Dryspell Series Instruction Manual

Low abrasion

The low abrasion ensures less dusting during transport, loading, and service

life which reduces pressure drop and minimizes downstream valve and filter

plugging, common with dustier products.

High adsorptive capacity.

The desiccant’s high surface area and tailored pore distribution provide a

high dynamic H2O adsorption capacity. It also has excellent cyclical stability

which leads to a long desiccant life.

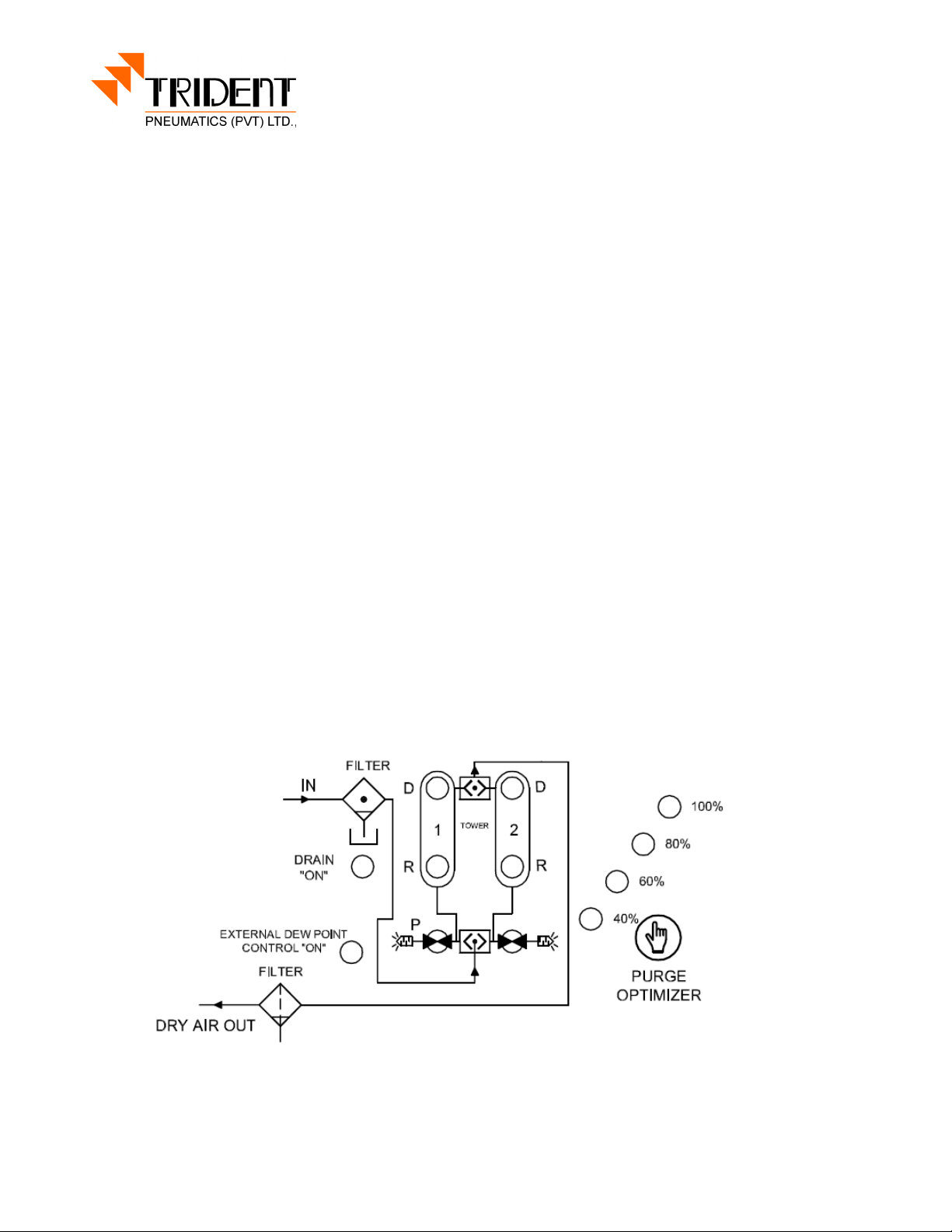

DESCRIPTION OF OPERATION

Operating Principles

Wet air enters the inlet prefilter and flows from the top block to the lower block via the air

transfer tubes. Air then flows to the shuttle inlet valve and is diverted to tower 1. The

compressed air flowing through tower 1 is dried to a –40°F ADP and exits via the outlet filter.

A small portion (12%) of the compressed air is expanded to near atmospheric pressure by

passing through the purge orifice. Expansion of this already-dry gas to near-atmospheric

pressure increases the ability of the purge air to strip the previously adsorbed water vapor

from the partially saturated desiccant bed in tower 2. The air exhausts through the opened

two-way purge valve. This cycle continues for 1.5 minutes then the purge valve closes and

tank 2 begins re- pressurization. After 30 seconds purge valve 1 opens and the process

repeats for tower 2.

the online tower dries for 2 minutes

the offline tower regenerates for 1 minute and 30 seconds

the offline tower re-pressurizes for 30 seconds

Warning

Failure to follow these instructions can lead to serious injury or death.

This dryer should be only be used for drying filtered, compressed air.

Ensure inlet air to this air dryer is filtered.

Only experienced and licensed electricians that are properly trained in compressed air

systems should service or repair Trident products. Before start-up or performing any

maintenance on any Trident air dryer, filter, drain system, or other equipment, you must first

turn off and disconnect all electrical power and service to the equipment at the main

disconnect switch. Also, be sure to bypass and depressurize the dryer to 0 PSIG. Do not start

or operate the dryer if there is a leak. Make sure the dryer’s protection rating is applicable to

the installation conditions. Do not operate the dryer at pressures and/or temperatures above

the maximum allowable marked on the data label. Likewise, verify that incoming voltage

matches the voltage marked on the data label. Do not lift the dryer by its piping or control box

or drop the dryer. Doing so may damage the dryer.