Midwest Mid-Tech Legacy 2000 User manual

Legacy 2000 System

USER GUIDE

®

PN: 98-05034

MID-TECH WARRANTY

MIDWEST TECHNOLOGIES ILLINOIS, LLC (herein called Mid-Tech) warrants to the original

purchaser that the product purchased shall be free of defect in material or workmanship. If the

product proves to be defective within the warranty period the purchaser must return, freight prepaid,

said product to Mid-Tech within thirty (30) days after such defect is discovered. Upon inspection and

examination by Mid-Tech, and at its option, Mid-Tech shall repair or replace, with a new or compa-

rable product. No product will be considered defective if it substantially fulfills the performance

specifications. Purchaser shall be responsible for all required maintenance service in accordance with

procedures outlined in Mid-Tech’s product operator manual or service bulletins.

All product(s) replaced or repaired under warranty shall carry the remainder of the warranty left on

the original purchase. All out of warranty product(s) serviced for fee or goodwill will have ninety

(90) days of warranty. The ninety (90) days shall begin on the date serviced by Mid-Tech.

Warranty periods for Mid-Tech products shall be:

Mid-Tech Legacy Consoles – 2 ½ years

Mid-Tech TASC Consoles – 2 ½ years

Mid-Tech ARC Consoles – 2 ½ years

Mid-Tech AgLogix Consoles – 2 ½ years

Mid-Tech Switch boxes – 2 ½ years (3, 5, 9 boom)

All other Mid-Tech products – 12 months (unless otherwise noted)

WARRANTY LIMITATIONS AND EXCLUSIONS

Mid-Tech will have no warranty obligation hereunder if the product is subjected to abuse, misuse,

improper or abnormal usage, acts of God, faulty installation, improper maintenance as outlined in

Mid-Tech’s product operator manual or service bulletins. Consumable items (items that are used

during normal operation) such as light bulbs, batteries, etc., and expendable items (items which wear

out in normal use) such as injection pump tubes, flow meter bearings, etc., will not be covered by

warranty. For products that come in direct contact with chemical, the specific recommendations

contained in Mid-Tech product bulletins must be adhered to, or this warranty is void.Any repairs or

alterations, other than those provided by Mid-Tech and/or its authorized representatives, will void the

warranty. Mid-Tech neither assumes nor authorizes anyone to assume for it any other obligation or

liability in connection with said product.

DISCLAIMER OF UNSTATED WARRANTY

The warranty printed above is the only warranty applicable to this purchase. Mid-Tech’s warranty

cannot be modified by any person or entity, including without limitation, any distributor or retailer

of Mid-Tech. All other warranties, express or implied, including but not limited to, the implied

warranties of merchantability and fitness for a particular purpose, are disclaimed.

LIMITATION OF LIABILITY

It is understood and agreed that Mid-Tech’s liability, whether in contract, in tort, under any warranty,

in negligence or otherwise, shall not exceed the return of the amount of the purchase price paid by

purchaser and under no circumstances shall Mid-Tech be liable for special, indirect or consequential

damages. In particular, Mid-Tech shall not be liable for damage to crops as the result of misuse or

negligence in the application of chemicals or operation of Mid-Tech products. The price stated for the

equipment is a consideration in limiting Mid-Tech’s liability. No action, regardless of form, arising

out of the transactions under this agreement may be brought by purchaser more than one year after

the cause of action has occurred.

FORM 19.1.2 09/07/00 REV-1

Switches

I

Legacy 2000

98-05034

R0

Introduction

Chapter 1 Introduction ------------------ 1-1

Chapter 2 Start-up ------------------------ 2-1

START-UP SEQUENCE ------------------------------ 2-1

Chapter 3 Operate ------------------------ 3-1

ENTERING THE OPERATE MODE ----------------- 3-1

PRODUCT MONITORING --------------------------- 3-1

PRODUCT CONTROL ------------------------------- 3-2

CHOOSING PRE-SELECTED RATES ----------- 3-2

MANUAL RATE CONTROL ------------------- 3-2

RESETTING ACCUMULATORS ---------------- 3-3

SPEED AND DISTANCE MONITORING ------------- 3-4

TOTAL DISTANCE RESET -------------------- 3-4

MANUAL SPEED ------------------------------ 3-4

AREA MONITORING ------------------------------- 3-5

AREA RESET FUNCTION --------------------- 3-6

DATA LOGGING ------------------------------------ 3-7

Chapter 4 Setup --------------------------- 4-1

FIELD SETUP --------------------------------------- 4-1

LIQUID MODE SETUP ------------------------ 4-2

PRESET APPLICATION RATES ---------- 4-2

FLOWMETER CAL. # SET -------------- 4-3

PRESSURE BASED SETUP --------------- 4-3

GRANULAR/NH3 SETUP --------------------- 4-6

PRESET APPLICATION RATES ---------- 4-6

GRANULAR CAL. # SET ---------------- 4-7

INITIAL SPREADER CONSTANT --------- 4-7

SEEDER SETUP -------------------------------- 4-8

PRESET APPLICATION RATES ---------- 4-8

SEEDER CAL # SET --------------------- 4-9

SPINNER MODE SETUP --------------------- 4-10

PRESET SPINNER RATES -------------- 4-10

SPINNER CAL # SET ------------------ 4-11

INJECTION PRIME/CALIBRATE FUNCTION 4-11

PRIME FUNCTION --------------------- 4-12

CALIBRATE FUNCTION ---------------- 4-13

MACHINE SETUP --------------------------------- 4-14

PRODUCT MODES -------------------------- 4-14

APPLICATION UNITS OF MEASURE -------- 4-15

VALVE/DRIVE TYPES ---------------------- 4-16

SERVO VALVE SETUP ----------------- 4-16

PWM VALVE SETUP ----------------- 4-20

INJECTION DRIVE SETUP ------------- 4-21

SYSTEM SETUP ----------------------------------- 4-22

SYSTEM UNITS ------------------------------ 4-22

KEY BEEP ---------------------------------- 4-23

Table of Contents

Legacy 2000

II

98-05034

R0

SHOW MODULES --------------------------- 4-23

LOG DATA ---------------------------------- 4-24

COM PORTS ------------------------------- 4-25

HARDWARE TEST --------------------------- 4-26

SOFTWARE RESET -------------------------- 4-26

TIME AND DATE ---------------------------- 4-27

SPEED SETUP ------------------------------------- 4-28

SPEED CALIBRATION ----------------------- 4-28

GSO SETUP -------------------------------- 4-29

BOOM SETUP ------------------------------------- 4-29

SWAT H SETUP ------------------------------------ 4-30

NUMBER OFSWATHS ---------------------- 4-30

BOOM ASSIGNMENT ------------------------ 4-30

GPS SPEED SETUP ------------------------------ 4-31

Chapter 5 Trouble Shooting ------------ 5-1

Chapter 6 Emergency Operations ---- 6-1

GROUND SPEED SENSOR FAILURE ---------------- 6-1

FLOW CONTROL VALVE FAILURE ---------------- 6-2

FLOWMETER/PRESSURE SENSOR FAILURE ------- 6-3

APPLICATION RATE SENSOR FAILURE ------------ 6-4

Appendix A System Diagram -----------A-1

SAMPLE SYSTEM DIAGRAM ---------------------- A-2

Appendix B - System Overview-------- B-1

System Components ---------------------- B-2

MODULES ----------------------------------------- B-2

CABLES AND HARNESSES ------------------------- B-4

LEGACY 2000 CONSOLE -------------------- B-4

POWER SPEED MODULE -------------------- B-4

SWITCH SENSE MODULE ------------------- B-5

PRODUCT CONTROL MODULE -------------- B-5

CAN EXTENSION CABLES ------------------ B-6

Appendix C - Glossary/Tables ---------- C-1

GLOSSARY ----------------------------------------- C-2

ENGLISH/METRIC CONVERSION ----------------- C-8

USEFUL FORMULAS ------------------------------- C-9

MISCELLANEOUS NOTES ------------------------C-10

CALIBRATION NUMBERS ------------------------C-10

NH3 DENSITY TABLE ---------------------------C-10

Index ------------------------------------------I-1

Mid-Tech, Auto-Range, & TASC are all registered trademarks of Midwest Technologies, Inc.

Switches

1-1

Legacy 2000

98-05034

R0

Introduction

Chapter 1 Introduction

Welcome to the Legacy 2000, the new genera-

tion of chemical control systems. The Legacy

2000 controls up to two different products,

automatically, manually, or under external control.

New technology allows the Legacy 2000 console to

communicate with remotely mounted control modules

through a single cable. These modules in turn control

and monitor the valves, sensors, pumps, etc. of the

system. Control modules can be “tapped” into the main

cable at any point, which means that they can be

mounted anywhere on the machine, near the compo-

nents that they are associated with. Using one cable to

connect the modules to the control console in the cab

eliminates the “rat’s nest” of cables running into the

cab from all over the vehicle.

The opeating program is contained on an SRAM card

inserted into the side of the console making it easy to

change or upgrade your program. (CAUTION: To

prevent damage to the program or the SRAM

Card, the console must be powered down while

inserting or removing the card)

This User Guide provides you with the basic

information needed to set up and operate the

MID-TECH®Legacy 2000 control system.

Actual procedures may vary, depending on the

configuration of your system.

When you see "Mitch", he is pointing out special

information that you should be aware of, regarding

safety, preventing equipment damage, an easier way to

perform an operation, etc..

A brief description of the console control buttons and

the icons that appear on the display are described at the

edges of the pages in Chapter 3 (Operate functions)

and Chapter 4 (Setup Functions)

The topics are presented with the most often used

information located toward the front of the guide.

HOW TO USE THIS MANUAL

Mid-T

Mid-T

ech

ech

Mid-T

Mid-T

ech

ech

Legacy 2000

1-2

98-05034

R0

Following is a listing of the chapters in this manual,

along with a brief description of the information found

in each chapter.

Chapter 1 - “Introduction” - A brief overview of the

User Guide.

Chapter 2 - “Start-up” - Describes the system start-up

sequence followed when powered on.

Chapter 3 - “Operation” - Describes how to control

the application process.

Chapter 4 - “Setup” - Takes you through the calibra-

tion of each sensor providing input to the system

and the entering of other necessary information.

Chapter 5 - “Trouble Shooting” - Lists possible

causes and remedies for the error messages that

may appear on the display.

Chapter 6 - “Emergency Operation” - Suggests ways

to operate, under reduced accuracy, in the event

of a major fault.

Appendix A - “Sample System Diagram.”

Appendix B - “System Components” - Describes the

major components of the Legacy 2000 system and

their individual functions.

Appendix C - Glossary/Tables

Back Cover - Quick Start/Quick Set Up Guides

2-1

Legacy 2000

98-05034

R0

Start-up

Sequence

START-UP SEQUENCE

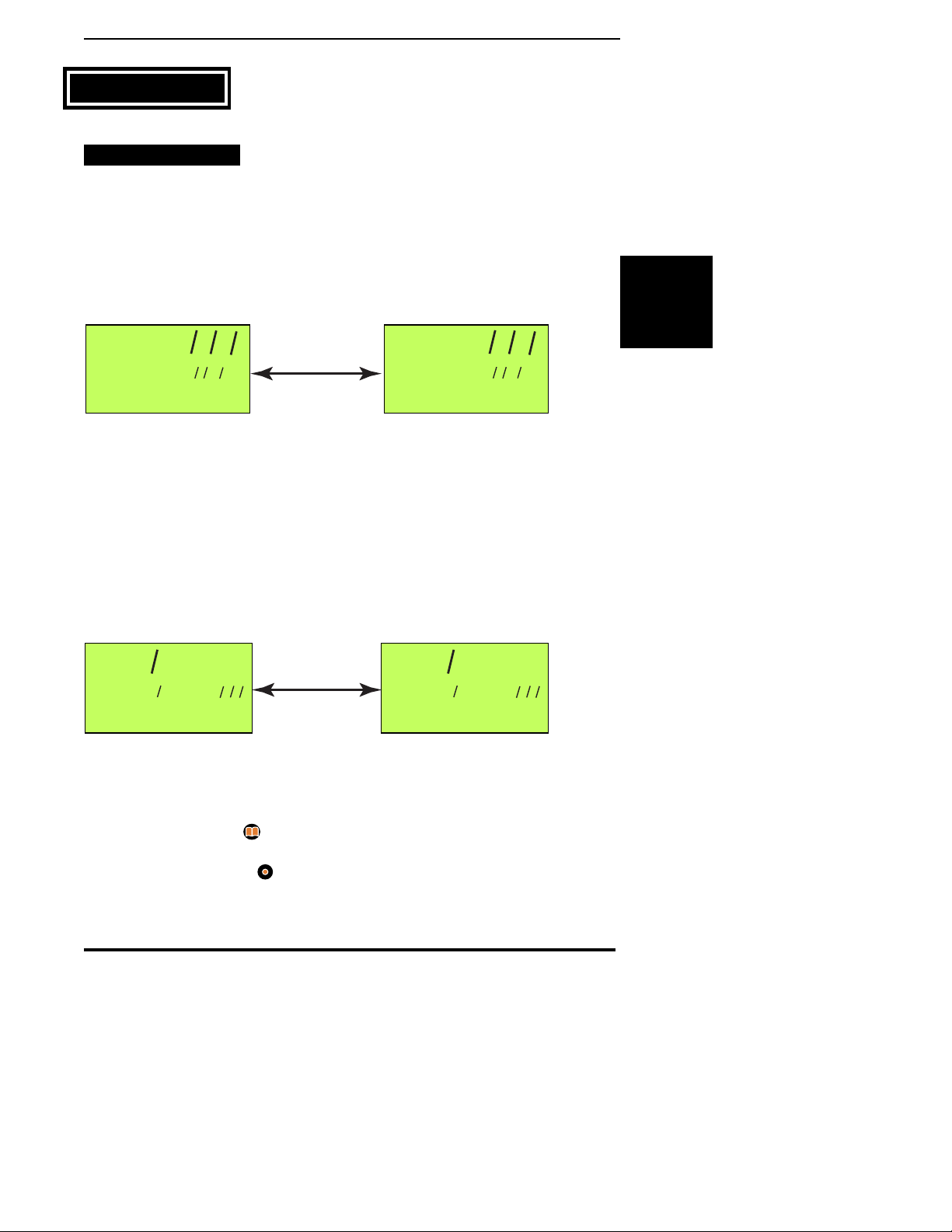

The Legacy system monitors the accessory

position of the ignition switch. When the

ignition switch is turned on the Legacy system

begins its start-up sequence. The console will alternate

between the two screens shown in Fig. 2-1 while it is

performing its system check.

During the system check each module (Console, PSM,

SSM, PCM) is verified to make sure nothing has

changed since the system was last powered up. If any

descrepancies are found the console asks for user

input to verify the module information.

Once the system check is complete the screens shown

in Fig. 2- 2 appear and three beeps are heard.

At this point the operator can:

•Press the Setup button ( ) to make any necessary

system setup changes to the Legacy system

•Press the Operate button ( ) to go directly to the

operate mode.

09:42

02/18/2000

PRESS OPERATE OR

09:42

02/18/2000

SETUP TO BEGIN

Alternate

Fig. 2-2. System Ready Screens

Chapter 2 Start-up

Fig. 2-1. Legacy System Check Screens

L2000

VER 00.01D

MID-TECH CONTROL

L2000

VER 00.01D

WELCOME TO

Alternate

Legacy 2000

2-2

98-05034

R0

This page left blank intentionally

3-1

Legacy 2000

98-05034

R0

Operate

Functions

2

1

Operate

Setup

Manual

Enter

Right

Left

Product 1

Product 2

Speed

Decrease

Increase

Area

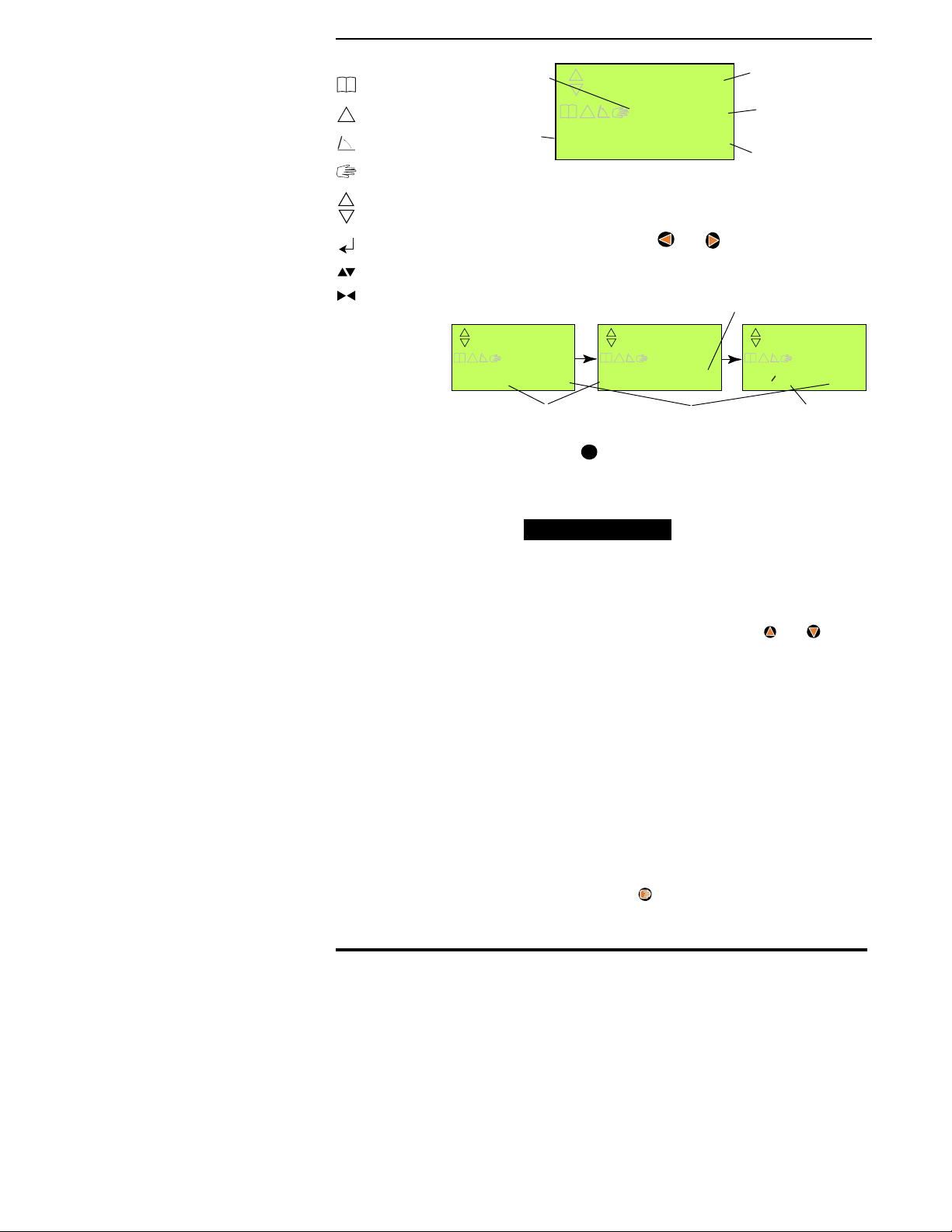

This chapter discusses the various “Operate”

screens that allow the operator to monitor and

control the application process.

ENTERING THE OPERATE MODE

Press to enter the “Operate”mode. The screen

shown in Fig. 3-1 appears. There are several

icons that may appear on the screen to provide

information to the operator. These icons are explained

in the corner of the even numbered pages.

PRODUCT MONITORING

Figures 3-1 through 3-4 give examples of the

types of information provided by some of the

different screens. The screen shown in Fig. 3-1

is the “Product Status OFF”screen, the first of several

“Product Information”screens. Pressing turns the

product ON, changing the

1

from red to green

indicating that the product is turned ON, and taking

you to the “Product Status ON”screen (Fig. 3-2).

Pressing

1

at this point causes the display to alternate

between Fig. 3-2 (Product ON) and Fig. 3-3 (Total

12.5

12.2MPH

P1 G/Ac

!

P2 OFF

Product 1

Screen

Current Product 1

Application rate

Application being

measured in gallons

per acre.

Product 2

Status

Current

ground

speed Fig. 3-2 Product Status ON

Can use and to change to

another pre-selected rate (A - E)

Chapter 3 Operate

Most examples in this User

Guide will use Product 1

screens and US units of

measure. Screen displays

will change accordingly

when monitoring Product 2

or using metric units.

Mid-T

ech

OFF

12.2MPH

P1 G/Ac

!

P2 OFF

Product 1

Screen

Product turned OFF

Application being

measured in

gallons

Product 2

Status

Current

ground

speed Fig. 3-1 Product Status OFF

Legacy 2000

3-2

98-05034

R0

!

Logging On

System Error

Not Used

Manual Mode

Control Active

Use Enter Key

Use Inc/Dec

Use Left/Right

Applied).

While in the “Product OFF”and “Product ON”screens

(Figs. 3-1 & 3-2) the and buttons can be used to

select the information to be displayed on the third line

of the display, as shown in Fig. 3-4.

Pressing

2

gives the operator the same set of screens,

displaying information about product 2, with Product 1

being monitored in the background.

PRODUCT CONTROL

CHOOSING PRE-SELECTED RATES

While in the “Product Off”or “Product ON”

screens (Figs. 3-1 & 3-2) the and

buttons can be used to step through the

application rates (A - E) preset in the “Field Setup”

routine. When the desired rate is being displayed, wait

for about 3 seconds. The selected rate will be locked in

and the display will revert back to the previous screen.

The selected rate is now the control rate.

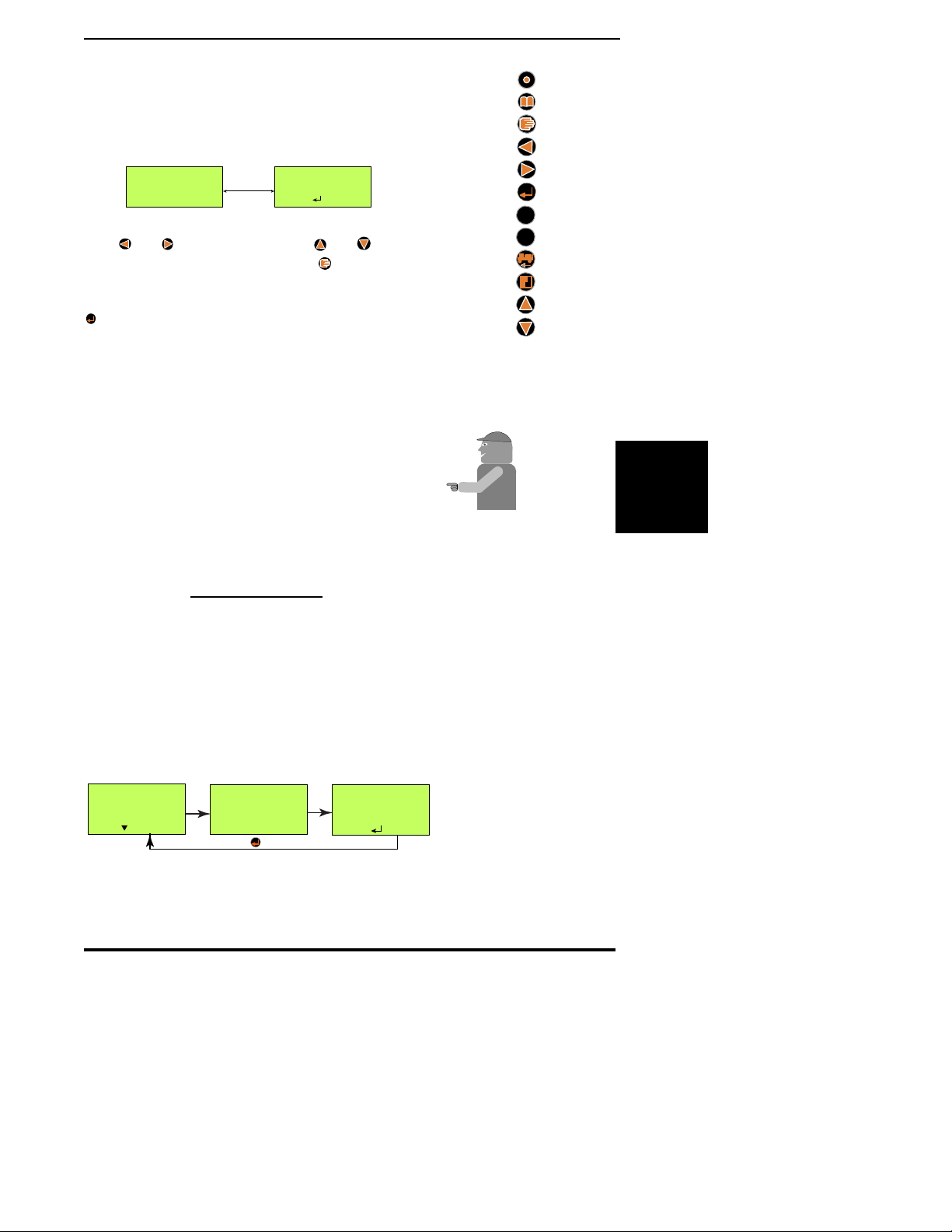

MANUAL RATE CONTROL

The application rate of each product can be

controlled manually, using the “Manual Mode”,

from either the “Product ON”or “Product OFF”

screens. To enter “Manual Mode”select the desired

product and press . The screen shown in Fig. 3-5 is

displayed and the associated control valve “holds”in

its present position (closed if product is turned OFF or

12.2MPH

P1 Vol Gal

12.5

!

22AC

Fig. 3-3 - Total Applied

Product being

Displayed

Current

Speed

Amount of product

that has been applied

Units of

measure

Area Treated

0RPM P2 OFF

P1 G/Ac

12.5

!

12.2MPH

P1 G/Ac

12.5

!

22AC

12.2MPH

P1 G/Ac

12.5

!

P2 11.9

Current Speed Product 2 Status

Product 1 Area covered

Fig. 3-4 - Third Line Display

RPM Monitor

3-3

Legacy 2000

98-05034

R0

Operate

Functions

2

1

Operate

Setup

Manual

Enter

Right

Left

Product 1

Product 2

Speed

Decrease

Increase

Area

at the current rate if the product is turned on) and can

only be changed using the and buttons, overrid-

ing any programmed rate or external variable rate

command. When “Manual Mode”is turned off, control

of the application rate returns to the previous input

source.

Each product works independently meaning one or

both products can be under manual control but only the

selected product will be affected by the and

buttons at any one time.

To return to automatic control select the desired

product (1 or 2) and press again. The “Manual

Mode”symbol on the display is turned off indicating

that the product is back under automatic control.

RESETTING ACCUMULATORS

The “Total Applied”accumulators for each

product can be reset independently, with the

product turned ON or OFF. Just display the

“Total Applied”screen (Fig. 3-3) for the desired

product and press . The confirmation message shown

in Fig. 3-6 appears in the third line of the display.

Press to reset the accumulator to zero.

Mid-T

ech

CAUTION: EXTREME

CARE MUST BE USED

WHEN OPERATING IN

“MANUAL MODE”. The

longer the and

buttons are held down the

faster the rate at which the

valve moves. This means

that the application rate

can change drastically in a

short amount of time

causing a severe over or

under application.

12.2MPH

P1 G/Ac

12.5

!

22AC

Indicates product 1

under manual control.

Fig. 3-5 Manual Mode

CLEAR?

Fig. 3-6 Clear Alert

Legacy 2000

3-4

98-05034

R0

!

Logging On

System Error

Not Used

Manual Mode

Control Active

Use Enter Key

Use Inc/Dec

Use Left/Right

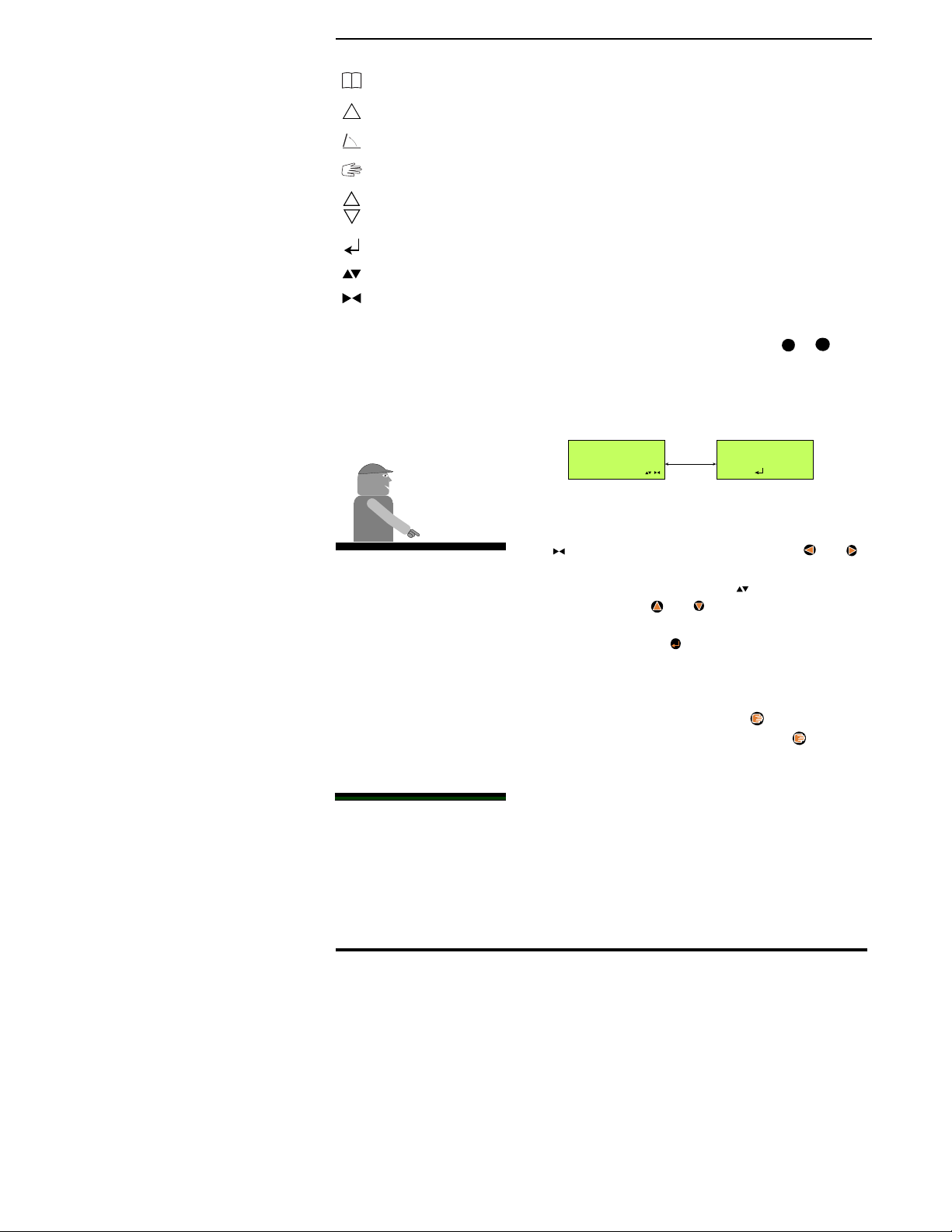

SPEED AND DISTANCE MONITORING

While in the “Operate Mode”pressing

accesses the “Speed/Distance”function. The

screens used in this function are shown in Fig.

3-7. The first screen that appears is screen “A” which

indicates the current vehicle speed with “Product 1 and

2” status alternating in the lower left corner. Pressing

now alternates the display between screen “A” and

screen “B” which indicates the total distance traveled.

To exit the “Speed/Distance”function press any other

function button.

TOTAL DISTANCE RESET

To reset the Total Distance accumulator go to

screen “B” of Fig. 3-7 and press . This takes

you to screen “D” with the alert at the bottom of

the display. To reset the accumulator press . To exit

the “Total Distance Reset”function without resetting

the accumulator press any other function button.

MANUAL SPEED

The Legacy 2000 has a “Manual Speed”function

that allows the operator to manually input a

simulated speed which overrides the actual

vehicle ground speed. This feature can be used to

perform static tests on the system or in an emergency

situation such as the failure of the vehicle speed

sensor.

SPEED

TOTAL DISTANCE

Alternates

between

Decrease

Resets the

accumulated distance

15.1

P1 RATE 10.0

MPH

!

153.13

MILES

!

20.3

MPH

!

153.13

CLEAR?

MILES

!

Manual

A

B

C

D

P2 RATE OFF

P2 RATE OFF

Fig. 3-7 Speed/Distance Screens

3-5

Legacy 2000

98-05034

R0

Operate

Functions

2

1

Operate

Setup

Manual

Enter

Right

Left

Product 1

Product 2

Speed

Decrease

Increase

Area

To switch to Manual Speed press from Screen “A”

in Fig. 3-7 taking you to screen “C” which is similar

except for the symbol indicating that you are

operating under Manual Speed control. While in

screen “C” the operator can use the and buttons to

adjust the speed being simulated by the system.

Pressing again turns the “Manual Speed”function

off and the speed control reverts to the previous input

source.

The Manual Speed selected is held in the console, even

when the feature is turned off, until the console is

powered OFF. The Manual Speed value then defaults

back to 5.0 MPH.

AREA MONITORING

To monitor the Total Area Accumulation of the

individual products and swaths press which

presents the screen shown in Fig. 3-8. Continu-

ing to press and release cycles the display through

the following screens:

•The total accumulated area for each active product

•The total accumulated area for each active Swath

•The swath width for each active swath

As each screen is being displayed the third line of the

screen continuously cycles through:

•P1 RATE

•P2 RATE

•Current Vehicle Speed

Press any other function to exit the “Area Display”

screen.

49.6

P2 RATE OFF

P1 AREA AC

!

Fig. 3-8 Area Display

Legacy 2000

3-6

98-05034

R0

!

Logging On

System Error

Not Used

Manual Mode

Control Active

Use Enter Key

Use Inc/Dec

Use Left/Right

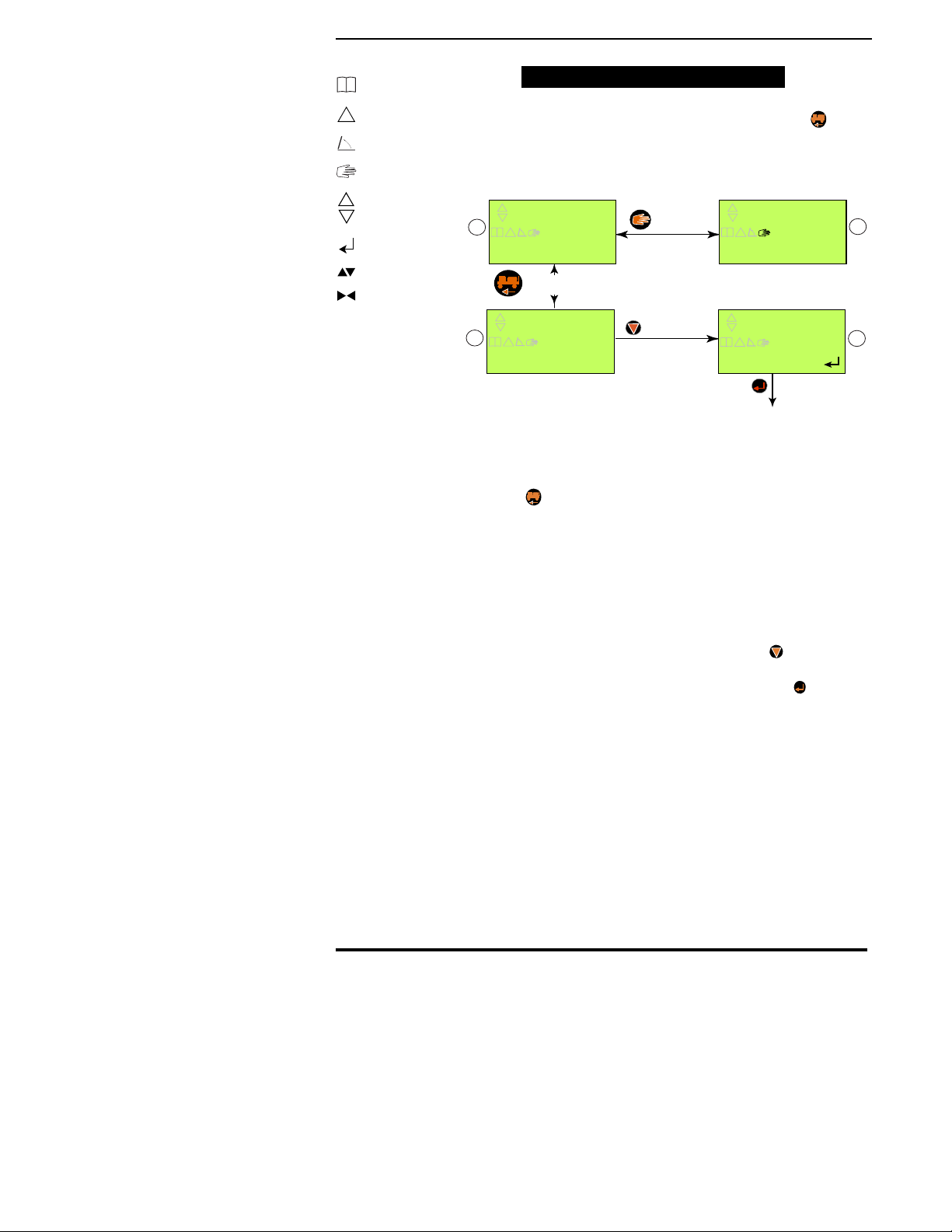

AREA RESET FUNCTION

Each area accumulator can be reset individually

or all can be reset at the same time. When

resetting a Product Area accumulator the

product must be turned OFF. Select the screen

displaying the accumulator (Product or Swath) that you

want to reset. Press to take you to the screen shown

in Fig. 3-9. (The information displayed on the center

line will vary depending on which accumulator you

have selected.) To reset the selected accumulator press

. To exit without resetting press any other function

button.

To reset all area accumulators at the same time press

from the screen in Fig. 3-9 taking you to the screen

in Fig. 3-10. Press to reset all area accumulators. To

exit without resetting press any other function button.

49.6

CLEAR?

S2 AREA AC

!

Fig. 3-9 - Area Reset Screen

49.6

CLEAR ALL?

S2 AREA AC

!

Fig. 3-10 Area clear all Screen

Mid-T

Mid-T

ech

CAUTION: When

performing a “Reset All”

on the Area accumulators.

even the accumulators for

active products will be

reset.

3-7

Legacy 2000

98-05034

R0

Operate

Functions

2

1

Operate

Setup

Manual

Enter

Right

Left

Product 1

Product 2

Speed

Decrease

Increase

Area

DATA LOGGING

The Legacy 2000 can log operational data to

either an external recording device, connected

to the COM 1 or COM 2 ports, or to the

SRAM Card (See caution at side) in the Legacy

console. To do this the Logging Function must first be

configured as described in Chapter 4 under “Log

Data”.

To initiate Data Logging hold the button down for

three seconds. The Logging Control Screen shown in

Fig. 3-11 will appear. Press to start the logging

process. Pressing any other button will take you out of

the Logging Control Screen without making any

changes.

With logging active the logging icon ( ) will appear

on all screens.

The same procedure is used to stop logging except the

screen will look like the one in Fig. 3-12. When is

pressed logging stops and the logging icon disappears

from the screen.

LOG

PRESS

STOPPED

!

TO START

Fig. 3-11 - Starting Logging

LOG

PRESS

STARTED

!

TO STOP

Fig. 3-12 Stopping Logging

CAUTION: Always make

sure the Legacy console is

powered down before

inserting or removing the

SRAM card.

Mid-T

ech

Legacy 2000

3-8

98-05034

R0

!

Logging On

System Error

Not Used

Manual Mode

Control Active

Use Enter Key

Use Inc/Dec

Use Left/Right

This page left blank intentionally

4-1

Legacy 2000

98-05034

R0

Setup

Functions

2

1

Operate

Setup

Manual

Enter

Right

Left

Product 1

Product 2

Speed

Decrease

Increase

Area

Before the Legacy system is used for chemical

application, important information must be

entered using the buttons on the face of the

console. The icons for these control buttons, and their

functions, are shown to the right.

NOTE: Always read and follow the prompts and

messages on the screen carefully. The first line

indicates the value currently being adjusted. The

second line indicates the function being set up,

instructions, or other information. The third line

provides information and instructions. The display may

cycle through several screens to provide all needed

information. See Fig. 4-1 for examples.

To enter the Setup mode press , taking you to the

“Main Setup”screen (fig. 4-2).

FIELD SETUP

The “Field Setup”functions allow you to adjust

values such as application rates, density,

calibration numbers, etc.. The “Field Setup”

mode is entered by pressing the desired product

button,

1

or

2

, from the Main Setup Screen (Fig. 4-2.

The “Product Application Modes”can be divided into

5 basic groups:

Mid-T

ech

PRESS TO CONT.

CLOSE

PRODUCT 1

VALVE RESPONSE

CLOSE

PRODUCT 1

CLOSE

PRODUCT 1

STATUS SW OFF

Cycles till is pressed

Fig. 4-1: Screen Cycling

Current

Value

Function

being

adjusted

Selects current

value and exits

Buttons

used to

adjust

Product affected

SETUP

CHOOSE FUNCTION

Fig. 4-2: Main Setup Screen

Chapter 4 Setup

Legacy 2000

4-2

98-05034

R0

!

Logging On

System Error

Not Used

Manual Mode

Control Active

Use Enter Key

Use Inc/Dec

Use Left/Right

•Liquid Mode (Page 4-2)

•Granular/NH3Mode (Page 4-6)

•Seeder Mode (Page 4-8)

•Spinner Mode (Page 4-10)

•Injection Mode (Page 4-11)

LIQUID MODE SETUP

Preset Application Rates

As many as five different rates (A - E) can be

preset into the Legacy 2000 Console.

With the desired “Product Application Mode”selected

under “Machine Setup”(Pg. 4-14) press

1

or

2

from

the “Main Setup”screen (Fig. 4-2) to enter the

appropriate setup function. (We are using “Liquid

Product 1”for this illustration.) This displays the

screens shown in Fig. 4-3. Which indicates that you are

setting Preset Rate “A”, it is being measured in

Gallons per Acre and the current value is 10.0 GPA.

The symbol indicates that you can use the and

buttons to select which digit of the Rate Value is

changed (The flashing digit). The symbol indicates

that you can use the and buttons to adjust the

value of the flashing digit. When the desired value has

been selected press the button to register the value

and advance to the Rate “B” preset screen. This

continues until all desired Preset Rates are set.

When setting the “Preset Rates”the button can be

used to move the decimal point. Each time is

pressed the decimal point moves one position to the

left until it disappears from the screen. The next press

of the button brings the decimal point back at the right

side of the screen.

If a flowmeter is used to control or monitor the

selected product continue to the next section. If only a

pressure sensor is involved go to the Pressure Calibra-

tion Section on page 4-3.

10.0

RATE A

P1 G/Ac Alternates

10.0

PRESS

P1 G/Ac

TO CONT.

Fig. 4-3 Setting preset Rates

Mid-T

Mid-T

ech

ech

When operating under

GPS control, Rate “C”

becomes the external,

“Variable Rate”. Rate “D”

becomes the Minimum

Allowable Rate and Rate

“E” the Maximum

Allowable Rate. Rates “A”

and “B” are preset rates,

which will override the

external rate command,

when either of them are

selected.

4-3

Legacy 2000

98-05034

R0

Setup

Functions

2

1

Operate

Setup

Manual

Enter

Right

Left

Product 1

Product 2

Speed

Decrease

Increase

Area

Flowmeter Cal. # Set

From the screen shown in Fig. 4-4 the initial

flowmeter calibration number can be set using

the same method as that for the Preset Rates

(Use and to select the digit and and to

adjust the value of the digit). Use the button to

adjust the position of the decimal point as described

on page 4-2. When the desired value is selected press

. If a pressure sensor is also used with this product

the next screen is Fig. 4-5. Otherwise the display exits

to the “Main Setup”screen (Fig. 4-2).

The flowmeter calibration number represents “Pulses/

Gallon”for US units and “Pulses/Liter”for metric

units. The flowmeter usually has a tag indicating the

“Initial Calibration Number”in Pulses/Gallon.

NOTE: Before starting actual application, a field test,

using water, should be done to verify the accuracy of

the Cal. #, and any necessary adjustments made. Use

the following formula to calculate a new Cal. #, if

necessary:

Pressure Based Setup

If a pressure sensor is used to control or monitor the

selected product, the low and high pressure values

of the sensor must be calibrated to match those of a

manual pressure gauge installed near the pressure

transducer. This process starts with the “Zero Set

Point”screen (Fig. 4-5).

From this screen we are setting the “Zero Pressure

Reference Point”for the console.

New Cal. # = MEASURED AMOUNT

INDICATED AMOUNT X OLD CAL. #

Mid-T

ech

0

SENSOR PSI

Cycles till is pressed

0

SENSOR PSI

0

SENSOR PSI

PRESS TO CONT.

HOLD TO SET ZERO POINT

Fig. 4-5 PSI Zero Point Set

Fig. 4-4 Flowmeter Cal. # Set

153.1

CHANGE CAL#

P1 CAL # Alternates

153.1

PRESS

P1 CAL #

TO CONT.

Legacy 2000

4-4

98-05034

R0

!

Logging On

System Error

Not Used

Manual Mode

Control Active

Use Enter Key

Use Inc/Dec

Use Left/Right

•The product pump must be turned OFF.

•At least one boom section of the associated swath must

be turned on to ensure that there is no pressure in the

boom. (It may be necessary to loosen a diaphragm check

valve to relieve all pressure.)

•Press and hold until the console beeps. The “Zero

Reference Point”is now set.

You should now see the screen sequence shown in Fig.

4-6, from which we set the “High Pressure Reference

Point”.

•Be sure to tighten any check valve loosened previously.

•The booms must be off (Master Switch OFF).

•The product pump must be turned ON.

•Slowly increase the engine RPM to adjust the pressure

reading on the manual pressure gauge to a maximum no

higher than the sensor’s specification.

•Set the pressure reading on the console to match that on

the manual pressure gauge.

•Use the and buttons to select the digit of the

display to be changed.

•Use the and buttons to adjust the selected

digit.

•When the console display has been set to match

the pressure gauge press .

NOTE: When using dual pressure sensors, both

sensors use the same Hi/Low pressure values.

The display reverts to the “Main Setup”screen (Fig. 4-

2) unless you are using a pressure sensor to control

product flow. In this case the screen shown in Fig 4-7

appears. This screen allows the operator to set the

“Nozzle Constant”into the console. The constant

should be taken from a nozzle chart for the particular

set of nozzles that you are using. Use the 10 MPH/30

PSI value (10KPH/2.0 Bar) for metric operation).

PRESS TO CONT.

30.0 30.0

REF PSI REF PSI

SET NOZZLE CONST

Fig. 4-7 Setting the Nozzle Constant

Fig. 4-6 High Set Point

0

SENSOR PSI

Cycles till is pressed

0

SENSOR PSI

0

SENSOR PSI

PRESS TO CONT.

PRESS MANUAL TO OPEN VALVE

Mid-T

Mid-T

ech

ech

Table of contents

Other Midwest Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Blue Diamond

Blue Diamond 127006 Operation and maintenance manual

Game Winner

Game Winner FSGWSF1017 Assembly instructions

Zipper Mowers

Zipper Mowers ZI-MD500HST user manual

ROPA

ROPA Panther 2S Translation of the original operating manual

LELY

LELY Hibiscus 725 CD Classic Operator's manual

brielmaier

brielmaier Multi-Twister MT220B Translation of the original instructions

Spearhead

Spearhead TRIDENT 400 Operator's instruction manual

Arrowquip

Arrowquip EASY FLOW CATTLE ALLEY product manual

Rotomec

Rotomec HURRICANE H40-048 Operator's manual

GREAT PLAINS

GREAT PLAINS Turbo Max 1800TM Operator's manual

IAE

IAE CORN BINS Installation & maintenance manual

Dairy Tech

Dairy Tech Perfect Udder 10G owner's manual