Tricel Vitae UK6 User manual

1

206 Rev 3 Jan 2019

Tricel® Vitae UK6

Wastewater Treatment Plants

Engineering a green future

2

Contents

1Health & safety precautions ......................................................................................................4

1.1 General..............................................................................................................................4

1.2 Electrical maintenance......................................................................................................4

1.3Installation ........................................................................................................................ 5

2Introduction: Tricel Vitae...........................................................................................................6

2.1 The Wastewater purification process................................................................................6

Stage 1: Buffer chamber ................................................................................................6

Stage 2: Aeration (treatment) chamber.........................................................................6

3Tricel Vitae specification...........................................................................................................7

3.1 Dimensions .......................................................................................................................7

3.2 Tank drawing.....................................................................................................................8

4Transportation & lifting.............................................................................................................9

4.1 Transportation .................................................................................................................. 9

4.2 Lifting................................................................................................................................9

5

Installation

.............................................................................................................................11

5.1 Installation planning .......................................................................................................11

5.2 Inspection on reception of tanks.....................................................................................12

5.3 Positioning and precautions............................................................................................12

5.4 Types of installation........................................................................................................12

5.5 Installation procedure: Tricel Tanks................................................................................13

Excavation (dry & wet sites): .......................................................................................13

Step by step – installation procedure ..........................................................................15

5.6 Gravel specification ........................................................................................................16

5.7 Concrete specification ....................................................................................................17

5.8 Topsoil requirements......................................................................................................17

5.9 Electrical requirements...................................................................................................17

5.10 Risers ..............................................................................................................................18

5.11 Non-standard ..................................................................................................................18

Alternative to concrete backfill (for wet sites without risers only):

...................18

Sloping ground: .......................................................................................................19

Proximity to rolling & static loads: ..........................................................................19

5.12 Additional accessories ....................................................................................................20

Grease trap ..............................................................................................................20

Sampling chamber...................................................................................................20

6Capsule installation.................................................................................................................21

3

7Commissioning ........................................................................................................................21

7.1 Control panel start-up.....................................................................................................22

7.2 Operation of the control panel........................................................................................24

Basic screen display.....................................................................................................24

Start-up phase ‘Start 150%.’.......................................................................................25

8Disposal of treated water ........................................................................................................26

9Maintenance ............................................................................................................................26

9.1 Regular maintenance ......................................................................................................26

9.2 Annual maintenance........................................................................................................26

9.3 Annual service(available from your supplier) .................................................................27

9.4 Production of sludge .......................................................................................................27

9.5 Desludging (emptying the solid waste from the primarychamber) ................................27

10 Operating conditions ..........................................................................................................28

11 Troubleshooting..................................................................................................................30

11.1 Odours.............................................................................................................................31

12 Certification........................................................................................................................32

12.1 Declaration of performance ............................................................................................32

13 Terms & conditions .............................................................................................................36

4

1Health & safety precautions

Reading the full technical manual prior to installation is important. Retain this document for the

lifetime of the product and in the event of a change of ownership of the site, transfer to the new

owner.

As health and safety are of vital importance, the following aspects are critical:

Precaution

Prior to installing, please consider the finished garden level. If you envisage that a

manholeriser/extensionmay be requiredto ensure manholecover remainsabove finished

ground level, the plant must be installed with the appropriateexcavationfoundationand

backfilltoaccommodatethe riser. Please refer to section 5.10, ‘Risers.’

1.1

General

•

It is important that all of the information contained in this manual be adhered to at

all times.

•

Treatedwastewaterisnotsuitableforhumanconsumption.

•

It is importantthatlocksbefittedto the manhole cover to preventaccidental access.

•

Manholes are ratedto125kgand are for pedestrianuseonly.

•

Neverenteratankunless qualifiedtodoso.

•

Do not use naked flames in the vicinityof the tank due tothe danger of combustion.

•

The manhole covers shall never be left off of an unattended tank. Always lock the

covers of the plant when work gets completed.

•

Sewage and sewage effluent can carry micro-organisms and gases harmful to human

health. Any person carrying out work on the

Vitae

must be appropriately trained.

•

Suitable protective clothing; including gloves, goggles should be worn at all times.

Always remove contaminated clothing and protective equipment after working with

sewage treatment plants.Wash handsand face prior to eating, drinkingorsmoking.

•

Lock all manhole covers for safety. Tanks are supplied with three locking points, as

shown below. All points should be locked with a suitable locking device to prevent

unauthorised access. Locks do not come supplied.

1.2

Electrical maintenance

•

All electrical work is to be carried out by a qualified electrician using suitable

materials for the application.

•Do not open the Tricel Vitae’s electrical unit cover without firstly isolating the mains

power.

•

Electrical work must be carried out strictly to the manufacturer’s instructions and to

the relevant national rules for electrical installations.

•

When working with machinery/electrical equipment, the proximity of water shall be

noted. Electrical equipmentshall not be wet when working with it.

•

There is the potential danger of falling into the tank during desludging while manholes

may be open – take all necessary safety precautions when desludging.

5

1.3

Installation

•

Plan excavationworkwithdueregardtohealth andsafetyrequirements.

•

Excavated material should either beshored or battenedbackto a“safe”angle.

•

Use appropriate liftingequipment.

•

Take carearoundgroundsworkmachinery.

•

Keepproper footing and balance at all time.

•

It is necessary to vent the Tricel Vitae at the inlet and the outlet of the plant.

6

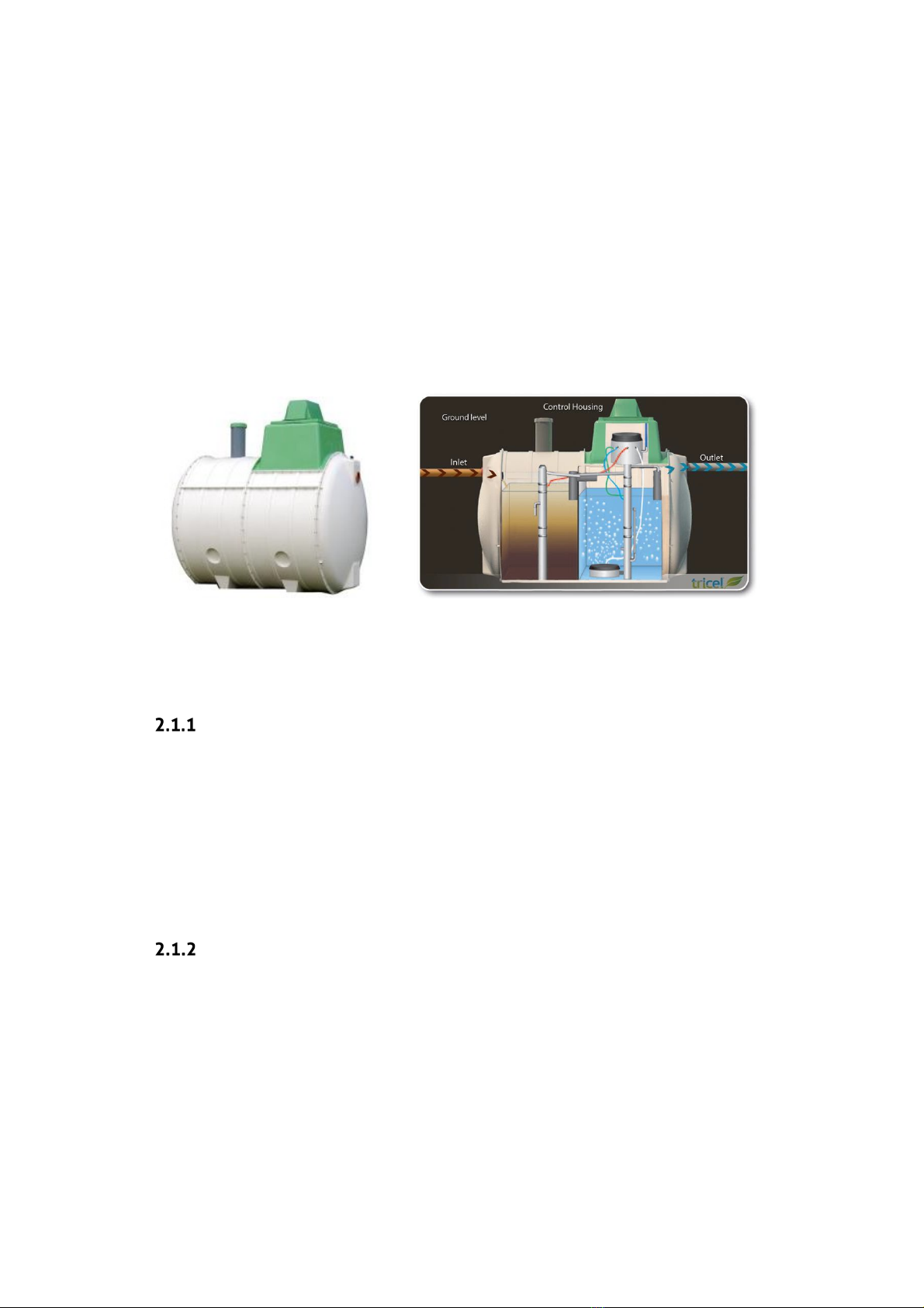

2Introduction: Tricel Vitae

Tricel Vitae wastewater treatment plants are manufactured from sheet moulding compound (SMC)

ensuring a durable and high-strength product. They are also constructed from modular

components; these modules are then fabricated together to make different size tanks.

The Tricel Vitae is suitable for domestic and light commercial applications and is a sequential batch

reactor (SBR). There are two zones in the SBR treatment system. The first is a buffer zone where the

wastewater gets stored. From here it is carried into the second zone for treatment in batches.

Wastewater is then treated for a set amount of time, after which it is expelled from the tank. As the

treatment is for a fixed amount of time in each batch, the water emitted from the tank is to the

highest quality standard even in times of high usage

.

2.1

The Wastewater purification process

Stage 1: Buffer chamber

The buffer chamber acts primarily as a storage zone to hold the wastewater until it is ready to be

treated. This ensures that even in times of low usage there is a constant supply of wastewater to

feed the bacteria. While being stored the heavy solids settle to the bottom of the tank and the light

particles, like fats or oils, float to the top of the water to create a scum. An airlift pump takes

wastewater from the buffer chamber to the aeration chamber in batches at the beginning of the

aeration cycle. The airlifter is designed to ensure that only the wastewater from the centre of the

chamber gets transferred into the aeration chamber.

Stage 2: Aeration (treatment) chamber

This stage of the process takes place in the second chamber where submerged aeration combines

the principles of the biofilm and activated sludge processes. Masses of naturally occurring bacteria

form in clumps at the bottom of the chamber. These bacteria get sustained with air delivered by

means of an aerator at the bottom of the tank which turns on intermittently throughout the cycle.

After the aeration takes place, there is a settling phase in which the aerator is turned off for 1.5 -2

hours. This process allows for the solids and the bacteria to settle to the bottom of the chamber. As

a result, the water above is cleared of any solid particles before it gets expelled from the tank.

7

During the settlement phase, the batch of liquid is kept in this chamber for a set amount of time

and then expelled from the tank using the clearwater lifter. Simultaneously, the excess sludge

lifter recirculates the excess sludge from the tank back to the primary chamber. Doing so ensures

that there is a constant level of sludge in the primary chamber to feed into the aerated zone.

The clearwater enters the sampling pot before leaving the tank. Doing so allows for the water to

get tested for purity. The remaining treated liquid now meets the required standard to be safely

passed out of the Tricel Vitae unit.

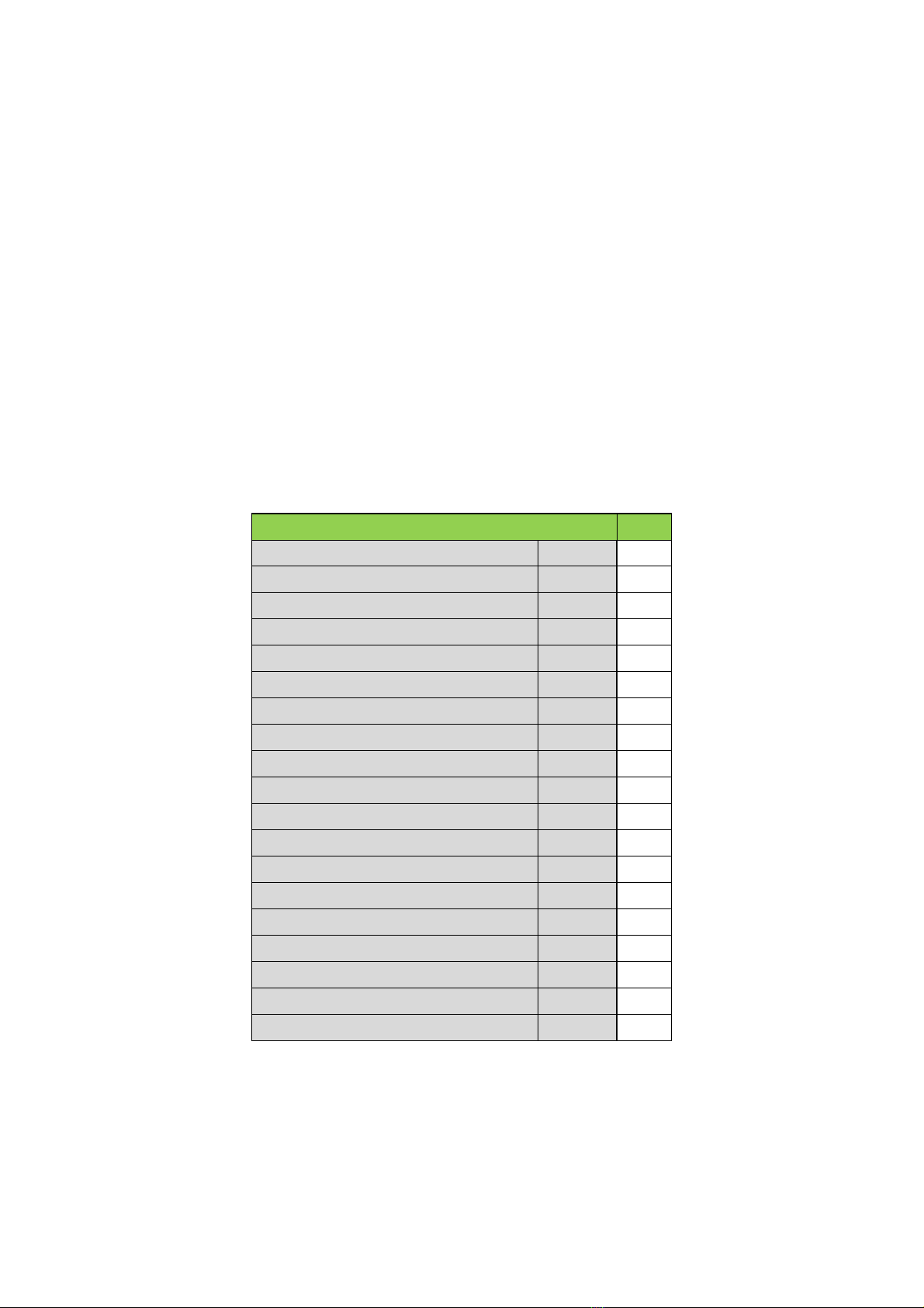

3Tricel Vitae specification

3.1

Dimensions

Tricel Vitae: certified to EN 12566-3:2005

Tricel Vitae

UK6

Maximum treatment capacity

PE

6

Design flow rate (max)

litres/day

900

BOD load (max)

kg/day

0.36

Primary chamber volume

litres

2630

Nominal Inlet pipe diameter

mm

110

Nominal Outlet pipe diameter

mm

110

Overall length

m

2.6

Overall width

m

1.64

Overall height

m

2.24

Inlet invert to base

m

1.4

Outlet invert to base

m

1.3

Inlet invert to ground level

m

0.51

Outlet invert to ground level

m

0.61

Weight empty**

kg

300

No. of persons

1-6

Air blower rating (mean)

W

86

Thickness (minimum)

mm

5

Desludge period (minimum)***

year

1.5 – 3

No. of Diffusers

Units

1

** Allow 100kg extra for lifting purposes

*** Depending on use & design value

8

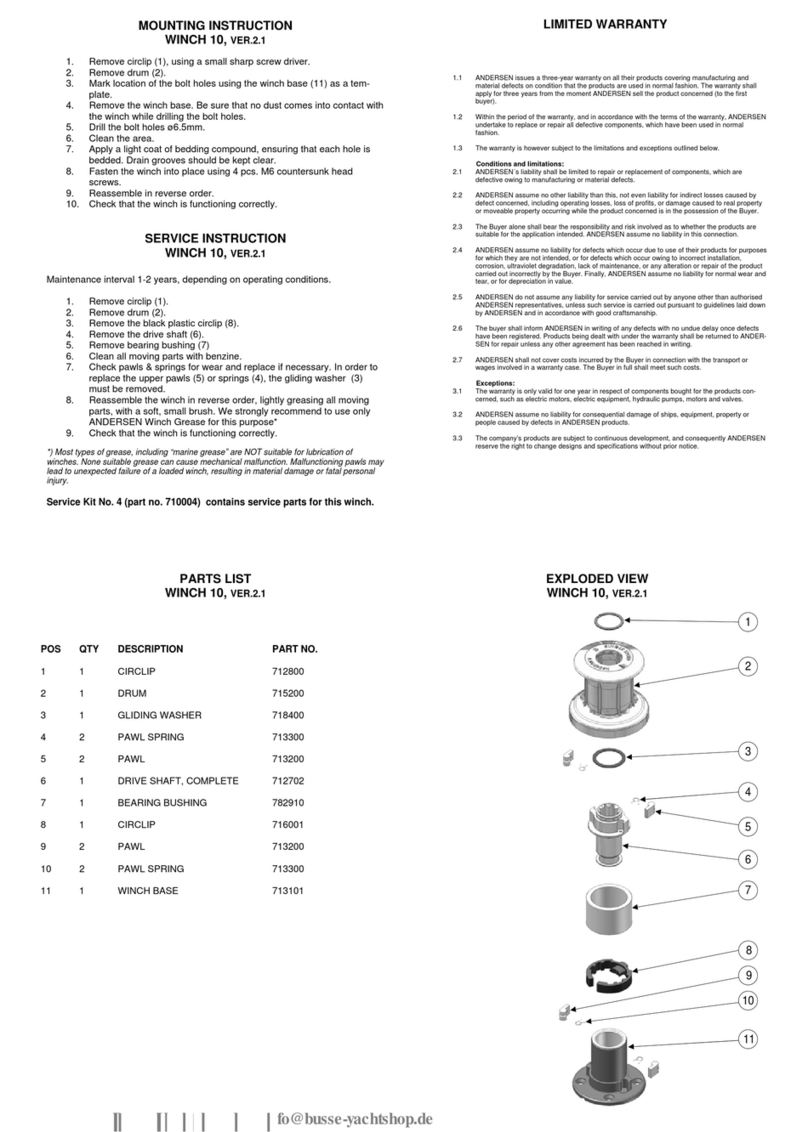

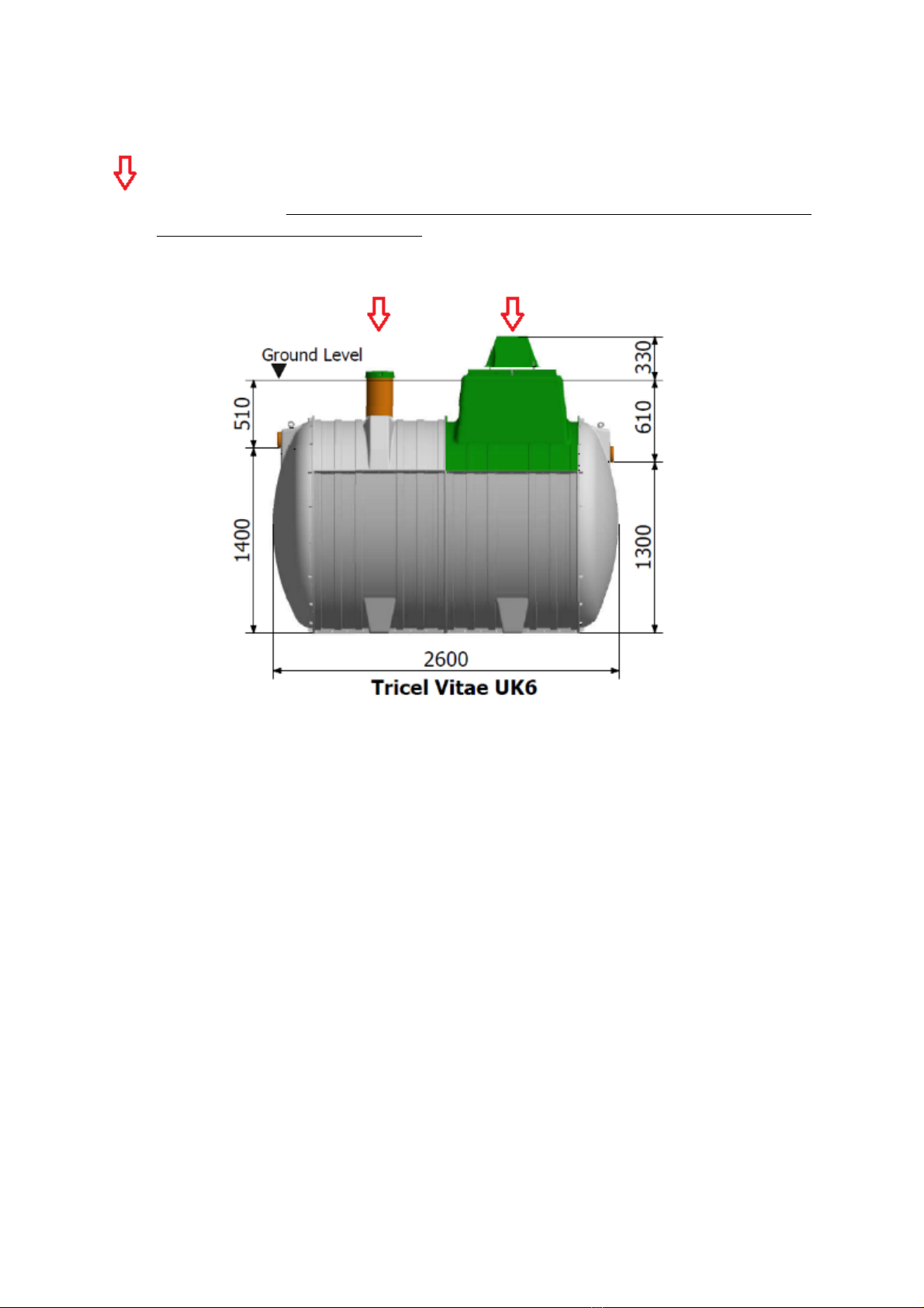

3.2

Tank drawing

The arrow indicates an access point which must be opened to facilitate the desludging of the

primary chamber. However, do not desludge the reactor/aeration chamber as this will affect

the treatment efficiency of the plant.

WARNING: care must be taken not to damage pipework when desludging the tank

9

4Transportation & lifting

4.1

Transportation

•

Tanks must be held down during transportation using nylon straps, do not use cables or

chains to secure tanks. Do not over tighten straps that can result in deformation of the

tank shell. Do not drop or roll tanks from the truck.

•

Move tanks only by lifting and setting, do not drag or roll.

•

Always set the tank(s) on flat, smooth ground clear of debris. In order to prevent

movement, tanks may need to be tied down and chocked. Position the chocks in the

locations shown below:

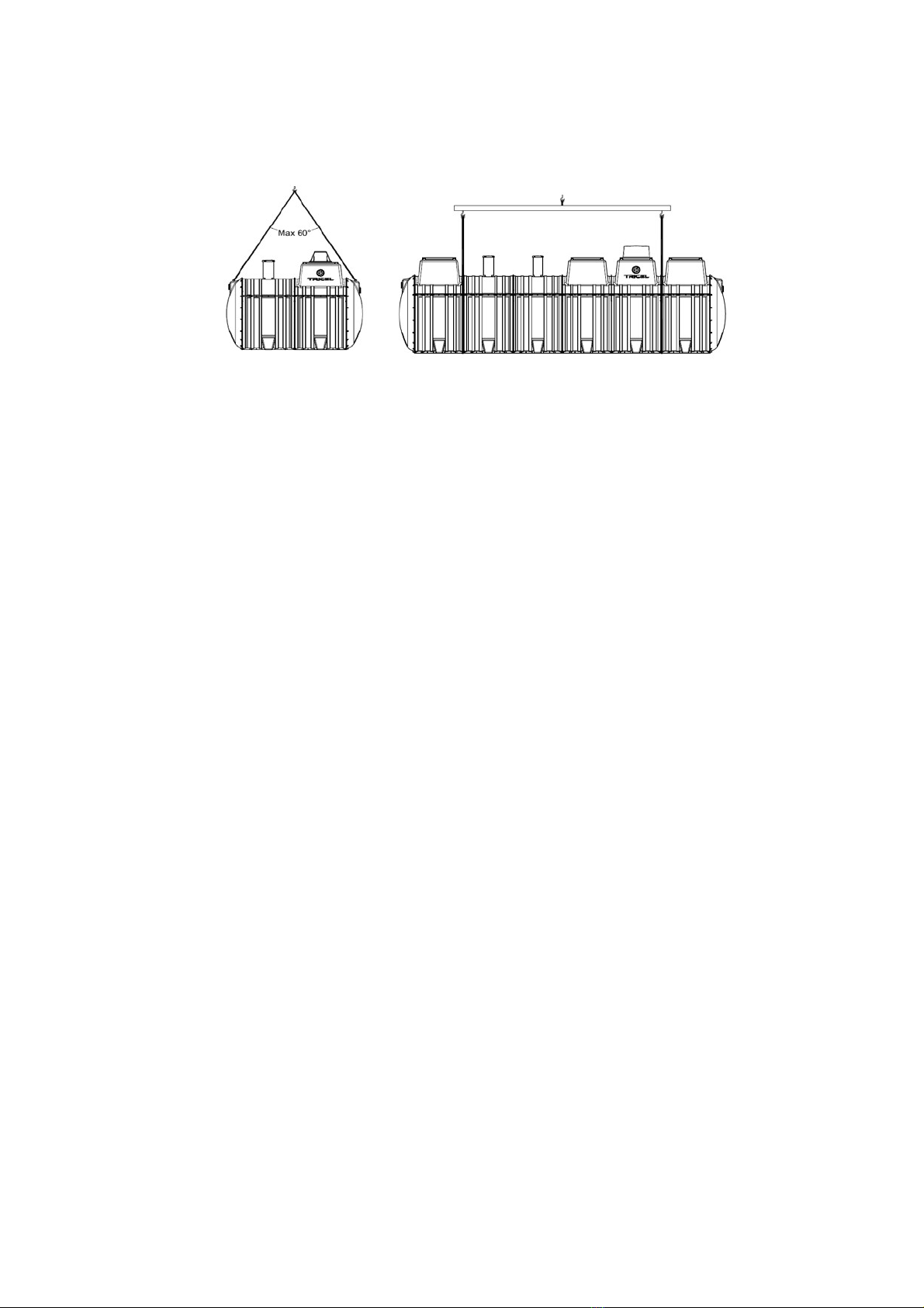

4.2

Lifting

•

A machine and webbing lifting straps best lift tanks – do not use chains or wire ropes in

contact with the tank.

•

Ensure tank is empty when lifting.

•

Tanks from one to four modules (4.6m) in length should be lifted using the eyebolts on

the tank. Ensure the angle between the slings is not greater than 60o when lifting the

tank. In order to ensure the angle is not greater than 60o the following sling lengths

are required:

Length of tank

Minimum length of the

sling

2.1

2.1

2.6

2.6

3.1

3.1

3.6

3.6

4.6

4.6

10

Ensure sufficient lifting height can be achieved and is available on site. If not a lifting bar, as per

option two below, is required.

Option 1 Option 2

11

5

Installation

5.1

Installation planning

Important

Before the installation of the Tricel Vitae, it is important to read these instructions carefully.

•When planning the installation of a Tricel Vitae, you must consider the following:

Backfill considerations:

oIs this a dry or wet site, i.e. the presence of a water table?

oWhich backfill material is appropriate for this site?

oWhat will the finished ground level be and will risers be required?

Site considerations:

oIs the site restricted regarding area or height?

oWhat is the topography of the site, i.e. being it sloping or flat?

oWhat is the proposed depth of the installed tank to ensure the required slope

upstream?

oAre static or rolling loads present on this site?

•Only suitably qualified personnel should install the Tricel Vitae.

•

Suitably sized equipment will be required to excavate the hole and to lift the

Tricel

Vitae

into place.

12

5.2

Inspection on reception of tanks

•

Visually inspect tanks for damage or fractures to the shell or ribs, de-laminations,

scratches, or abrasions deeper than 1.5mm, which may have occurredduringtransport,

prior to installation.Notify the delivery driver and/or your supplier of any found.Do not

attempt to carry out any unauthorisedrepairs, as this will invalidate the warrantyon the

tank.

•

Onceinstalled,Tricelcannotacceptanyclaimsfordamage to the tank.

5.3

Positioning and precautions

•The Tricel Vitae should not get installed in an area subject to flooding or excessive water

runoff as no flood waters should enter the tank.

•The area around the Tricel Vitae should be adequately drained to permanently remove

groundwater and surface water from proximity to the tank.

•The Tricel Vitae is not suitable to be used in water-logged sites where the groundwater

may rise above the inlet pipe.

•When selecting the location of the Tricel Vitae, ensure that it is always accessible for future

maintenance.

•The Tricel Vitae must be vented at the outlet and the inlet of the plant.

5.4

Types of installation

All installations must be “fit for purpose” to suit the on-site conditions, which will vary from site

to site. Ensuring this is the responsibility of the on-site contractor.

When installing a Tricel Vitae, there are two types of standard installation methods:

1. Gravel installation

2. Concrete installation

It is essential to consider two factors when determining which installation must be implemented:

1. Is the Tricel Vitae being installed in a ‘dry site’ or a ‘wet site’?

•A ‘dry site’ is a site in which the water table never rises higher than the base of

the tank.

•A ‘wet site’ is a site in which the water table may rise higher than the base of

the tank but will not climb higher than the invert of the inlet. Where a higher

water level is present on site, ensure that the installation is suitable for the site

conditions.

Tricel

strongly advises the installation of a vertical water table inspection pipe.

This inspection pipe will facilitate convenient monitoring of the water table

long after the installation is complete.

Note: In difficult soils (e.g., clay with a high t-value), a site could be potentially

classified as wet if there is no drainage for surface water that enters the

13

excavation and it rises higher than the base of the tank. The installer must

determine this when selecting the correct backfill.

2. Is a riser required (inlet invert >510mm from ground level), and if yes, what height riser

is necessary? (For more information on risers, please refer to section 5.10, ‘Risers’).

The following table specifies the required installation for on-site conditions:

Factors that determine the required installation

Installation required

Type of site

Riser required

Dry

None

Gravel

Dry

250mm

Gravel

Dry

500mm & 750mm

Concrete

Wet

None

Concrete

Wet

250mm, 500mm & 750mm

Concrete

Important

•

Incorrectly installed tanks that are subject to movement, rotation, excessive loading

or floatation may become damaged, for which Tricel cannot accept liability.

•

During installation, tanks must not be subjected to buoyant forces.

•

Contact a qualified engineer if there are difficulties on site due to adverse

waterlogging.

•

Ballasting the tank is essential to avoid the tank from lifting when backfilling.

5.5

Installation procedure: Tricel Tanks

Excavation (dry & wet sites):

5.5.1.1

Excavation: length & width

Length and width of the excavation must exceed the dimensions of the

Tricel Vitae

by at least

500mm to maintain a minimum space of 250mm all around the tank.

Tricel Vitae UK6

Tank length (m) 2.6

Tank width (m) 1.64

Excavation size (L x W) (m) 3.1 x

2.14

Note: The size of the area for excavation applies to both dry and wet sites. However,

unstable

ground including regions with excessive sand, peat swamps, etc., may require larger

excavations.Theexcavation should be maintained dryby pumpingor whatever suitable means.

14

5.5.1.2

Excavation: depth

The inlet and outlet pipes determine the excavation depth, invert levels are relative to the

bottom of the tank and allowing for the minimum base thickness. Dimensiondetails of the tank

provided on the relevant drawing; please refer to section 3, ‘Tricel Vitae Specification.’ Ground

instability, e.g. running sand may necessitate over-excavation and stabilisationwith hard core

or blinding concrete. The standard depth of the excavation for both gravel and concrete

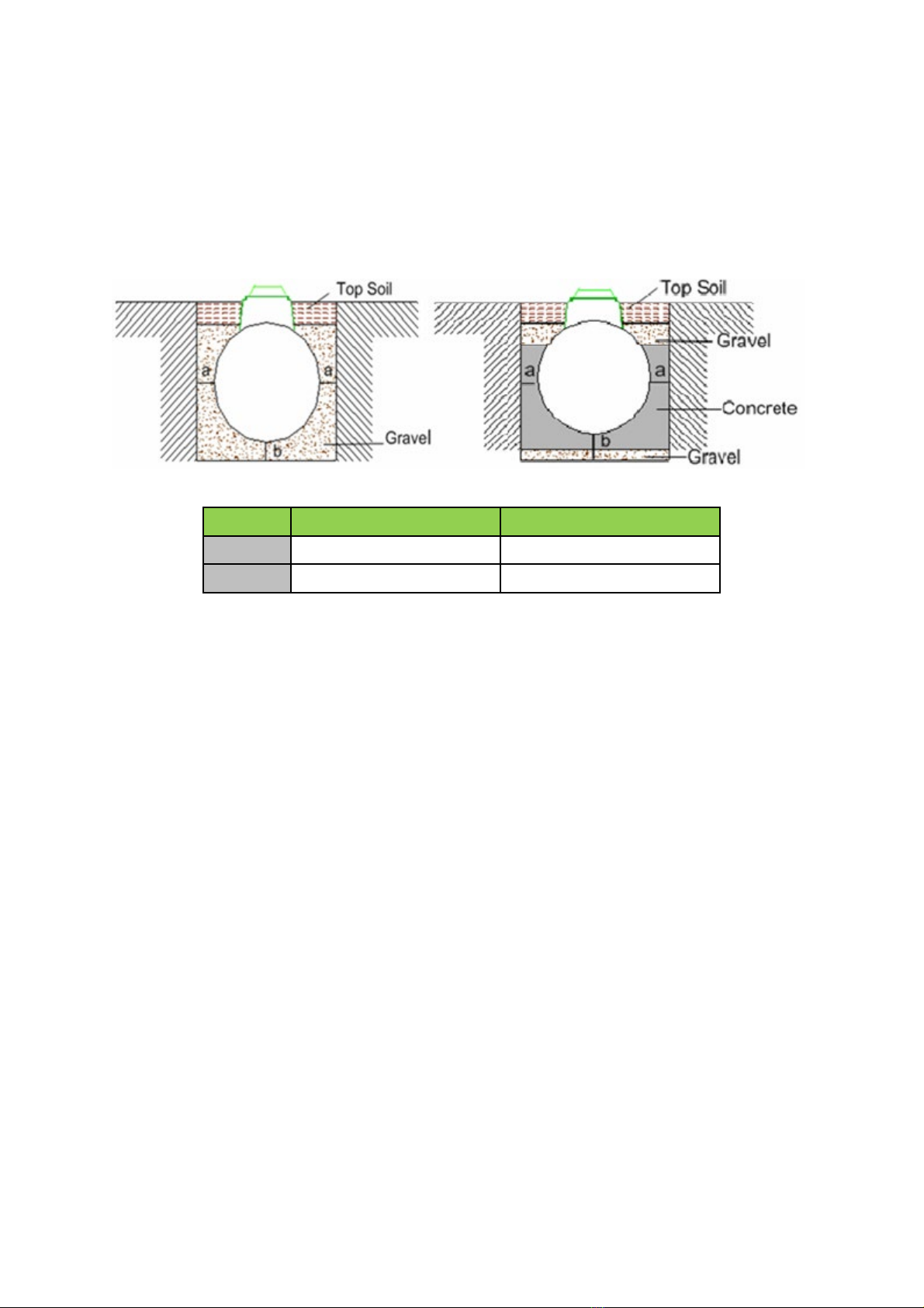

installations are outlined as follows:

“a” minimum (mm)

“b” minimum (mm)

Dry site

250

250

Wet site

250

300

15

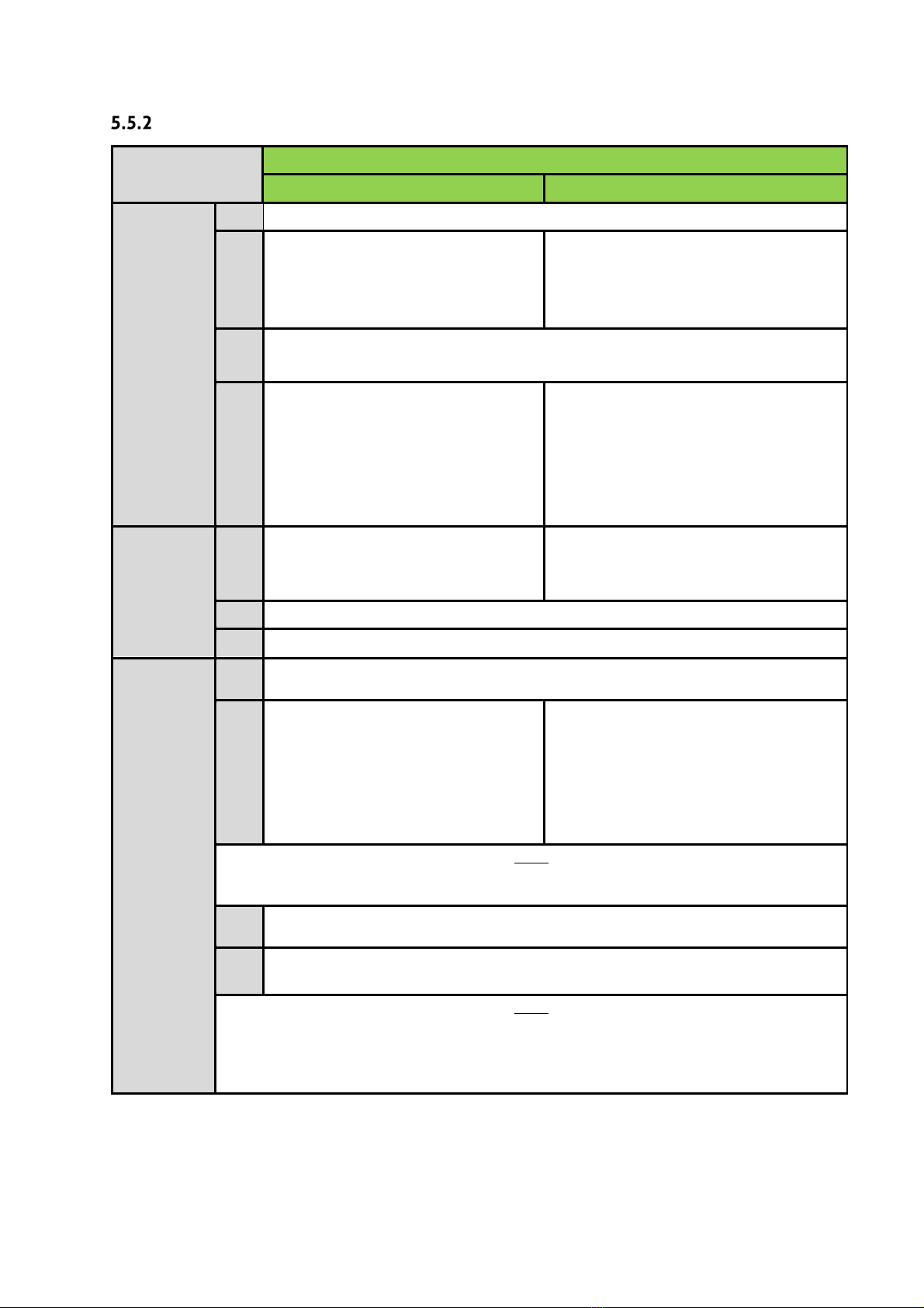

Step by step – installation procedure

Steps

Installation required (post-excavation)

Gravel

Concrete

Installation

of the tank

base:

1

Remove any soft spots or large stones and boulders.

2

The base is constructed of a 250mm

layer of suitably compacted gravel.

The base is constructed of a 50mm layer

of suitably compacted gravel, covered

with a 250mm layer of semi-dry

concrete.

3

Ensure that base is level and at the correct height to accommodate the

incoming pipework.

4

It is important to maintain a completely

dry excavation until the final pour of

concrete is set. It may be necessary to

line the excavation with a continuous

layer of 1200-gauge polythene to

maintain the integrity of the concrete.

How to

position the

tank on to

the base:

5

Mechanically lift the plant carefully

into the centre of the hole and place

on the prepared base.

Mechanically lift the plant carefully

into the centre of the hole.

6

The plant must sit level on the base.

7

Connect and seal the pipework to the tank.

Backfilling

around the

tank:

8

Ballast the plant by filling each chamber with clean water to a depth of 300mm

and recheck the pipework levels.

9

Commence backfilling with gravel in

layers of 225mm evenly around the

tank ensuring that there are no voids

until gravel has reached 50mm over

the cylindrical body of the tank.

Compact each layer in succession. *

Commence backfilling with concrete in

layers evenly around the tank, ensuring

that there are no voids until it has

reached the outlet invert. Continue

backfilling with gravel, until it has

reached 50mm over the cylindrical

body of the tank. *

Note

* Continue filling the chambers with water while backfilling, ensure that the rising

water level is no more than 300mm above the backfill level.

10

Mount and seal manhole risers (if required). Please refer to section 5.10,

‘Risers.’

11

Complete backfilling with topsoil up to the max ground level. Allow for

subsequent settlement of topsoil.

Note

The use of geotextile barrier fabrics over the gravel backfill is considered good

installation practice. The fabric must be chosen to allow the flow of water in and

out of the excavation but to prevent the movement of fine soil particles into the

gravel backfill.

16

5.6

Gravel specification

Primary backfill specification:

•

Primary backfill material should be free-flowing granular material.

•

Compaction should be by lightweight rollers or vibratory plate. Compact gravel evenly

to ensure proper support for the tank. Make sure the vibrating machine does not come

in contact with the shell of the tank.

•

Tanks installations require primary backfill only within the region immediately

surrounding the tanks. Thisbackfill must extend a minimum of250mmoutward fromthe

tank, and directlybeneaththe tank.

•Backfill material shall not be frozen or contain lumps of frozen material at any time during

installation.

•Use of other than specified backfill and bedding materials will void the tank warranty.

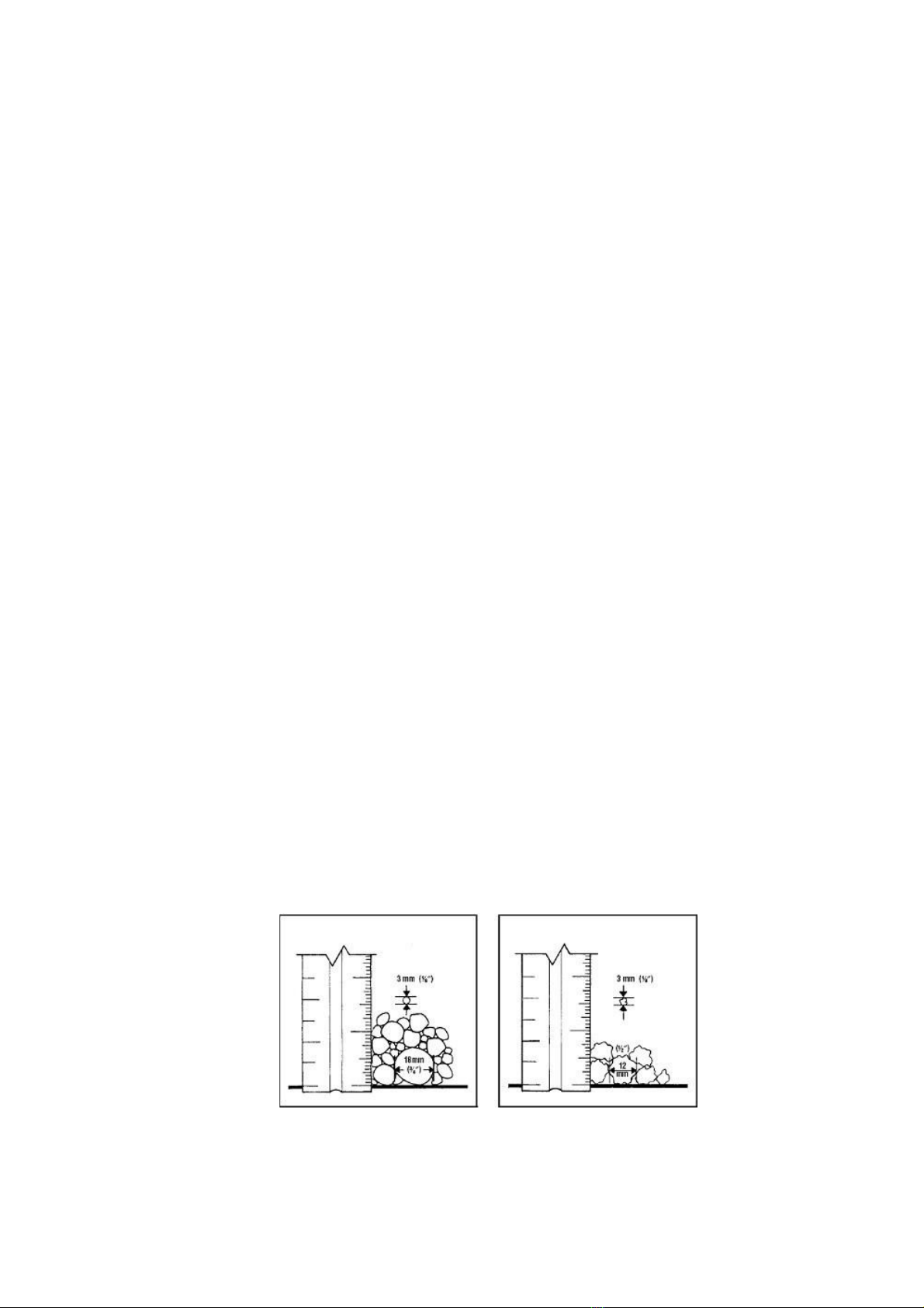

The following materials are approved as primary backfill:

Rounded pea gravel:

•

Minimum particle size 3mm, maximum 18 mm, compacted to a relative density of

>70%.

•

Gravel shall be clean and free flowing, free from large rocks, dirt, sand, roots, organic

materials or debris.

•

Upon screening analysis, the backfill material shall have no more than 5% by weight

passing 2.36 mmsieve.

Or

Crushed or processed stone:

•

Minimum particle size 3 mm, maximum 12 mm, compacted to a relative density of

>40%.

•Dry gravel density must be at least 1500 kg/m3. The material should be washed or screened

to remove fine particles.

•Upon screening analysis, the backfill material shall have no more than 5% by weight

passing a 2.36 mm sieve.

Pea Gravel Crushed Stone

17

5.7

Concrete specification

Semi dry concrete 25n grade with a ratio of 4.5 aggregate to 1 cement.

Important:

•

Do not use standard concrete mixes where sulphates or similarly aggressive chemicals

are present in the groundwater.

•

Lift height (rate of rise): Determine the lift height (m), or rate of rise (m/h) for the

specific, concrete type used, to ensure that a design pressure (P max) of 15kN/m2 on the

tank does not get exceeded.

•

Vibration: The tank design assumes minimal compaction of the surrounding concrete.

Where necessary, this may be extended to include internal light vibration. Never use

deep revibration which will substantially increase the pressure on the tank, possibly

causing failure.

•

Impact of concrete on discharge: Under no circumstances should concrete be discharged

directly onto the tank.

5.8

Topsoil requirements

Clean native topsoil shall not contain rocks larger than 36mm on largest dimension.

5.9

Electrical requirements

Important

•

Please ensure the electrical installation complies with all national regulations and

requirements

.

•

Electrical installations must be carried out by a qualified

and certified electrician.

•

Please note different electrical requirements are dependant on the size of the Tricel

Vitae system, read the following sections carefully.

T

he customers’ minimum responsibility shall consist of:

•

A single run of 1.5mm² three core (two conductors plus earth conductor) steel wire

armoured (SWA) cable from the customer’s distribution cabinet to the tank unit socket

box.

•

Cableprotectionvia10-ampMCBprotectedby(RCD),rated230V,30mA.

•

Bond thecablearmourproperly to themainearth at the premises.

•

Never disconnectthe power to the air pump. It is imperative that it be running 24 hours a

day,everyday.

18

5.10

Risers

In the event that a Tricel Vitae requires a deeper than standard installation to align with the

wastewater outlet from the premises, manhole risers are available. These are to avoid the

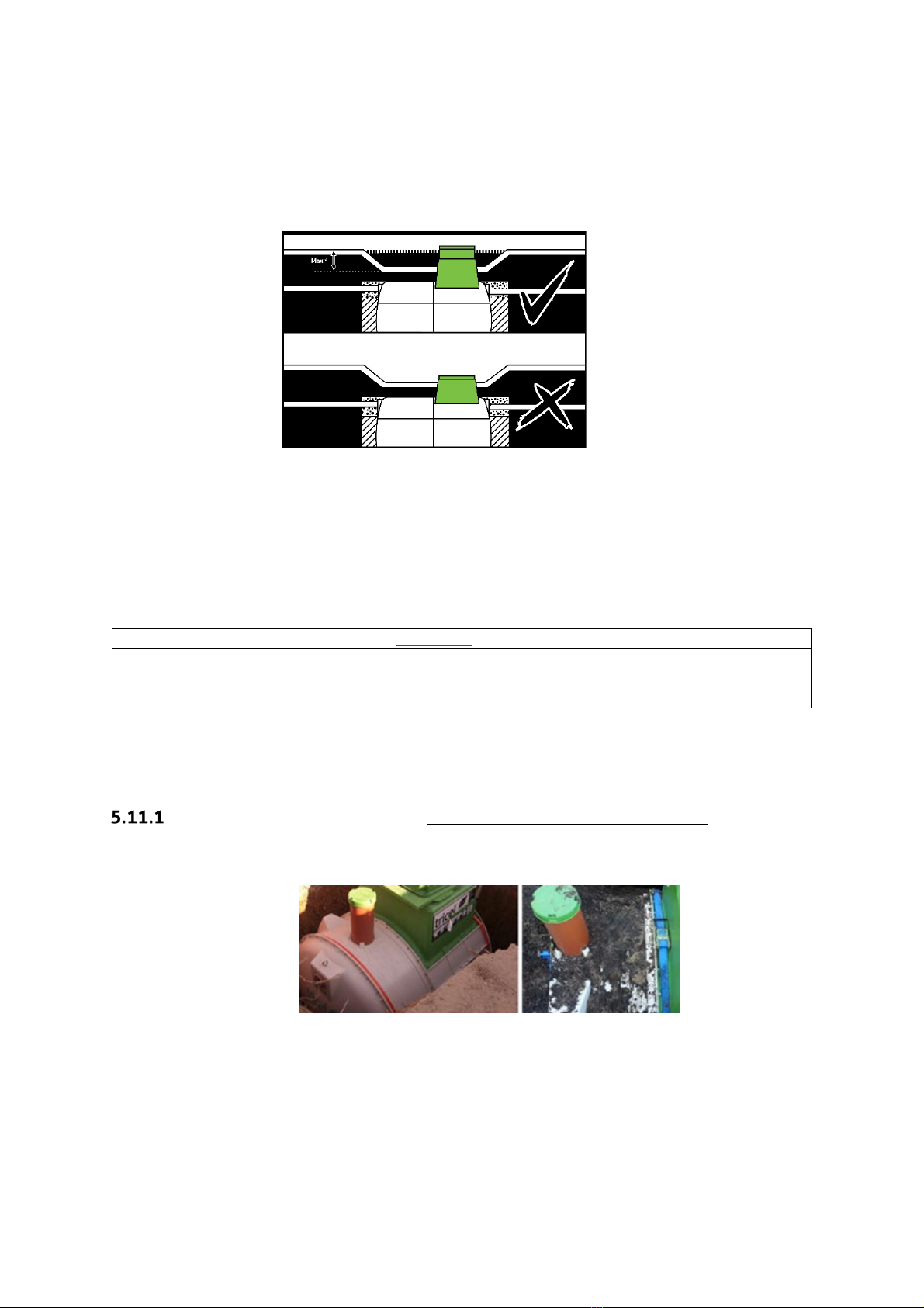

access cover being positioning in a depression, as shown in the following diagram:

•

250mm, 500mm, and 750mm risers are available for the Tricel Vitae if required

(requires installation suitable for the site conditions, please refer to section 5.4,

‘Types of installation’).

•

TheTricelVitae issuitableforamanholeriserwhich givesa maximuminletinvertof

1260mm

. However, the Tricel Vitae is not suited to areas where a more in-

depth installation is necessary.

Important:

•Never place the manhole covers below ground level.

•Only use

Tricelmanhole covers and risers.

•

Do not allow ground water to enter the plant.

5.11

Non-standard

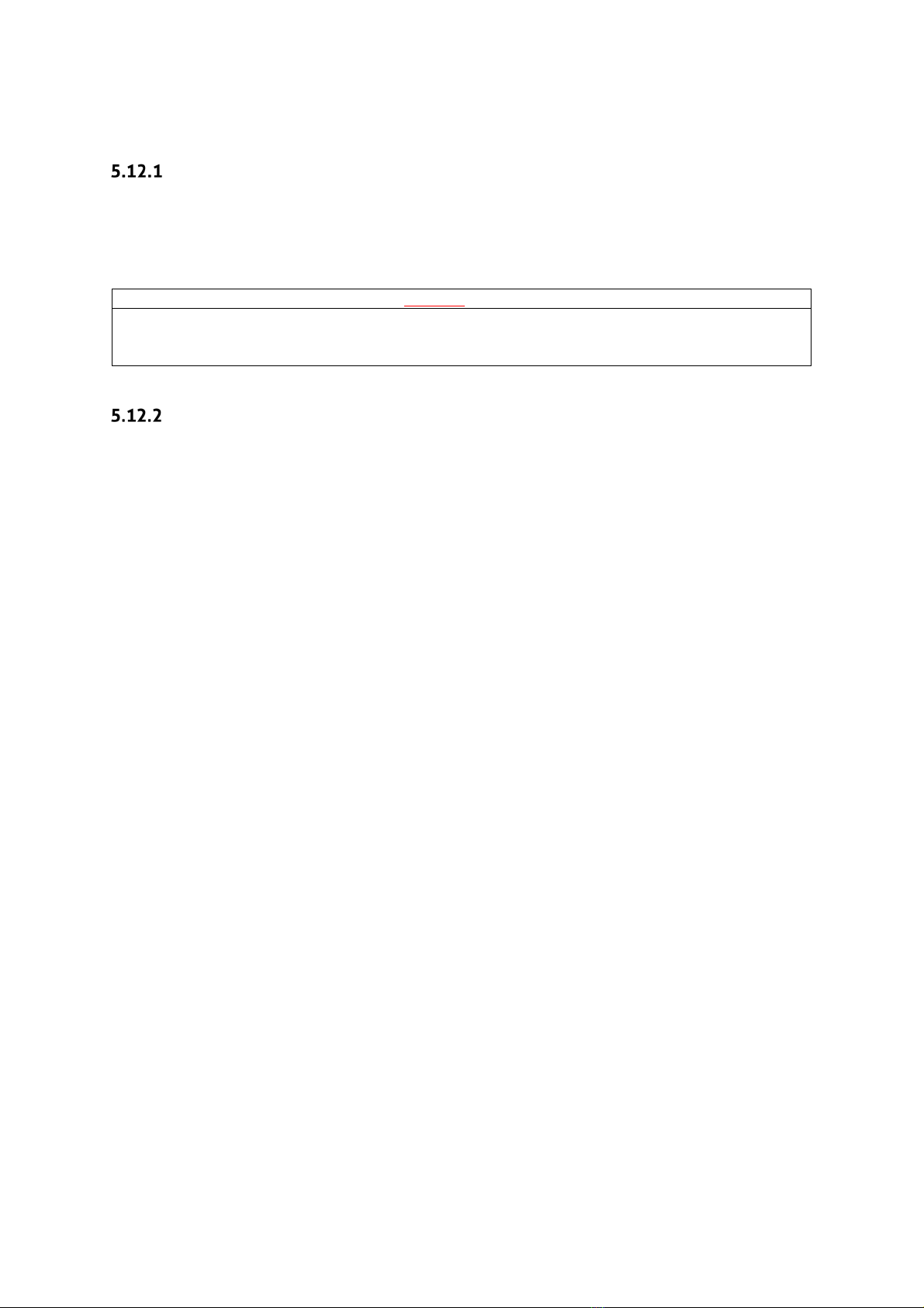

Alternative to concrete backfill (for wet sites without risers only):

•

The option of securing the Tricel Vitae to a reinforced concrete slab or Deadman anchor by

way of straps may also be applied, as shown below:

•

Tricel accepts no responsibility for the design of the concrete slab/Deadman

anchor. This solution should bedesigned byan on-sitestructuralengineerto suitsite

conditions.

•

If implemented, position the straps as close to the bolted joints as possible.

19

Sloping ground:

When the slope of the ground is 5% or more, it is recommended to install a retaining wall to protect

the tank from the lateral thrust. Concrete backfill may also in some cases be sufficient to protect

the tank. A qualified structural engineer must determine if a retaining wall is required in the

presence of a steep slope as shown in the picture below:

Proximity to rolling & static loads:

Minimum separation distances from:

•Rolling loads (e.g., vehicle traffic): 4 metres

•Static loads (e.g., dwelling house, shed): 3 metres

If the tank installation is in an area where traffic or other superimposed loadings can be

applied, consult a structural engineer for the design of a reinforced concrete slab to prevent

any load getting transferred to the tank (or its concrete surround). If this slab is constructed

immediately above the tank, separate it from the surrounding concrete by a compressible

material.

20

5.12

Additional accessories

Grease trap

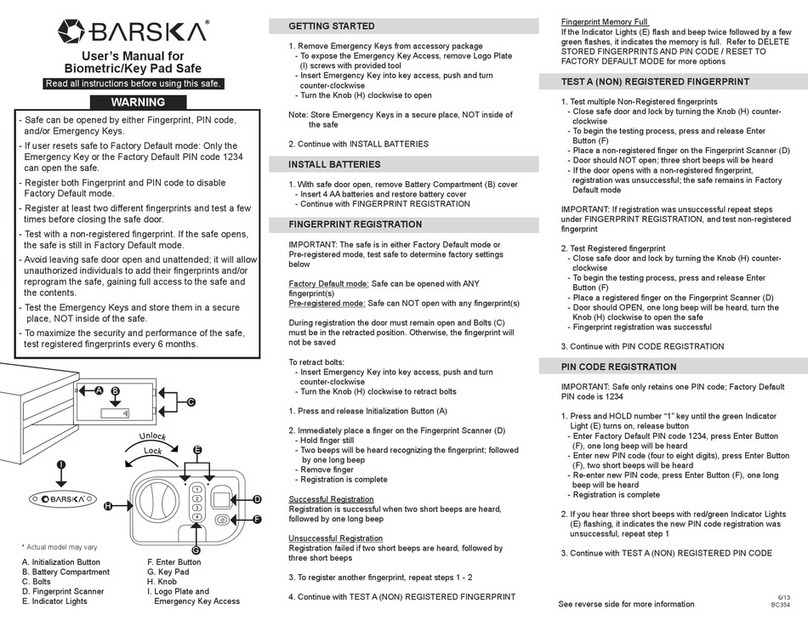

•Best practice indicates that a grease trap gets fitted before the

TricelVitae, particularly in

applications where high quantities of grease/oil exist in the wastewater.

•

For the grease trap tp continue to perform effectively, it must be

monitored/maintained on a regular basis and emptied when required.

Warning

If high levels of grease/oil are present within the Tricel Vitae, the plant will not

achieve the required treatment quality and it will reduce the lifespan of plant

components.

Sampling chamber

•

Best practice indicates that a sampling chamber is fitted after every

Tricel Vitae

to allow

easy access for sampling purposes.

•Care should be taken to ensure that the sampling apparatus does not come into contact with

the pipework or walls of the sampling chamber to avoid contamination of the sample.

•

Ensure that the outlet is installed high enough in the sampling chamber to allow for the

required sampling volume to be retained in the bottom of the sampling chamber.

•The inlet/outlet pipework installed in the sampling chamber must be minimum diameter of

110mm.

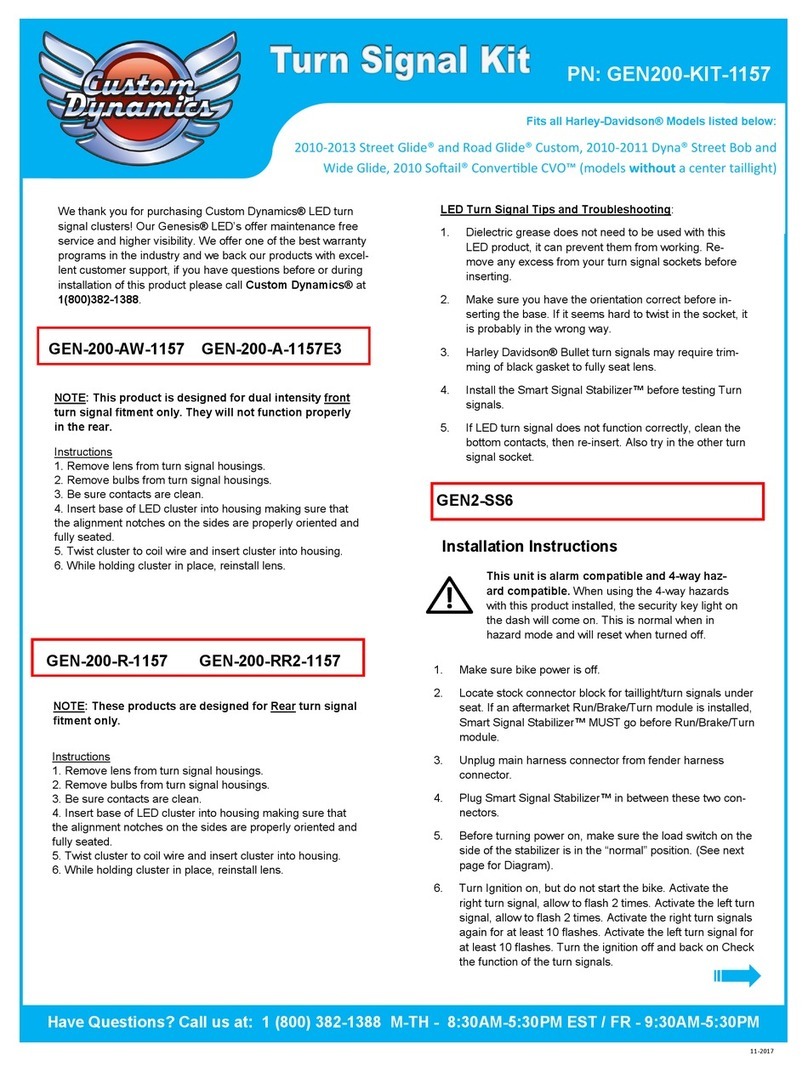

Table of contents

Popular Other manuals by other brands

Barska

Barska AX11646 user manual

Custom Dynamics

Custom Dynamics GEN200-KIT-1157 Installation instructions manual

Invengo

Invengo XC2600 user manual

Orla

Orla GT5000 owner's manual

Westfalia

Westfalia 303 164 installation instructions

Whelen Engineering Company

Whelen Engineering Company Outer Edge Pillar Mount LC Lightbar Installation guides

Parker

Parker Sporlan SMART Pro/R quick start guide

Duncan

Duncan STK-S4 Classic Stack Plus Wiring diagram

ATS

ATS Allison Transmission Pan kit installation manual

Bazzaz

Bazzaz T143 installation instructions

Datalogic

Datalogic DLR-DK001 Series User quick reference guide

SMART DESIGN

SMART DESIGN C SANS SEUIL installation instructions