Trelawny 540.2030 User manual

CONCRETE GRINDER

Original instructions

540.2030 • 540.2040

TCG 180L • TCG 180

9

78

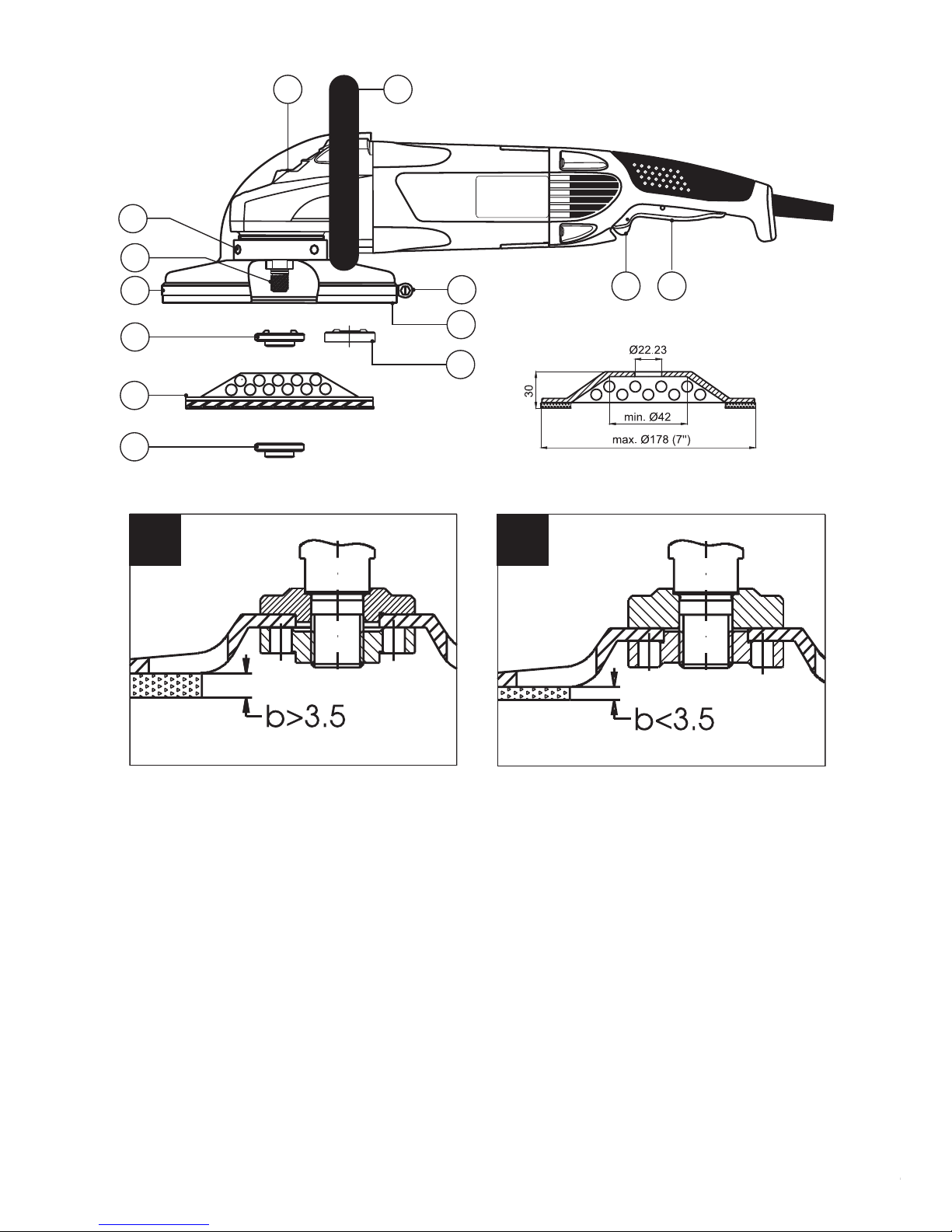

1

11

6

10

2

4

3

5

13

12

12

3

Original instructions

EN

Contents

Introduction........................................................................................................................................................................................... 3

Technical specications .................................................................................................................................................................... 5

General power tool safety warnings............................................................................................................................................... 6

Concrete grinder safety warnings.................................................................................................................................... 7

Know your product ............................................................................................................................................................ 7

Operation............................................................................................................................................................................ 8

Maintenance ...................................................................................................................................................................... 9

UNPACKING

Due to modern mass production techniques, it is unlikely that your power tool is faulty or that a part is missing. If you nd

anything wrong, do not operate the tool until the parts have been replaced or the fault has been rectied. Failure to do

so could result in serious personal injury.

ASSEMBLY

The concrete grinder is packed fully assembled except for the diamond cup wheel.

Introduction

Your new TRELAWNY power tool will more than satisfy your expectations. It has been manufactured under stringent

TRELAWNY Quality Standards to meet superior performance criteria. You will nd your new tool easy and safe to

operate, and, with proper care, it will give you many years of dependable service.

WARNING:

Carefully read through these original instructions before using your new TRELAWNY power tool Take special

care to heed the Warnings. Your TRELAWNY power tool has many features that will make your job faster and

easier. Safety, performance, and dependability have been given top priority in the development of this tool,

making it easy to maintain and operate.

Do not dispose of electrical products together with household waste!

Waste electrical products should not be disposed of with household waste. Please recycle where facilities

exist. Check with your local authority or retailer for recycling advice.

ENVIRONMENTAL PROTECTION

The machine, accessories and packaging should be sorted for environmental-friendly recycling.

The plastic components are labelled for categorised recycling.

4

TCG 180L • TCG 180

EN

DESCRIPTION OF SYMBOLS

The rating plate on your tool may show symbols. These represent important information about the product or instruc-

tions on its use.

Double insulated for additional protection

Spindle thread: M14

Conforms to the relevant European Directives

Refer to original instructions

YYYY-Www Production period, where the variable symbols are:

YYYY - year of manufacture, ww - calendar week number

5

Original instructions

EN

Technical specications

Model TCG 180L TCG 180

Part Number 540.2030 540.2040

Voltage 110V~ 5 0Hz 230V~50Hz

Power input 2000 W 2600 W

No load speed 6500 min-1 6500 min-1

Spindle thread M14 M14

Spindle thread length 20 mm 20 mm

Cup wheel arbor Ø22.23 mm Ø22.23 mm

Cup wheel maximum diameter 178 mm (7”) 178 mm (7”)

New cup wheel maximum thickness 30 mm 30 mm

Dust extraction port diameter Ø35 mm Ø35 mm

Weight (EPTA Procedure 01/2003) 6.9 kg 6.9 kg

Safety class (EN 60745-1) II II

NOISE AND VIBRATION INFORMATION (Measured values determined according to EN 60745.)

Noise emission

A-weighted sound pressure level LpA 91 dB (A) 91 dB (A)

Uncertainty КpA 3 dB 3 dB

A-weighted sound power level LwA 102 dB (A) 102 dB (A)

Uncertainty КwA 3 dB 3 dB

Wear hearing protection!

Vibration emission*

Total vibration values (vector sum in the three axes) determined according to EN 60745:

Grinding concrete

Vibration emission value ah13.5 m/s213.5 m/s2

Uncertainty K 1.5 m/s21.5 m/s2

* The vibration emission values are determined according to 6.2.7 EN 60745-1.

The vibration emission level given in this information sheet has been measured in accordance with a standardised test

given in EN 60745 and may be used to compare one tool with another. It may be used for a preliminary assessment of

exposure.

The declared vibration emission level represents the main applications of the tool. However if the tool is used for

different applications, with different accessories or poorly maintained, the vibration emission may differ. This may

signicantly increase the exposure level over the total working period.

An estimation of the level of exposure to vibration should also take into account the times when the tool is switched

off or when it is running but not actually doing the job. This may signicantly reduce the exposure level over the total

working period.

Maintain the power tool and the accessories and keep your hands warm during operation to reduce the harmful effect

of vibrations.

Dust from material such as paint containing lead, some wood species, minerals and metal may be harmful. Contact

with or inhalation of the dust may cause allergic reactions and/or respiratory diseases to the operator or bystanders.

Certain kinds of dust are classied as carcinogenic such as oak and beech dust especially in conjunction with additives

for wood conditioning (chromate, wood preservative). Material containing asbestos must only be treated by specialists.

▪Where the use of a dust extraction device is possible it shall be used.

▪To achieve a high level of dust collection, use vacuum cleaner for wood or for wood and/or minerals together with

this tool.

▪The work place must be well ventilated.

▪The use of a dust mask of filter class P2 is recommended.

Follow national requirements for the materials you want to work with.

All models are equipped with electronic device for soft start and restriction of starting current to 16 A. Models feature

safety upon mains drop-out. In case of mains drop-out or unplugging for more than 0.5 s the power tool remains

switched off and can be started only after switching off and on the ON/OFF switch. (This safety feature is described in

part “Operation”.)

6

TCG 180L • TCG 180

EN

General power tool

safety warnings

WARNING! Read all safety warnings and

all instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or

serious injury.

Save all warnings and instructions for future

reference.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

1. WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

2. ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e) When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

3. PERSONAL SAFETY

a) Stay alert, watch what you are doing and

use common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol

or medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools with

your finger on the switch or energising power tools

that have the switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes,

jewellery or long hair can be caught in moving

parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

4. POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions

to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts

and any other condition that may affect the

power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the power

tool for operations different from those intended

could result in a hazardous situation.

7

Original instructions

EN

5. SERVICE

a) Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

Concrete grinder

safety warnings

WARNING: Before connecting a tool to a power

source be sure that the voltage supply is the same as that

specied on the nameplate of the tool.

▪A power source with a voltage greater than that

specified for the tool can result in serious injury to the

user, as well as damage to the tool.

▪If in doubt, do not plug in the tool.

▪Using a power source with a voltage less than the

nameplate rating is harmful to the motor.

Always wear eye and ear protection

and use a dust mask. The dust and abrasive particles

separated during operation may seriously injure your

health.

▪Hold power tool by insulated gripping surfaces

only, when performing an operation where the

cutting accessory may contact hidden wiring or

its own cord. Cutting accessory contacting a “live”

wire may make exposed metal parts of the power tool

“live” and could give the operator an electric shock.

WARNING: Always switch off and unplug the

power tool prior to any adjustment, servicing or main-

tenance.

▪Never switch on the grinder under load, and leave it

down only after final rotation stop.

▪Always keep the cord away from the working area of

the cup wheel.

▪Fasten the cup wheel only by a special wrench, using

the original base support washer and lock nut.

▪Do not use damaged cup wheels.

WARNING: The grinding accessory continues

rotation even after the machine is switched off.

▪Never apply side pressure to stop the cup wheel

rotation after switching off the grinder.

▪The outer metal parts and the bits may get hot after

continuous operation.

▪Use clamps or a vice to secure your work whenever

possible.

▪Always switch off the machine and wait until the

spindle has come to a complete standstill before

placing it down.

▪Do not force the machine: let the tool do the work at a

reasonable speed. Overloading will occur if too much

pressure is applied and the motor slows resulting in

inefficient work and possible damage to the motor.

▪Rags, cloths, cord, string and the like should never be

left around the work area.

▪Remove any nails, screws, etc. from the processed

surface.

▪Before using the tool on an actual work piece, switch

on and let it run for a while. Operate the tool at least

200 mm away from your face and body.

▪Always be sure you have a firm footing. Be sure no

one is below when using the tool in high locations.

▪Hold the power tool firmly.

▪Keep your hands away from rotating parts. Do not

touch the bit or the work piece immediately after

operation - they may be extremely hot and you may

get serious burns.

▪The tool must be used only for its prescribed purpose.

Any use other than those mentioned in this Manual

will be considered a case of misuse. The user and not

the manufacturer shall be liable for any damage or

injury resulting from such cases of misuse.

▪To use this tool properly, you must observe the

safety regulations, the assembly instructions and

the operating instructions found in this Manual. All

persons who use and service the machine have to

be acquainted with this Manual and must be informed

about its potential hazards. Children and frail people

must not use this tool. Children should be supervised

at all times if they are in the area in which the tool is

being used. It is also imperative that you observe the

accident prevention regulations in force in your area.

The same applies for general rules of occupational

health and safety.

▪The manufacturer shall not be liable for any changes

made to the tool nor for any damage resulting from

such changes.

Even when the tool is used as prescribed it is not

possible to eliminate all residual risk factors. The

following hazards may arise in connection with the tool’s

construction and design:

▪Damage to hearing if effective hearing protection is

not worn.

▪Always unplug the machine prior to any adjustment,

servicing or maintenance including replacing the

accessories.

▪The power tools must not be used outdoors in rainy

weather, or in moist environment (after rain) or in close

vicinity with easily flammable liquids and gases. The

working place should be well lit.

Know your product

Before using the power tool, familiarize yourself with all

the operating features and safety requirements.

Use the tool and accessories only for the applications

intended. All other applications are expressly ruled out.

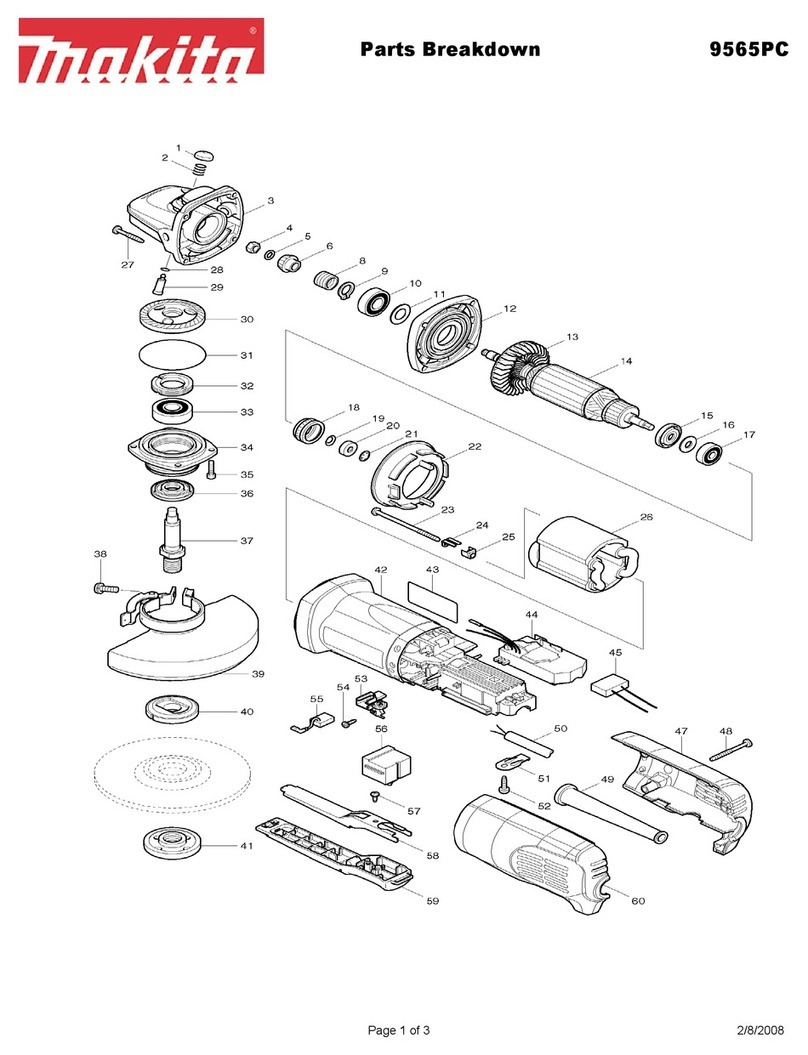

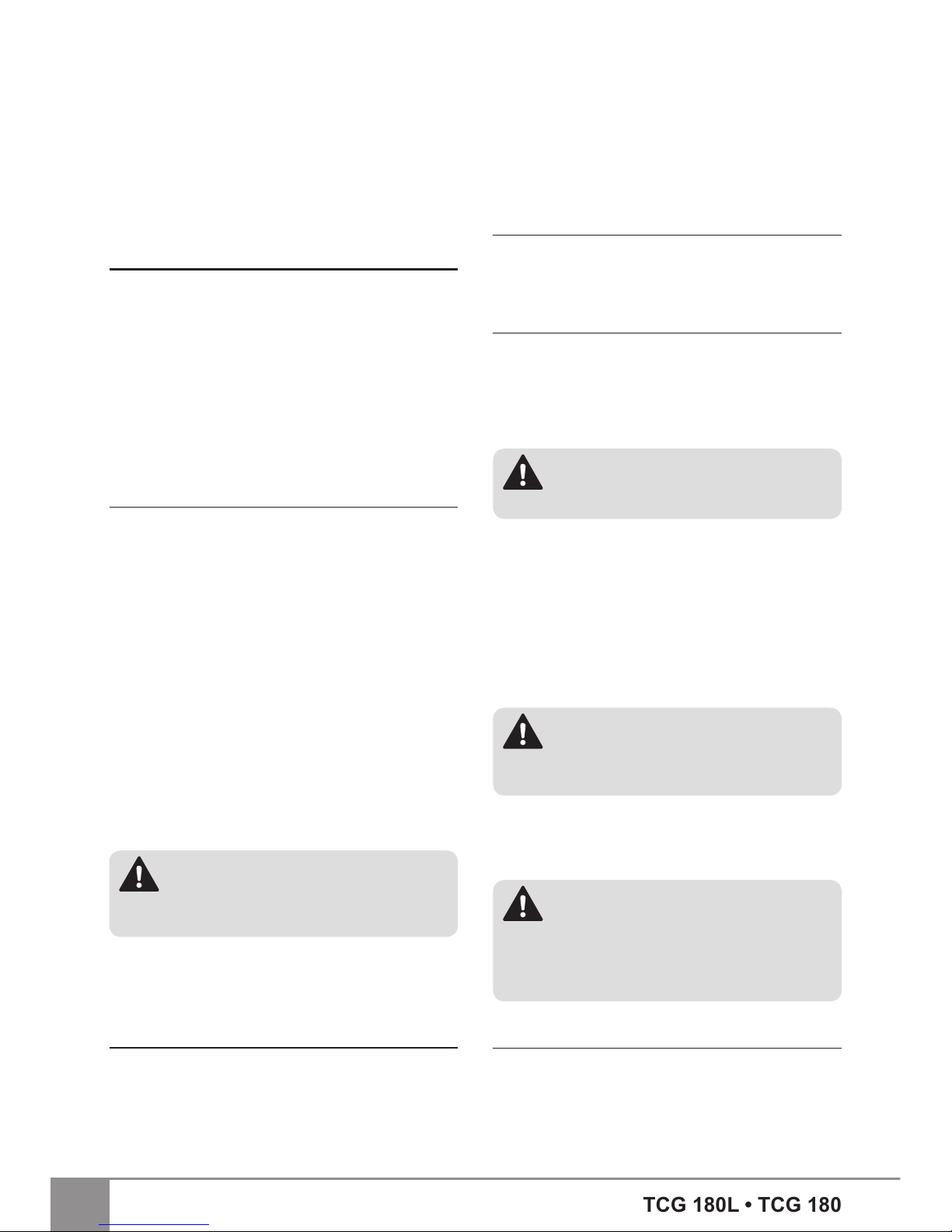

1. Spindle

2. Wheel guard

3. Support ange

4. Diamond cup wheel

5. Fixing ange

8

TCG 180L • TCG 180

EN

6. Auxiliary handle

7. ON/OFF switch

8. ON/OFF switch locking button

9. Spindle lock button

10. Rubber seal

11. Fastening bracket

12. Flat face support washer

13. Screw

Operation

This power tool is supplied from single-phase alternating

current mains only. It is double insulated according to

EN 60745-1, IEC 60745 and can be connected to

grounded or not grounded sockets. This power tool is

radio suppressed in compliance with EMC Directive

2004/108/EC.

This power tool is designed for rough and ne grinding

concrete and rock material with the purpose of

refurbishing before laying plaster and protective coating.

The machine is designed for dry grinding only.

PRIOR TO INITIAL OPERATION

▪The machine may be delivered with the wheel

mounted at the factory. Ensure that the wheel is

mounted properly and fixed reliably prior to the initial

and any following operation.

▪Make sure the power supply voltage corresponds to

the value indicated on the name plate with technical

data of the tool.

▪Always check the position of ON/OFF switch. The

power tool must be connected to the power supply

socket only when this switch is in OFF position.

▪Make sure that the cord and the plug are in order. If the

replacement of the supply cord is necessary, this has

to be done by the manufacturer or his agent in order

to avoid a safety hazard.

▪Make sure the cup wheel diameter and thick ness do

not exceed the values specified on the name plate.

The maximum number of revolutions indicated on

the cup wheel must not be less that the number of

revolutions of the machine at no load!

WARNING: Always switch off and unplug the

power tool prior to any adjustment, servicing or main-

tenance.

▪Always use the auxiliary handle and hold the machine

firmly with both hands for maximum control over

torque reaction or kickback upon starting.

SWITCHING ON - SWITCHING OFF

The concrete grinder is secured against unintentional

switching on.

▪Switch on: First press the auxiliary button (8)

positioned at the front of ON/OFF switch, then press

ON/OFF switch (7). For continuous operation switch

(7) can be locked. In this case while holding switch (7),

press button (8) and the release switch (7).

▪Switching off: Release switch (7); in case the switch is

locked, first press and then release that switch.

In case of mains drop-out (or temporary drop-out

for time t > 0.5 s), when the ON/OFF switch is in

ON position, the machine should not operate after

supply recovering. To start operating the machine,

rst switch off and then switch on the lever of ON/

OFF switch.

WHEEL GUARD

The wheel guard (2) must always be mounted on the

machine!

ASSEMBLY, REPLACING AND ADJUSTING THE

CUP WHEEL POSITION

Make sure the cup wheel diameter and thickness do not

exceed the values stated in the technical specications.

The maximum admissible speed indicated on the wheel

must not be less than the machine no load speed.

Fix the spindle (1) by pressing the lock button (9) on the

gear case.

WARNING: Never press button (9) while the

spindle is still rotating!

With this button depressed turn the spindle till its

pronounced going deeper. Unscrew lock nut (5) by the

lock nut wrench.

In view of the cup wheel wear and in order to achieve

optimum dust extraction a possibility is provided to adjust

the cup wheel position to the wear of the cup wheel.

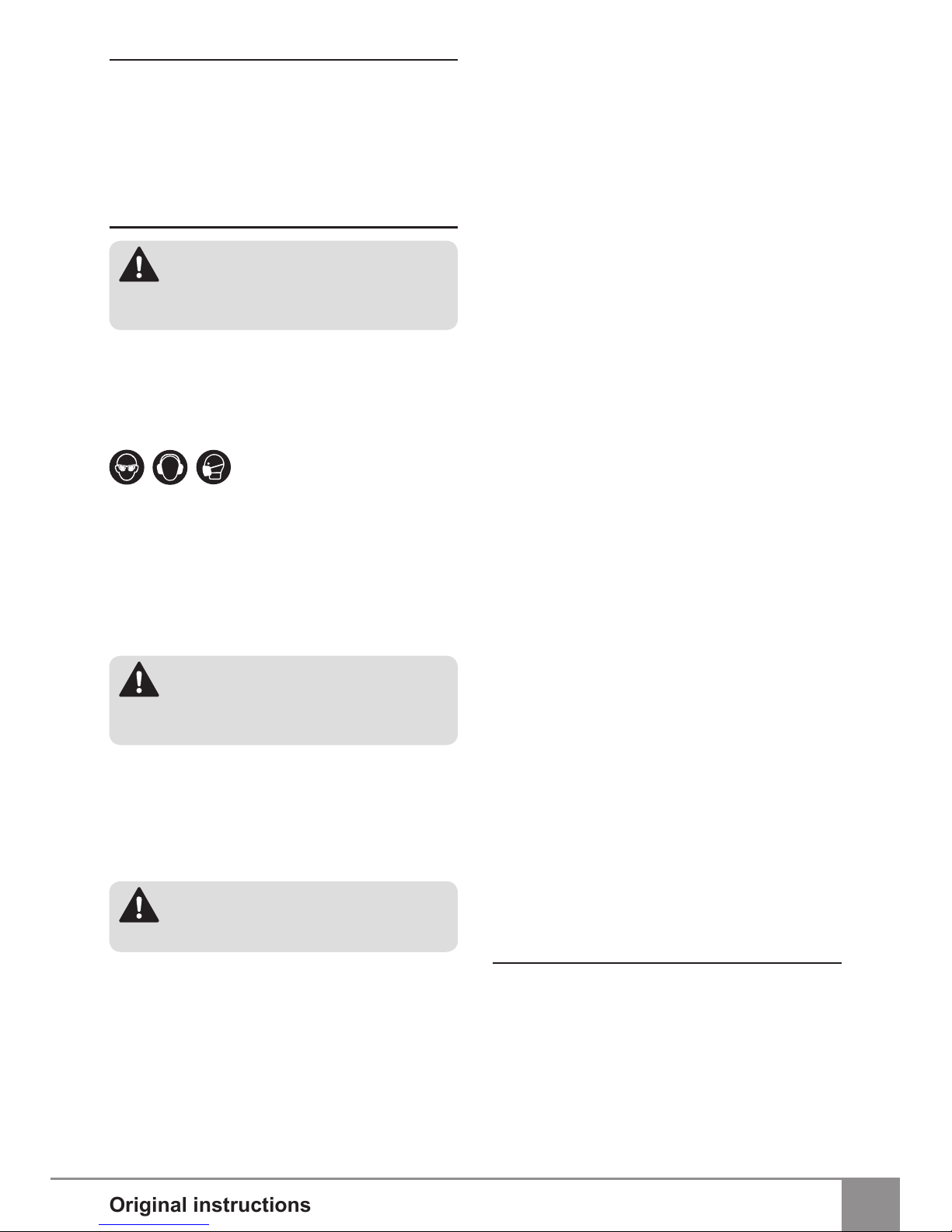

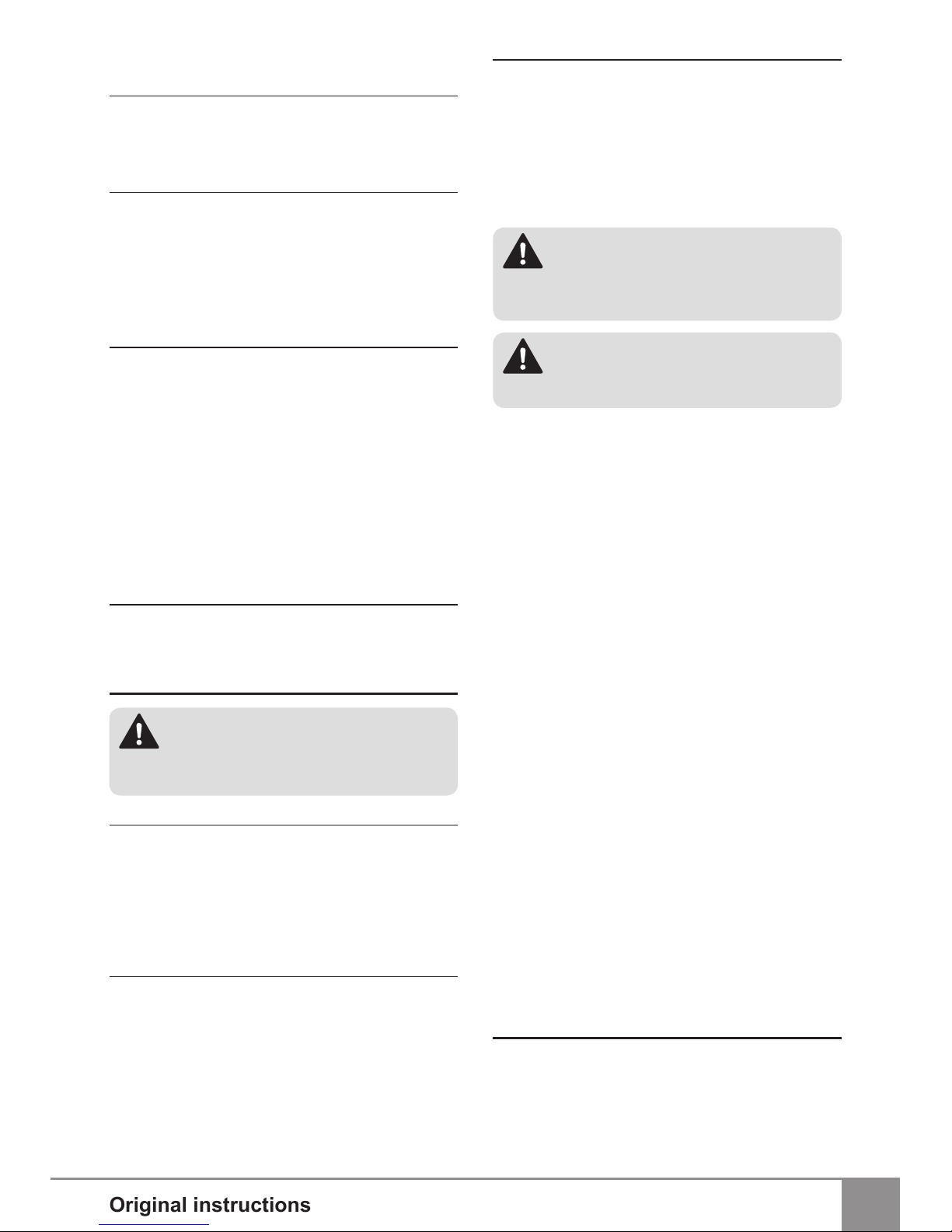

When placing a new cup wheel arrange the components

on the spindle in the following order: base support

washer (3); cup wheel (4); lock nut (5) with its at end

towards the cup wheel as shown on Fig. 1.

WARNING: Placing the lock nut (5) with its

convex end towards the cup wheel shall make tighten-

ing the cup wheel impossible.

In case the cup wheel is half worn out or more, arrange

the components on the spindle in the following order: at

support washer (12); cup wheel (4); lock nut (5) with its

convex end towards the cup wheel as shown on Fig. 2.

WARNING: After replacing the wheel, operate

the machine with the new wheel at no load mode for

minimum 30 seconds. Vibrating or otherwise improp-

erly rotating wheels must be replaced immediately and

discarded.

REPLACING THE BRUSH SHIELD

The rubber seal (10) provides maximum decreasing the

dust emission in the environment. It wears out along with

the wheel. When replacing the wheel, change the rubber

seal as well. Loosen the screw in bracket (11) and remove

the old rubber seal. Place the new seal, taking care the

edge of the wheel guard (2) will enter the provided in the

9

Original instructions

EN

seal groove. Place back the bracket (11) and fasten it.

AUXILIARY HANDLE

The auxiliary handle (6) is fastened to the gear case

through two screws. Always use the auxiliary handle and

hold the machine rmly with both hands.

DUST EXTRACTION

This power tool should only be used with a dust extraction

system. In addition, always wear approved dust mask.

Always make sure the vacuum cleaner that you use is

designed for extraction of masonry dust. Connect the

vacuum cleaner to the dust extraction port on the wheel

guard.

RECOMMENDATIONS

When grinding do not apply pressure to the processed

surface by bearing down on the machine but move the

wheel smoothly. Upon overloading the built-in electronic

protection will actuate and the speed of the wheels will

be reduced considerably.

To resume normal speed draw the machine back from

the processed material. Use the appropriate type of

wheel for the specic operation and the material.

In case the screws (13) loosen they have to be tightened

rmly. Prior to tightening you must lay thread locking

adhesive over each screw thread.

ACCESSORIES TO BE USED

WITH THIS POWER TOOL

▪ Diamond cup wheel Ø178 mm (7’’)

Maintenance

WARNING: Always ensure that the tool is

switched off and unplugged before attempting to per-

form inspection or maintenance.

BRUSH REPLACEMENT

This power tool is equipped with auto-stop brushes.

When the carbon brushes are worn out, the machine

switches itself off. In this case both brushes must be

replaced simultaneously with genuine brushes at

TRELAWNY service centre for warranty and post-

warranty service.

GENERAL INSPECTION

Regularly inspect all fasteners and ensure they are

properly tightened. Should any of the screws be loose,

retighten it immediately to avoid hazards.

In case the screws (13) loosen they have to be tightened

rmly. Prior to tightening you must lay thread locking

adhesive over each screw thread.

Re-lubricate all moving parts at regular intervals.

If the replacement of the supply cord is necessary, this

has to be done by the manufacturer or his agent in order

to avoid a safety hazard.

CLEANING

For safe operation always keep the machine and its

ventilation slots clean.

Regularly check to see if any dust or foreign matter

has entered the grills near the motor and around the

switches. Use a soft brush and/or air jet to remove any

accumulated dust. Wear safety glasses to protect your

eyes whilst cleaning.

Exterior plastic parts may be cleaned with a damp cloth

and mild detergent if necessary.

WARNING: Never use alcohol, petrol or other

cleaning agent. Never use caustic agents to clean

plastic parts.

WARNING: Water must never come into con-

tact with the tool.

IMPORTANT! To assure product safety and reliability,

repairs, maintenance and adjustment (including brush

inspection and replacement) should be performed

by certied service centres or other qualied service

organisations, always using genuine replacement parts.

Notes

Carefully read the entire Original Instructions before

using this product.

The manufacturer reserves the right to make changes

and improvements to the products and to alter

specications without prior notice.

Specications may differ from country to country.

TCG 180L • TCG 180

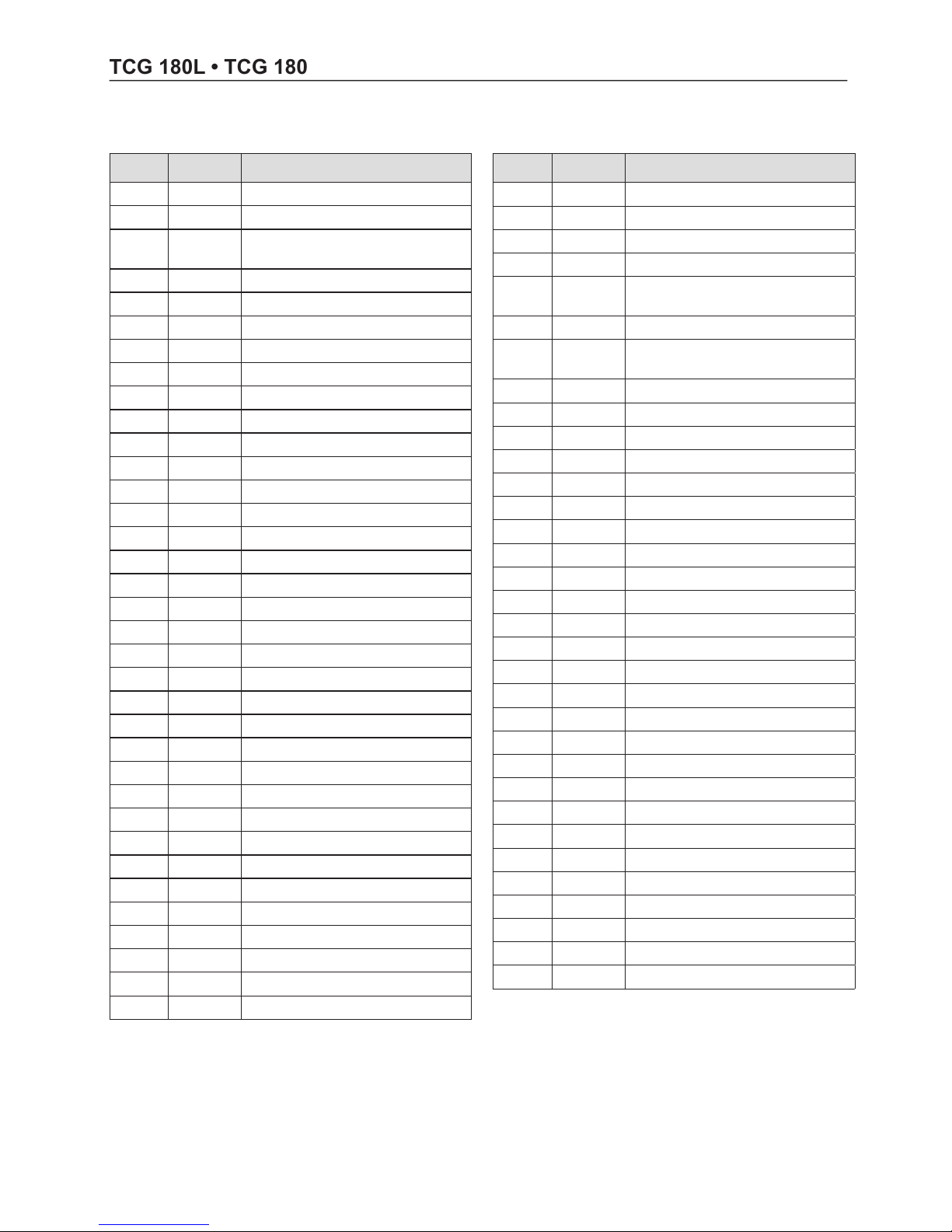

Pos. No. Ref.No. Description

1540.178878 Gear box

2540.330125 Bearing HK 1212

3540.330944 Bearing 6300 2RSL P63

LDS18SpA

454 0.153 341 Gasket

554 0.173 93 6 Inner Flange

654 0.173 93 4 Circlip

7540.174022 Spindle

8540.173935 Rubber bush

954 0.158247 Bearing bed

10 54 0.11750 4 Spacer washer

11 54 0.11750 5 Spacer washer

12 540.152666 Gear set

13 540.113256 Nut

14 540.174007 Bush

15 540.174021 Spring

16 540.174008 Pin

17 540.330344 O-ring 6X1.5B NBR70

18 540.330352 O-ring 80X2B

19 540.360246 Screw M5x16

20 54 0.175915 Button

21 540.175959 Protective washer

22 540.330473 Circlip А40-1D

23 540.331355 Bearing 6203-2RS (17x40x12)

24 54 0.17593 5 Body

24A 5 40.175910 Body

25 54 0.175911 Brush holder cover

26 540.174004 Diffuser

27 54 0.176 452 Stator set

27A 540.156721 Stator set 110V

28 540.175040 Armature set

28A 540.156722 Armature set 110V

29 54 0.19 002 0 Brush holder set

30 54 0.153 014 Brush

31 540.153015 Brush with a switch

32 540.164934 Rubber bush

TCG 180L • TCG 180

Pos. No. Ref.No. Description

33 540.361360 Screw К 4Х9.5 TORX 20

34 540.361433 Screw 3.9x80

35 540.154350 Fan

36 54 0.1516 48 Protective washer

37 54 0. 331149 Bearing 608-2RS-P63

LDS18SpA

38 54 0.175913 Handle

39 54 0.153 89 4 Switch PS16 E03/RAL9005/

B P 16,5A

39A 5 40.15 3020 Switch 1267

40 540.361328 Screw K4x18 TORX 20

41 540.151671 Cord clamp

42 540.361360 Screw К 4Х9.5 TORX 20

43 540.361371 Screw К5Х40(D10) TORX 20

44 540.120724 Cord protector

45 54 0.152574 Cord with a plug

45A 5 40.16 649 4 Cord with a plug

46 540.361369 Screw A-K 5x25 TORX 20

47 540.152929 Back up disc washer

48 54 0.1218 38 Locking nut

49 540.150015 Special spanner 200

50 540.370399 Spanner 22 DIN 894

51 54 0.1652 38 Handle set

52 540.360791 Washer 2-14

53 540.360790 Bolt D2-M14x20

54 540.361342 Screw M6X6 DIN 914

55 54 0.15825 3 Disk guard

56 54 0.153 037 Bracket

57 540.152722 Gasket 7"

59 540.158254 Disk guard

60 54 0.158248 Bearing bed set

61 54 0.11324 4 Spiral spring

62 540.330331 O-ring 2-10x1,5-2

63 540.330704 O-ring 5x1,5 NBR 70

100a 5 40.1573 64 Electronic block 110V

Parts with “a” prex related to TCG 180L

www.trelawnyspt.co.uk

Email: sales@trelawny.co.uk

Tel: +44 (0)1926 883781

Fax: +44 (0)1926 450352

DECLARATION OF CONFORMITY

We,

Trelawny SPT Limited of

Trelawny House, 13 Highdown Road, Sydenham Industrial Estate, Leamington Spa,

Warwickshire, CV31 1XT, United Kingdom,

Declare that under our sole responsibility for supply/manufacture of the product

Name of product

Part Numbers

Year of production

to which this document related is in conformity with the provisions of the following Directive(s),

Normative Documents and their relevant Standards:

2006/42/EC MACHINERY DIRECTIVE

2004/108/EC DIRECTIVE OF ELECTROMAGNETIC COMPATIBILITY

2011/65/EC RoHS DIRECTIVE

EN 60745-1, EN 55014-1, EN 55014, EN 61000-3-2, EN 61000-3-3

Registered Ofce: Trelawny SPT Ltd, Trelawny House, 13 Highdown Road, Sydenham Industrial Estate, Leamington Spa, Warwickshire, CV31 1XT, United Kingdom

Date and place of issue,

1st January 2014

Leamington Spa, England.

Rob Chapman,

Commercial Director.

DOCUMENT No. Q:57/4

CONCRETE GRINDER

540.2030; 540.2040

2014

This manual suits for next models

3

Table of contents

Other Trelawny Grinder manuals