TrestleJacks USA TJ220ADJ Manual

Trestle Jacks Mini

TJ220ADJ

Release 0.1

Standard Operating

Procedure

BEFORE USING TRESTLEJACKS, READ THESE INSTRUCTIONS AND THE PRODUCT LABEL COMPLETELY AND

THOROUGHLY, UNDERSTAND THEIR OPERATING PROCEDURES, SAFETY WARNINGS AND MAINTENANCE

REQUIREMENTS. FAILURE TO DO SO COULD CAUSE ACCIDENTS RESULTING IN SERIOUS OR FATAL

PERSONAL INJURY AND/OR PROPERTY DAMAGE.

2

TRAILER LIFTING & SUPPORT STAND HAZARDS

Study, understand and follow all instructions before operating this device. Failure to heed these instructions may result in

property damage and/or personnel injury or death:

Do not exceed rated capacity

Use TrestleJacks on a hard, level surface capable of supporting

the weight of the trailer

Use as a matched pair to support each end of the trailer when

lifting an entire axle

Because of the potential hazards associated with the misuse of

equipment of this type, no modifications should be made to the

product without consent from manufacturer

Chock trailer & towing vehicle wheels to prevent trailer

movement

Never use a single TrestleJack to raise an entire trailer in the

center of the axle

WARNING SUMMARY

This document contains general safety warnings that must be understood and applied during operation of this equipment. Failure

to observe these precautions could result in serious injury or death to personnel.

HEAVY OBJECT –Heavy object on human figure shows that heavy parts present a danger to life or limb

HEAVY OBJECT –Foot with heavy object on top shows that heavy parts can crush and harm.

HEAVY OBJECT –Hand with heavy object on top shows that heavy parts can crush and harm.

The use of damaged, corroded or otherwise defective TrestleJacks could result in stand failure, causing severe injury

or death to user. Always inspect TrestleJacks prior to use.

Each stand shall be inspected immediately if the device is believed to have been subject to an abnormal load or

shock.

Check the TrestleJacks for bends, separated welds, cracks, corrosion, damaged, loose, or missing parts, excessive

wear or other evidence of mishandling.

! WARNING

•Study, understand, and follow all instructions

with and on this device before use.

•Donot exceed rated capacity.

•Use only on hard, level surfaces capable of

sustaining rated capacity loads.

•Use as a matched pair to support one end of

a trailer only.

•Support only on the axle of the trailer as

specified.

•Ensure there are no cables, break tube lines

or other utilities running on the axle that can

be damaged by the jack.

•Product to be used on trailer axles only –

square, triangular and round axles are

supported.

•No alterations shall be made to this

product.

•Failure to heed product markings or

warnings may result in personal injury or

property damage.

3

ProductOverview

TrestleJacks TJ220ADJ (TJ-Mini) is a specialised, trailer axle lifting and standing device that utilises driving motion from the

towing vehicle for lifting and lowering light load trailer/and caravan axles. Once in the upright position, TJ-Mini becomes an

axle support stand with a carrying capacity of 10 (ten) Tons.

Always ensure there are no cables, break tube lines or other utilities running on the axle that can be

damaged by the jack.

Application:

The TJ220ADJ (TJ-Mini) product range has an adjustable Ratchet Bar and supports all light load trailers, camp trailers,

horseboxes, caravans and boat trailers, irrespective of tyre/rim size. Square, triangular and round axles are supported.

Incorrect Application:

Although TJ220ADJ (TJ-Mini) products might be usable on some solid axle 4x4 vehicles, the product has

not been designed to be used on towing vehicles.

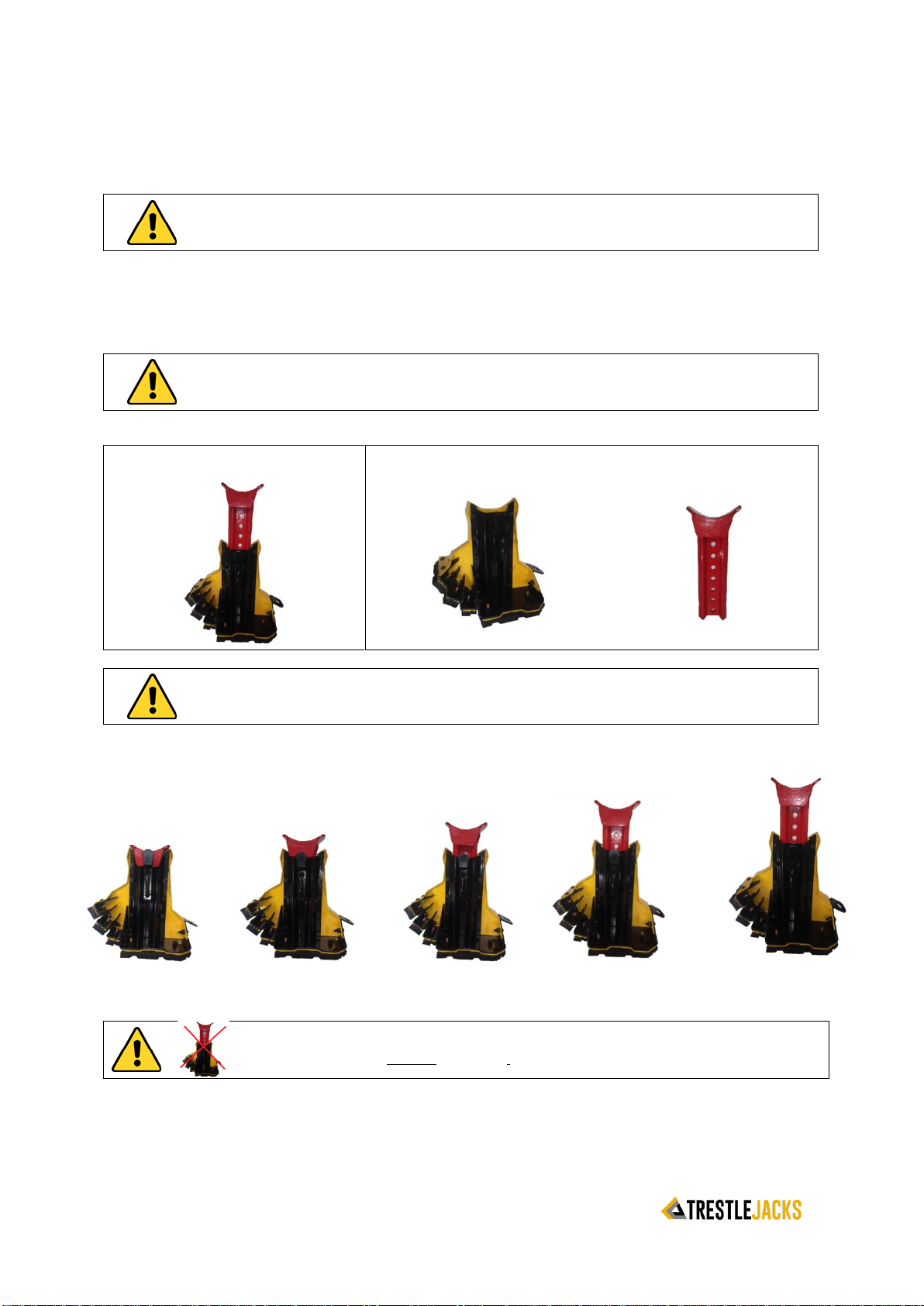

Components:

TJ Mini

A - Base Section

B - Ratchet Bar

NEVER disassemble the base of the TJ220ADJ (TJ-Mini) –regularly check that all nuts and bolts and

securely fastened.

Four (4) adjustable heights

Standard Height

Height Adjustment 1

Height Adjustment 2

Height Adjustment 3

Height Adjustment 4

NEVER extend the TJ220ADJ (TJ-Mini) beyond the indicated heights above. The two-pronged lock

pin must securely lock through two holes in the ratchet bar at all times.

4

Operating Procedures

1

Apply park brakes, turn off ignition, chock the wheels

and apply trailer brakes before any preparation work

is started

6

Release all trailer brakes, remove wheel chocks,

release park brakes and turn on ignition.

2

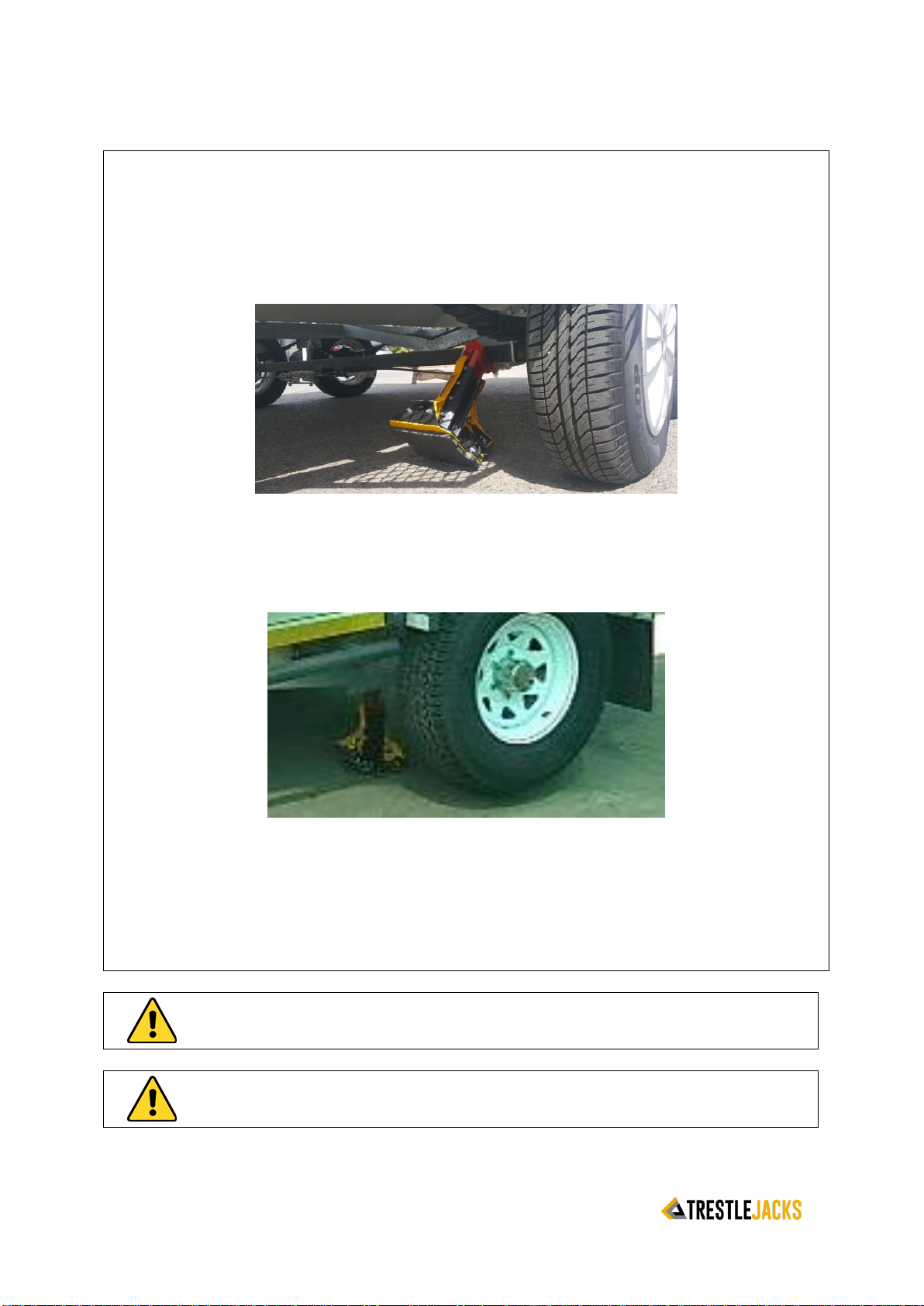

Place the TJ220ADJ unit in the loading position

underneath the trailer axle as close to the troubled

wheel as possible. Illustration A

7

Reverse the towing vehicle slowly for lifting process to

start and continue to reverse until a positive stop is

received from the trailer or the towing vehicle has

moved approximately 20cm.

Illustration A

3

Ensure that the TrestleJacks’s cup is positioned

against the axle utilizing a clear space that is free

from axle-mounted components and/or utilities.

8

Lifting is complete once the TrestleJack is in the

upright position, the cup is holding the axle securely in

place and the base plate is level to the ground surface.

Illustration B

Illustration B

4

Move any wiring out of the way that could

potentially be damaged during the lifting process

9

Releasing the brakes will in most cases cause the

TrestleJacks to settle in the correct upright standing &

supporting position.

5

The driver of the vehicle must ensure that there

are no persons within 10 meters from the trailer

axles or any person underneath the trailer

10

Apply park brakes, switch off ignition, apply trailer

brakes, chock the wheels and lower the trailer stands.

All persons must keep clear of at least 5 meters from the vehicle once the TJ220ADJ unit is secured and

before axle lifting procedure starts.

IMPORTANT: Engage park brakes, switch off ignition, apply trailer brakes, chock the wheels and lower

the trailer stands (where appropriate) to ensure no further rig movement is possible while repairs are

taking place.

5

Lowering process

1

After all repairs have been done and the wheel is

replaced and secured, the lowering process is ready

to begin.

5

The trailer wheels will take over the load and the

TrestleJacks will be released from the axle after about

200mm of forward movement.

2

Ensure that no person is underneath or near the

vehicle within a 5m range from the trailer axles.

6

Immediately bring the rig to a halt once the TrestleJacks

have been released from the axle or a distance of

200mm has been covered.

3

Release trailer brakes (where appropriate), remove

wheel chocks, switch on ignition and release park

brakes.

7

Apply park brakes, switch off tractor engine, chock the

wheels and apply the trailer brakes before removing the

TrestleJacks from underneath the trailer.

4

Drive the vehicle forward slowly and the lowering

process will begin.

Stop immediately after driving forward for 200mm. Remove the TrestleJack before

continuing driving. During the lowering process do not drive further than 400mm to ensure

none of the TrestleJacks used are causing any obstruction that may result in damage to

equipment.

During lifting and lowering procedures, no person is allowed underneath the trailer or within 5m from

the TJ Mini. The driver is required to be in the towing vehicle. The TrestleJacks’ base plate covers more

ground surface area than a single tyre, providing trusted stability. The axle cup holds the axle securely

in place. The product design provides a safe upright stand as the axle moves over the top dead center

and no other lifting support is required in normal working conditions.

Limited Warranty:

TrestleJacks warrants this product against defects in workmanship for one year from the date of purchase. During this

warranty period, this product will be repaired or replaced, at Trestle Jacks Pty Ltd discretion, without charge. Please read your

instructions thoroughly and use this product only as directed.

This warranty does not cover any damage due to accidental misuse, abuse or negligence. Repair or replacement as provided

under this warranty is the exclusive remedy of the consumer. Seller shall not be liable for any incidental or consequential

damage for breach of any expressed or implied warranty of merchantability or fitness for a particular purpose on this product

is limited to the duration of the warranty.

Table of contents

Popular Jack manuals by other brands

URIAH

URIAH UC200020 quick start guide

Berger & Schroter

Berger & Schroter 20292 Operation manual

Sealey

Sealey 3000HL instructions

TQ Pro

TQ Pro PROBJ30TA owner's manual

HEIN-WERNER AUTOMOTIVE

HEIN-WERNER AUTOMOTIVE HW93659 Operating instructions & parts manual

Tronair

Tronair 02-7813C0100 Operation & service manual