CHALLENGER

Natural Gas to Propane Instructions

4

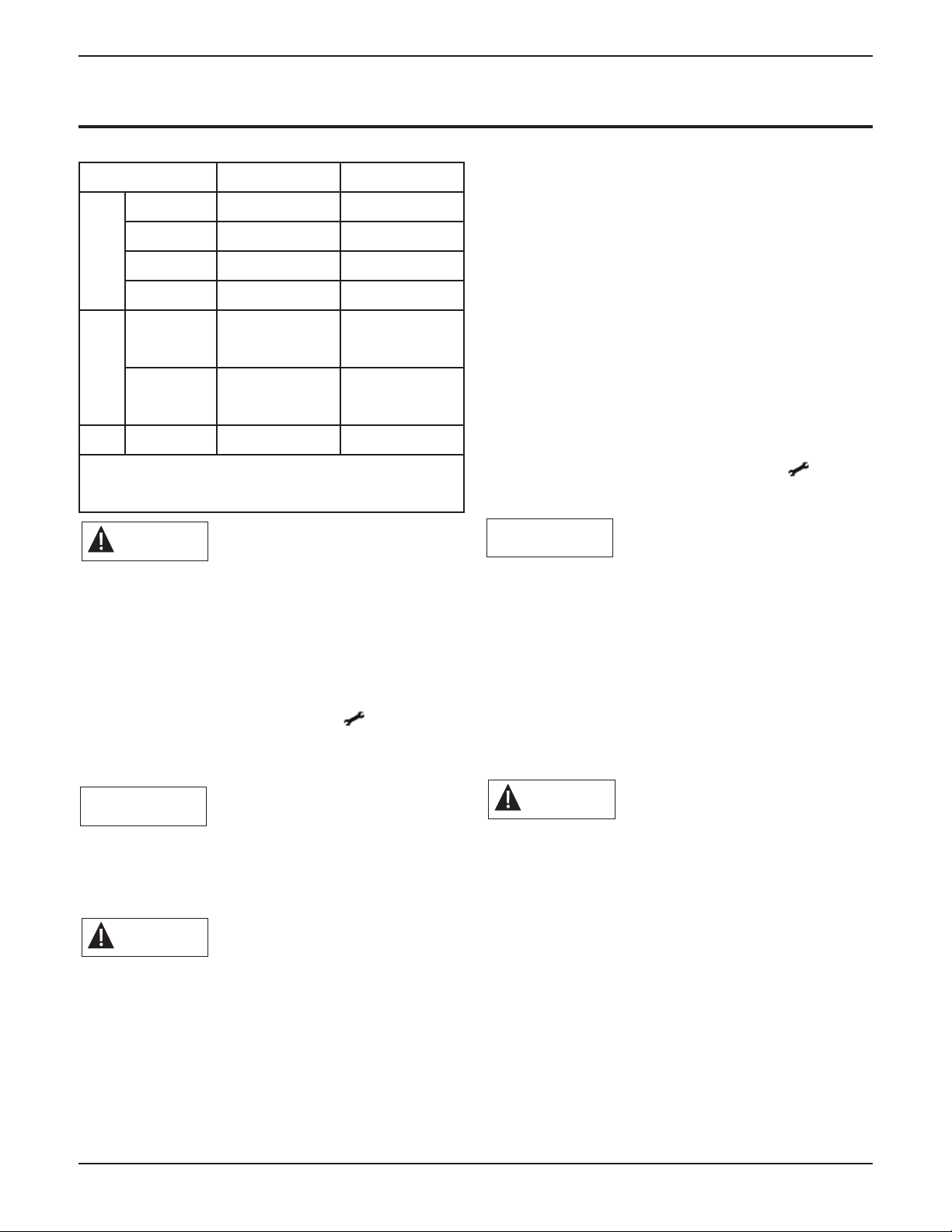

Table 2: Recommended Combustion Levels

Failure to perform a complete combustion test at both

high and low input rates may result in incomplete combus-

tion and the production of carbon monoxide, which can

cause severe personal injury, death or substantial property

damage.

2. Manually place the appliance into high fire mode by

pressing both the service button “ ” with “+” but-

ton simultaneously on the control panel display two

times.

The control panel will display a H followed by the current

appliance temperature when placed into high fire test

mode.

The THROTTLE SCRE on the CHALLENGER’s gas valve

works opposite than the PRESTIGE. If you turn the

CHALLENGER’s throttle screw clockwise you increase the

input, CO2and CO of the appliance. EXERCISE CARE!

3. f the combustion levels during high fire are outside

the recommended combustion settings adjust the

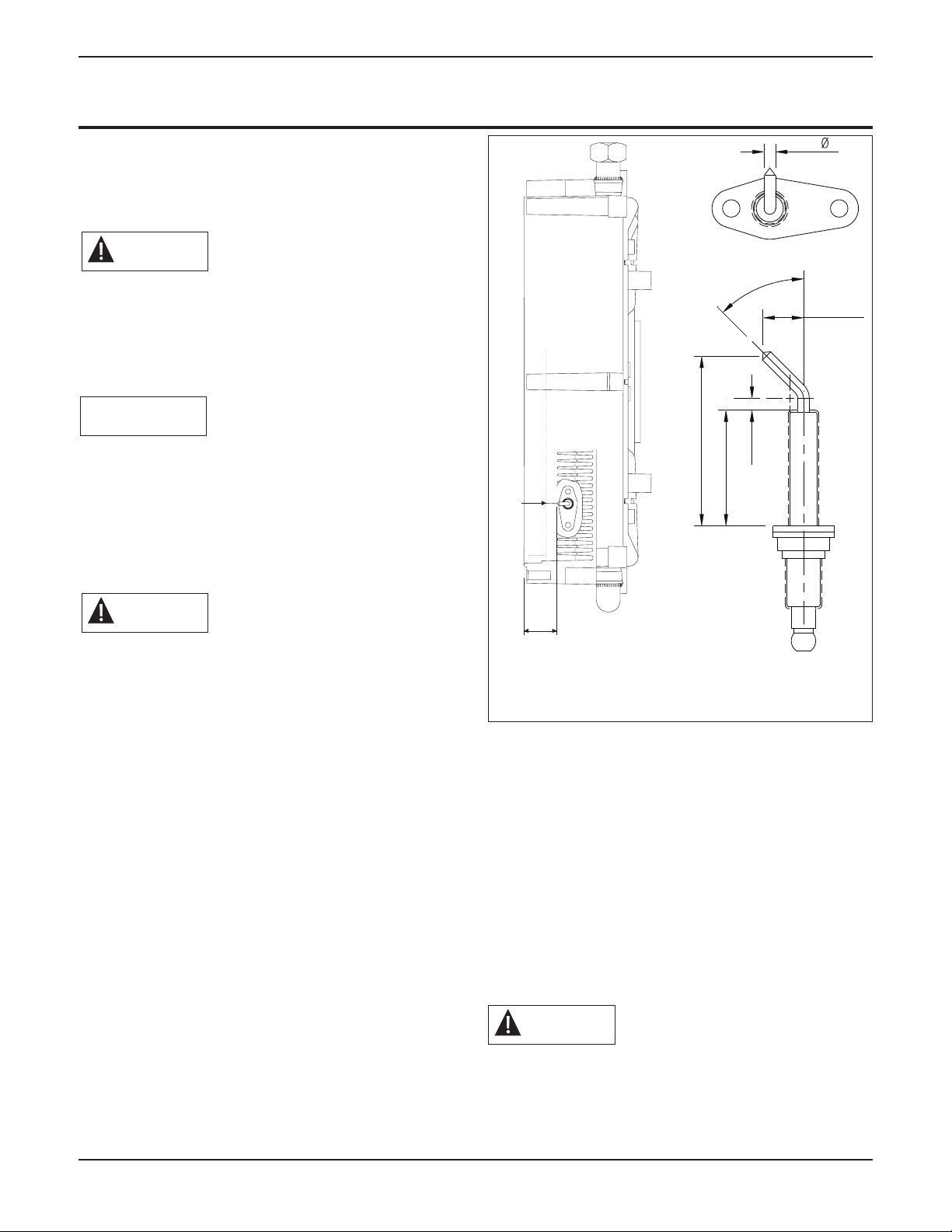

THROTTLE SCREW (see Figs. 3 & 4 on page 5)

using a T15 Torx wrench as follows:

Counter-clockwise adjustment of the THROTTLE

SCREW at High Fire:

O2 increases and CO2 decreases

Clockwise adjustment of the THROTTLE SCREW

at High Fire:

O2 decreases and CO2 increases

4. Once the combustion level is set and recorded at

high fire, manually place the appliance into low fire

mode by pressing the service button “ ” with “-”

button simultaneously on the control display once.

The control panel will display a L followed by the current

appliance temperature when placed into low fire test

mode.

5. f the combustion levels during low fire are not within

0.0 to 0.4% CO2 lower than the combustion level

measured at high fire, remove the offset pressure

cover screw and adjust the OFFSET SCREW using

a T15 Torx wrench as follows (see Figs. 3 & 4 on

page 5):

The OFFSET SCRE adjustment on the CHALLENGER’S gas

valve is very sensitive. A small adjustment will have a sig-

nificant effect.

Counter-clockwise adjustment of the OFFSET

SCREW at Low Fire:

O2increases and CO2 decreases

Clockwise adjustment of the OFFSET SCREW at

Low Fire:

O2decreases and CO2 increases

NOTICE

WARNING

NOTICE

WARNING

WARNING

Combustion Levels Natural Gas Propane Gas

High Fire

DOOR OFF*

CO2Range 9% to 10.1% 10.5% to 11.1%

CO2Target 9.0% 10.8%

O2Range 3.0% - 5.0% 4.1% - 5.0%

O2Target 5.0% 4.5%

Low Fire

CO2Range 0% - 0.4% < H.F

9.0% min.

0% - 0.4% < H.F

10.5% min.

O2Range 0% - 0.6% > H.F

5.0% max.

0% - 0.6% > H.F

5.0% max.

CO Max. 100 ppm 150 ppm

* Door On can raise the maximum allowable CO2by

0.4 or lower the minimum allowable 02by 0.6.