Instinct

Condensate Pan Replacement

7

jacket panel.

2. Push and twist the ue tube into the ue tube seat.

Ensure the rubber seal is in place in the ue tube

seat. Orient the ue tube so that the ue sensor is

facing forward.

3. Ensure the rubber seal is in place in the top of the

ue tube. Reinstall the vent outlet adapter, pushing

it down rmly to secure it to the ue tube.

WARNING

!

Ensure the gasket is in place before reassembly. Fail-

ure to do so can result death, serious injury or sub-

stantial property damage.

4. Reinstall the four screws to secure the vent adapter.

WARNING

!

Ensure the screws are in firmly installed prior to start-

ing the boiler. Failure to do so can result death, seri-

ous injury or substantial property damage.

5. Reconnect the vent piping to the vent outlet

adapter. Tighten the banding clamp with a at-

head screwdriver to secure the vent piping to the

adapter.

WARNING

!

Ensure the venting is tight and secure prior to start up.

Failure to do so can result death, serious injury or sub-

stantial property damage.

6. Reinstall the ue temperature sensor by pushing it

into the rubber boot.

7. Plug in the molex plug into the ue sensor.

11a. Installation of Condensate Trap (Combi Models)

1. Install the retaining nut and both seals onto the

drain nipple. See Fig. 10.

2. Push the condensate trap onto the condensate

nipple as far as it will go.

3. Tighten the retaining nut to the condensate trap to

secure the condensate trap.

4. Pull the condensate drain hose out the bottom of

the boiler.

5. Install the access panel and tighten the three Phil-

lips screw.

11b. Installation of Condensate Trap (Solo Models)

1. Push the retaining nut and both seals onto the

drain nipple. See Fig. 10.

2. Push the condensate trap onto the drain nipple as

far as it will go.

3. Tighten the retaining nut to the condensate trap to

secure the condensate trap.

4. Pinch and install the retention clip to secure the

condensate trap.

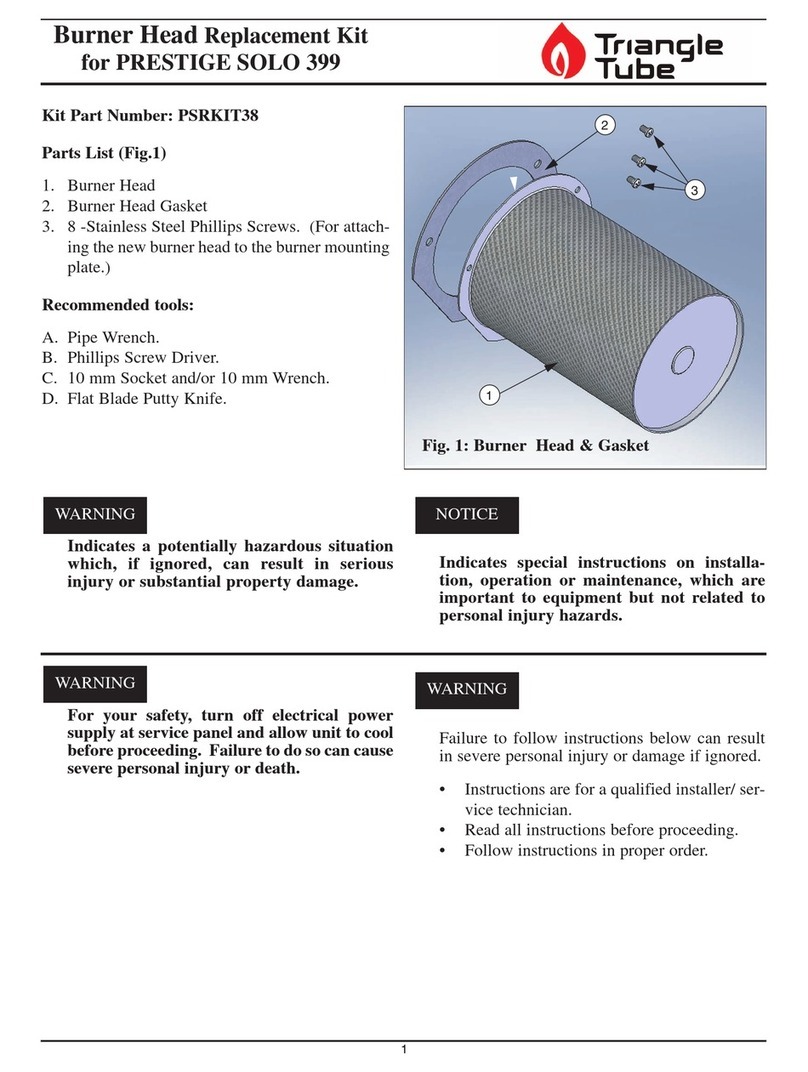

12. Install Burner Assembly

1. Align the burner/combustion chamber insulation

with the gas valve facing the front of the boiler. See

Fig. 1, Fig. 2, Fig. 3.

2. Align the bolt holes in the insulation and burner

mounting plate. Carefully install the assembly into

the heat exchanger, pushing the heat exchanger

studs through the bolt holes.

WARNING

!

Ensure the burner/gas valve/igniter are not damaged.

Contact Triangle Tube right away if any item is dam-

aged in any way.

3. Reinstall the burner plate nuts. Make all nuts hand

tight. Once all nuts are nger tight, torque all nuts

to 44-53 in-lbs in a star pattern.

4. Place the blower gasket in place onto the burner

mounting plate.

5. Place the blower/venturi assembly onto the mount-

ing plate by sliding the two slotted holes onto the

two partially installed bolts. Tighten all four 8mm