Burner Head Replacement Kit

for PRESTIGE 60 through 250

3

Do not over tighten. Pinching or tearing of the

burner plate gasket may occur causing the

possible escape of combustion gases from the

combustion chamber resulting in death, seri-

ous injury or substantial property damage.

12. Re-attach the ignition cable and the ground

wire to the ignitor.

13. Reconnect the gas valve rectifier plug.

14. Reconnect and tighten the brass gas pipe

union before placing the PRESTIGE unit

back into operation.

15. Turn on gas supply to the inlet of the unit at

the main manual shutoff valve to the unit.

Check and test all gas connections for leaks.

Repair leaks if found.

Do not check for gas leaks with an open flame.

Use a bubble test. Failure to check for gas

leaks can cause severe personal injury, death

or substantial property damage.

16. Turn power to the unit “ N”. The unit is

now ready to be placed back into service.

17. It is recommended that the installer per-

forms a complete combustion test to ensure

the combustion levels, in table 1 on page 4.

are met at high input and the burner is oper-

ating at optimum conditions.

The combustion testing and adjustments

must be performed by a qualified installer,

service agency or the gas supplier. All com-

bustion measurements must be perform with

calibrated equipment to ensure proper read-

ings and accuracy.

Failure to perform a complete combustion

test at high input rate may result in incom-

plete combustion and the production of car-

bon monoxide, which can cause severe per-

sonal injury, death or substantial property

damage.

18. Manually place the boiler into high fire mode

by pressing the M DE button with “+” button

simultaneously on the control panel display

while in the standby (STBY) mode.

The control panel will display an H followed

by the current boiler temperature when

placed into high fire test mode.

If the combustion levels during high fire is outside

the recommended combustion settings adjust the

THR TTLE SCREW (see Fig. 3) as follows:

Counter-clockwise adjustment of the throttle

screw at high fire:

2decreases and C02increases

Clockwise adjustment of the throttle screw at

high fire:

2increases and C 2decreases

19. Reinstall Top jacket panel and front door.

WARNING

N TICE

WARNING

WARNING

WARNING

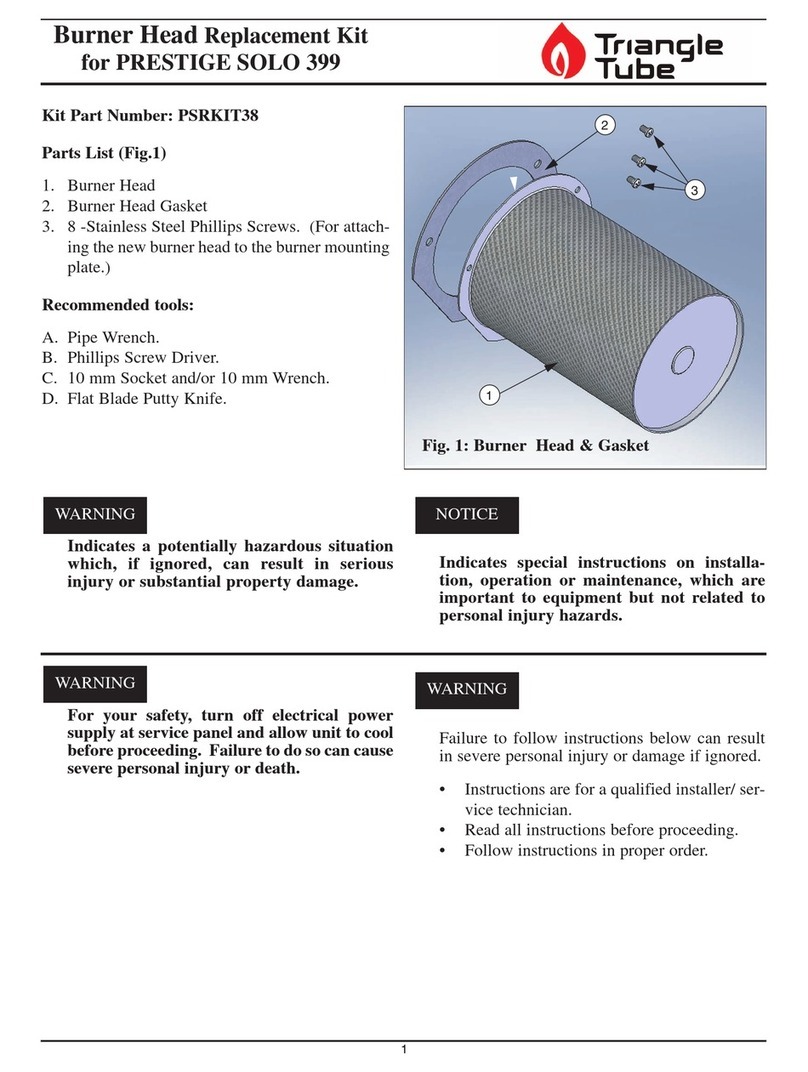

Fig. 3: Combustion Adjustment - Prestige Burner