Sensor Therm METIS M311 User manual

Pyrometers

METIS M311 / M322

METIS H311 / H322

With letter identifier L: Pyrometer series optimized especially for laser applications.

With 17-pin connector and PID controller

User Manual

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

Content

2

Content

1General ...............................................................................................................................................4

1.1 Information to this Manual.........................................................................................................4

1.2 CE Conformity and Standards ..................................................................................................4

1.3 Limitation of Liability..................................................................................................................4

1.3.1 PID controller .......................................................................................................................4

1.4 Terms of Warranty ....................................................................................................................4

1.5 Copyright...................................................................................................................................4

1.6 Spare Parts ...............................................................................................................................5

1.7 Returning Goods .......................................................................................................................5

1.8 Disposal ....................................................................................................................................5

2Safety..................................................................................................................................................6

2.1 Use of the Manual .....................................................................................................................6

2.2 Supplementary Information about the Operation......................................................................6

2.2.1 Warning Notes .....................................................................................................................6

2.2.2 Safety Labels / Symbols ......................................................................................................6

2.3 Laser Targeting Light ................................................................................................................7

2.4 Device Labels............................................................................................................................7

2.5 Electrical Connection ................................................................................................................7

2.6 Responsibility of the Operators / Process Responsibility .........................................................7

3Overview ............................................................................................................................................8

3.1 Intended Use.............................................................................................................................8

3.2 Scope of Delivery......................................................................................................................8

3.3 Model Design ............................................................................................................................8

3.4 Identification Label ....................................................................................................................8

4Electrical Connection........................................................................................................................9

4.1 Cable Colors and Pin Assignment ............................................................................................9

4.1.1 Factory Settings ...................................................................................................................9

4.1.2 Power Supply.....................................................................................................................10

4.1.3 Analog Output 1 and 2.......................................................................................................11

4.1.4 Digital Inputs / Outputs and Analog Input ..........................................................................11

4.1.5 Serial Interface RS232 / RS485 (M3: switchable RS232 / RS485; H3: only RS485)........12

4.1.5.1 USB Interface Converter (Accessory) ..........................................................................13

4.1.6 Shielding ............................................................................................................................14

5Mechanical Installation ...................................................................................................................14

5.1 Mounting .................................................................................................................................14

5.2 Mounting Optical Fiber / Optics (optical fiber devices) ...........................................................14

5.2.1 Bending Radius Optical Fiber ............................................................................................14

5.2.2 Winding and Unwinding the Optical Fiber .........................................................................14

5.2.3 Mounting of Optical Fiber...................................................................................................14

5.2.4 Connect the Optics ............................................................................................................15

5.3 Ambient Temperature .............................................................................................................15

5.4 Ratio Technology / Alignment onto the Measuring Object .....................................................16

5.4.1 Alignment with the Laser Targeting Light ..........................................................................16

5.5 Setting the Measuring / Focus Distance .................................................................................17

5.5.1 Focusable Fiber Optics......................................................................................................17

5.6 Spot Size Table.......................................................................................................................18

5.6.1 Focusable Fiber-Optics OQ30-90......................................................................................18

5.7 Coupling and Alignment of Optics in a Processing Optics .....................................................19

5.8 Adapt the Optics to the Laser Processing Optics ...................................................................19

5.8.1 Replacement of the Aperture Unit .....................................................................................19

6Pyrometer Parameters / Settings...................................................................................................20

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

Content

3

6.1 Emissivity Slope......................................................................................................................20

6.2 Emissivity Ɛ (when used in 1-color mode) ..............................................................................20

6.3 Transmittance .........................................................................................................................21

6.4 Spot Size Fill Factor................................................................................................................21

6.5 Switch-off Level / Signal Strength...........................................................................................22

6.5.1 Switch-off Verification ........................................................................................................22

6.6 Dirty Window Alarm ................................................................................................................22

6.7 Response Time t90 ..................................................................................................................22

6.7.1 Dynamic Adaptation at Low Signal Levels ........................................................................22

6.8 Storage Mode Maximum Value Storage (Peak Picker) / Clear Time tCL ................................22

6.9 Temperature Sub Range ........................................................................................................23

6.10 Customize Analog Output .......................................................................................................23

6.11 Analog Output .........................................................................................................................23

6.11.1 Test Current.......................................................................................................................23

6.11.2 Upscale-Burnout ................................................................................................................23

6.12 Interface Type (only M3 devices)............................................................................................24

6.13 Baud Rate ...............................................................................................................................24

6.14 Address...................................................................................................................................24

6.15 Temperature Unit ....................................................................................................................24

6.16 Interface Delay / Answer Delay ..............................................................................................24

7SensorTools Software ....................................................................................................................25

7.1 Program Start / Connecting the Pyrometer ............................................................................25

7.2 Software Window ....................................................................................................................27

7.2.1 Main Window Graphs ....................................................................................................27

7.3 Settings for the Fastest Possible Measurement Data Recording ...........................................30

7.3.1 Control Window .................................................................................................................31

7.3.2 Device Settings and Configuration ....................................................................................32

7.3.2.1 Digital Input / Output Configuration ..............................................................................33

7.3.2.2 Service functions ..........................................................................................................35

7.3.2.3 Interface........................................................................................................................36

7.3.2.4 Data Collection (Buffer Mode) ......................................................................................36

7.3.2.5 Single-Point Adjustment ...............................................................................................37

7.3.3 PID Controller ....................................................................................................................39

7.3.4 Setups................................................................................................................................41

7.4 Graphical Measurement Data Playback in the SensorTools Viewer......................................42

7.5 Communication / Options .......................................................................................................44

7.6 Spot Size Calculator ...............................................................................................................44

8SensorFlash Software (Update Firmware)....................................................................................45

9Technical Data .................................................................................................................................46

9.1 Dimensions .............................................................................................................................48

9.2 Composition of the Type Number ...........................................................................................48

9.3 Accessories.............................................................................................................................49

10 Maintenance.....................................................................................................................................50

10.1 Cleaning..................................................................................................................................50

10.2 Pyrometer Calibration .............................................................................................................50

10.3 Trouble-Shooting ....................................................................................................................50

11 Communication via Serial Interface / Interface Commands .......................................................51

Index.........................................................................................................................................................55

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

General

4

1 General

1.1 Information to this Manual

This manual enables the safe and efficient use with the device. The manual is part of the instrument and

has to be kept in a location where users always have access to.

Read this manual carefully before operating. For secure working all security notes and operation proce-

dures in this manual has to be followed.

Additionally the local accident prevention regulations and common safety regulations of the instruments’

operational area are valid.

The descriptions may differ from the current delivery status, since the pyrometer is continuously devel-

oped. Illustrations in this manual are for basic understanding and can differ from the actual construction.

1.2 CE Conformity and Standards

The product conforms to the following standards:

CE conformity: DIN EN 61326-1 (electromagnetic compatibility)

Laser safety: IEC 60825-1, laser class 2 (only devices equipped with laser targeting light)

RoHS: 2011/65/EU

1.3 Limitation of Liability

All information and notes in this manual are made under consideration of valid standards and rules,

state of technology and our expert knowledge for many years.

The producer assumes no liability for damages due to:

Non-observance of this manual

Usage out of intended use

Assignment of unskilled personnel

Unauthorized modifications

Technical modifications

Usage of spare parts not approved

The responsibilities of the delivery contract are valid as well as our general terms and conditions and

terms of delivery and the valid statutory rule at date of the conclusion of contract.

1.3.1 PID controller

The PID controller has been designed to control temperatures in a variety of applications, especially for

controlling fast processes. The temperature control accuracy depends on the appropriate choice of con-

trol parameters and on the process itself. Sensortherm excludes process responsibility.

1.4 Terms of Warranty

The general terms and conditions for sales and services of Sensortherm GmbH apply.

1.5 Copyright

This manual is protected by copyright and is intended solely for the operation of this pyrometer.

It is not permitted to transfer these instructions to third parties, duplication in any kind and form - includ-

ing excerpts - as well as recovery and / or notification of contents without written permission of the man-

ufacturer, except are internal purposes.

Contraventions are liable for damages. All other rights reserved.

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

General

5

1.6 Spare Parts

It is recommended to purchase spare parts and accessories direct from Sensortherm (manufacturer).

1.7 Returning Goods

We ask you to request an RMA number for each returned goods. Due to system technical reasons it is

not possible to edit the process without RMA number.

You will receive an RMA form, which has to be completed and sent to us by e-mail before delivery of the

goods. It is important to pay attention to a short, accurate error description, as this can considerably re-

duce the repair time. You will immediately receive an RMA number. In order to be able to perform a

warranty check in advance, we require the serial number(s) of the device(s).

Please return the items in suitable packaging to avoid damage during transport.

If you need to send this device back to us, the battery must be removed and may not be sent. Excep-

tions apply to trained resellers who have knowledge of the special transport and labeling regulations of

the dangerous goods.

1.8 Disposal

Do not dispose of the product in the household waste (WEEE Directive).

Dispose of the product properly when it is no longer usable: pyrometers include electrical and

electronic waste and have to be recycled or disposed environmentally friendly or to send to the

manufacturer for disposal.

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

Safety

6

2 Safety

2.1 Use of the Manual

Any person who is going to work with the device must have read and understood the operating man-

ual before beginning.

Operation and maintenance of the system is only to be performed by trained personnel.

This manual is to be kept and handed over when passed on.

2.2 Supplementary Information about the Operation

The following symbol is used to simplify the search for useful information:

|INFO| indicates useful tips, recommendations and information for efficient and trouble free operation.

2.2.1 Warning Notes

The following symbols are used in this manual and, if applicable, on the device as a mark for infor-

mation, restrictions, preventive measures and security notes. This information indicates risks and how

they can be avoided.

Please pay attention to this symbols for safety reasons.

|CAUTION|This combination of symbol and signal word indicates a hazardous situation which, if

not avoided, could result in minor or moderate injury.

|NOTICE|indicates a potentially hazardous situation that can lead to property and environmental dam-

age if not avoided.

|SAFETY INSTRUCTIONS|indicate specific safety-related instructions or procedures.

2.2.2 Safety Labels / Symbols

Additionally to the warning notes used in this manual, the following warning symbols are used. Warning

symbols are also to find on the device. Follow all measures marked with the label to avoid injury.

Indicates general hazards.

Indicates the hazard for the eyes due to a class 2 laser targeting light.

Indicates the hazard for the eyes from optical radiation.

Indicates the hazard of automatic startup of machine parts.

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

Safety

7

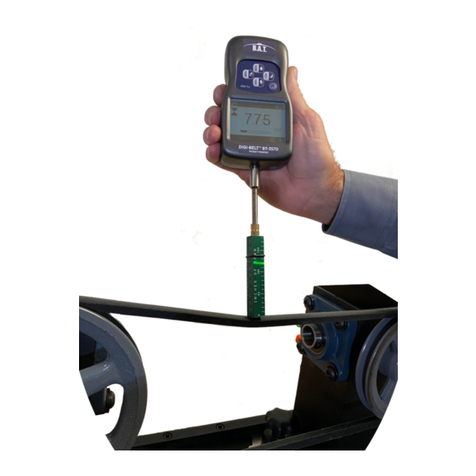

2.3 Laser Targeting Light

For easy alignment, the py-

rometers may be equipped

with a laser targeting light, la-

ser class 2 (according to IEC

60825-1. The laser emits a

visible red light with a maxi-

mum power of < 1 mW and a

wavelength around 650 nm.

|SAFETY INSTRUCTIONS|:

Never look into the direct or reflected laser beam.

Do not point the laser to anyone.

If laser radiation hits the eye, avert one's eyes immediately.

2.4 Device Labels

On the top of the device there is the type label (nameplate) as well as a warning sticker for devices with

laser targeting light.

Mount the device in a manner that the labels are still clearly visible after installation.

Keep the warning signs in always legible condition

Replace damaged labels

2.5 Electrical Connection

When connecting or when working on the mains voltage, the general safety guidelines are to be ob-

served, e.g. when connecting power transformers. Supply voltage can be lethal when touching. Improp-

er installation can cause serious injury or physical damage. Only qualified personnel are allowed to work

with mains voltage.

2.6 Responsibility of the Operators / Process Responsibility

If the device is used in the commercial sector the operator is subject to the legal responsibilities for

workplace safety.

In addition to the safety instructions in this manual follow the regulations of safety, accident prevention

and environmental protection. If the device is integrated into a system, the safety of the system in which

the device is integrated is in the responsibility of the installer of the system.

Sensortherm does not guarantee that the temperature control in all processes will meet the desired re-

quirements. Sensortherm excludes the process responsibility.

Laser warning label on the device (depending on the country of delivery):

US sticker

EU sticker

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

Overview

8

3 Overview

3.1 Intended Use

The 2-color pyrometers Metis M3 and H3 with letter identifier L (see 9.2, Type Number) are devices for

non-contact temperature measurement, optimized especially for laser applications.

They are suitable for measurements on metals, ceramics, graphite and similar with temperature ranges

between 300 and 3300°C (M3) or 350 and 3300°C (H3), depending on the model.

3.2 Scope of Delivery

Pyrometer, software SensorTools, works certificate, user manual

(connecting cables are not included in scope of delivery and have to be ordered separately).

3.3 Model Design

1

Laser warning label

2

Device identification label

3

Laser targeting light push button

4

LED to indicate operating status

5

Connectors for power supply, 2 linear

analog current outputs for manipulated

variable and actual value, 4 digital inputs,

2 digital outputs, 1 analog input, PID con-

troller, a serial interface (M3: RS232 /

RS485 switchable; H3: RS485)

6

Mounting rail

7

Mounting thread (M5) for front mounting

the pyrometer or accessory

8

Mounting thread (M5) for front mounting

the pyrometer or accessory

9

Optical fiber for transporting the heat

radiation to the pyrometer

10

Tube to protect the optical fiber connec-

tion

11

Fiber optics with adjustable focus dis-

tance

3.4 Identification Label

The identification label on top of the device shows information to:

manufacturer, reference number, temperature range, serial number, serial

interface output (=digital output), analog output, power supply, country of

manufacture and CE sign.

The composition of the type number is given in Chap. 9.2.

9

8

10

7

6

2

7

5

4

3

1

M3

22 0500 1800 158 13L 0423-X

Temp. range: 750 - 1800 °C

1382 - 3272 °F

Serial no: 1234

Digital output: RS 485

Analog output: 2x 0/4 - 20mA

Made in Germany Power supply: 18 - 30V DC

Sensortherm GmbH

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

Electrical Connection

9

4 Electrical Connection

4.1 Cable Colors and Pin Assignment

The electrical connection of the pyrometer (supply voltage and measuring signal) will be done via the

17-pin connector on the device’s rear side. For this purpose, pre-assembled connection cables are

available as accessories (cables 20-wire + shield, with straight connector and optionally with integrated

USB interface converter, see 9.3 Accessories).

|NOTICE|The unit has 3 separate circuits: supply, interface and power outputs. The reference poten-

tials GND should not be connected together. To prevent accidental short circuits, cable wires not in use

should be secured to the supplied screw terminals.

Cable colors

No.

Function

Pins

White

1

+ 24 V DC Power supply (18–30 V DC)

3

7

8

9

10

11

5

6

4

3

2

1

12

13

14

15

16 17

View from outside

to the 17-pin

device plug

Brown

2

0 V DC Power supply

1

Green

3

+ Analog output 1 (0 / 4–20 mA)

4

Yellow

4

- Analog output 1 (0 / 4–20 mA)

6

Blue

7

+ Analog output 2 (0 / 4–20 mA)

2

Red

8

- Analog output 2 (0 / 4–20 mA)

9

Black

9

Digital input 1 1)

7

Violet

10

Digital input 2 1)

10

Pink

6

Digital input 3 1)

5

Grey

5

Digital input 4 1)

8

Brown-green

14

Analog input 1)

14

Grey-pink

11

Digital output 1 1)

11

Red-blue

12

Digital output 2 1)

12

White-yellow

15

RS232: RxD

RS485: B (+) 2)

15

White-grey

17

Brown-yellow

16

RS232: TxD

RS485: A (-) 2)

17

Brown-grey

18

White-pink

19

DGND (ground for interface)

16

Brown-pink

White-green

13

Reference voltage output (10 V ±1%, max. 10 mA) 1)

13

Housing

20

Shield (connect only for cable extension, do not connect in the control cabinet)

1) Reference potential 0 V, brown 2) H3 models only RS485

4.1.1 Factory Settings

Parameters Factory settings

Temperature sub range ........................................ Corresponds to basic range

Response time t90 ................................................. Minimal (corresponds to: M3: <1 ms; H3: <80 µs)

Emissivity slope .................................................... 1.000

Switch-off limit....................................................... 10%

Switch-off verification ............................................ 0 ms

Emissivity ε (channel 1 and 2) .............................. 1.00 (corresponds to 100%)

Transmittance ....................................................... 100%

Spot size fill factor................................................. 100%

Serial interface RS232 / 485................................. RS485

Data transmission speed (baud rate).................... 115.2 kBd

Buffer mode .......................................................... off (at “on”: buffer interval: 100 ms, single reading)

Upscale Burnout function...................................... off

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

Electrical Connection

10

M3 / H3

White

Brown

+24 V

0 V

Device address ..................................................... 00

Interface delay ...................................................... 00 (for RS232 and RS485)

Maximum value storage........................................ off

Laser targeting switch-off time .............................. 180 s

Analog output 1 ..................................................... 4–20 mA, output temperature: measured temperature

Analog output 2 ..................................................... 0–20 mA, output temperature: PID control output

Digital input 1 ........................................................ Controller start/stop

Digital input 2 ........................................................ No function

Digital input 3 ........................................................ Clearing of peak picker

Digital input 4 ........................................................ Laser targeting light on / off

Analog input .......................................................... No function

Digital output 1 ...................................................... Contact ready to use (device ready to operate)

Digital output 2 ...................................................... Controller active

Inputs / outputs

Input debounce time ............................................. 100 ms

Output activation time ........................................... 0 ms

Output hold time.................................................... 10 ms

Limit switch:........................................................... center of temp. range °C / °F; hysteresis: 10°C / 20°F

Device over temperature:...................................... 50°C / 120°F; hysteresis: 2°C / 5°F

PID controller

Setpoint ............................Center of temp. range

Proportional band Xp........1%

Derivative time Td.............0 ms

Integral time Ti..................10 ms

Sampling time...................10 ms

Ramp time ........................0 ms

P-zsc.................................100%

P-max ............... 100%

P-min ................ 0%

P-Dyn................ 100%

AutoTune .......... at each start

(AutoTune target temp: 50%)

Ramp time ........ 0 ms

Hold time........... 0 ms

|INFO| to baud rate / buffer mode: The factory setting of the baud rate is set to 115 kBd to ensure al-

so at longer interface cables a working data transfer. For data transmissions with the highest speed,

baud rate and buffer mode must be adjusted (see 7.3.2.4).

4.1.2 Power Supply

When connected to the supply voltage (standard 24 V DC, possible range 18–

30 V) the unit is ready for operation with the following factory settings (chang-

ing the settings is possible via interface and Software SensorTools, see 7).

The supply voltage must be protected with a slow-blow fuse of 800 mA.

Interrupt the power supply to turn off the pyrometer, e.g. by disconnecting the connector.

Power status LED: Indicates the operating status of the pyrometer:

Orange in the self-test phase, H3 during the initialization and thermostatic

phase

Green when the pyrometer is ready to operate

Red when an error occurred (see 10.3 Trouble-shooting).

LED

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

Electrical Connection

11

M3 / H3

0...20 mA

4...20 mA

A

0...20 mA

4...20 mA

A

+IOUT1

-IOUT1

+IOUT2

-IOUT2

Green (+)

Yellow (-)

Red (-)

Blue (+)

Note: The outputs are galvanically

isolated from the supply voltage.

Max. 100 mA

0 V

Min. 240 Ω

M3 / H3

Output

+24 V

100 kΩ

White

Grey-pink

Brown

0 V

Red-blue

4.1.3 Analog Output 1 and 2

2 analog outputs are available (e.g. for a temperature display de-

vice):

adjustable to 0–20 mA or 4–20 mA

Analog output 1 always provides the measured temperature.

The measuring temperature is assigned in the control window

in SensorTools; see 7.3.1 Control window in SensorTools).

Analog output 2 can be assigned to provide different signals:

- 2-color temperature

- 1 channel temperature (optional channel 1 or 2)

- Device temperature

- Control output (= manipulated variable) for PID controller

|INFO| on older models: If the same settings are possible on analog output 1 as on analog output 2,

the device has an older firmware version. A firmware update to the latest version eliminates this possi-

bility and thus prevents the analog output 1 from accidentally provide a different temperature signal than

is displayed (Firmware update see section 8).

4.1.4 Digital Inputs / Outputs and Analog Input

7 ports are each available as (configuration under 7.3.2 Device settings and configuration Digital

Input / Output):

2 Digital outputs: output of a switching signal (invertible, see under 7.3.2 Various settings Log-

ic NO / NC) to:

- Device ready to operate (device ready and error-

free after self-test)

- Material detection (limit switch turns on when ex-

ceeding the beginning of temperature range)

- Limit switch when a certain temperature threshold

is exceeded or falling below

- Exceeding the maximum allowed device tem-

perature

- Signal strength too low (as dirty window alarm

function: enables to detect the degree of contamination of the pyrometer‘s optics, viewing window

or identify interferences (dust...) in the IR sensor’s sight path and trigger an alarm if necessary).

- Controller activity of PID controller, control process within adjustable setpoint limits, control pro-

cess successfully completed, hold time finished.

4 Digital inputs: A voltage pulse of 24 V (excep-

tion: continuous voltage at "Activate controller"),

pulse length adjustable via software (minimum 3

ms, factory settings 100 ms) under 7.3.2 Digital

Input / Output debounce time enables:

- Clear of peak picker (see 6.8)

- Start / stop controller (PID controller, see 7.3.3).

- Activate controller: The control process is acti-

vated as long as voltage at the terminal is pre-

sent.

- Load (stored) pyrometer configuration (also PID controller parameters) (only digital inputs 1-3, see

under 7.3.4 Setups).

- Switch on / off laser targeting light.

(the targeting light will automatically switched off after 3 minutes if it is not switched off manually.

Adjustable via software under 7.3.2 Laser targeting light settings).

|CAUTION |Laser radiation, laser class 2, do not look into the beam.

|SAFETY INSTRUCTIONS|

Never look into the direct or reflected laser beam.

Do not point the laser to anyone.

If laser radiation hits the eye, avert one's eyes immediately.

>10 kOhm

0 V

+24 V

Push

button

0 V

+24 V

White

Brown

Black

Violet

Pink

Grey

Note: The input is safely detected as “high” at a voltage

> 15.5 V and safely detected as “low” at a voltage < 3.0 V.

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

Electrical Connection

12

Setpoint input via external voltage 0...10 V: This voltage can

also be made via the 10 V reference voltage output and a 2 kΩ

potentiometer (connected as a voltage divider, the internal re-

sistance of the input is 40 kΩ).

The external voltage does not have to be galvanically isolated,

0 V (brown) is ground reference, i.e. the ground of the external

voltage must be connected to the device ground.

2 kΩ

M3 / H3

Internal resistance

40 kΩ

0 V

+10 V reference voltage

Voltage

divider

Power supply

0-10 V

White-green

Brown-green

Brown

Analog input (input 5): An external voltage of

0-10 V can be used to externally adjust some

parameters between their minimum and max-

imum setting values (settings about Sensor-

Tools software Digital Input / Output

Analog input

- The emissivity slope

(0 V = 0.8; 10 V = 1.2)

- The emissivity for every channel

(0 V = 0.05; 10 V = 1.2)

- The setpoint for PID controller

(0 V = zero scale temperature,

10 V = full scale temperature)

4.1.5 Serial Interface RS232 / RS485 (M3: switchable RS232 / RS485; H3: only RS485)

The serial interface is used for digital communication of the pyrometer with another computer, for exam-

ple a PC for data transmission to the software SensorTools. The interface transmits all measured data

according to the setting as well as device information and parameters.

The maximum transmission speed (in Baud) is limited by the cable length; it is halved with each dou-

bling of the transmission path.

RS232: about 7 m cable length with 19.2 Bd. Adjustable are values from 4.8 to 115.2 kBd.

RS485: about 2 km with 19.2 kBd. Adjustable are values from 4.8 to 921.6 kBd.

Connecting one pyrometer via

RS232 or RS485:

In a short RS232 or RS485 connection to the mas-

ter (computer receiving the data), the pyrometer is

connected directly as a point-to-point connection

with the master.

All interface cables must be connected in order to

avoid reflections.

Connecting several pyrometers via RS485:

For a reflection-free operation with longer cables, pay attention to the correct cable termination. Termi-

nation at the physical bus is at the beginning and at the end.

Master

A (-)

B (+)

DGND

120 Ω

... Pyrometer n

Terminating

resistor 120 Ω

Pyrometer 2

Pyrometer 1

Terminating

resistor 120 Ω

in the master

or manually

A

B

GND

A

B

GND

A

B

GND

A

B

GND

GND

B

A

B

A

120 Ω

... Pyrometer n

Terminating

resistor 120 Ω

Pyrometer 1

A

B

GND

B

A

B

A

120 Ω

Master

A (-)

B (+)

DGND

A

B

GND

Terminating

resistor 120 Ω

Master at

the beginning:

Master in

the middle:

RxD

TxD

GND

Pin 2

Pin 3

Pin 5

A (-)

B (+)

GND

RS485

(Master /

PC)

RS232 (PC)

Pyrometer

Pyrometer

A (-) Brown-grey

B (+) White-yellow

B (+) White-grey

A (-) Brown-yellow

TxD Brown-grey

RxD White-yellow

RxD White-grey

TxD Brown-yellow

DGND White-pink

DGND Brown-pink

DGND White-pink

DGND Brown-pink

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

Electrical Connection

13

When operating multiple devices (up to 32 are possible), each device needs to assign its own address

(directly on the device or via software SensorTools), under which it can be addressed later. For this

purpose, initially, each device must be connected individually and provided with an address (00-97). Af-

ter that, all devices can be connected.

If specific parameters for all devices should be changed simultaneously, the global address 98 is used

(there is no response from the device). If the address of a device is unknown, you have the opportunity

to address each device independently of the set address with the global address 99 (connect only one

device).

4.1.5.1 USB Interface Converter (Accessory)

A quick and easy way to

connect the pyrometer with

a PC is to use an interface

converter or a connecting

cable with integrated inter-

face converter (see 9.3 Ac-

cessories). Depending on

the operating system, suita-

ble drivers are installed automatically or can be found on the CD supplied with the software Sensor-

Tools in the directory Drivers FTDI_USB_COM or after installing SensorTools in the installation direc-

tory (updated driver for Windows from the FTDI website: http://www.ftdichip.com/Drivers/VCP.htm).

To achieve the maximum

transfer speed, it is absolute-

ly necessary to change the

latency time in the advanced

port settings from 16 ms to

1 ms:

Open Device Manager

(Windows 10: Right-click

on the Windows key and

select "Device Manager"

in the menu.

Windows 7: Open Control

Panel and select Device

Manager).

1. Double click on "Ports

(COM and LPT)" USB

Serial Port (COMx) of the

interface converter.

2. Select the tab "Port set-

tings" and then click on

"Advanced".

Set the waiting time to

1 ms (in "BM Options").

More information is available

in the FTDI application note

AN_107 - Advanced Driver

Options.

Cable colors

Metis M3 / H3

(12-pin connector)

Cable colors

interface converter

RS232USB (TxD / RxD)

RS485USB (A‾ / B+)

White-pink or brown-pink (DGND)

Black (GND)

White-yellow or white-grey (B+/ RxD)

Orange (B+/ TxD)

Brown-yellow or brown-grea (A‾ / TxD)

Yellow (A‾ / RxD)

1.

2.

3.

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

Mechanical Installation

14

4.1.6 Shielding

To meet the requirements for electromagnetic compatibility (EMC), only shielded cables should be

used. The shield of our connection cables is connected on the pyrometer side in the plug housing. If

faults occur during the pyrometer operation, the pyrometer should be connected to system ground. For

this, the front-side end screws have to be used, the anodized housing is not a reliable electrical connec-

tion. The shielding wire is not connected to prevent ground loops and damage caused by transient cur-

rents. When extending the cable, the screen must be extended with.

5 Mechanical Installation

5.1 Mounting

The mounting rail on the bottom case is for the stable take-up of for example of a ball and socket

mounting (for fiber optics devices a mounting angle is recommended, see 9.3 Accessories)

Front M5 threaded screws can also be used for mounting (all 4 threads has to be used for fixing).

Unusual oscillations or vibrations should be damped by appropriate measures, if necessary, helps the

use of rubber absorbers when mounting.

To protect the optical fiber, it should be exposed as little as possible to permanent movement and

mechanical stress. Lay the optical fiber as possible with a large bending radius, especially if it is car-

ried along moving parts.

During installation of the optical fiber, it is advisable that both plug ends are not yet connected to the

pyrometer and the optics. Tensile and torsional stresses are to be avoided.

5.2 Mounting Optical Fiber / Optics (optical fiber devices)

5.2.1 Bending Radius Optical Fiber

The color code on the optical fiber identi-

fies the optic diameter and minimum bend-

ing radius associated.

When laying the optical fiber it is to ob-

serve the minimum bending radius. A

bending radius smaller than the specified minimum radius can cause a break of the optical fiber.

5.2.2 Winding and Unwinding the Optical Fiber

Always ensure that the minimum bending radius is not exceeded.

During winding and unwinding the optical fiber must be able to move easily

and should not be twisted. Ideally, one hand winds up the light guide careful-

ly, while the other hand guides the cable roll. For torsion-free winding only

one side of the optical fiber should be connected, than the other can be

moved freely.

|NOTICE|Avoid strong tensile and torsional forces during rolling and

mounting.

5.2.3 Mounting of Optical Fiber

Assignment fiber to pyrometer and optics: Each fiber is uniquely associated to a pyrometer and op-

tics. For identification, all three components are tagged with the same device number. The measure-

ment accuracy can

only be guaranteed

with proper as-

signment.

Color code

of the optical fiber

Fiber diameter

Minimum

bending radius

Blue

0.4 mm

150 mm

Red

0.2 mm

75 mm

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

Mechanical Installation

15

|INFO| When replacing the optics or the optical fiber, the instrument must be recalibrated to maintain

the high measurement accuracy.

|NOTICE|Remove the protective caps from the pyrometer and optics and fiber just before in-

stallation to keep the connectors clean and to prevent the ingress of dirt.

Keep the protective caps to be able to protect against dirt in any subsequent dismantling or storage.

The optical fiber must be mounted on correct side:

The side with the shrink tube marking is to be mount

on the pyrometer side, the side without marking on

the optics side.

Unscrew the light guide protective tube from the

pyrometer’s housing

Pull the protective tube somewhat about the light

guide on the colored side to avoid pulling it over

the complete fiber after fiber assembly.

Remove the protective caps from the pyrometer

and optical fiber, insert the side with the turn pro-

tected fiber connector to the pyrometer, and make

sure that pin and recess snap together.

Tighten lock nut hand-tight (do not use a tool, otherwise

the screw or optical fiber can be damaged).

Finally screw the protective tube back on the pyrometer

housing.

5.2.4 Connect the Optics

Remove the protective caps from optical fiber

and optics

The fiber-optic connectors on the side of the op-

tics does not require special adjustment and is

just plugged and screwed

Tighten lock nut hand-tight (do not use a tool,

otherwise the screw or optical fiber can be damaged).

5.3 Ambient Temperature

The internal housing temperature can be read out via the software

SensorTools (see 7).

It is also possible to configure one of the digital (switching) out-

puts in such a way that a corresponding signal is switched if ex-

ceeding the maximum temperature (see 4.1.4 Configurable In-

puts / Outputs and under 7.3.2.1 Digital Input / Output configuration).

The laser targeting light is deactivated at a device temperature above 55°C.

Connector pyrometer’s side (turn protected)

Connector optics side

Recess

Pin

Lock nut

Opt. fiber

Protective tube

Color mark

DT: internal de-

vice temperature

via software

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

Mechanical Installation

16

5.4 Ratio Technology / Alignment onto the Measuring Object

In opposition to radiation pyrometers, 2-color pyrometer measure in two spectral ranges simultaneously

and determine the temperature by forming the radiation ratio (quotient).

In this method, it is not necessary to know the emissivity of the measurement material when it is a gray

body.

Via the SensorTools software the 2-color temperature and the

temperatures of the individual channels can be shown simulta-

neously to identify possible wavelength dependency (see 6.1

Emissivity slope).

To detect the temperature correctly, the pyrometer must be

properly aligned to the object to be measured. At the focus point

of the optics (infrared focus distance) the spot size diameter is

the smallest. Also measurements in the defocused area can be

done to determine the average temperature of a bigger spot.

To get a correct measurement result, the following requirements must be observed:

When measuring through windows, the optical properties of the window material must be taken into

account.

If the measuring diameter is larger than the object to be measured, care must be taken about the sig-

nal strength is not to be lower than the preset value, otherwise the system will switch off.

The factory setting is 10%.

Entering a fill factor that indicates how much percent of

the measuring field is filled, has no influence if using

the 2-color measuring mode. In 1-color mode meas-

urements can be performed with objects smaller than

the spot size.

5.4.1 Alignment with the Laser Targeting Light

The laser targeting light is a conical red laser beam with the largest diameter directly at the lens and the

smallest in the focus distance.

|INFO| The position of laser targeting light focus and pyrometer focus do not match.

|CAUTION |Laser radiation, laser class 2, do not look into the beam.

|SAFETY INSTRUCTIONS|

Never look into the direct or reflected laser beam.

Do not point the laser to anyone.

If laser radiation hits the eye, avert one's eyes immediately.

Turn on / off: Via the targeting light button on rear panel or via software

SensorTools (see 7.3.1,Control window).

(The targeting light will automatically switched off after 3 minutes if it is not

switched off manually. Adjustable via software under 7.3.2 Device Set-

tings Laser targeting light settings).

|INFO| The laser targeting light is turned off at a device temperature

above 55°C.

If the targeting light cannot be turned on, the device's internal temperature

may be too high. In this case, the installation location of the pyrometer

must be checked.

Laser target-

ing button

Software

Spot size smaller than measuring object

Measuring object

Pyrometer’s spot size bigger than measur-

ing object, note background radiation.

Focus point

Spot size bigger

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

Mechanical Installation

17

5.5 Setting the Measuring / Focus Distance

The focus distance is the distance in which the pyrometer's measuring diameter is the smallest.

For optics with focus adjustment, the focus distance can be changed continuously within a predeter-

mined range.

5.5.1 Focusable Fiber Optics

Slightly loosen the optics lock ring so that the optics

adjusting unit is just still movable.

Slightly loosen the optics locking ring so that the op-

tics adjusting unit can be pushed in and out.

Switch on the laser targeting light of the pyrometer.

To focus on the required measurement distance, the

optics adjustment unit must be pulled out or inserted.

Note: Infrared focus and laser focus are not at the

same place, the infrared focus distance is about 5%

farther away from the lens than the laser focus.

|NOTICE|Beware of tearing the optical fiber.

Never pull on the flexible part of the optical fiber for fo-

cusing.

Optics

locking ring

Optics

adjusting unit

Tube

Focus adjustment

Infrared focus

Laser focus

Flexible part of the optical fiber

Fixed part of the optical fiber

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

Mechanical Installation

18

5.6 Spot Size Table

The following table show the optical data of the optics. The values in the tables are exemplary, interme-

diate measurement distances can be determined by interpolation. If the measuring distance (= focused

distance) differs from the adjusted or specified, a measurement is also possible, but the spot size

changes. The specified focus distances are valid from the front of the lens.

5.6.1 Focusable Fiber-Optics OQ30-90

Optics

Model

Temperature ranges [°C]

M322: 300-1000°C

H311: FSC <1500°C

H322: FSC <1200°C

M311/ M322: all

other temp. ranges

H311: FSC ≥1500°C

H322: FSC ≥1200°C

Meas. distance a [mm]

Spot size diameter M [mm]

OQ30-90

340

1.3

0,8

400

1.7

1

450

2

1.15

500

2.3

1.31

600

2.8

1.62

700

3.3

2

800

4

2.26

900

4.3

2.5

1000

4.5

2.9

1500

7

3.5

2000

10

4.7

2500

10.4

5.2

3000

14

7.5

3500

15.5

8

4000

19

11

Aperture diameter D: 10-13 mm

Fiber Ø 0.4 mm

Fiber Ø 0.2 mm

(D is dependent on the optics pull-out: optics pulled out: higher value, optics inserted: smaller value)

FSC = Full scale temperature

Delivery versions optics OQ30-90:

Optics

Characteristics

For models with end of temperature

range

OQ30-90 L1

3 mm aperture (delivery status,

incl. 9.5 mm replacement aperture)

H311: ≥ 2000°C

M311: ≥ 2100°C

OQ30-90 L2

M322 / H322: ≥ 2300°C

OQ30-90 11

9.5 mm aperture (delivery status)

H311: < 2000°C

M311: < 2100°C

OQ30-90 22

M322 / H322: < 2300°C

The appropriate signal height of the pyrometer is controlled by apertures.

Using the 9.5 mm replacement aperture: For measuring objects smaller than the spot size diameter

or measurements through the processing optics of a laser system, the radiation intensity received by the

pyrometer may under certain circumstances be reduced so much that a measurement is no longer pos-

sible (see also 6.5, Switch-off Level / Signal Strength). In this case, the measurement can be made

possible again by installing the 9.5 mm aperture (see 5.8.1 Replacement of the adjustment unit).

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

Mechanical Installation

19

5.7 Coupling and Alignment of Optics in a Processing Optics

If the pyrometer’s fiber optics is coupled into the processing op-

tics, it must be aligned. For this purpose, switch on the laser tar-

geting light of the pyrometer.

First the focus distance of the pyrometer optics should be ad-

justed in relation to the HAZ (HAZ, heat affected zone) of the

laser spot in order to meet the targeted diameter relation be-

tween HAZ and measuring spot of the pyrometer. Only for 2

color pyrometers it can be selected larger or smaller. For 1-

color devices, the pyrometer spot size must be smaller than the

HAZ. The pyrometer IR focus position can be determined with

the HE1200 using suitable measuring methods.

Second step is to adjust the pyrometer axis (represented by the

pyrometer’s laser targeting light) and IR laser axis (represented

by the pilot laser of the IR laser) at least to be coincident in the

working distance, in best case to be collinear.

5.8 Adapt the Optics to the Laser Processing Optics

Pyrometers have a factory calibration and adjustment for a direct

view to the measurement object. When the pyrometer or optics is

coupled into a laser processing optics, signal losses and spectral

changes result from transmission properties of the lenses, coating

influences or when the object size is smaller than the pyrometer

spot size.

The SensorTools software's single-point adjustment function

(see 7.3.2.5), allows the pyrometer to be adjusted for these signal

losses at the main measurement temperature used.

If the signal strength after single-point adjustment is still too low, it

can be increased by factor of 10 by changing the aperture unit in

the pyrometer optics to the next larger one, e.g. change from diameter 3 mm to 9.5 mm.

5.8.1 Replacement of the Aperture Unit

Aperture units are available with apertures

with different aperture diameters, 3 and

9.5 mm.

Remove the optical fiber from the optical

fiber connector

Unscrew the screwing and pull it out to-

gether with the optics adjustment unit.

Loosen the optics locking ring slightly.

Move the optics adjustment unit with the

next larger apert in the screwing.

Screw the unit of screwing and the op-

tics adjustment unit back into the optics

and firmly tighten the screwed connec-

tion.

Optics locking ring

Aperture unit

Fiber con-

nection

Aperture

Screwing

Working

distance

Processing

optics

Fiber

optics

Fiber

Pyrometer

HE1200

Working

distance

Spot size of

processing

laser

Typical

pyrometer

spot size

Aperture

METIS M311 / M322 / H311 / H322 for laser applications (17-pin)

Pyrometer Parameters / Settings

20

6 Pyrometer Parameters / Settings

The pyrometer is ex works ready to measure with the factory settings. The connection to a PC is re-

quired for further adaptation to the measuring task and to configure the inputs and outputs, all settings

can be made via the included software SensorTools (see 7,SensorTools Software).

Further it is possible to communicate via interface commands directly to the pyrometer (see 11, Inter-

face Commands). The commands can be used for writing an own control or can be entered via a ter-

minal software.

6.1 Emissivity Slope

Measuring objects having the same emissivity at the two different wavelength are called grey bodies

(e.g. well oxidized iron or steel surfaces). They can be measured accurately with the setting 1.00 for the

emissivity slope without correction.

Measuring objects whose emissivity is different on the two wavelengths of the pyrometer (e.g. shiny un-

oxidized metal surfaces) need for accurate temperature measurement a correction setting, the so-called

emissivity slope Ɛ2/ Ɛ1. The value can be larger or less than 1, depending on whether the emissivity of

channel 1 or 2 is higher (gain from 1.000 to 0.800, attenuation from 1.000 to 1.200).

For correct 2 color measurement the emissivity ratio for an object should be constant over the measur-

ing temperature range. If that does not apply, the accuracy will be affected.

In the SensorTools software the 2-color temperature and

those of the two channels can be displayed at the same

time. A 2-color measurement is usually correct if the

curves of the two channels in the required measuring

range run uniformly parallel, so the ratio is constant. If

the temperature values of the curves are identical (at the

same emissivity setting), then the emissivity slope is 1.

Do they run parallel, so the correct value for the emissiv-

ity ratio must be found, such by comparative measure-

ment with a thermocouple and subsequent ratio setting

until the temperatures match.

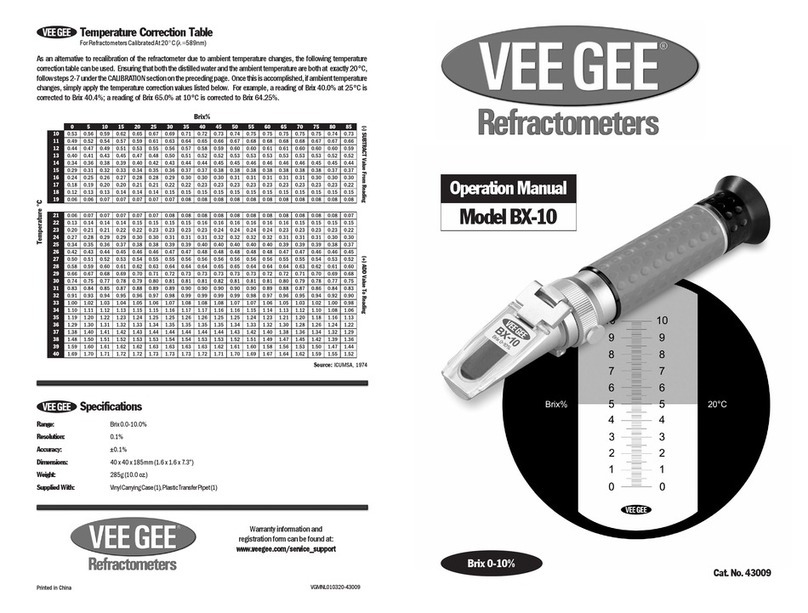

6.2 Emissivity Ɛ(when used in 1-color mode)

If the pyrometer is used in 1-color

mode, the measurement corresponds

to that of a conventional radiation py-

rometer. For correct 1-color measure-

ment the emissivity needs to be set

correctly.

The emissivity indicates the radiated

power of an object in relation to a so

called blackbody source with emissivi-

ty 1. To obtain correct readings, the

emissivity must be taken into account

in the measurement and adapted for

the respective measuring material on

the pyrometer. Each material has a

max. emissivity of 1 which can be set,

an adjustment of up to 1.2 can be

used. The emissivity adjustment above

1 allows for temperature corrections

due to higher background reflection.

For temperature measurement of met-

al surfaces, it is helpful to use short

Measuring object

Emissivity Ɛ(Epsilon)

M311/H311

0.7-1.1 µm

M322/H322

1.45-1.8 µm

Blackbody

1

1

Aluminum, shiny

n.s.

0.05-0.2

Aluminum, oxidized

n.s.

0.3-0.4

Aluminum, sandblasted, rough

n.s.

0.4-0.5

Aluminum, black anodized

n.s.

0.9

Lead oxidized

n.s.

n.s.

Bronze

0.2-0.4

0.2-0.4

Iron, liquid

0.15-0.3

0.1-0.25

Iron, shiny

0.3-0.4

n.s.

Iron, oxidized

0.7-0.9

0.65-0.85

Graphite

0.8-0.92

0.8-0.9

Gold, shiny

0.02-0.05

0.02-0.05

Inconel, shiny

0.35-0.45

0.4

Inconel, oxidized

0.65-0.75

0.6-0.7

Copper, shiny

0.10

0.05-0.1

Copper, oxidized

0.3-0.7

0.2-0.8

Other manuals for METIS M311

1

This manual suits for next models

3

Table of contents

Other Sensor Therm Measuring Instrument manuals

Sensor Therm

Sensor Therm METIS M3F1 User manual

Sensor Therm

Sensor Therm Metis MS User manual

Sensor Therm

Sensor Therm METIS M311 User manual

Sensor Therm

Sensor Therm METIS MF11 User manual

Sensor Therm

Sensor Therm METIS M3F1 User manual

Sensor Therm

Sensor Therm METIS M311 User manual

Sensor Therm

Sensor Therm METIS H3 series User manual