Read Instructions Before Installing

To Install:

Product Ordering:

Replacement Parts:

See Reverse Side For Specific Instructions On Installing The Closed System

TRICO CORP. 1235 HICKORY STREET, PEWAUKEE, WI 53072 TEL. (262) 691-9336 FAX (262) 691-2576

www.tricocorp.com 69509 01/15

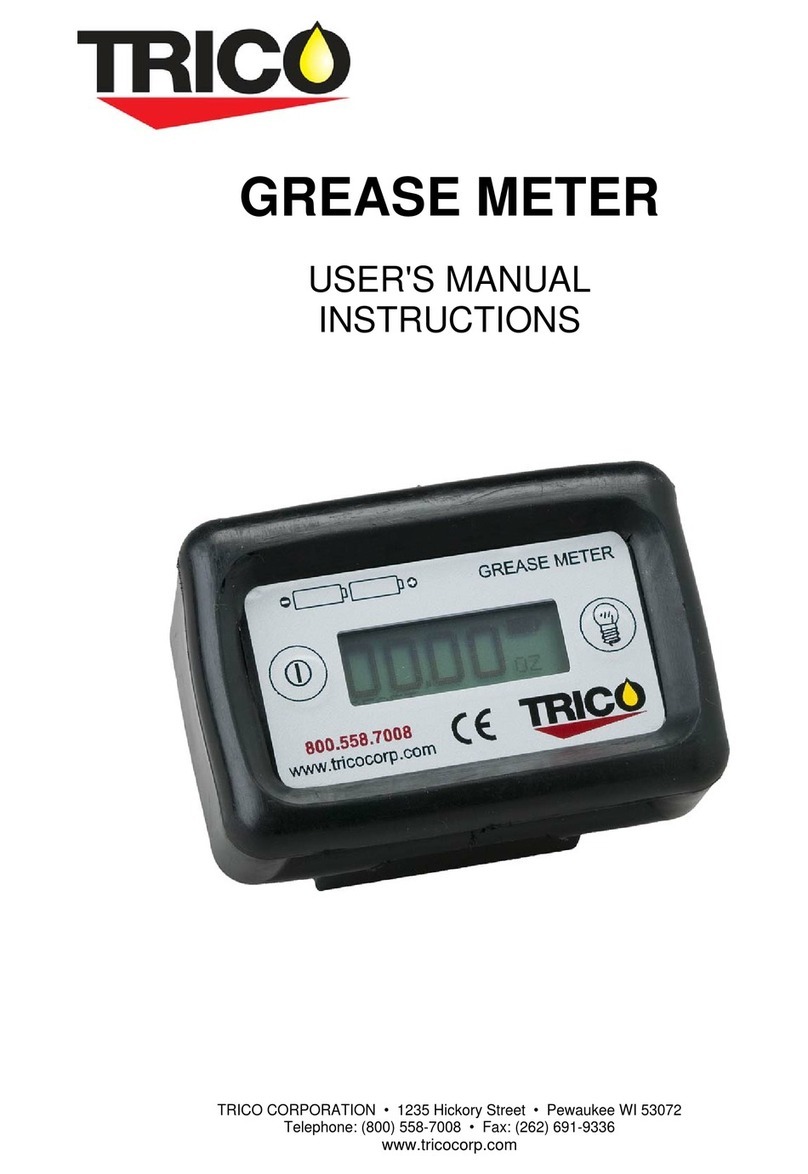

Loosen set screw on reservoir assembly. Remove reservoir

and put aside (Fig. 2).

2.

Verify that there are no contaminants or noticeable particles

in the CLOSED SYSTEM or bearing housing.

3.

Tighten supplied plug in side or bottom fluid port, sealant is

not necessary on plug. If using side fluid port to connect

CLOSED SYSTEM to the bearing housing, tighten plug in

bottom fluid port. If using bottom fluid port to connect

CLOSED SYSTEM to the bearing housing, tighten plug in

side fluid port (Fig. 2).

4.

Apply pipe thread sealant to a 1/8"NPT x 1/4"OD male

connector and tighten it into the vent port on the CLOSED

SYSTEM.

6.

Apply pipe thread sealant to a 1/8"NPT x 1/4"OD male

connector and tighten it into the vent port on the bearing

housing.

7.

Connect a section of 1/4"O.D. copper or nylon tubing to the

1/8" NPT connectors. This will serve as the vent line (fig. 3).

8.

Fill the bearing chamber through the main body of the

CLOSED SYSTEM until it reaches just below the optimum

fluid level visible in the sight. Use the reservoir to feed oil

to the proper level.

10.

Place thumb over reservoir spout, invert, and insert the spout

into the main body of CLOSED SYSTEM until upper casting

bottoms out on the collar.

12.

Oil may drain out of the reservoir and into bearing housing.

Secure set screws on upper casting.

13.

Start up machine and verify proper oil level is being

maintained.

14.

CLOSED SYSTEM

ITEM #

1

2

3

4

5

6

DESCRIPTION

4 Ounce Reservoir Assy.

8 Ounce Reservoir Assy.

16 Ounce Reservoir Assy

Set Screw

O-Ring 1.375" ID x .062 CS

Hex Socket Screw

Sight Gauge

¼" Square Plug

CATOLOG #

26113R

26115R

26120R

10267R

12829

10262R

26121R

10321R

With Sight Gauge / Constant Level Oiler

Adjust the collar to the desired fluid level. Bottom of collar

indicates fluid level (see back side for dimensions from

centerline of side port to bottom of collar.)

9.

Reservoir

Set screw

Collar

Fluid Port

Fig. 2

Bottom and Side

CLOSED SYSTEM

With Sight Gauge / Constant Level Oiler

Vent Line

Fig. 3

1

3

4

5

6

2

0.090” MIN.

0.840” MAX.

3/4” RANGE

OF ADJUSTMENT

MOUNTING DIMENSIONS

5

DO NOT install or remove the CLOSED SYSTEM with or by use of the reservoir assembly.

DO NOT use the CLOSED SYSTEM for stepping, standing, or heavy loading as these actions could

cause a change in oil level settings and may cause leaks.

DO remove the reservoir from the CLOSED SYSTEM during installation and removal.

DO use the bottom fluid port if oil level is set at the lowest level for optimal oil feeding.

Apply pipe thread sealant to both ends of a 1/4" NPT male

nipple. Tighten nipple in remaining fluid port and bearing

housing. If bottom fluid port is remaining, an elbow may need

to be used. The CLOSED SYSTEM should be parallel to the

bearing housing in a vertical position within ±1º (Fig. 3).

5.

Prior to installing the CLOSED SYSTEM, shaft rotation direction must be determined, typically

indicated by an arrow on the casting of the equipment. Install oiler on the side of the equipment

facing the direction of shaft rotation to prevent misfeeding of the oiler (see Fig 1).

1.

Using a funnel, fill the reservoir.

11.

Fig. 1

Direction of shaft rotation