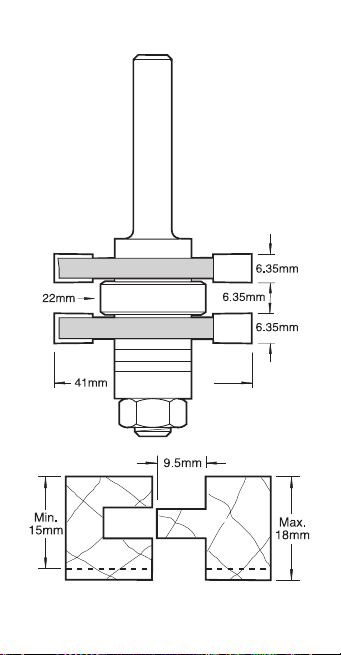

Groove Set Up

Tongue & groove joint showing minimum and

maximum possible timber thickness.

OPERATION

Carefully remove the protective wax from the cutter

and dispose.

Insert the cutter shank into the collet at least all

the way to the marked line indicated on the shank.

This ensures at least 3/4 of the shank length is

held in the collet.

Cutting the Groove

Undo nut with a 13mm A/F spanner, remove all

parts and reassemble as per the groove set up

diagram. Set the cutter to the desired height

against the timber (this will be dependant on

the thickness of the timber).

The bearing will automatically give the correct

depth of cut. If a side fence is not used, a lead

on piece will be required.

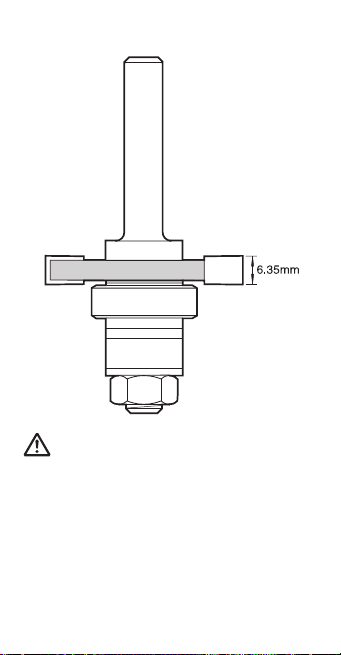

Cutting the Tongue

Undo the nut with a 13mm A/F spanner,

remove all parts and reassemble as per the

tongue set up diagram. Groovers C should

be at 90° to each other to reduce the cutting

impact. The height of the cutter will need to be

adjusted to match the groove.

The joint produced will be slightly loose to allow

for ease of assembly of the finished joint. For a

tight joint extra shims E should be added either

side of the bearing in the tongue set up.

MAINTENANCE

Continual satisfactory operation depends upon

proper tool care and regular cleaning.

Cleaning

■Remove resin build-up regularly.

■Apply a rust protector to shanks. Do not

use rust protector on ball bearing guides.

Lubrication

■Use a PTFE dry lubricant spray on tool.

■Apply a rust protector to shanks. Do not

use rust protector on ball bearing guides.

Storage

Always return cutter to its packaging after

use.

Before using cutter, please ensure it is

correctly assembled and locking nut is fully

tightened to correct torque setting.

Recommended speed is 18,000 rpm.

SPARE PARTS

Please use only Trend original spare parts

and accessories.

Item Qty. Desc. Ref. (1 off)

A 1 Arbor 1/4” shank 33/30X1/4”

Arbor 8mm shank 33/30X8MM

B 1 Replacement arbor nut ANUT/33/30

C 2 Groover 6.3mm Kerf SP-C149C

D 2 Bearing 22mm dia. SP-C149C

F 1 Spacer set SPACER/8

G 1 Instructions INST/C158

Our policy of continuous improvements mean that

specifications may change without notice. Trend

Machinery & Cutting Tools Ltd. cannot be held liable

for any material rendered unusable, or for any form of

consequential loss.

Safety Points

1. Disconnect power tool and attachment from power supply when not in

use, before servicing, when making adjustments and when changing

accessories such as cutters. Ensure switch is in “off” position and cutter

has stopped rotating.

2. Read and understand instructions supplied with power tool, attachment

and cutter.

3. Current Personal Protective Equipment (PPE) for eye, ear and

respiratory protection must be worn. Keep hands, hair and clothes

clear of the cutter.

4. Before each use check cutter is sharp and free from damage. Do not

use if cutter is dull, broken or cracked or if any damage is noticeable or

suspected.

5. The maximum speed (nmax) marked on tool or in instructions or on

packaging shall not be exceeded. Where stated, the speed range

should be adhered to.

6. Insert the shank into the router collet at least all the way to the marked

line indicated on the shank. This ensures at least 3/4 of shank length is

held in collet. Ensure clamping surfaces are clean.

7. Check all fixing and fastening nuts, bolts and screws on power tool,

attachment and cutting tools are correctly assembled, tight and to

correct torque setting before use.

8. Ensure all visors, guards and dust extraction is fitted.

9. The direction of routing must always be opposite to the cutter’s

direction of rotation.

10. Do not switch power tool on with the cutter touching the workpiece.

11. Trial cuts should be made in waste material before starting any project.

12. Repair of tools is only allowed according to tool manufacturers

instructions.

13. Do not take deep cuts in one pass, take shallow passes to reduce the

side load applied to the cutter.

Please see www.trend-uk.com/safety for more safety advice.