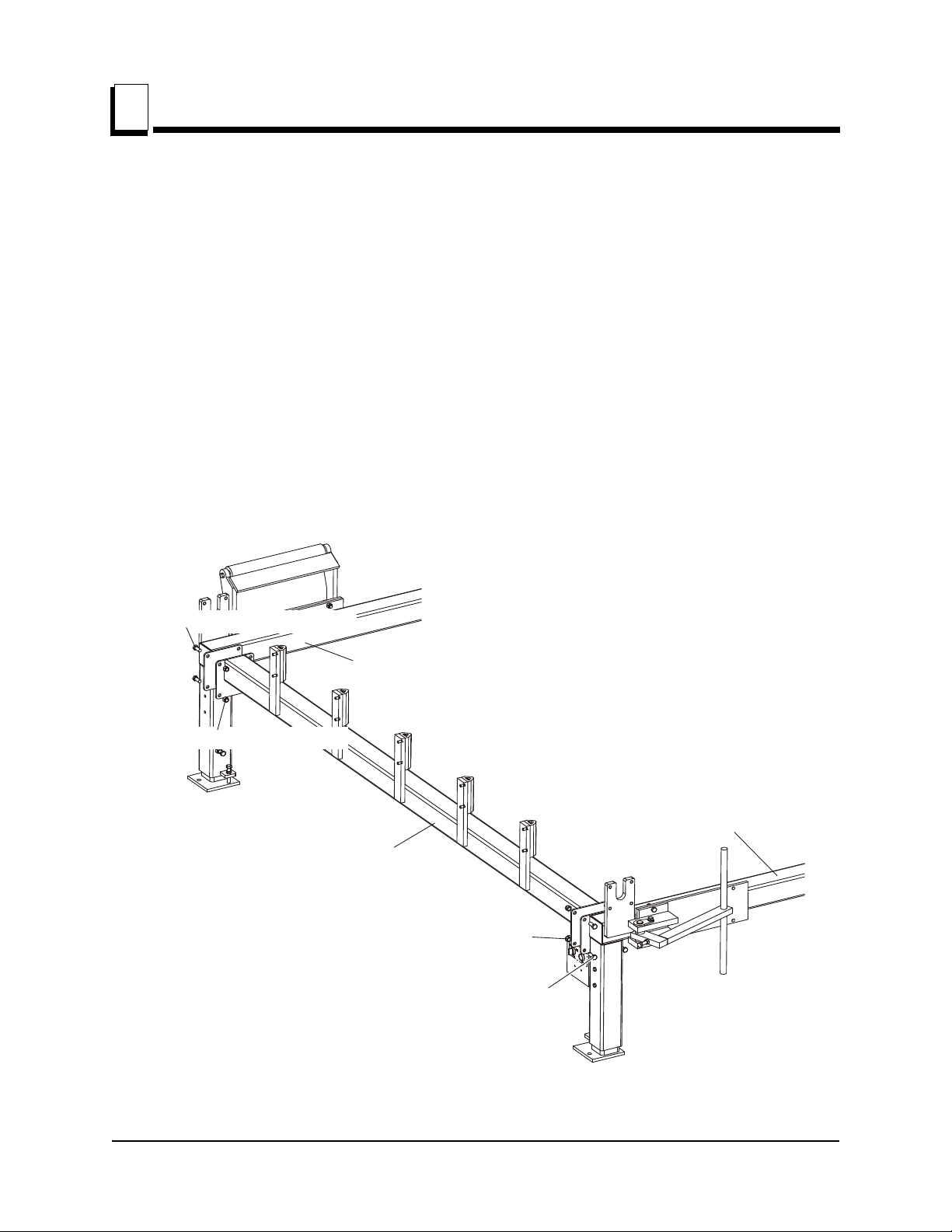

3.1 Installation ..............................................................................................3-1

3.2 Air Installation........................................................................................3-8

3.3 Setup .....................................................................................................3-10

3.4 Electrical Installation............................................................................3-12

3.5 Board Stop Adjustment ........................................................................3-15

SECTION 4 OPERATION 4-1

4.1 Control Box Operation ...........................................................................4-1

4.2 Swing Stop..............................................................................................4-3

SECTION 5 REPLACEMENT PARTS 5-1

5.1 Table Assembly......................................................................................5-1

5.2 Board Stop/Air Bag Assembly ...............................................................5-3

TD1 Rev. A4.00

5.3 Board Stop/Air Bag Assembly ...............................................................5-5

TD1 Rev. A1.00 - A3.01

5.4 Kicker & Air Cylinder............................................................................5-7

5.5 Lower Frame ..........................................................................................5-8

5.6 Swing Stop............................................................................................5-10

5.7 Control Box ..........................................................................................5-11

5.8 Photo Sensors .......................................................................................5-12

TD1 Retrofit

5.9 Photo Sensors .......................................................................................5-14

TD1 Rev. A1.00 - A4.00

SECTION 6 ELECTRICAL INFORMATION 6-1

6.1 Electrical Diagrams ................................................................................6-1

6.2 Electrical Component List......................................................................6-2

INDEX I

TOC