Trico DR-7 User manual

Page 1 of 28

DR-7

DIRECT READING FERROGRAPH

USER MANUAL

November 2022 Revision F

Trico Corporation

1235 Hickory Street

Pewaukee, WI 53072

Phone: 262.691.9336

www.tricocorp.com

Model: ___________________________________

Serial Number: ____________________________

Date of Purchase: __________________________

Windows Product Serial Number: ________________________________________

Page 2 of 28

Table Of Contents

1. Introduction .......................................................................................................................................... 3

2. Packing List and Assembly .................................................................................................................... 4

2.1 – DR-7 Unit Assembly.......................................................................................................................... 4

3. Specification and Operating Parameters .............................................................................................. 5

4. DR-7 Nomenclature .............................................................................................................................. 6

5. Consumables and Accessories .............................................................................................................. 8

6. Oil Sample Preparation ......................................................................................................................... 9

6.1 – Preparing an Oil Sample for Testing................................................................................................. 9

6.2 – Dilutions ........................................................................................................................................... 9

7. Operating Procedures .........................................................................................................................10

7.1 – RUN DR Tab....................................................................................................................................10

7.1.1 – STANDARD Operation .............................................................................................................11

7.1.2 – OPAQUE Operation ................................................................................................................. 14

7.1.3 – MENU Button ..........................................................................................................................16

7.1.4 –Shutdown Procedures..............................................................................................................16

7.2 – CHARTING Tab................................................................................................................................17

7.3 – BASELINE Tab .................................................................................................................................17

7.4 – CALIBRATION Tab...........................................................................................................................18

7.4.1 – OPTICAL Calibration ................................................................................................................18

7.4.1.1 – Optical Calibration Check with Trico #DR7-FIL................................................................. 20

7.4.2 – END OF OIL Sensor Adjustment .............................................................................................. 21

7.5 – HELP Tab......................................................................................................................................... 22

7.6 – ABOUT Tab .....................................................................................................................................22

8. Downloading and Understanding DR Data .........................................................................................23

8.1 – Quantifying DR Data....................................................................................................................... 23

8.2 – DL and DSReadings ......................................................................................................................... 26

9. Maintaining the DR-7.......................................................................................................................... 27

9.1 – Sensor Cleasning ............................................................................................................................ 27

10. Limited Warranty ................................................................................................................................28

Page 3 of 28

1. Introduction

The Direct Reading Ferrograph is a trending instrument, providing readings which measure the amount of

metallic particles, both large (DL) and small (DS) in a known oil sample. The numbers given do NOT

relate to any other numbers such as parts per million (ppm). The DL and DS numbers of the DR-7 will

correspond to those reading generated by a DR-5 and will be slightly higher than a DR-3. In turn these

numbers can be used to calculate the wear particle count (WPC).

The DR-7 is much more versatile than its predecessors. Running on a Windows platform allows users to

quickly upgrade DR software to the latest version, interface through the internet, and set up e-mail

capabilities. The USB connections can easily be used to set up multiple DR-7 units together and connect

to the user lab software. The provided Ethernet port allows users to network into their current systems and

to each externally.

The first Direct Reading Ferrograph was developed in the early 1970’s as the whole science of

Ferrography was being developed under a contract with the US Navy. Early DR Instruments were large

and had to be adjusted before every test. The large density particles and small density particles had to be

read separately by turning a switch. Over the years, the Direct Reader (DR) progressed from the original

manual instrument to a Duplex. The Duplex was a manual DR with a Ferrogram Maker in the same

instrument. The DR-2 was the next version which contained the first attempt at a self-adjusting

instrument. Throughout the years the DR-3, DR-5 and DR-6 series of Instruments were created, finally

with this current DR-7 design.

During the development of the Ferrography instruments, it was discovered the most sensitive locations for

detecting a changing wear situation were found, this point was determined to be at the entry point of the

magnets, at a position approximately 5 millimeters downstream. Particles of 5 microns or greater

collected at the entry point. Particles with the size of 1-2 microns collect at the 5 mm position.

Accordingly, the Direct Reader Ferrograph was designed to quantify particles into these two size ranges.

This is where the Density Large (DL) and Density Small (DS) numbers come from. These densities are

found by shining a monochromatic light through the bottom of the glass part of the precipitator tube. The

amount of light cut off by the particle builds up in the glass tube, and therefore blocks the sensors, and

this blockage is read by sensors. The DR then converts this attenuated light into the DL and DS readings.

The digital output has a range of 0 to 190 units. A reading of 100 units corresponds to approximately one-

half of the area covered and is the recommended upper limit. For readings greater than 100, the

instrument response is non-linear due to the particles piling on top of one another so that less light is

attenuated. Trico recommends not using a reading over 90 and the instrument indicates a warning

message to indicate that the sample should be diluted.

Because this is a trending instrument, results on the same sample will vary due to accuracy of sample

preparation, sample temperature, settling of the particles, and other factors. Comparative unit testing

proves that a given sample can produce results repetitively within a range on a single DR-7 and across

multiple units.

Page 4 of 28

2. Packing List and Assembly

After receiving the DR-7, check the package for any shipping damage, and report the damage to the

carrier that delivered the package to you. Shipping damage is the receiver’s responsibility.

Packing items:

1 – DR-7 Direct Reading Ferrograph Unit 1 – Universal Power Cord

1 – Stainless Steel Sample Vial Holder 1 – Spare 1A Fuse

1 – Stainless Steel 125 ml Beaker 1 – DR-7 User’s Manual

3 – Spare “End of Oil Sensor” Doors 1 – Calibration Tube PN: 43021

2.1 – DR-7 Unit Assembly

Required tools for Assembly:

1 – #2 Philips Head Screwdriver

1. Remove the 125 ml beaker from the packing paper. Place the beaker into the recessed cup for waste

collection.

2. The drain tube on the right (facing the instrument) bulkhead should be placed into beaker. During

factory conformity testing a test liquid is circulated through the pump tubing to verify function and

check units for leakage. Excess fluid may still be in the tubing upon arrival. After time the drain tube

will become hard and brittle. A new tube can be attached using the tubing cut from a used precipitator

tube as a replacement.

3. Remove the two screws from the top of the instrument where the vial holder goes. Place the stainless

vial holder on top of the tower with the fingers pointing toward you and thread the two screws back

into the holes at the top left side of the Instrument. Tighten the screws using a #2 Phillips head.

4. Plug the universal power cord into the back of the DR-7 into the power jack and then into an

electrical outlet.

NOTE: If the electric supply is other than 120v, 60/50 Hz, the standard Universal Power Cord

provided will need to be replaced or adapted to the host country’s receptacle. Ensure that the power

supplied is within the range outlined in the specifications of this manual. It is the user’s responsibility

to supply the correct plug for the available power. Install the correct plug, then plug the power supply

into the back of the DR-7 and then into the electrical outlet.

To lift and move the DR-7, turn off the instrument and disconnect the power cord and the computer cable,

if attached. Place your hands under the instrument two thirds of the way back and lift. This will balance

the instrument while lifting.

Page 5 of 28

3. Specification and Operating Parameters

Physical Specifications

Length (Front to Back):

9.00 in.

22.8 cm

Width (Side to Side):

12.00 in.

30.5 cm

Height:

19.75 in.

50.2 cm

Weight (Instrument Only):

13 lbs.

5.9 kg

Power

Voltage:

100-240V AC

Frequency:

50/60 Hz

Amperage:

1A

Instrument contains a 1A power fuse located at the power plug inlet

Hardware

Operating system:

Windows 10 IoT

Memory:

64 GB Flash

External USB Ports:

2 x USB “A”

Ethernet Connection:

RJ45 cat 5

RAM:

4 GB DDR2 RAM

Processor:

Intel® Celeron® CPU N2807 @ 1.58 Ghz

Environmental Conditions

For indoor use on a solid level surface without movement or vibration.

Use in a well-ventilated area.

Room temperature:

50ºF to 85ºF

10ºC to 29ºC

Humidity:

5% to 50% non-condensing

CAUTION: DO NOT operate the DR-7 with the back panel removed. Unplug the DR-7 from the power

supply before removing the back panel for adjustments. Check with Trico before removing as this could

void the unit warranty. All other repairs must be done at the factory.

Page 6 of 28

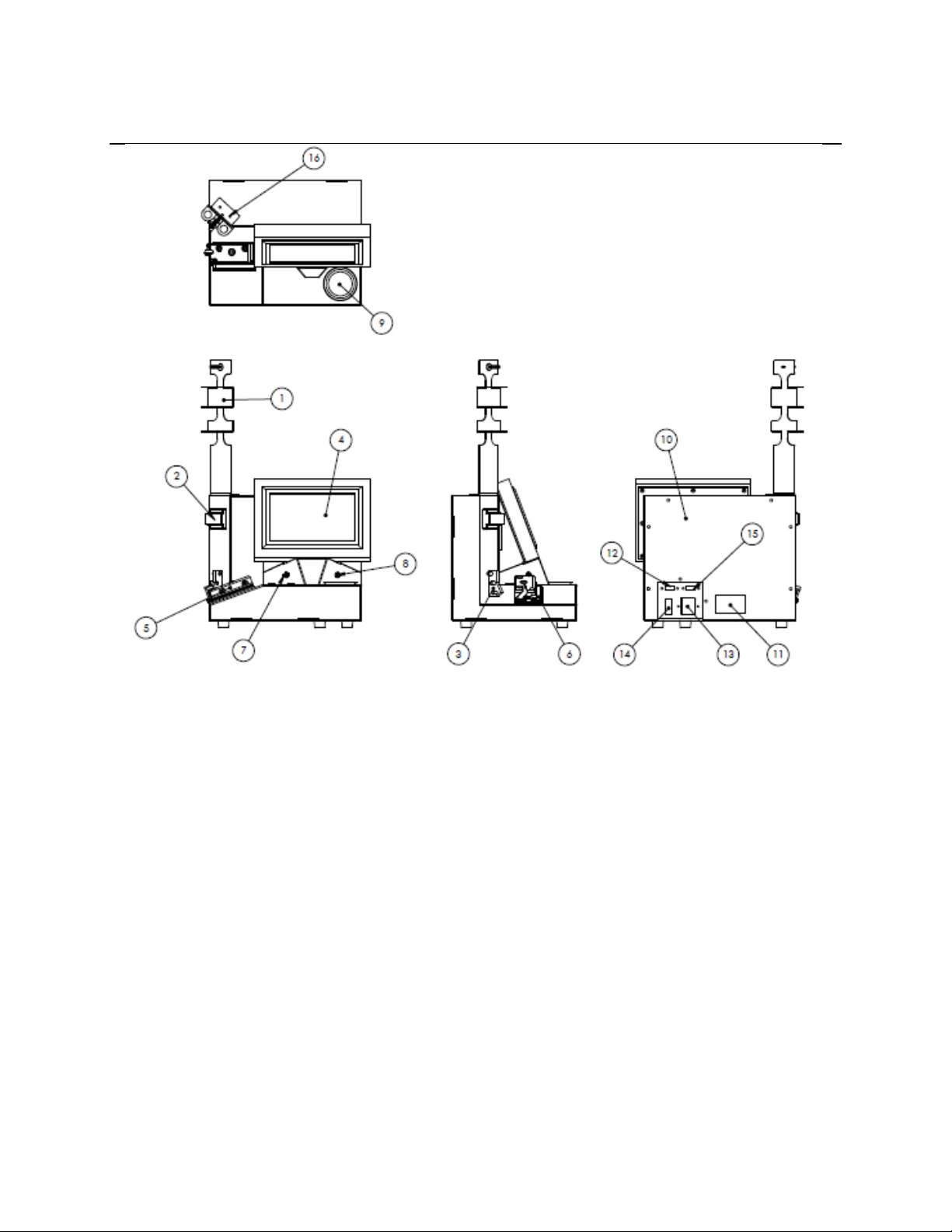

4. DR-7 Nomenclature

This section introduces the user to the major components of the DR-7 Direct Reading Ferrograph

Instrument. The following subparagraphs discuss the major components, their location, and the

nomenclature for each item on the DR-7 Direct Reading Ferrograph Instrument shown above.

1) Vial Holder: Holds two sample vials and mounts on the top of the DR-7 with two screws. Do not use

this as a handle to pick up the unit.

2) End of Oil Sensor: The end of oil sensor will sense the meniscus created in the precipitator capillary

tubing when the test is completed, automatically freezing the DL and DS readings. The DR-7 will

record the readings if the sensor is bypassed by pressing the STOP button when the technician

determines that the test is completed.

3) Tubing Guide: Used to bend and guide the capillary tubing without kinking from the vertical position

to the inclined magnet assembly. Tubing is held in place by weaving it through the three pins.

4) LCD Screen: This touch screen displays the set up and operational screens which have several options

available besides the calibration menu.

5) Optics Assembly: Holds the glass precipitator tube assembly.

6) Magnet Assembly: Magnets designed to attract the ferrous particles on the bottom of the glass

precipitator tube to obtain the DL and DS readings.

7) Left Bulkhead: Where the end of the precipitator tube connects to the pump head.

Page 7 of 28

8) Right Bulkhead: The drain connects here and goes into the waste beaker. Drain tubes can be made by

taking the tubing off the end of a used precipitator tube.

9) 125 ml Waste Beaker: Used to catch the used oil. Discard the mixture of oil and solvent properly

when nearing the end of the drain tube.

10) Back Cover: Removable with eight (8) screws. Check with the factory before removing as this

could void the unit warranty.

11) Windows Product ID Number/ DR-7 Model and Serial Number: The Windows Product ID

number is located on the back of the unit and is used for Windows product support through Microsoft.

The DR-7 Model, and Serial Number Label is located on the bottom or back of the unit and used when

calling Trico for DR-7 support. Record these numbers on the DR-7 user manual for future reference.

12) Ethernet Network Jack: Ethernet cable may be used to download the DR-7 data to a database

and utilize internet/ intranet Windows functions.

13) Power Input Jack: The standard universal power cord supplied with the unit is first plugged into

the power input jack and then plugged into the power receptacle that supplies appropriate power within

the unit specifications.

14) On-Off Power Rocker Switch: Red indicates “ON” position, black indicates “OFF” position.

15) USB Ports: External peripheral devices such as the provided mouse, keyboard or monitor may be

utilized through the USB connections, provided they are compatible with Windows.

16) Vial Mounting Screw Location: During assembly, screws provided with the unit are threaded

into the top location shown to hold the vial assembly onto the unit.

NOTE: Tampering with the Instrument will void the warranty.

Page 8 of 28

5. Consumables and Accessories

It will become necessary to reorder the consumables to continue testing on the DR-7 unit. This section

contains reordering information. Many of the test equipment items should not be reused. Contaminated

devices can cause inaccurate or incorrect interpretation.

Part # 73-0050 Pipette Tips- GLASS (Package of 200) – Disposable glass tips used with the pipettor.

Part # 73-0060 Sample Vials (Package of 250) – Disposable glass vial holds the oil and heptane and fit

properly into the vial holder.

Part # 73-0090 Sample Vial Rack – Will hold up to 18 sample vials in preparation for testing.

Heptane – A filtered solvent used to thin the oil sample for testing to run through the precipitator tube at

a quicker rate. The fixer can be used to clean between the optics assembly and magnet assembly. This

solvent is non-carcinogenic, but flammable. (n-Heptane 99+% for Spectrophotometry can be purchased

from VWR at https://us.vwr.com or call 1-800-932-5000)

Part # 74-0020 Diluent Oil – Used when the oil sample tested exceeds a DL or DS reading of 90 or more

and the sample must be diluted to get a reading under 90 units.

Part # 74-0040 Precipitator Tubes (Package of 250) – This disposable tube carries the oil sample from

the sample vial, over the magnet assembly to the waste bottle. The precipitator tube is constructed of four

parts. The first is a 33” piece of capillary tubing. This runs into a 4-inch piece of glass and is held in place

by a black shrink tube. A piece of tygon tubing is added to the other end of the glass to connect the glass

tube with the left bulkhead.

Part # 74-0250 Grease Solvent – An agent used to dissolve grease into a form that can be tested with the

DR-7 unit.

Part # 75-0010 Bottle Top Dispenser, 1 ml – Use in the fixer bottle to dispense one milliliter of heptane

with each pump.

Part # 75-0030 Pipette Dispenser (Pipettor) – Used to draw one milliliter of the oil sample for the test.

Part # 75-0040 Pipette Tips- PLASTIC (Package of 250) – Disposable plastic tips used with the pipettor.

Part # 76-0030 Wear Particle Atlas – A guide to wear particle identification containing photographs of

critical wear particles found in used lubricating oil, illustrative case histories, and operational procedures

for wear debris analysis.

Part # 43021 DR-7 Calibration Tube - Used in calibration procedure to correct unit light intensity

output.

Part # DR-7FIL - Used for calibration purposes on the DR-7 to confirm the calibration and alignment

readings over time.

NOTE: Part # 73-0060, Part # 74-0040, and Part # 73-0050 must be discarded after one use in order to

eliminate cross contamination.

CAUTION:Heptane and Part # 74-0250 Grease Solvent are considered hazardous materials and should

be handled with caution and disposed of properly. Consult the Safety Data Sheet (SDS) enclosed with

these chemicals for more information.

Page 9 of 28

6. Oil Sample Preparation

6.1 – Preparing an Oil Sample for Testing

Gravimetric settling of wear particles in lubricating oil starts immediately after a sample is left standing.

To obtain a representative sample from a larger sample, the particles must be evenly dispersed. To make a

homogenous mixture, the following procedure is recommended:

1. The oil should be in a clear container to allow for observation of the oil and large contaminants. Make

sure the container is two-thirds full to allow for agitation to completely mix the particles into the oil,

thus giving the sample a homogenous mixture.

2. Heat the oil to approximately 150°F (65°C). This is according to ASTM standard procedure to keep

the particles suspended as long as possible.

3. Remove from the heat source and vigorously shake the bottle.

4. With the pipettor and clean pipette tip, remove 1 ml of oil and dispense into a clean sample vial.

5. Add 1 or 2 ml of heptane to the 1 ml of oil in the sample vial. The viscosity of the oil determines the

amount of heptane added to the oil in the sample vial. For high-viscosity fluids add 2 ml of heptane to

reduce the viscosity. This will allow the viscous oil to flow along the precipitator tube at a similar rate

as lower viscosity fluids. For low-viscosity fluids 1 ml of heptane is enough to provide fluid flow

through the precipitator tube. It does not matter if 1 or 2 ml of heptane is used, as long as the required

1 ml of oil is used for each test. However, higher viscosity samples moving at too slow of a rate will

affect particle deposition by increasing the amount material deposited on the DL compared to the DS.

6. The quicker a sample is tested, the better the results. Allowing the sample to settle in the test vial may

cause bunching of particles in the precipitator tube since most of the material will be collected at the

bottom of the vial and deposited in the precipitator tube around the DL sensor. To avoid this, use the

prepared sample as soon as possible or re-mix the sample before testing so that wear particles are

properly dispersed.

6.2 – Dilutions

Readings on the DR-7 greater than 90 in the 1:1 or 1:2 dilution modes are not linear due to the particles

piling on top of one another. When the DR-7 readings reach 90, the test is invalid and should be repeated

using a dilution of the base sample.

1. To prepare dilutions, start with the base mixture. In a clean sample vial, place 1ml of the base

mixture. To this add 9 ml of diluent oil. This will make a 10:1 dilution.

2. In another clean sample vial, place 1ml of the 10:1 dilution. To this, add the heptane as done to make

the base solution (1 or 2 ml). This is the 10:1 sample to be run on the DR-7.

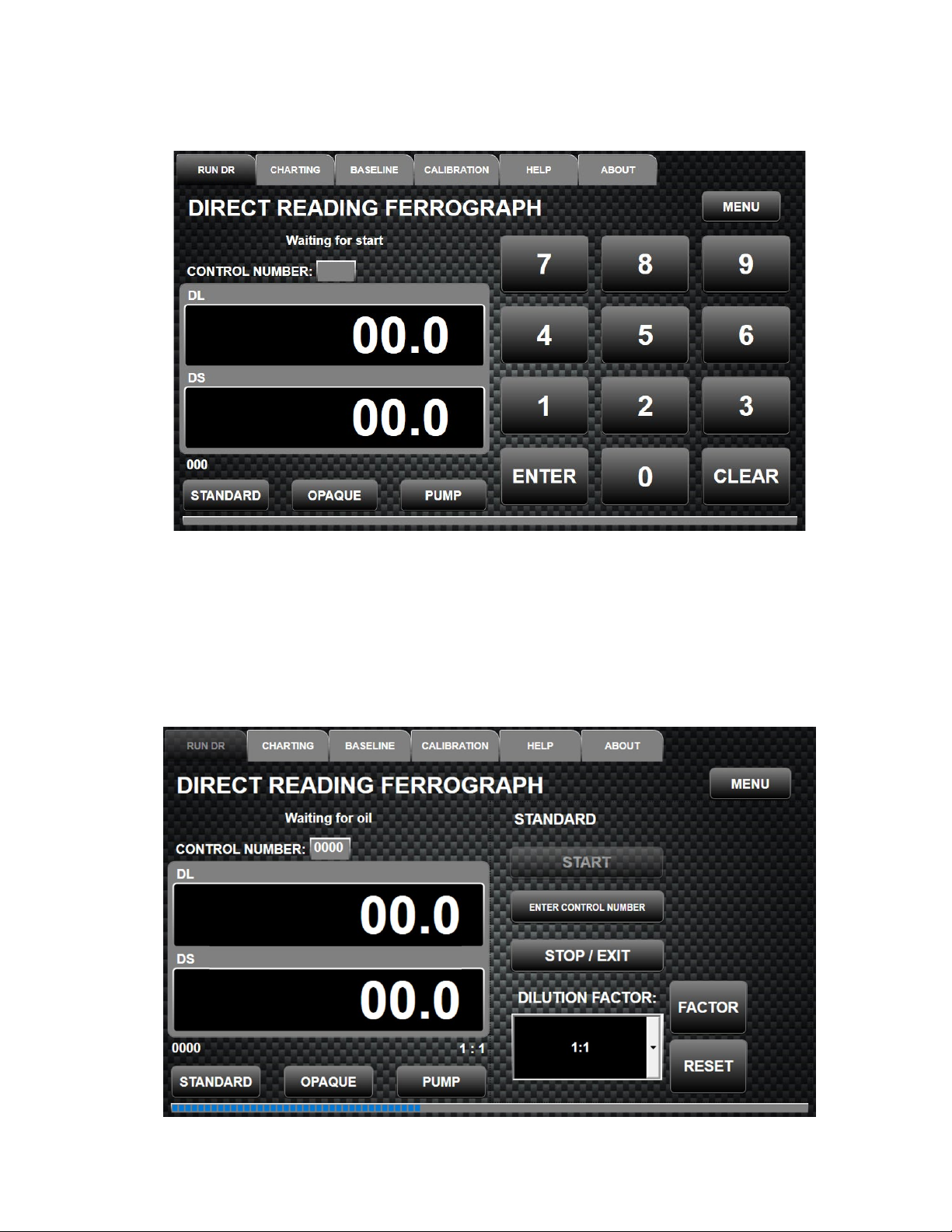

3. On the RUN DR tab MENU display, change the dilution ratio to 10:1 and the readings will be

corrected for this dilution. The upper limit will automatically be changed to 900 instead of 90. If the

DL and DS readings go over 900 a 100:1 dilution must be made.

4. To make a 100:1 dilution, start with 1 ml of the 10:1 dilution and add 9 ml of the diluent oil. Take 1

ml of this dilution and the standard amount of heptane in a clean sample vial to run the 100:1 dilution.

Change the dilution ration to 100:1 in the menu so the final DL and DS readings will be corrected for

the dilution and the upper limit of the test will be changed to 9000.

5. When the dilution factor is changed, the DR-7 will automatically multiply the DL and DS readings to

give you the correct dilution readings and the limits of the test will be increased. This means that in a

normal test the display will warn the user if the reading goes over 90. In a 10:1 dilution, that number

increases to 900 if the DR-7 is set at that dilution ratio. The 100:1 would have a high limit of 9000.

NOTE: If the dilution factors are not changed in the menu, the DL and DS readings must be multiplied

by the dilution factor to get the correct readings. In a 10:1 dilution the DL and DS readings would have to

be multiplied by 10.

Page 10 of 28

7. Operating Procedures

Always use the DR-7 on a sturdy, level surface in a well-ventilated room. To start the DR-7 system, flip

the rocker switch on the back of the unit to the “ON” position. The operating system will automatically

start booting and the Trico logo will illuminate. Once the windows system has booted the DR-7 program

will automatically open to the RUN DR tab, otherwise there is a shortcut on the desktop to launch the

DR-7 program.

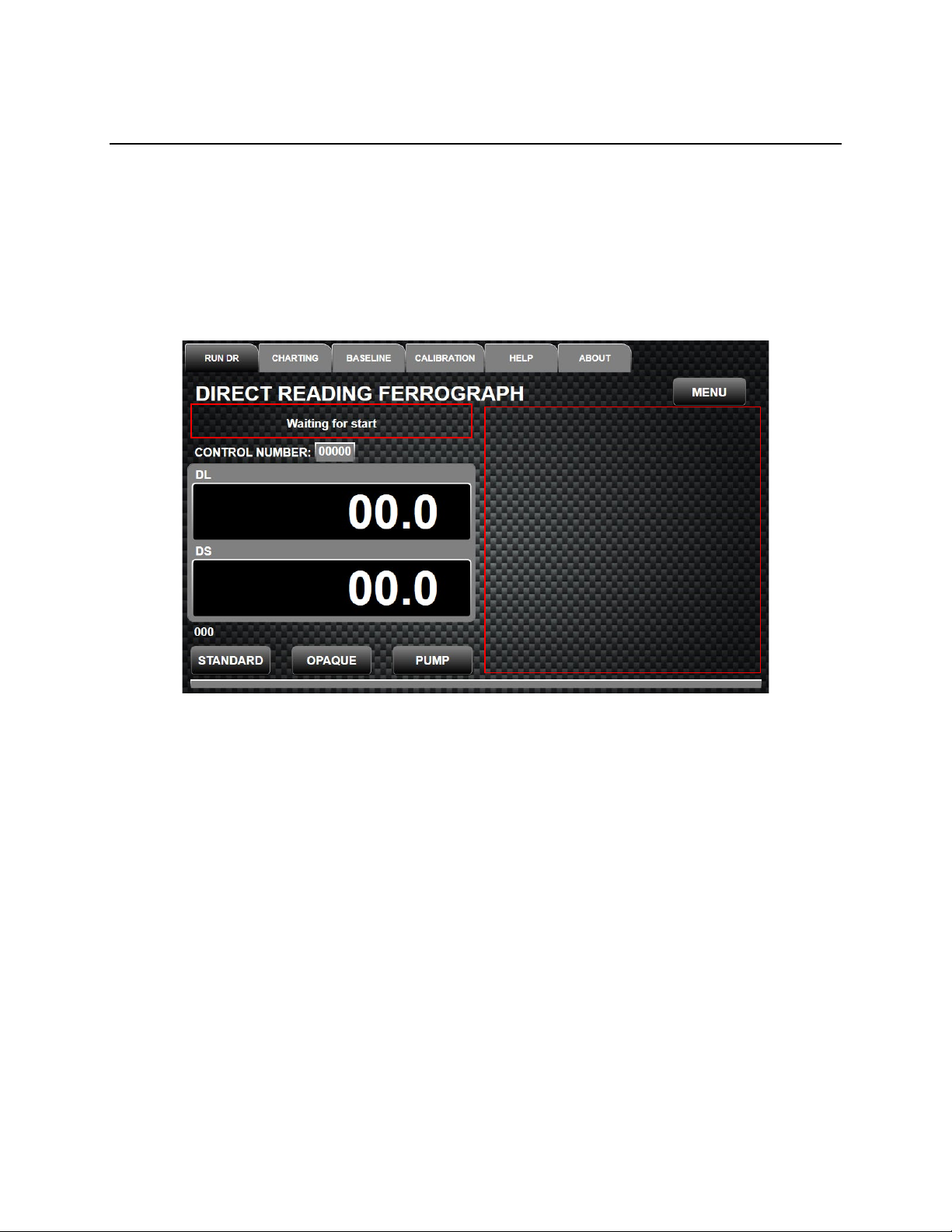

At system startup the main DR-7 menu appears. The first start up screen is shown below. This start up

screen allows the user to quickly change settings, calibrate optics or end of oil sensor or start the testing

process. At the very top of the main menu six tabs appear: RUN DR, CHARTING, BASELINE,

CALIBRATION, HELP, and ABOUT, which are explained in further detail.

7.1 – RUN DR Tab

The Run DR tab is the functional work areas for operating the DR-7 system and allows users to change

settings on the fly, or operate the program and circulate the pump.

Located on the right side of the RUN DR tab is the Submenu Selection Area. In this area all sub menues

will appear when the MENU, STANDARD, or OPAQUE buttons are selected.

In the left half of the screen two black blocks appear indicating the DL and DS numbers during the test.

Above these blocks, system messages will appear prompting the user or indicating warning messages

when parameters are out of range.

Three touch buttons are also located at the lower left side of the screen under the DL and DS reading

boxes. These buttons allow the user to start tests using the STANDARD or OPAQUE functions. By

pressing these buttons, a new menu appears in the submenu selection area for running the specific test.

The PUMP button, when pressed rotates the peristaltic pump one revolution and can be used to start the

sample flow through the precipitator tube if the sample viscosity is too high and flow is unable to be

achieved through the current rotation settings. The PUMP button should only be used to start the flow and

should not be continually used to process the sample at a faster pace. Doing so will give false DL and DS

readings because of inconsistency of flow over the magnet assembly.

Submenu Area

Page 11 of 28

The DR-7 displays the time (in seconds) that each sample takes to complete. The sample time is defined

as the time required from when the DR-7 detects the oil at its DL and DS sensors, to the time the last of

the oil passes the end of oil sensor. The timer is located under the DL and DS blocks just above the

STANDARD button indicated as 000.

Knowing the time each sample takes to complete can be used to catch a bad sample test. For example, if

previous samples required an average of 200 seconds to complete and the next sample, of the same oil,

requires only 100 seconds, the sample test is in error and must be repeated. Sample times will vary

somewhat, however, significant differences in time are usually caused by false tripping of the end of oil

sensor by a large particle in the sample. This requires adjustment to the end of oil sensor’s threshold or

bypassing the End of Oil Sensor by leaving the capillary tube outside of the sensor during the test. See the

END OF OIL SENSOR CALIBRATION in section 8. Calibration of this manual. The time will retain the

last sample time until the next sample is started.

If, for some reason, a sample is running through the precipitator tube for 12 minutes, the DR-7 will end

the test and freeze the readings at this time. “TIMED OUT” will appear next to the timer below the DL

and DS boxes. This might be caused by the sample being too viscous. The sample should be thinned with

more heptane or diluent oil and run again for accurate results.

7.1.1 – STANDARD Operation

The black shrink tubing should be placed against the left edge of this assembly to run the test to ensure no

light intrusion. A depress lever is located to the left of the optics assembly to open and hold the

precipitator gate in the up position to allow for the precipitator insertion under the optics. Moving the

lever forward opens the gate while moving the lever back will close the gate. When closing the gate, the

lever should be pushed back until its stops which will clamp and hole the precipitator tube.

1. Mix the oil sample as described in section 6.1 Preparing an Oil Sample for Testing of this manual.

Put the sample in the vial tube holder at the top of the instrument.

2. Install a precipitator tube by first moving the depress lever forward on the left-hand side of the optics

assembly to open and hold the precipitator gate in the up position. Insert the glass part of the

precipitator tube under the optics block and then move the lever backwards while pressing down on

the gate until its stops to hold the precipitator tube in place. The black shrink tubing of the precipitator

tube should be tight against the left-hand side of the Optics Block. Next, place the short end of tygon

tubing onto the barb fitting on the left bulkhead barb under the display screen.

3. Weave the capillary tube between the tubing guide pins as shown below. Weaving the tube through

the pins will help keep the precipitator tube from sliding out of position. Then place the capillary tube

in the center groove of the end of oil sensor and close the door by snapping it shut. Be careful not to

pinch the tubing with the door.

Page 12 of 28

4. Place the end of the capillary tube in the oil sample in the vial holder until it touches the bottom of the

sample vial and press the tubing into the spring at the top of the sample vial holder to hold the tubing

in place.

5. Press the STANDARD button.

a. “YES” Control Number is Required in MENU Settings

i. A system message will indicate that the user will need to enter a control number for

the sample and the START button will be gray and un-selectable.

ii. Press the ENTER CONTROL NUMBER button and the keypad will now appear.

iii. Enter the control number. Make sure the control number is correct and press ENTER,

otherwise press CLEAR to clear out the control number to enter a new one. Entering

a control number will store the data into a coma separated values (csv) file, in which

Page 13 of 28

a script can be written to load the data into a given lab data tracking software or

spread sheet.

iv. After ENTER has been selected the keypad will disappear and the RUN DR will

again be displayed.

6. Press START and the unit will begin the test until it is completed. When pressed the pump activates

and starts the siphoning effect in the precipitator tube. For full suction to begin, the oil level in the

precipitator tube must flow past the bottom of the vial in the vial holder. If this does not happen the

viscosity of the solution is too viscous, and the PUMP button can be pressed until flow starts. The

default for pump revolutions is set at 2 and can be changed by changing the settings in the MENU.

Thin oil samples only need one revolution of the peristaltic pump to start the flow. Thicker oil

samples need two or more revolutions of the pump, or heptane can be added to thin the solution.

Page 14 of 28

7. As oil flows through the precipitator tube, the Display Messages will change through the following

phrases, colored white, letting the operator know the progression of the test.

•Waiting for Start

•Waiting for Oil

•Oil – Start Testing

•Waiting on End of Oil

•Done – Waiting for Start

8. When DONE – WAITING FOR START appears the DL and DS readings will be frozen. This is

when the DL and DS readings are recorded for the oil sample; but only if a control number was

entered for the sample. This data is written to the DR-7 data folder of the program and can be

accessed through windows explorer under the C:\Programs\Trico folder. If downloading data, your

software will need a script written to pull this data from the file. Files are named per control number

along with a date time stamp.

9. This completes a STANDARD test, and another test can then be performed. Remove the used

precipitator tube and install a new one for the next test to give accurate results.

NOTE:While the test is running the precipitator tube should not be moved or readjusted in the holder.

Doing so will give false readings and inaccurate results. If a problem occurs remove and discard the

precipitator tube and oil sample to begin a new test.

7.1.2 – OPAQUE Operation

An opaque sample is defined as one which is too dark to read under the optical sensors. Usually, samples

filled with carbonaceous material produce a reading of 190 in one or both sensors as soon as they start to

flow through the glass section of the precipitator tube. These dark particles cut off all the monochromatic

light going to the sensors. Diesel oil is a good example of an opaque sample. If an opaque sample is run

as a regular sample on the DR-7, the top line of the display will read TOO DARK – USE OPAQUE.

A special procedure is used to test opaque samples. Filtered heptane is run through the DR-7 to establish a

baseline for the wash fluid. The opaque sample is then run using the same precipitator tube. After the oil

has drained from the sample vial, heptane is used again to wash out the dark oil in the precipitator tube

while the magnet assembly holds the metallic wear particles in place to provide the actual DL and DS

readings.

The first time the DR-7 is used for an opaque test, you are prompted to perform a baseline test using

heptane. This baseline will stay in the DR-7’s memory until the program is shutdown. A sample vial of

the heptane does not have to be run at the beginning of every test for a baseline, just at the end to wash

away the dark oil.

Page 15 of 28

Running an Opaque Sample:

1. Press the OPAQUE button.

2. Enter the control number, if used, by pressing the ENTER CONTROL NUMBER button, as

explained in the Standard Operation section.

3. Pump 4 ml of heptane into a clean sample vial to be placed in the vial holder on top of the DR-7 next

to the prepared oil sample.

4. A base line must be created the first time an opaque sample is run. Place the small end of the

precipitator tube in the sample vial of heptane and press RUN BASELINE.

5. When the DR-7 is calibrated on the heptane, the pump will reverse and shut off the flow of the

heptane. At this point change the precipitator tube to the sample vial with the oil sample, inserting the

tube all the way to the bottom of the sample vial. Press the START button and this starts the flow

again.

6. When the last of the oil sample is in the precipitator tube, quickly move the tube to the vial that

contains the heptane. This will wash the dark material out of the precipitator tube, and you will get

the actual DL and DS readings. By moving the precipitator tube in and out of the heptane, air bubbles

will be introduced into the capillary tube. These bubbles will help remove the opaque oil and

nonmagnetic material in the precipitator tube.

7. When the heptane is gone and the flow has stopped in the capillary tube, take the DL and DS

readings. Press the COMPLETE button to save these readings.

8. To start another opaque test. Place a newly prepared sample into the vial holder along with a sample

vial of heptane for washing. Replace the precipitator tube and place the capillary tube end into the

new sample and then push the START button again to use existing baseline that was established with

the first opaque test. Run this test with the capillary end of the precipitator tube in the oil sample

transferring it to the heptane at the end of the test to flush the precipitator tube and obtain the DL and

DS readings.

9. To end the OPAQUE operation press STOP to exit out.

Page 16 of 28

7.1.3 – MENU Button

The MENU button is in the upper right corner of the RUN DR tab. By pressing this button, the DR-7

settings menu appears in the Submenu Selection area. Different settings can be selected from the pull-

down menu to control beep on key hit, if a control number is required per sample before testing, and the

number of pump revolutions to start suction during a test.

Selections can be made by touching the desired setting pull down and hitting the up or down arrows to the

side to scroll through the selections. After all changes are made press the SAVE & EXIT button to set the

new selections and then exit to exit out of the menu. Default settings are, Beep on key hit: No, Control

number required: No, Pump revolutions: 2.

7.1.4 –Shutdown Procedures

To close the DR-7 program and exit to Windows, enter the MENU Screen under the RUN DR Tab and

press the EXIIT button. In doing this the user enters the Windows Desktop screen. Here is all of the

functions of a normal Windows based operating system. To shut down the power fully, either use the

shortcut on the desktop, or go to the start menu and click on shutdown to close the operating system. This

may take a few seconds to close windows applications and fully shut down.

Once the operating system is fully shut down and the touch screen turns black the user may flip the rocker

switch on the back of the unit to the “OFF” position. By turning the power off, the illuminated Trico logo

will dim to black.

Page 17 of 28

7.2 – CHARTING Tab

The Charting Tab is the function that will plot the DL and DS. Pressing GENERATE GRAPHS button

will graph the L and S Base levels and L and S Count levels over time. Pressing CLEAR GRAPHS then

clears all the data from the graph.

7.3 – BASELINE Tab

The Baseline Tab is used when runing Opaque samples and is covered under the Opaque Operation

section. Values are never input into this tab.

Page 18 of 28

7.4 – CALIBRATION Tab

The DR-7 has two calibration features OPTICS calibration and END OF OIL sensor calibration located in

the CALIBRATION tab. This helps maintain optimum performance during operation. This is controlled

by the lab technician when maintenance and cleaning is performed or performed on a routine basis before

sample testing. These features are in place to allow the equipment to be in service for lengthy periods of

time without the need to ship the unit back to the factory for optics cleaning or optics calibration.

7.4.1 – OPTICAL Calibration

The optics guide block is aligned with the LED light source during factory alignment calibration. Unlike

previous DR versions, the optics block should never be removed for cleaning (see section 9 Maintaining

the DR-7). The new design of the Optics block uses a special fluid filled calibration tube for both the

alignment procedure during the factory build, and in calibrating the LED light source by the lab

technician.

The LED light source calibration should be done daily, or every time the instrument is turned on. This is

done by selecting the OPTICS button in the CALIBRATION tab. In the process, the fluid filled

calibration tube is used to focus light changes in the instrument. In addition, an OPTICAL CALIBRATION

CHECK is used to check the optical calibration to ensure the unit falls within a specified range. This

check should be performed monthly if the unit is used frequently. Although increased sensitivity has been

enhanced throughout the development of this instrument, because of particle distribution and other

variables within the oil sample being tested, the DR-7 is still considered a trending instrument.

Page 19 of 28

To calibrate the LED light source in the OPTICS submenu:

1. Insert the Optics Calibration Tube (Part #43021) supplied with the unit by lifting the gate and placing the

tube under the optics sensor. Close the gate and ensure the Calibration tube protrudes evenly from both

ends of the optics block.

NOTE: The tube should be wiped down to clean fingerprints or smudges from the glass. Before

inserting the tube, inspect the tube for air bubbles which could affect the reading. If air bubbles are

present in the area to be inserted into the sensor path, place the calibration tube back into the holder and

stand it upright to allow air to move to the top end of the glass tube.

2. Select the CALIBRATION tab.

3. Press the OPTICS button.

4. Press the CALIBRATE button in the submenu. The DR-7 will automatically calibrate the light intensity

by determining the maximum intensity and then balancing the optical channels to a predetermined offset

to produce the most effective results.

5. After the Calibration is finished the numbers in the DL and DS will read around 2550 and the message

will appear "Complete" in the message area.

6. Press EXIT/STOP to save the calibration.

7. Remove the Calibration tube and place it back into the holder, then press the RUN DR tab to return to

the test area.

NOTE: The ALIGNMENT button is used only by factory technicians to mechanically align the optics

to the light source. Users do not need to use this feature. Accidently pressing the button will not affect

the instrument readings. Allow the alignment program to reach its target and then press the EXIT/STOP

button. Then conduct the LED light source calibration outlined in the steps above.

Page 20 of 28

7.4.1.1 – Optical Calibration Check with Trico #DR7-FIL

Optical Calibration Checks are performed on the DR-7 optics using the neutral density films and

calibration tube purchased separately in the DR-7 Neutral Density Calibration test kit, Trico Part # DR7-

FIL. Following this procedure will check the optical sensors are within limits and the correct readings are

being obtained from the instrument. The test kit comes with three specific neutral density filters used in

the development of the DR instruments. Neutral density filters can vary in density range, use only those

filters provided in the test kit which have been specifically graded for the purpose of the DR calibration

check. Neutral Density films can vary due to manufacturing variances, and each kit should be measured to

establish its own set of calibration numbers. Follow the calibration guild provided with the Calibration

test kit to refine reading ranges.

NOTE: Neutral density filters should be handled with care. Fingerprints, smears, or scratches will change

the calibration readings. Density filters from older model DR's can still be used on the DR-7. However,

note the changes in instrument reads in the table below.

Checking Optical Calibration:

1. Make sure the Optics block and photocell area is clean and free of dirt and oil.

2. Insert the glass Calibration tube (PN:43021) from the calibration kit into the optics by pressing the

lever forward on the left side of the optic block, lifting the gate and then sliding the calibration tube

into place.

3. On the RUN DR tab press STANDARD and then START. Enter a false control number if needed.

4. Insert a filter under the sensor area and quickly remove it.

5. The screen will now say “Oil- Starting Test”. Wait for this message to change to “Waiting on End of

Oil” and then insert the filter under the sensors again and hold steady until the readings stop climbing.

6. Record the reading.

7. Repeat the same procedures for the two other density filters.

NOTE: When inserting and removing density films, failure to remove films during sensor

zeroing will cause L and S reading to output 30 units lower than expected since sensors will zero

on the density filter.

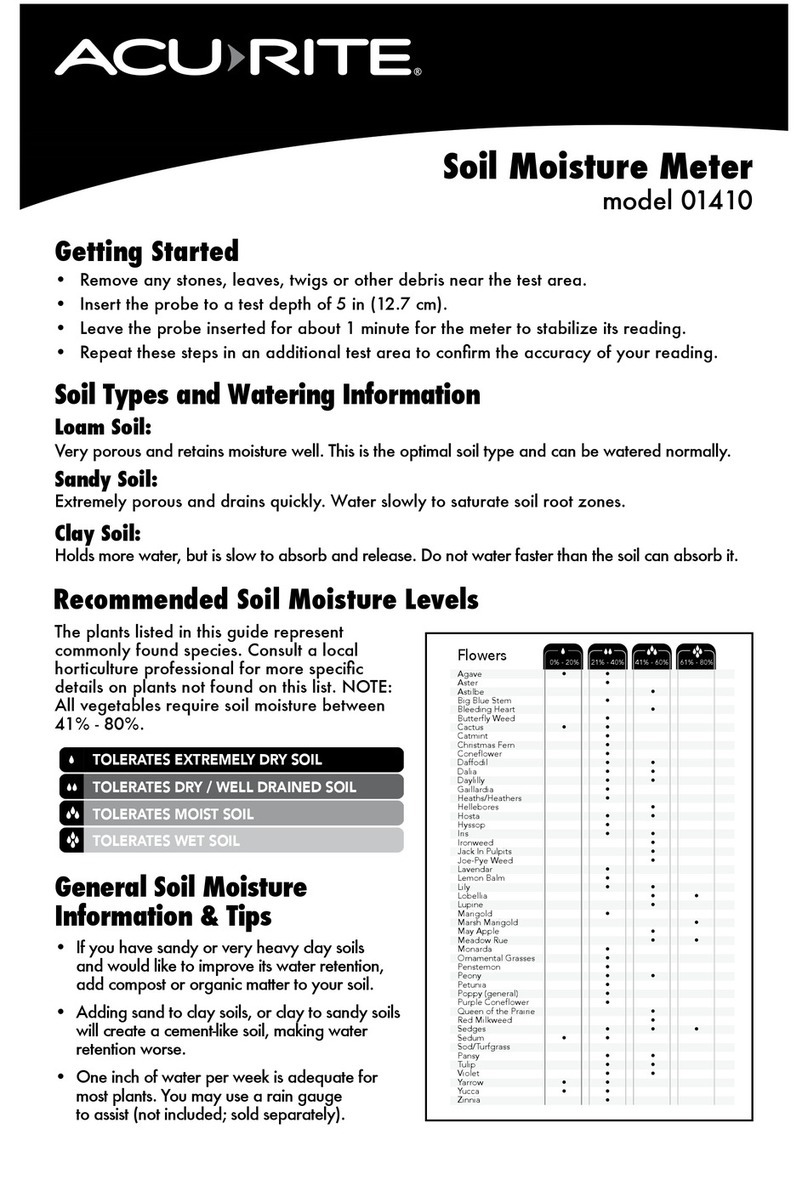

Typical neutral density filter reading ranges for the L and S:

Filter Density

L/ S Typical Mean Reading

L/S Range

.10

35

31-42

.20

66

60-74

.30

89

81-98

Calibration Check Troubleshooting:

Issue

Reason

Solution

All density filter

values out of range

Values out of range <10 units

Recalibrate LED light source and recheck

Value out of range > 10 units

Optical sensor zeroed on density film, repeat

check following procedure

Recalibrate LED light source and recheck

Photocell detector faulty, replace photocell

Optics block out of alignment, consult Trico

Only one density filter

value out of calculated

range

Value out of range <10 units Check density film for scratches, smears, or

fingerprints

Table of contents

Other Trico Measuring Instrument manuals