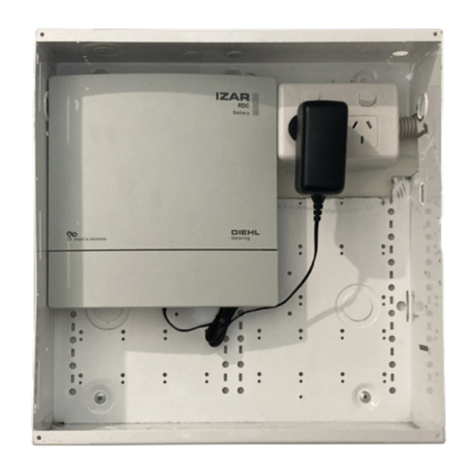

Prostat PWA-805 User manual

Other manuals for PWA-805

1

Other Prostat Measuring Instrument manuals

Prostat

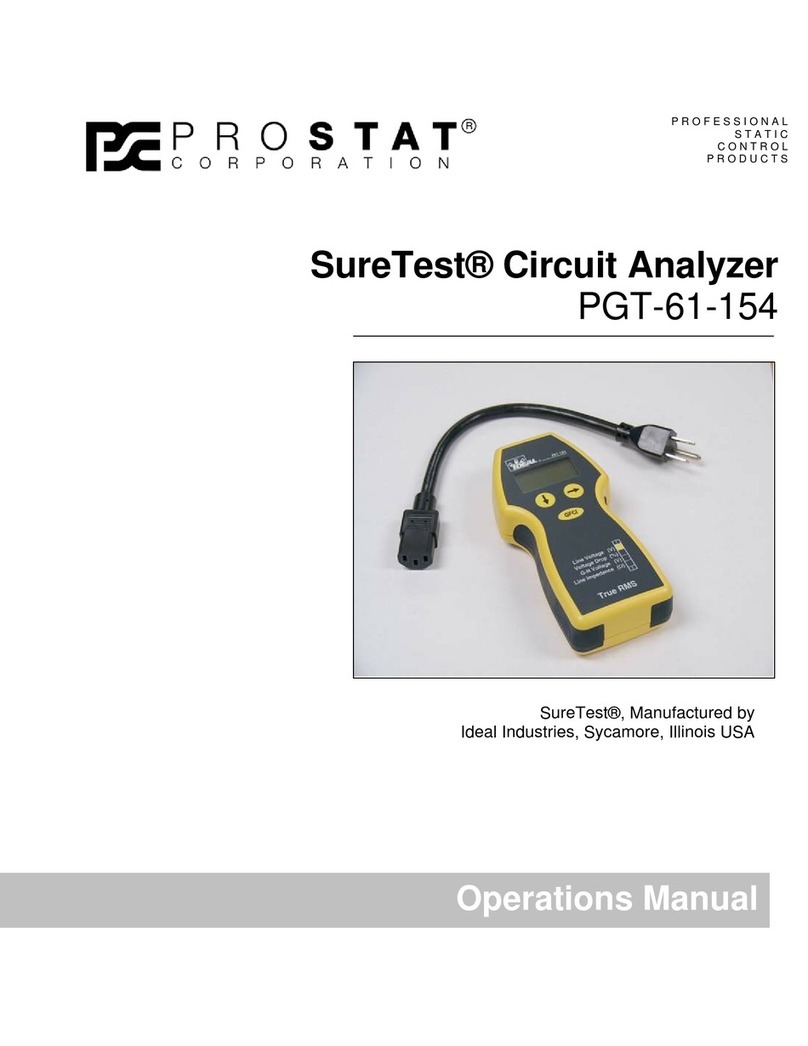

Prostat SureTest PGT-61-154 User manual

Prostat

Prostat CVM-780 User manual

Prostat

Prostat PRF-930 User manual

Prostat

Prostat PRF-912B User manual

Prostat

Prostat PRF-922B User manual

Prostat

Prostat PRS-812 User manual

Prostat

Prostat PFK-100 User manual

Prostat

Prostat PFA-860 User manual

Prostat

Prostat PRS-801B User manual

Prostat

Prostat PFM-711B User manual

Prostat

Prostat PFM-711A User manual

Prostat

Prostat PGA-710 User manual

Prostat

Prostat PFK-100 User manual

Prostat

Prostat PFM-711A User manual

Prostat

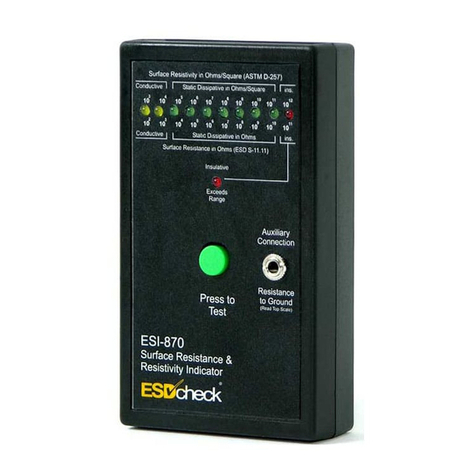

Prostat ESD check ESI-870 User manual

Prostat

Prostat PRS-812 User manual

Prostat

Prostat PAS-853B User manual

Prostat

Prostat PAN-750 User manual

Prostat

Prostat SureTest PGT-61-164 User manual

Prostat

Prostat CVM-780 User manual

Popular Measuring Instrument manuals by other brands

Endress+Hauser

Endress+Hauser IO-Link Ceraphant PTC31B operating instructions

Onicon

Onicon F-1100 Series Installation and operation guide

Ametek

Ametek MFC 1000.1 manual

Bacharach

Bacharach Fyrite Tech 50 Instruction, Operation & Maintenance

RST Instruments

RST Instruments VW2100-DP instruction manual

Major tech

Major tech MT155 instruction manual