Triex LLC Filabot Original User manual

Filabot

Vermont, USA, Earth

1-802-505-6772

Filabot Original and Filabot EX2

Operation Manual

This manual applies to the Filabot Original and Filabot EX2 by Triex LLC.

Triex LLC, Barre, VT 05641, USA

EXOGMR1 – REV 3 – 9/18/2019

General Specifications and Application

The Filabot EX2 is a filament extruder system, which produces plastic

filament for 3D printers.

Filabot extruders produce plastic filament in 3 common diameters:

1.75mm, 2.85mm, and 3mm. Custom size nozzles can be ordered on

Filabot.com.

The Filabot Original and Filabot EX2 can produce filament from a wide

variety of plastics that can be in pellet, re-ground plastic, and in fine

powder form. Input material should be less than 3mm in diameter.

Inputs: The following plastics have been verified for extrusion on the

Filabot Original or EX2. Other plastics may be extrudable, however they

are untested. We are constantly testing new plastics, please contact us

for the most up to date information on verified plastics. Also, check out

our Learn Tab on Filabot.com for our Public Filabot Extruder Settings for

fine-tuned settings on some of our polymers.

l PLA (Polylactide)

l ABS (Acrylonitrile Butadiene Styrene)

l HIPS (High Impact Polystyrene)

l ULTEM

l PC (Polycarbonate)

Electrical requirements: 100VAC - 240VAC 50/60Hz

Power Consumption: The Filabot Original and Filabot EX2 will use 300

watts max, depending on heater temperature settings and motor speed.

Filament Diameter Output: 3mm, 2.85mm or 1.75mm diameter plastic

filament, using provided interchangeable nozzles. The customer may

also purchase pre-drilled nozzles or modify them for a custom diameter.

Dimensions: 18 1/4in x 7in x 9 1/4in (46cm x 18cm x 24cm)

Weight: 20 pounds (13kg)

CAUTION! Read Carefully

• HOT MATERIALS & SURFACES Use gloves and eye protection

while operating the EX2 Extruder. The barrel and nozzle are HOT

and melted plastic can stick to the skin and cause serious injury.

• HIGH-PRESSURE EXPLOSION Air trapped inside the barrel

becomes highly pressurized during operation and can cause small

explosions out of the nozzle which will throw molten plastic away in

any direction.

• TOXIC FUMES Some plastics like PVC can produce dangerously

toxic fumes when they are heated. Always carefully review the

MSDS of any material before using it in the EX2 to avoid dangers to

your health. Always use the EX2 in a well-ventilated area.

• In Case of Emergency pull the power cord out of the machine.

• Only use the EX2 to extrude thermoplastic polymers. No other use

has been tested or approved by Filabot.

• Always STOP the extruder before clearing the feed port or removing

the screw. Never stick anything into the feed port while the screw is

turning as this could damage your system.

• The EX2 is designed for indoor use only. Operate in a clean, dry

area.

• Check the AC input voltage specified on the S/N Label near the

power inlet. Only use the specified input voltage to operate the EX2

or damage to the components could occur.

• Do not use this device if any parts appear missing or damaged.

• Do not modify this device without authorization from Filabot.

Contact Filabot with any questions

1-802-505-6772

Setup

Position the Filabot on a suitable work surface. The work surface should

be large enough to safely support the extruder at a comfortable height for

the user. Additional space is ideal for convenient access to tools and

supplies. The device must be located no further away from an electrical

outlet than the length of the provided power cord.

Do not place any objects against the Filabot.

Operation

PLASTIC NOTE: When using commercial pellets, rely on the

manufacturer's identification of the type of plastic. When using recycled

plastic, check the markings on the item(s) to determine which type of

plastic you are using. Do not mix types of plastic, as this may cause

issues extruding or affect processing times, both in the extruder and in

the printer.

The following is a table of general processing temperatures. Note that

the processing temperature may not be the same as the melt

temperature. Check out our Learn Tab on Filabot.com for our Public

Filabot Extruder Settings for fine-tuned settings on some of our

polymers.

Plastic Type

Processing Temperature

PLA

175ºC - 195ºC

ABS

165ºC - 185ºC

HIPS

175ºC - 195ºC

Ultem

350ºC - 400ºC

PC

250ºC - 320ºC

NOTE: The temperature ranges in the chart are approximate. Plastics of

the same type are available in different grades; each grade may perform

differently.

Operation (continued)

It may require trial and error to determine the right processing

temperatures as the ambient temperature you are extruding in will affect

the extrusion. It will help to maintain a log of actual temperature settings

with different types of plastics along with other operational notes. This

will assist in developing a procedure that works well in your application.

Blank pages are provided at the end of this manual for this purpose.

Break-in Procedure: These steps need to be followed with a new

Filabot extruder to ensure proper break-in. These steps are to clean out

the extruder from the manufacturing process. This should be done in a

well-ventilated area. For general cleaning steps look at the Cleaning and

Maintenance section of this manual.

1: Install the supplied 2.85mm nozzle. Use a ⅝” socket or wrench to

tighten the nozzle into the end of the extruder. This can be done with the

extruder unheated.

2: With all switches off, flip the ‘MAIN POWER’ and ‘TEMPERATURE

CONTROLLER’ switches from ‘OFF’ to ‘ON’.

3: Tuning – Initial Use

Set the PID controller to within ±30°C of your expected operating

temperatures. For break-in we recommend setting the extruder to 180ᐤC.

a. To program the set temp, press the

or key once, and the decimal

point will flash at the first selected

digit:

b. Use the and keys to adjust the

selected digit value. Use the key to

select the next digit:

Operation (continued)

.

c. Once the set temp is adjusted to the

desired value, press the key twice

to set the value. The “OUT” indicator

will turn on when power to the

heaters for that zone is switched on:

Be sure the measured temp “PV” is at least 30°C cooler than your set

temp "SV" before starting self-tuning function. Doing this increases the

accuracy of the calculated PID parameters. If temperatures reach the set

temp before self-tuning can be started, set all temperatures low until

temperatures decrease. Return set temps to your previous setting, then

begin self-tuning the controllers:

d. Hold the key until the display

shows “HI AL 9999”:

e. Press the key 5 times until the

display shows “CtrL 3”:

Operation (continued)

f. Press the key once to change the

value to “2”:

g. Hold the key to scroll back to the

main display. “PV” will display the

current temp, and "SV" will flash

between “At” and your set temp while

the auto-tuning function is running:

NOTE: While the auto-tuning function is running, temperatures will overshoot

the set temp significantly. This is normal during the tuning process which can

take around ½ hour. After the “At” function completes, wait until the

temperatures stabilize at their set temp before beginning to extrude. To

ensure the PID controllers perform at their highest accuracy, we recommend

re-tuning whenever operating at a temperature more than 30°C higher or

lower than the temperature the previous tune was set at. For advanced

users, the full Inkbird manual can be found on the EX2 page at Filabot.com.

6: Once 180ᐤC is reached, fill the hopper of the extruder halfway with the

supplied pellets, next, flip the ‘EXTRUDE’ switch from ‘OFF’ to ‘ON’. This

will activate the feed screw and begin conveying material forward. Light

smoke may come out of the extruder at this point. This will only occur

during the break in procedure.

7: As filament begins to extrude, guide it to the ground so that it can coil

up. This filament will likely have debris and contaminants in it from the

manufacturing process. Do not use this filament in your 3D printer.

Extrude all the pellets that were placed in the hopper, if the filament

Operation (continued)

coming out still appears to have contaminates after this step, extrude

additional pellets to further clean the system.

8: Discard the ‘break in’ filament that was just extruded.

.

Filament Production:

1: Select the nozzle for the size filament you desire to make. ANYTIME

after first use will require you to heat the system up before switching

nozzles, doing otherwise could damage the machine or components

inside. Once the extruder is up to temperature, and the ‘EXTRUDE’

switch is off, you can remove the nozzle with a ⅝ socket or wrench. Be

mindful that you are working with hot materials, BE CAREFUL when

removing the nozzles, and never touch with your hands. Once the

nozzle is removed, replace it with your desired size.

2: With the extruder at the correct temperature for the plastic that is

being extruded, add pellets to the hopper and flip the ‘EXTRUDE’ switch

from ‘OFF’ to ‘ON’.

3: If using our Filabot Spooler system, refer to the Spooler operation

manual on how to set it up. If you do not have a spooler, you can use the

ground coil method. Place the extruder so that the front (where the

filament comes out) is next to the edge of a table. The table should be

between 24in to 40in tall.

4: Once enough filament has extruded to the ground, guide it into its

natural spiral. Once it has spiraled around twice it generally will take care

of itself and continue to neatly coil. Be sure to extrude your coil onto a

clean surface to avoid contaminants collecting on your filament.

5: After the filament has coiled a few more times, carefully measure the

filament diameter from the filament in the coil. If filament is too large,

increase the temperature of the of the extruder by a few degrees. If the

filament is too small, lower the temperature by a few degrees. Dial this in

for your desired diameter.

6: Once you have extruded enough of your filament you are now ready to

either spool it or feed it directly into your printer.

Care and Maintenance

Filabot extruders require only minimal, occasional maintenance. This

consists of cleaning the device as needed, vacuuming out the hopper, or

purging out the plastic inside the extruder chamber.

Check for any signs of damage, wear, or deterioration while using and

cleaning the device. If there are any signs of wear, overheating, or

deterioration, contact Filabot for guidance on how to proceed.

Purging procedure when switching materials:

1: Remove any remaining pellets from the hopper. With the

extruder at the proper extrusion temperature for the plastic,

begin extruding and run the unit until plastic is no longer coming

out of the nozzle.

2: Flip the ‘EXTRUDE’ switch to ‘OFF’ and remove the large

nozzle from the end of the extruder and pour roughly 1/4 hopper

full of purge pellets into the hopper. Flip the ‘EXTRUDE’ switch

to ‘ON’ and begin extruding the purge compound with the nozzle

removed. Depending on what you were extruding previously, you

may need to use additional pellets to fully purge the material.

Use additional purge pellets until the purge coming out is back to

its normal white color.

3: With the purge pellets fully extruded, add your base resin that

you plan to extrude next into the hopper and continue to extrude

with the nozzle still removed. Once your base resin appears pure

and without any purge remnants in it, run the unit dry, shut down

your extruder, and replace the large nozzle.

4: You are now ready to begin extruding your new filament.

Troubleshooting

Use the below grid to resolve common issues.

Problem

Possible Issue

Solution

Extruding slow

-Low temperature

-Bridge/block

Raise temperature

Not extruding

-Low temperature

-Bridge/block

-Raise temperature

-Raise temp. to 30ºC-

50ºC cover the

extrusion

temperature. Let it

stand, begin trying to

extrude again

Bubbles in filament

-Too high temp.

-Damp plastic

-Lower temp.

-Dry plastic

Filament diameter too

small

Temperature too high

Lower temperature

and recheck after two

minutes

Filament diameter too

big

Temperature too low

Raise temperature

and recheck after two

minutes.

Main power not

turning on

-Blown input plug fuse

-Power supply tripped

Replace fuse with the

correct voltage fuse

Unplug unit for 5

seconds to reset

power supply

If problems persist, please call or email Filabot for further assistance.

Warranty Information

The Filabot Original and Filabot EX2 have a one-year warranty. This

includes replacement of any part that fails. More information about our

warranty is available on www.filabot.com.

Parts, Supplies, and Accessories

Filabot provides replacement parts, supplies, and accessories. If you

have any questions or need any special parts, please let us know.

2019, Triex LLC, Barre VT, USA. No part of this manual may be copied, stored,

transmitted, or otherwise released without the express written consent of Triex LLC. This

manual applies only to the Filabot EX2. While Triex LLC has applied all possible caution in

producing this manual, we urge the customer or user of this device to contact Triex LLC

with any questions or concerns about operation, before operating the device or making any

adjustments. Triex LLC provides no assurance of applicability of the product to customers'

requirements.

.

This manual suits for next models

2

Table of contents

Popular Industrial Equipment manuals by other brands

TriangleTube

TriangleTube MAXI-FLO MF 350 PT Series Installation and maintenance manual

VIBCO

VIBCO DC manual

Maxon

Maxon EC frameless DT installation manual

Festo

Festo VABM-B10-25EEE manual

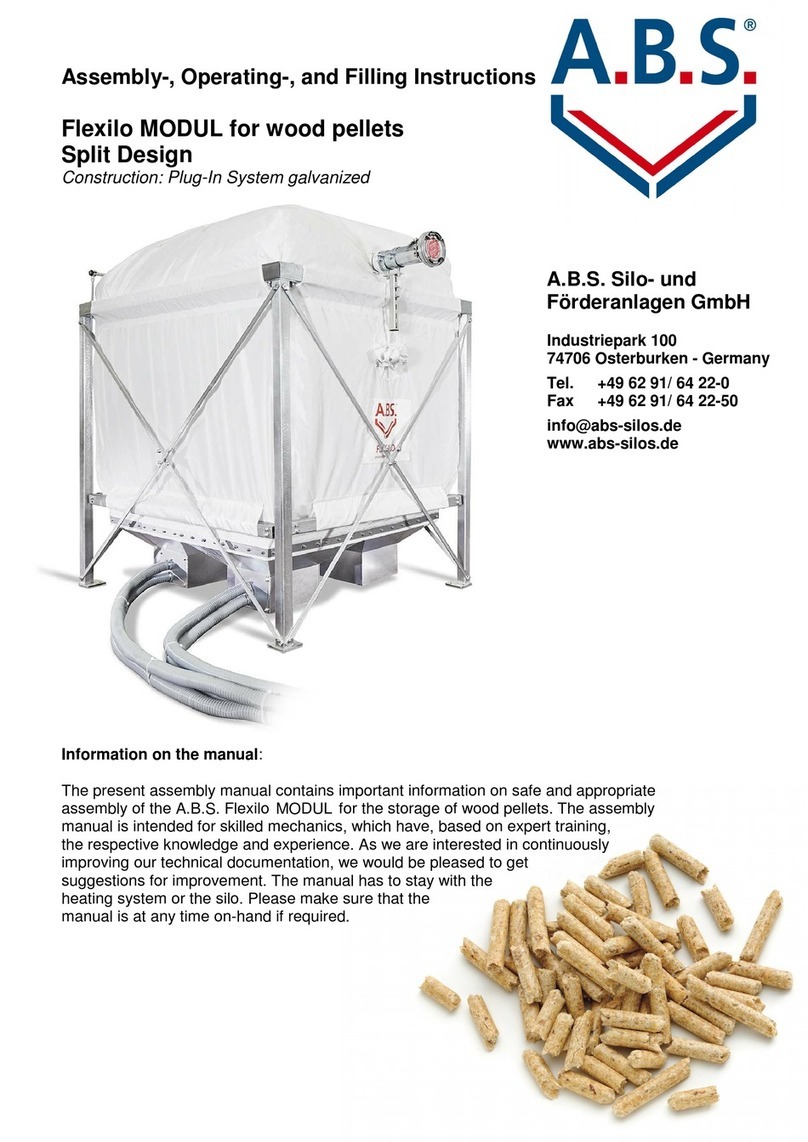

A.B.S.

A.B.S. Flexilo MODUL Assembly-, Operating-, and Filling Instructions

Xylem

Xylem WEDECO EFFIZON SMOevo Series manual